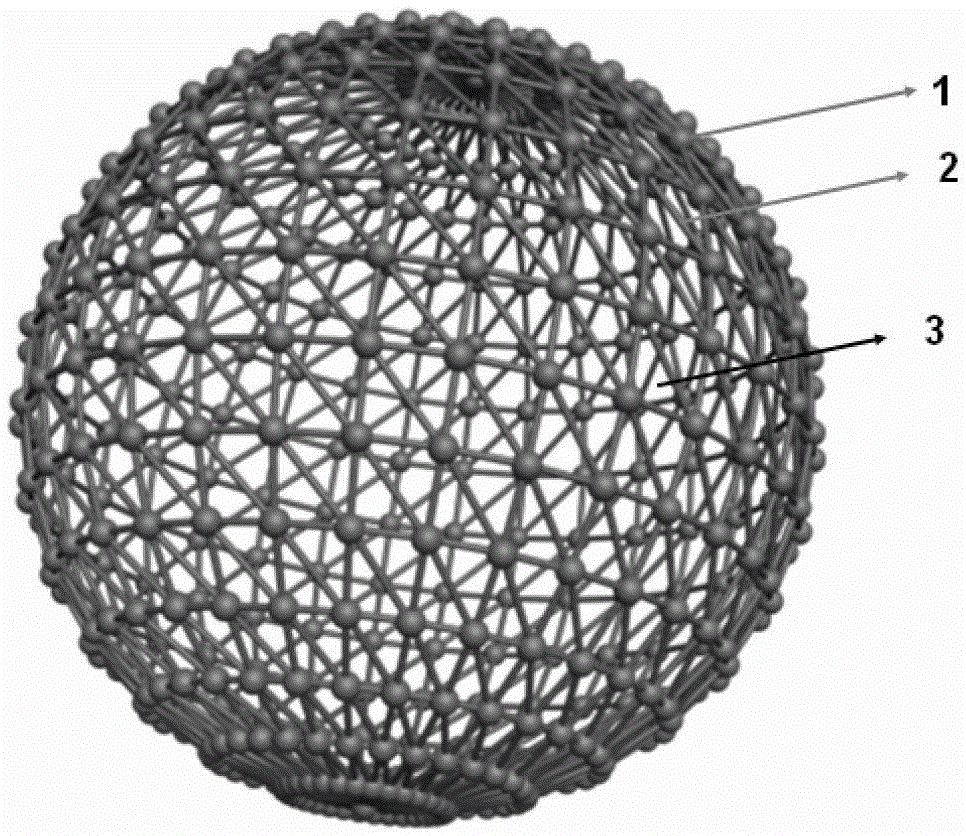

A kind of silicon-based composite negative electrode material for lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of nano-silicon material agglomeration, volume change and fragmentation, and achieve good electrochemical stability and stable material structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

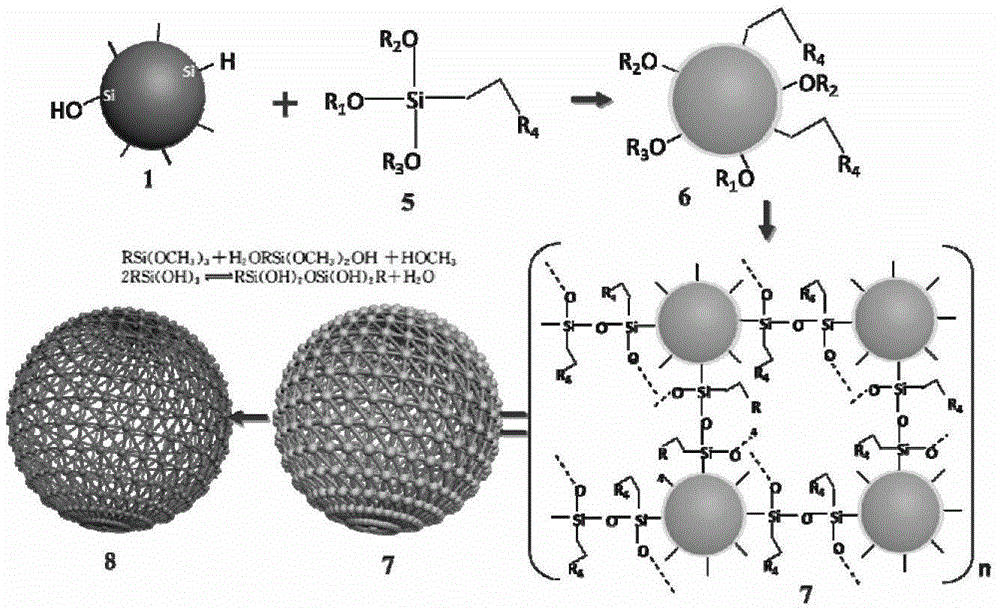

Method used

Image

Examples

Embodiment 1

[0039] Get 0.84g of silicon nanoparticles (particle diameter D50 is 30nm) and disperse in 8g of liquid vinyl tris (2-methoxyethoxy) silane monomer compound and stir for 6h. Add 1 mL of deionized water with a pH of 6.8, and keep stirring for 24 hours, add 12.32 g of ethanol solution of phenolic resin with a mass fraction of 50%, and continue stirring for 48 hours. While stirring, heat to 80 ° C for 48 hours to remove the solvent. The mixed solution solidifies.

[0040] The obtained cured precursor was treated at 750°C for 1h in a protective atmosphere, and then calcined at 1050°C for 1.5h to obtain a theoretical stoichiometric ratio of 1.86Si-SiO 1.5 C 8.7 Si-based composite bulk material.

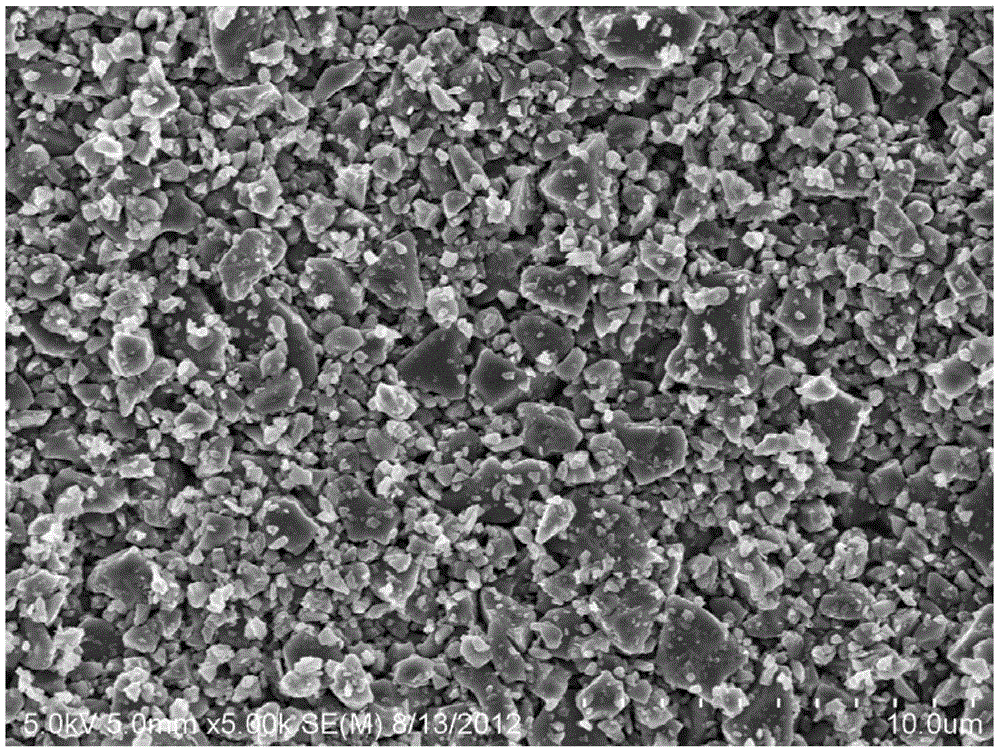

[0041] The obtained silicon-oxygen-carbon composite material was magnetically crushed for 1 min, and processed under a planetary ball mill at 500 rpm for 12 h to obtain a negative electrode material for a lithium-ion battery with a particle size D90 of less than 30 μm. The scanning electr...

Embodiment 2

[0044] Get 1.78g of silicon nanoparticles (particle diameter D50 is 30nm) and disperse in 8g of liquid vinyl tris (2-methoxyethoxy) silane monomer compound and stir for 12h. Add 2 mL of deionized water with a pH of 6.8, and keep stirring for 48 hours, add 12.32 g of phenolic resin ethanol solution with a mass fraction of 50%, and continue stirring for 48 hours. Under the condition of stirring, heat to 80°C for 48 hours to remove the solvent. The mixed solution solidifies.

[0045] The obtained cured precursor was treated at 750 °C for 1 h in a protective atmosphere, and then calcined at 1050 °C for 1.5 h to obtain a theoretical stoichiometric ratio of 3.31 Si-SiO 1.5 C 8.7 Si-based composite bulk material. The obtained composite material was crushed by magnetic force for 1min, and processed under a planetary ball mill at 500rpm for 12h to obtain a lithium-ion battery negative electrode material with a particle size D90 lower than 30 μm. The X-ray diffraction pattern of the m...

Embodiment 3

[0048] Get 0.422g of silicon nanoparticles (particle diameter D50 is 30nm) and disperse in 8g of liquid vinyl tris (2-methoxyethoxy) silane monomer compound and stir for 3h. Add 1 mL of deionized water with a pH of 6.8, and keep stirring for 12 hours, add 12.32 g of phenolic resin ethanol solution with a mass fraction of 50%, and continue stirring for 24 hours. While stirring, heat at 150°C for 0.5 hours to remove the solvent The mixed solution is allowed to solidify.

[0049] The obtained cured precursor was treated at 750 °C for 1 h in a protective atmosphere, and then calcined at 1050 °C for 1.5 h to obtain a theoretical stoichiometric ratio of 0.93 Si-SiO 1.5 C 8.7 Si-based composite bulk material. The obtained composite material was crushed by magnetic force for 1 min, and processed under a planetary ball mill at 500 rpm for 12 h to obtain a silicon-based lithium-ion battery negative electrode material with a particle size D90 of less than 30 μm.

[0050] The preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com