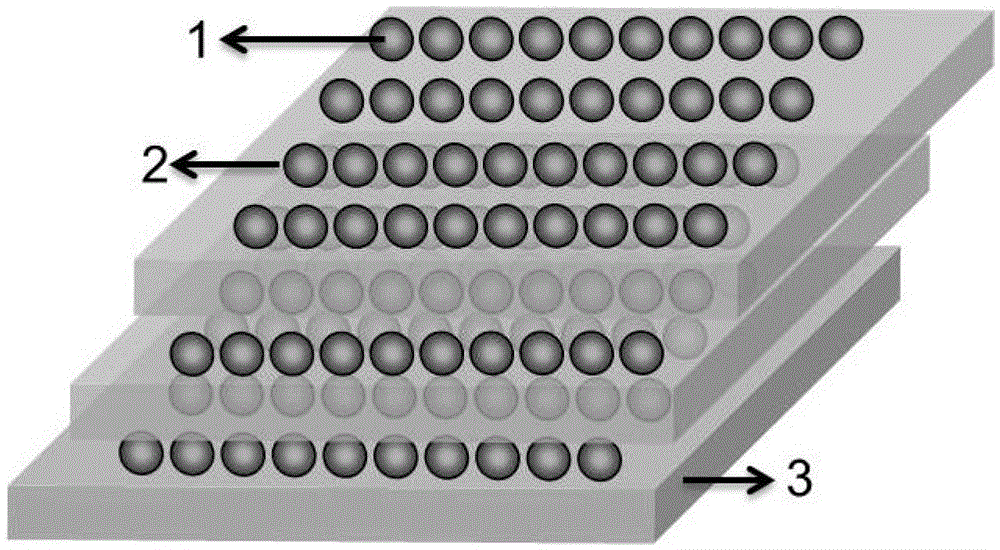

A kind of silicon/silicon carbon/graphite composite negative electrode material for lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve problems such as accelerated transmission speed, battery capacity attenuation, agglomeration, etc., achieve good electrochemical stability, reduce volume change, the effect of material structure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

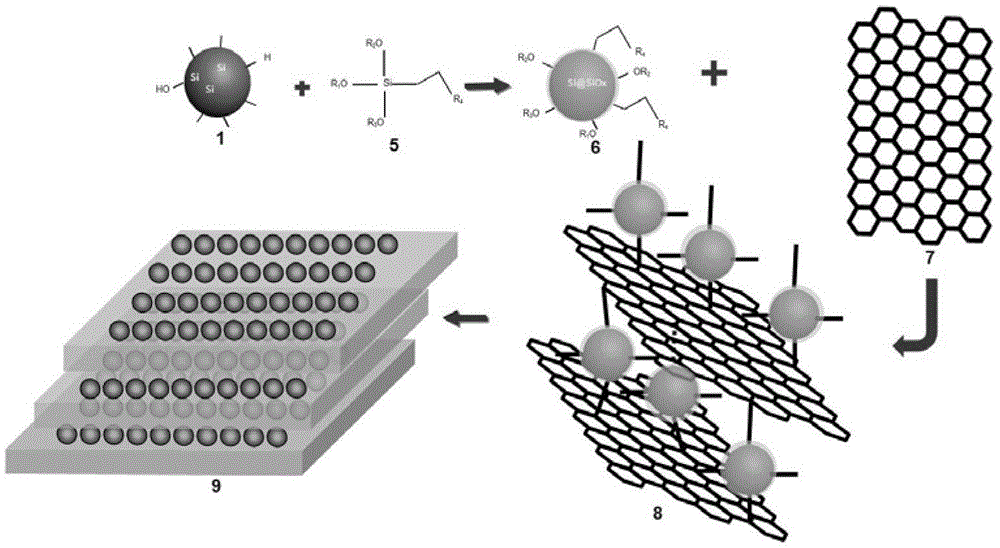

Method used

Image

Examples

Embodiment 1

[0051] Take 100g of silicon nanoparticles (particle size D50 is 100nm) and disperse in 1000g of liquid vinyl tris (2-methoxyethoxy) silane monomer compound, stir for 0.5h by a vacuum stirrer, under the condition of stirring , add 500mLpH to the above-mentioned dispersion liquid and be the ethanol-water mixed solution (ethanol / water=9 / 1, volume ratio) of 6.8, and keep stirring for 4h, add 700g conductive graphite (model is KS-6) and continue stirring for 4h, obtain Viscous mixture, the viscous mixture is extruded 4 times through a screw extruder to obtain a paste mixture.

[0052] The obtained paste mixture precursor was treated at 700°C for 1 h in a protective atmosphere to obtain a theoretical stoichiometric ratio of 0.06Si-0.012SiO 1.5 C 2.1 -C silicon / silicon carbon / graphite composite bulk material.

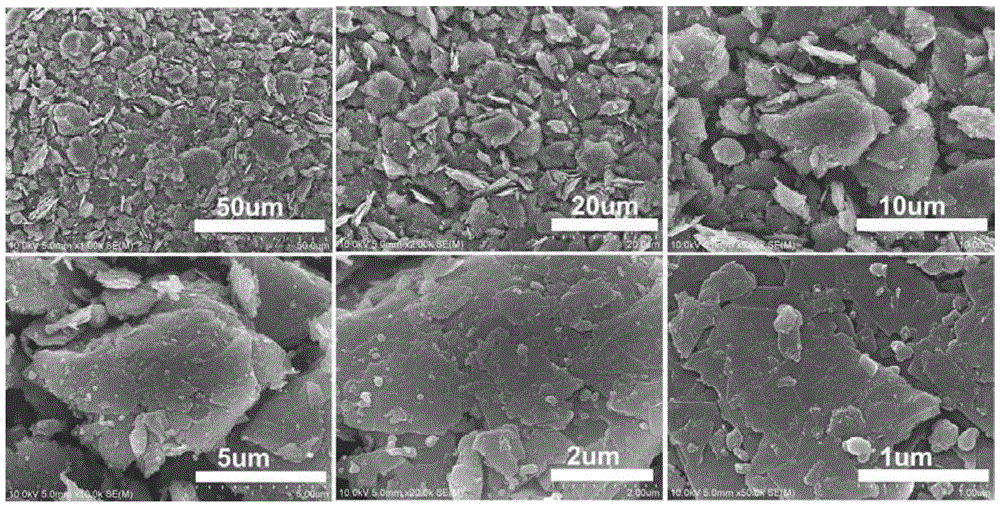

[0053] The obtained silicon / silicon carbon / graphite composite material was crushed by magnetic force for 1min, and processed under a planetary ball mill at 500rpm for 12h to...

Embodiment 2

[0056] The same process as in Example 1, the difference is that the number of times of screw extrusion becomes 3 times. The initial charging and discharging points of the composite materials are 746mAh / g and 614.1mAh / g respectively, the first Coulombic efficiency is 82.3%, the specific capacity after 10 cycles is 556.2mAh / g, and the capacity retention rate is 90.57%.

Embodiment 3

[0058] The same process as in Example 1, except that the number of times of screw extrusion becomes 2 times. The first reversible specific capacity of the composite material is 459.9mAh / g, the specific capacity after 5 cycles is 548.8mAh / g, the specific capacity after 10 cycles is 533.5mAh / g, and the capacity retention rate is 116%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com