Swirl flocculation device and coal-fired power plant high-salt and high-turbidity waste water treatment system and application thereof

A flocculation device, a high-level technology, applied in the fields of flocculation/sedimentation water/sewage treatment, gaseous discharge wastewater treatment, water/sewage treatment, etc., can solve the problems of high energy consumption, large investment, complex evaporation and crystallization equipment, etc. The effect of flocculation, equipment footprint reduction, and flocculation-clarification time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

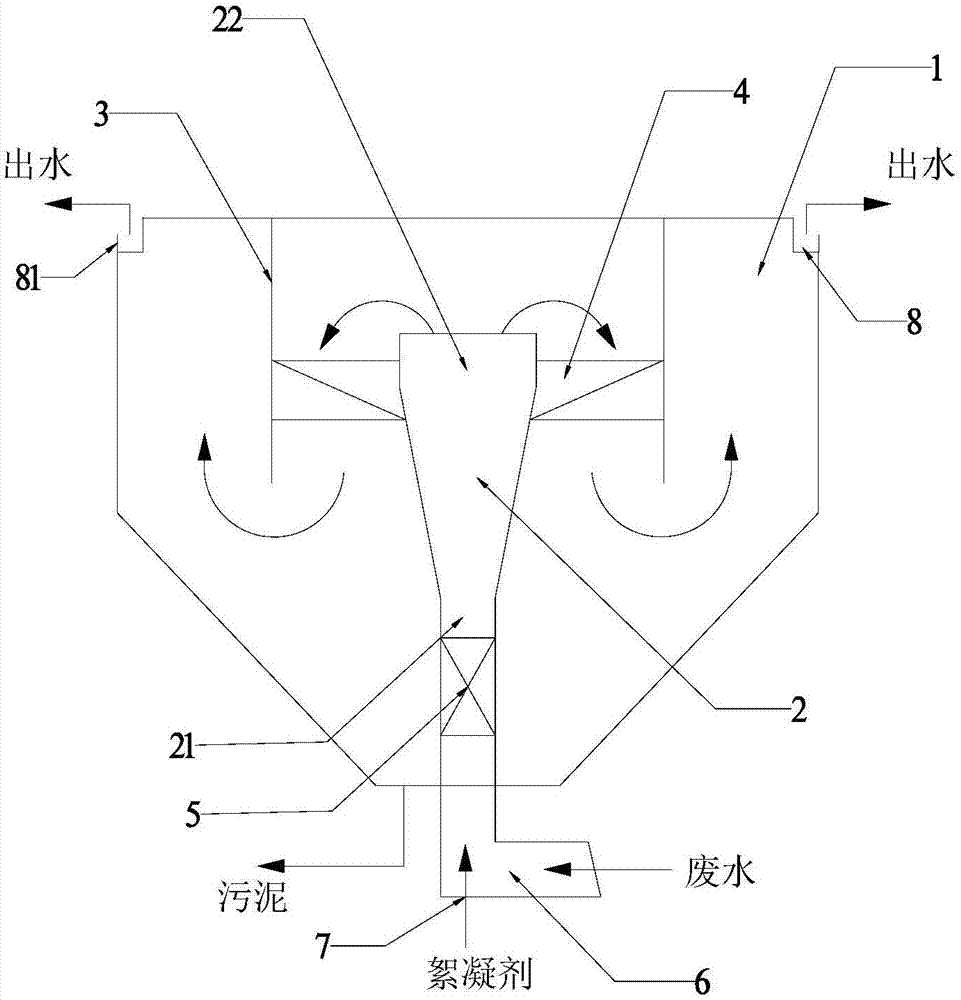

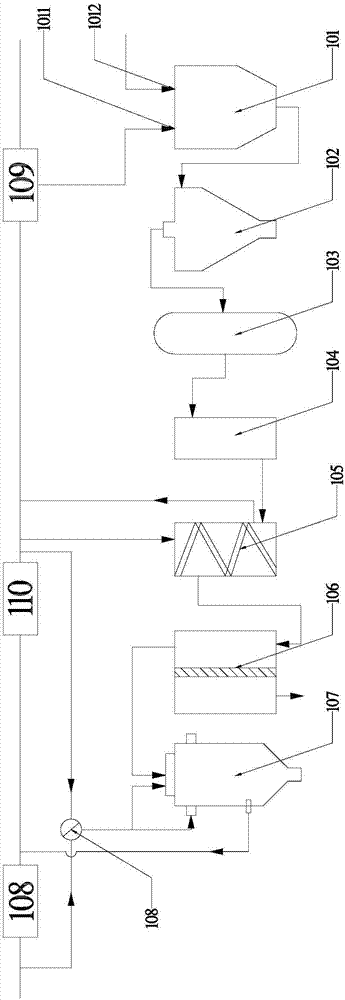

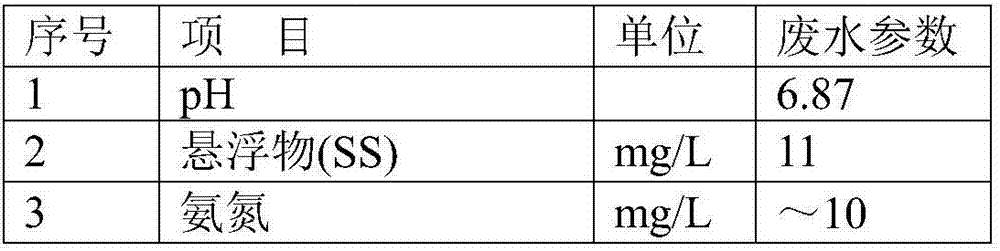

[0050] use as figure 2 The waste water treatment system shown, waste water (pre-treatment indicators are shown in Table 1) treatment process: (1) softened by adding soda to the softened water device, and then enter the cyclone flocculation device (such as figure 1 As shown), adding polyferric chloride coagulant and polyacrylamide flocculant in turn, the SS content in the outlet wastewater of the cyclone flocculator will be reduced to 12mg / L, the copper ion content will be 5mg / L, and other components will remain basically unchanged; ( 2) The filtration process adopts a multi-media filter. At this time, the content of suspended solids is less than 3mg / L, calcium ions (Ca 2+ )657mg / L, magnesium ion (Mg 2+ ) 366mg / L; (3) Two-stage reverse osmosis treatment is used for pre-shrinking, the wastewater TDS is concentrated from 25000mg / L to about 60000mg / L, fresh water is reused, and concentrated brine enters the membrane distillation treatment unit; (4) The membrane distillation proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com