Preparation method of all-solid-state lithium-air battery cathode

An air battery, all-solid-state technology, applied in battery electrodes, fuel cell half-cells and secondary battery-type half-cells, circuits, etc. Less problems, to achieve good lithium ion transport capacity and electronic conductivity, high electronic conductivity, rich pore channels and pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

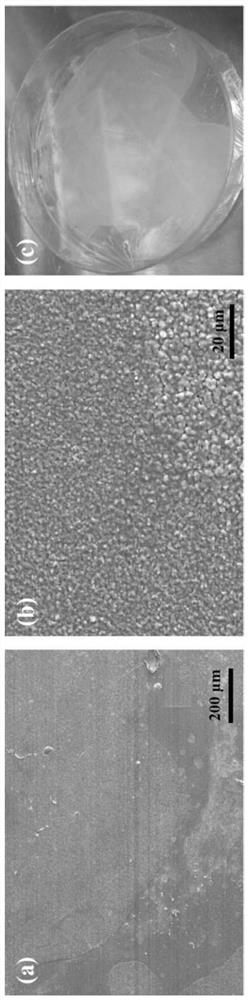

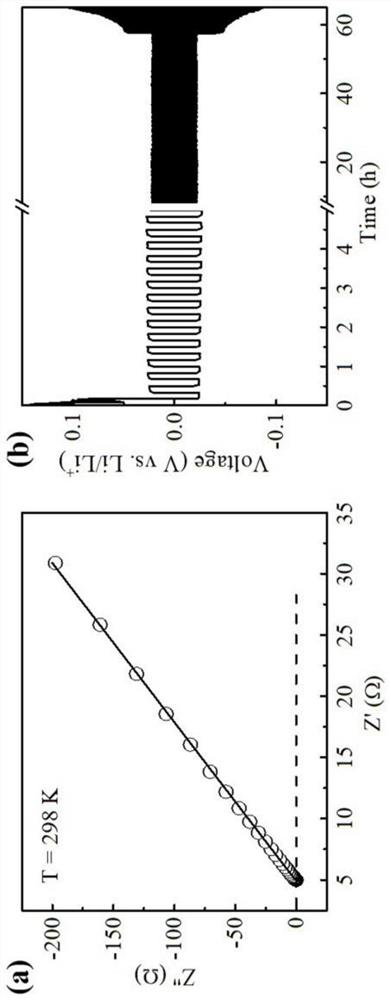

[0031] 1. Preparation of polymer solid electrolyte membrane.

[0032] Weigh 2.87g of lithium bistrifluoromethanesulfonylimide (LiTFSI) and dissolve it in 10ml of dimethyl sulfoxide (DMSO), stir and dissolve evenly, and mark it as solution A. Weigh 2 g of poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) and add it into 15 ml of acetone, stir and dissolve evenly, and mark it as solution B. Weigh 7g of solution A, add it to the above solution B, stir evenly to form a mixed solution, which is marked as solution C. Slowly pour solution C onto a glass plate with a flat surface, wait for the liquid to evaporate naturally, and then peel off from the glass plate to obtain a polymer solid electrolyte membrane.

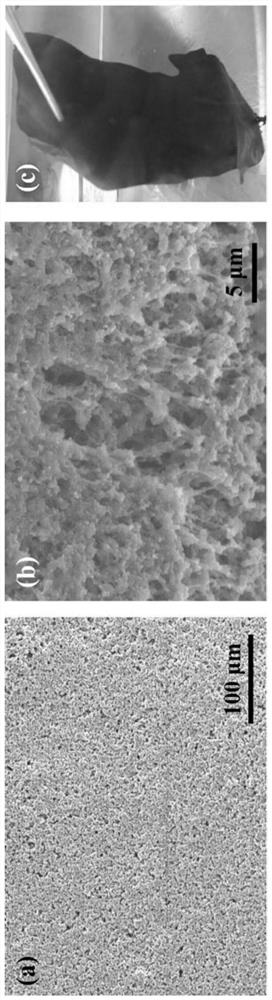

[0033] 2. Preparation of flexible solid cathode.

[0034] Preparation of Co by hydrothermal method 3 o 4 Catalyst material: Weigh 0.5g of cobalt acetate tetrahydrate and dissolve it in a mixed solution of 30ml of deionized water and 30ml of absolute ethanol, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com