Electrode sheet for capacitor and its manufacturing method, and electrolytic capacitor

A technology for electrolytic capacitors and electrode sheets, applied in the field of electrode sheets, can solve the problem of inability to reduce leakage current, and achieve the effects of small size, large capacity and small leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

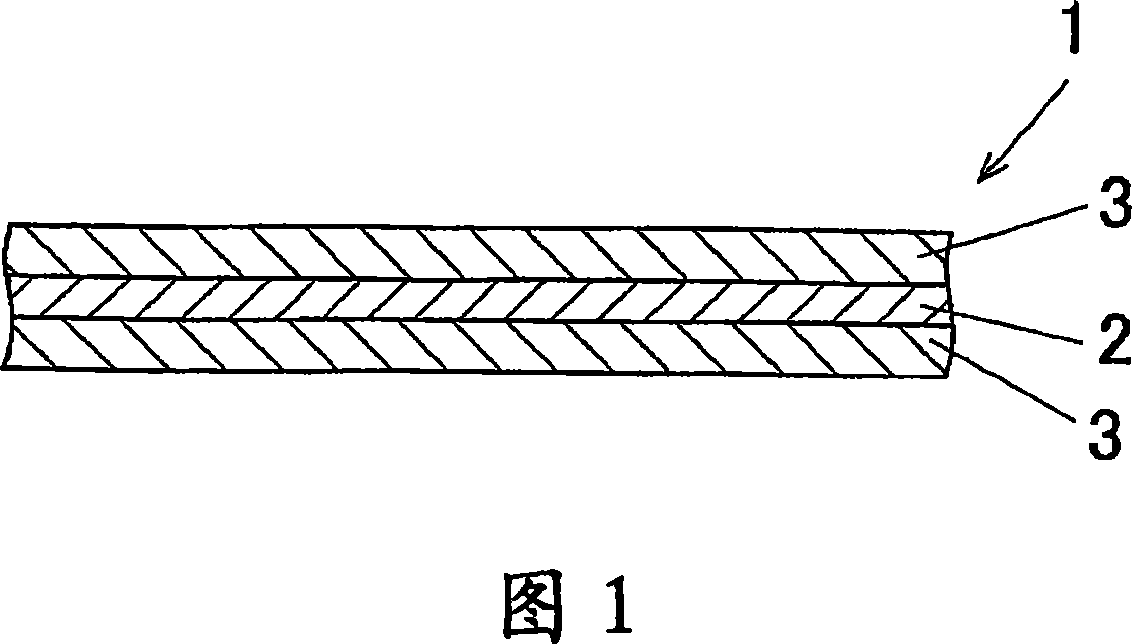

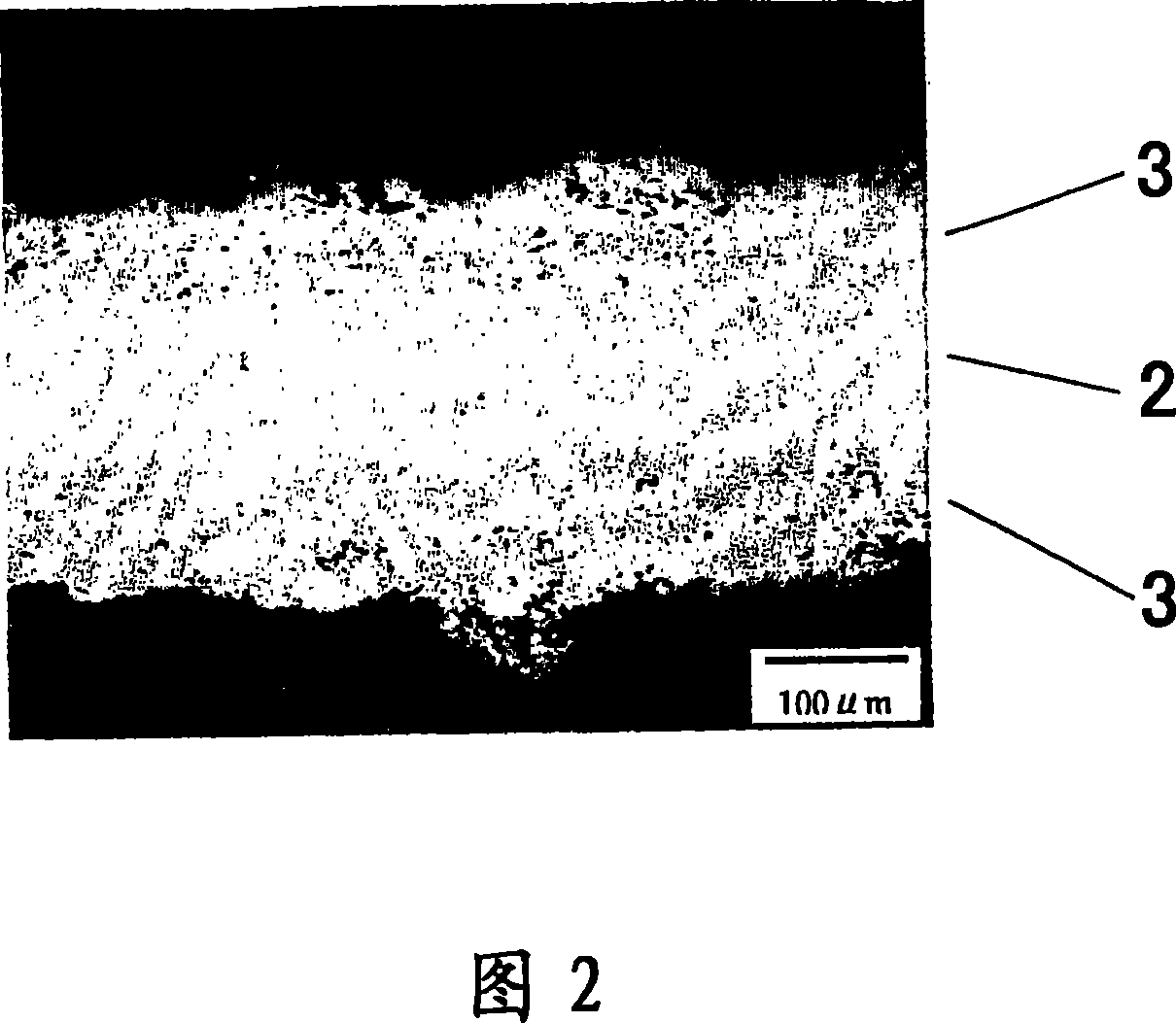

[0093] By arc spraying (spraying heat: 5kJ / l) Al-Zr alloy (Al: 73wt%, Zr: 27wt%) powder to form a 120 μm thick sprayed layer 3 on each surface of the core 2 to obtain an electrode sheet 1 as shown in FIG. 1 . The α-phase content ratio of the Al-Zr alloy powder was 40%. The spraying current was 180A, the spraying mixed gas flow was 250 L / min, and the ratio of the spraying mixed gas was hydrogen:nitrogen:argon=10:10:80 (volume %). A scanning electron micrograph of a section of the obtained electrode sheet is shown in FIG. 2 . The pore content ratio of the sprayed layer 3 was 3% by volume.

[0094] Dip the electrode sheet into 3% (mass%)-H 3 PO 4 solution and boiled at 90° C. for 120 seconds, then washed with running water, and further subjected to ultrasonic cleaning in acetone solvent.

[0095] Also, the electrode sheet was dipped in a 3% (mass %) nitric acid solution for 3 minutes to perform acid cleaning, and then dried at 50° C. for 5 minutes.

[0096] Next, the dried ...

example 2、3、 and comparative example 1 and 2

[0101] In each of these examples, electrode sheets were obtained in the same manner as in Example 1, except that spraying was performed by setting the spraying heat when spraying Al—Zr alloy powder to the value shown in Table 1.

[0102] Alloy powder

example 4、 comparative example 3

[0104] In each example, an electrode sheet was obtained in the same manner as in Example 2, except that Al-Zr alloy powder having the particle diameter shown in Table 2 was used as the Al-Zr alloy powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com