Animal glue binder for lithium-sulfur battery cathode and preparation method of animal glue binder

A technology of lithium-sulfur battery and adhesive binder, applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of environmental pollution, difficult process control and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

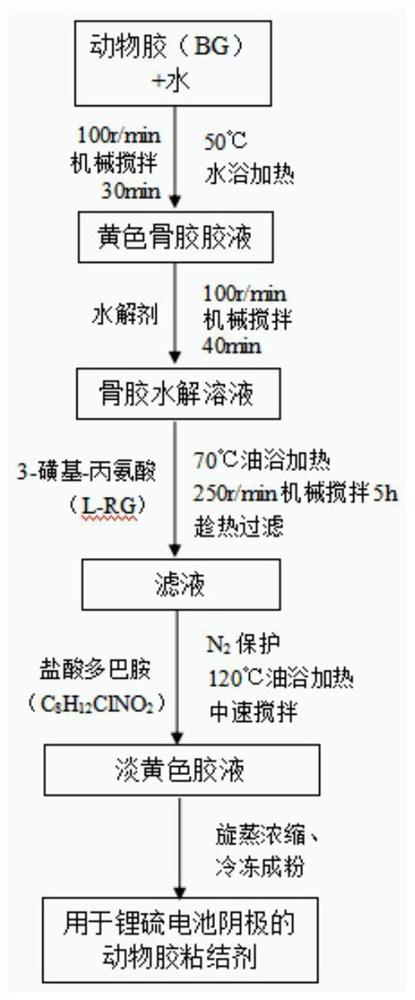

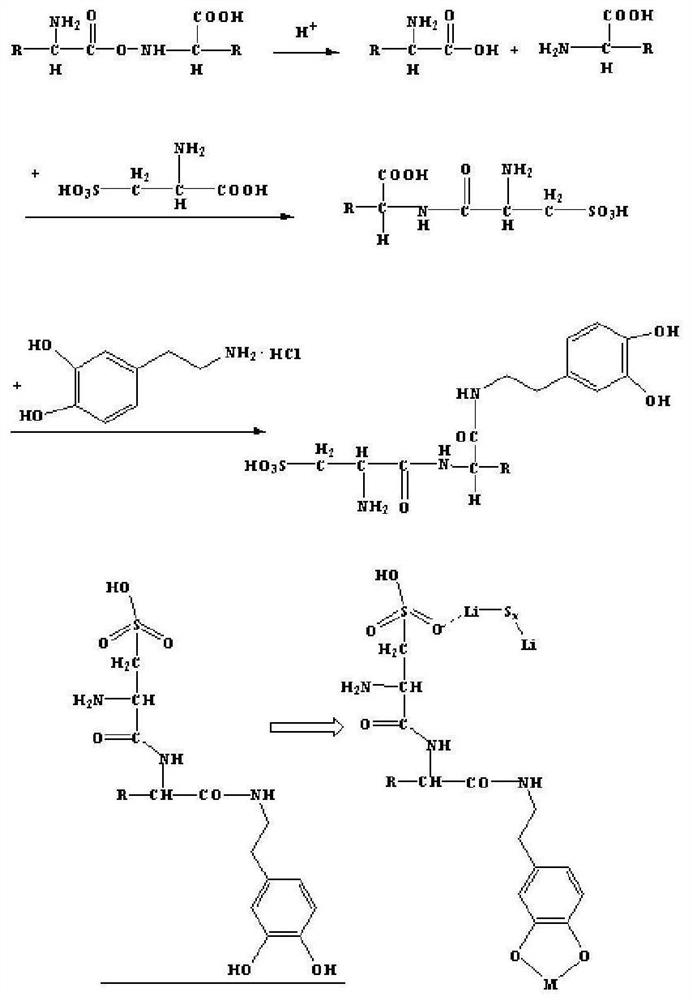

[0029] Put 28.0wt.% BG and 54wt.% water in a three-necked flask, heat it in a water bath at 50°C, stir mechanically at 100r / min for 30min, then slowly add 100mL of 1mol / L citric acid, and continue at 100r / min in a water bath at 50°C After mechanically stirring for 40 minutes, take out the three-neck flask and place it in an oil bath at 70°C, slowly add 7.0wt.% of L-RG powder, stir mechanically at 250r / min for 5 hours, and filter while hot to remove the incompletely dissolved bone glue gel; then , pass 1.2% N 2 , under heating in an oil bath at 100°C, add 11.0wt.% of C 8 h 12 ClNO 2 , heated in an oil bath at 100°C, stirred at 400r / min for 12h, poured out the glue solution in a rotary evaporator, evaporated and concentrated at 200r / min for 60min, then placed it in a vacuum dryer at -30°C to freeze into powder, and obtained Animal glue binders for lithium-sulfur battery cathodes.

Embodiment 2

[0031] Put 35.0wt.% BG and 47wt.% water in a three-necked flask, heat it in a water bath at 50°C, stir it mechanically at 100r / min for 30min, then slowly add 100mL of 1mol / L tartaric acid, and continue to stir it mechanically at 100r / min under a water bath at 50°C. After stirring for 40 minutes, take out the three-neck flask and place it in an oil bath at 70°C, slowly add 8.0wt.% of L-RG powder, stir mechanically at 250r / min for 5 hours, and filter while hot to remove the incompletely dissolved bone glue gel; then, Inject 1.2% N 2 , under heating in an oil bath at 100°C, add 10.0wt.% of C 8 h 12 ClNO 2 , heated in an oil bath at 100°C, stirred at 400r / min for 12h, poured out the glue solution in a rotary evaporator, evaporated and concentrated at 200r / min for 60min, then placed it in a vacuum dryer at -30°C to freeze into powder, and obtained Animal glue binders for lithium-sulfur battery cathodes.

Embodiment 3

[0033] Put 38.0wt.% BG and 40.1wt.% water in a three-necked flask, heat it in a water bath at 50°C, stir mechanically at 100r / min for 30min, then slowly add 100mL of 1mol / L malic acid, and continue 100r / min in a water bath at 50°C After stirring mechanically for 40 minutes, take out the three-neck flask and place it in an oil bath at 70°C, slowly add 7.6wt.% of L-RG powder, stir mechanically at 250r / min for 5 hours, and filter while hot to remove the incompletely dissolved bone glue gel; Subsequently, pass 1.2% N 2 , under heating in an oil bath at 100°C, add 14.3wt.% of C 8 h 12 ClNO 2, heated in an oil bath at 100°C, stirred at 400r / min for 12h, poured out the glue solution in a rotary evaporator, evaporated and concentrated at 200r / min for 60min, then placed it in a vacuum dryer at -30°C to freeze into powder, and obtained Animal glue binders for lithium-sulfur battery cathodes.

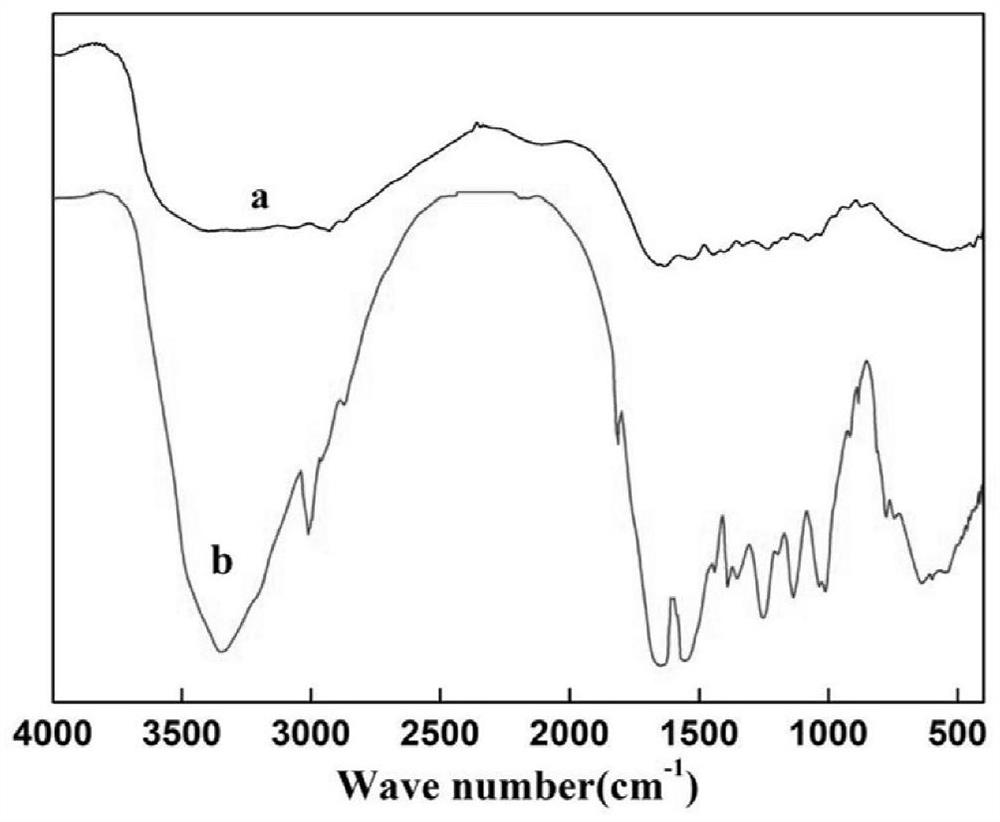

[0034] 2. Electrochemical performance test and characterization of animal glue binder for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Initial discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com