Lithium ion battery anode material and manufacturing method thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems affecting the effect of coating treatment, and achieve stable electrochemical cycle performance, uniform particle size, and simple coating process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

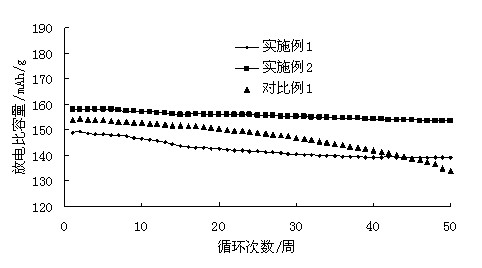

Examples

Embodiment 1

[0032] Embodiment 1: The preparation method of lithium-ion battery cathode material of this embodiment:

[0033] (1) The prepared zinc phosphate containing phosphate and zinc ions has a concentration of 20wt% zinc dihydrogen phosphate, and the nickel oxide cobalt manganese lithium cathode material powder with a particle size distribution of 5 to 10 microns is suspended in a fluidized bed with nitrogen gas , the temperature is controlled at 60°C, and then the aqueous solution containing phosphate and zinc ions is atomized and passed into the fluidized bed for 30 minutes, so that the surface of the positive electrode material particles absorbs the phosphate liquid film until the coating amount is phosphate Accounting for 1.5% of the weight of the positive electrode material;

[0034](2) Stop feeding the atomized aqueous solution containing phosphate and zinc ions, keep the nickel oxide cobalt manganese lithium cathode material powder suspended in the fluidized bed with carrier g...

Embodiment 2

[0038] Embodiment 2: The preparation method of lithium-ion battery cathode material in this embodiment:

[0039] The processing steps of embodiment 2 and embodiment 1 are the same, and the difference is to pass into the reaction chamber after atomizing with 15wt% lithium zinc phosphate aqueous solution, the temperature of the reactor is controlled at 50 ℃, and the time of passing into the atomized solution is 15 minutes,

[0040] The obtained coating content of lithium zinc phosphate is 0.73%.

[0041] The positive electrode material of the lithium-ion battery prepared in this example is nickel-cobalt-manganese-lithium oxide coated with metal phosphate, the nickel-cobalt-manganese lithium oxide has a layered crystal structure, and the chemical composition is LiNi 1-x-y co x mn y o 2 , wherein x=0.3, y=0.3 The particle size distribution of the nickel-cobalt-manganese-lithium oxide powder material is 5-10 microns. The metal phosphate of the coating is zinc phosphate, and the...

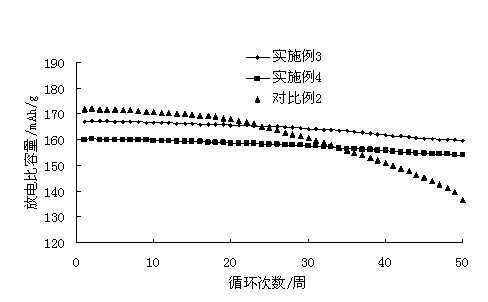

Embodiment 3

[0043] Embodiment 3: the preparation method of lithium-ion battery cathode material of the present embodiment:

[0044] The treatment steps of Example 3 and Example 1 are the same, except that 10 wt% zinc phosphate aqueous solution is atomized and then passed into the reaction chamber, and the temperature of the reactor is controlled at 65°C. Then increase the temperature of the fluidized bed reactor to 400°C and keep it for 0.8 hours, thus obtaining a zinc phosphate coating content of 0.96%. Charge and discharge at a rate of 0.2C for 50 cycles, the voltage is 2.7 - 4.2V, the ambient temperature of the charge and discharge test is 55°C, the 0.2C discharge capacity of the battery is 167 mAh / g, and the battery capacity retention rate after 50 cycles of the battery is 95.7%.

[0045] The positive electrode material of the lithium-ion battery prepared in this example is nickel-cobalt-manganese-lithium oxide coated with metal phosphate, the nickel-cobalt-manganese lithium oxide has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com