Graphene nano-ribbon-based lithium iron phosphate composite material and preparation method and application thereof

A technology based on lithium iron phosphate and nano strips, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of limited improvement in the conductivity of amorphous carbon, decreased battery energy density, block Solve the problems of uneven heating of bulk materials, and achieve the effect of good ion and electronic conductivity, high conductivity, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] As an aspect of the technical solution of the present invention, it relates to a graphene nanoribbon-based lithium iron phosphate composite material (also known as lithium iron phosphate / amorphous carbon / graphene nanoribbon composite active material) Preparation method, which comprises:

[0033] Mix ferric compound, lithium source, phosphorus source, carbon source, graphene oxide nanoribbons and solvent uniformly and dry to obtain precursor powder;

[0034] The precursor powder is sintered at a high temperature in a protective atmosphere to obtain a graphene nanoribbon-based lithium iron phosphate composite material.

[0035] In some embodiments, the molar ratio of ferric element, lithium element and phosphorus element in the graphene nanoribbon-based lithium iron phosphate composite material is 1:(1.01˜1.05):1.

[0036] Further, the content of carbon element in the graphene nanoribbon-based lithium iron phosphate composite material is 1-5 wt%.

[0037] Further, the m...

Embodiment 1

[0071] In this embodiment, the preparation process of graphene nanoribbon-based lithium iron phosphate composite material (hereinafter referred to as "lithium iron phosphate / amorphous carbon / graphene nanoribbon composite active material") comprises the following steps:

[0072] 1) Mix 0.21g of graphene oxide nanoribbons, 45.25g of iron phosphate, 11.42g of lithium carbonate, 6.94g of glucose monohydrate, and 160g of deionized water, and stir at a high speed of 1000r / min for 2h to obtain a uniformly mixed precursor slurry material;

[0073] 2) Spray-dry the precursor slurry (at an inlet temperature of 270°C) and dry it in a vacuum oven at 60°C overnight;

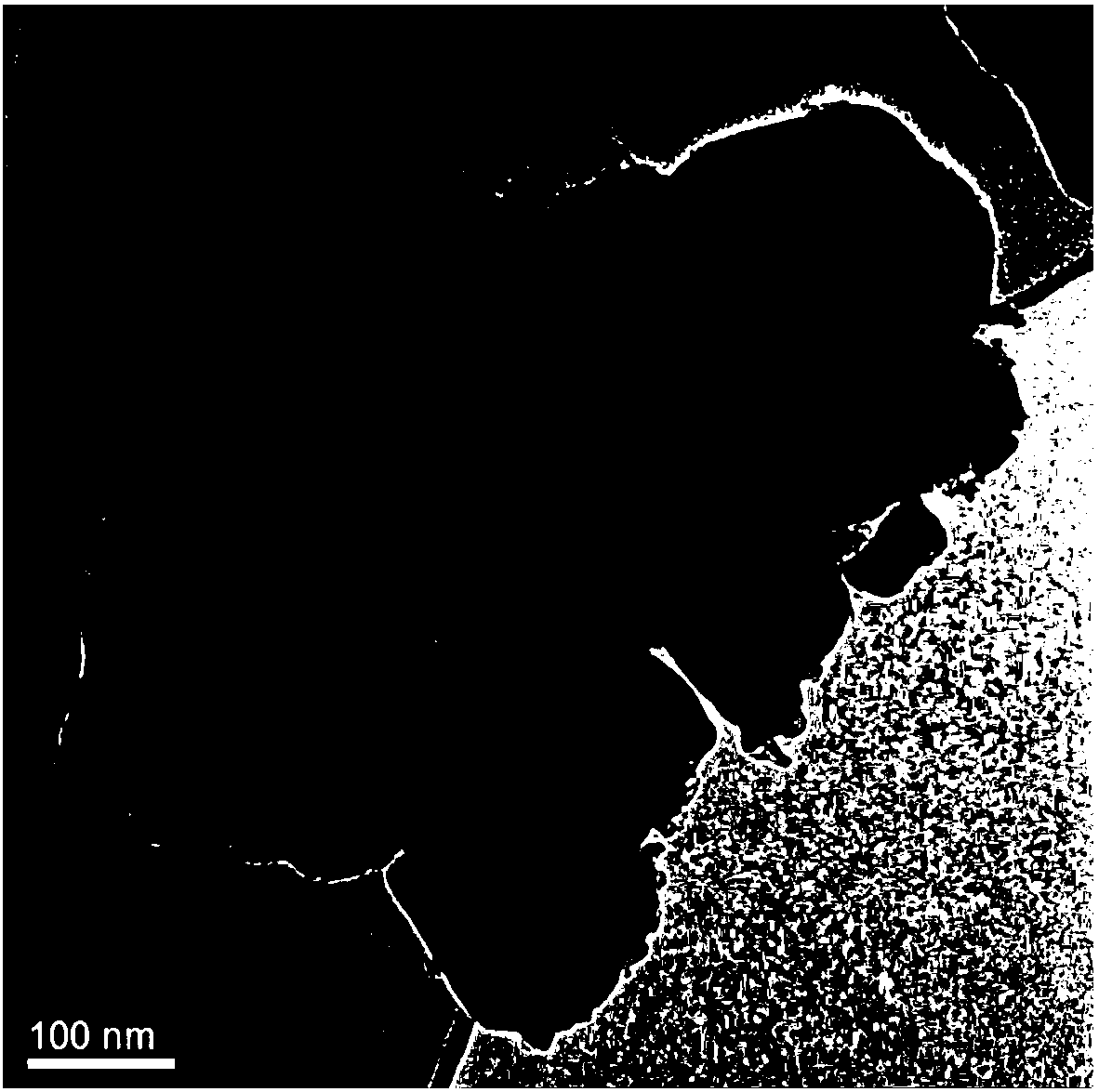

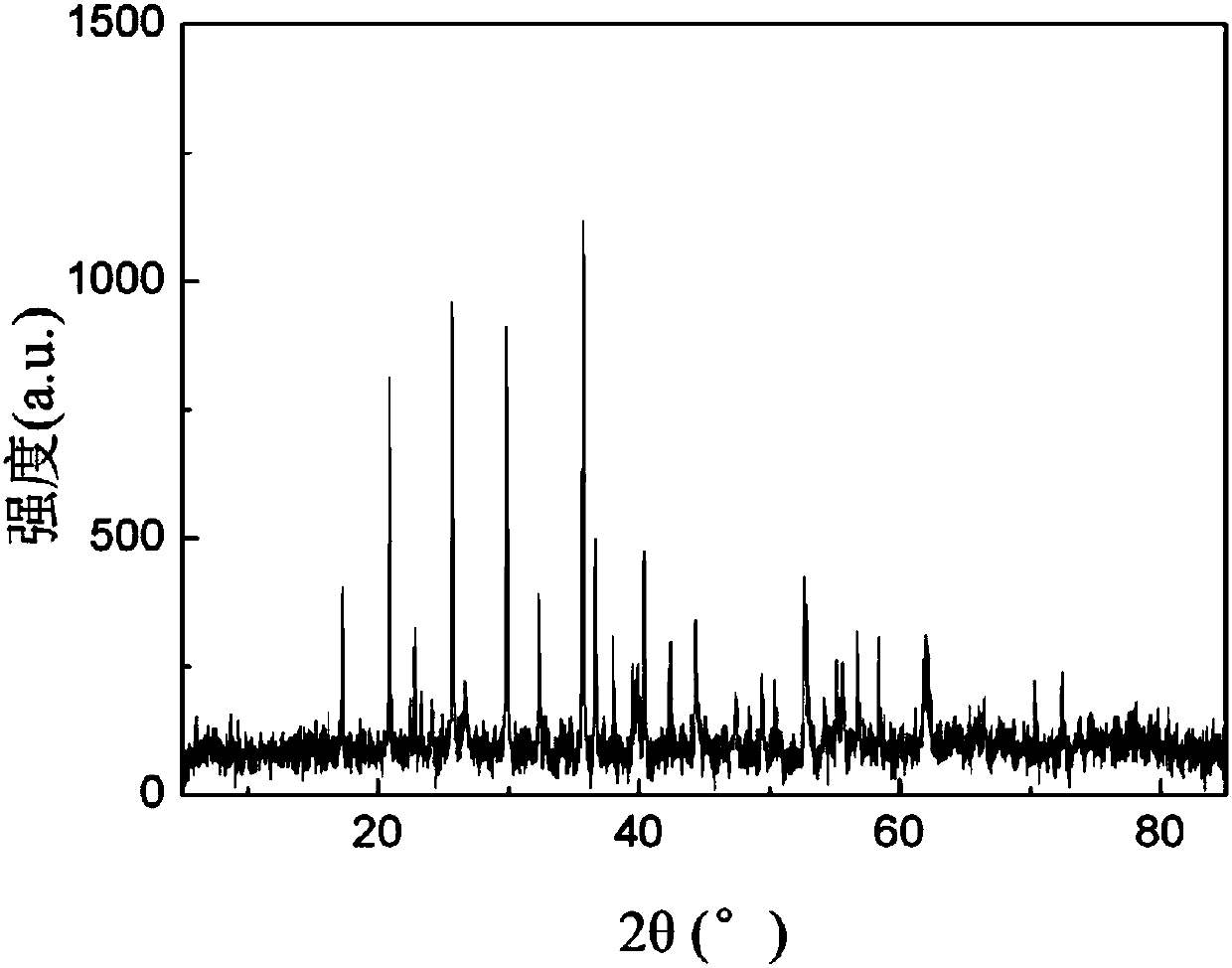

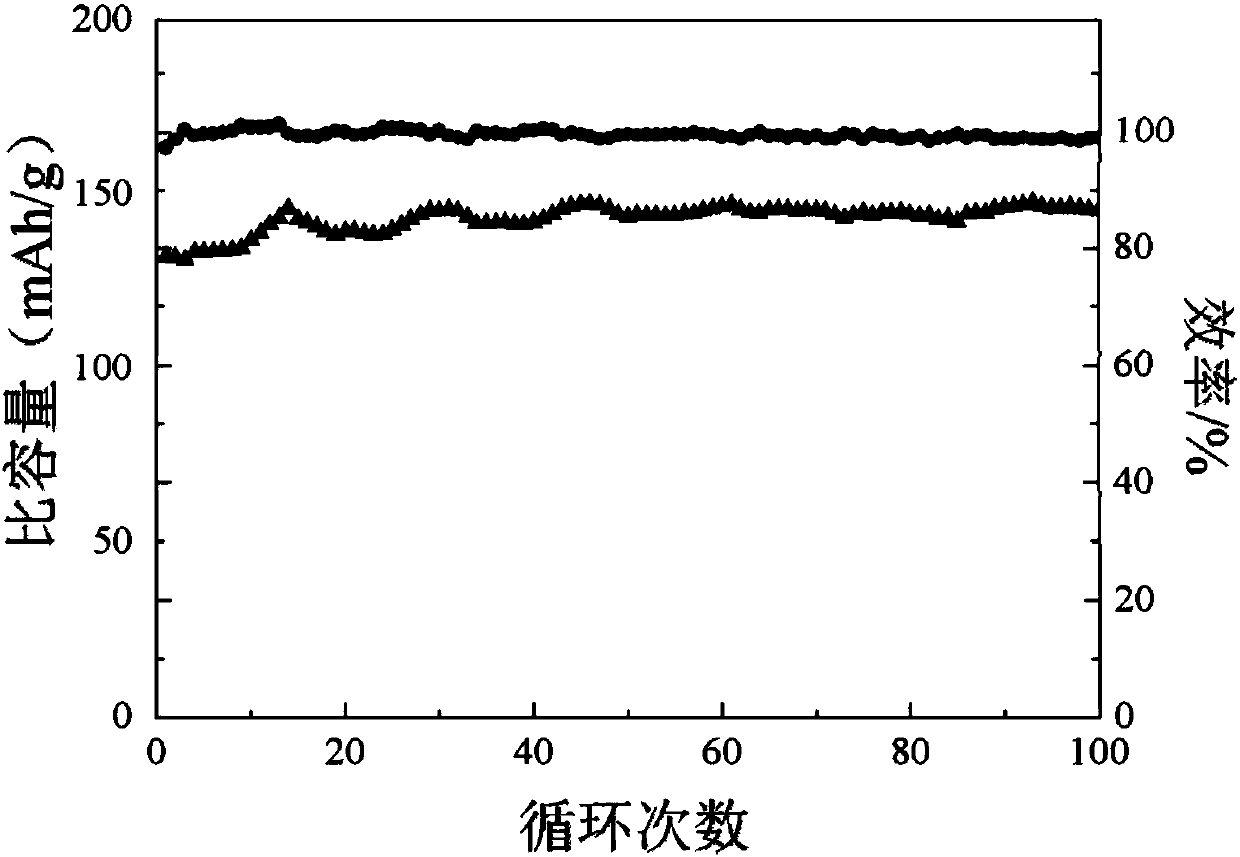

[0074] 3) Put the precursor powder into a tube furnace, raise the temperature to 750°C at a rate of 10°C / min in a nitrogen atmosphere, and then sinter at a constant temperature for 4 hours. After the powder is naturally cooled to room temperature, use a jet mill to pulverize the particles to obtain iron phosphate Lithium / amo...

Embodiment 2

[0077] In this embodiment, the preparation process of lithium iron phosphate / amorphous carbon / graphene nanoribbon composite active material comprises the following steps:

[0078] 1) Mix 0.57g of graphene oxide nanoribbons, 40g of iron oxide, 52.48g of lithium dihydrogen phosphate, 11.58g of glucose monohydrate, and 156g of deionized water, and stir at a high speed of 1000r / min for 2h to obtain a uniformly mixed precursor slurry;

[0079] 2) Spray-dry the precursor slurry (at an inlet temperature of 270°C) and dry it in a vacuum oven at 60°C overnight;

[0080] 3) Put the precursor powder into a tube furnace, raise the temperature to 900°C at a rate of 10°C / min in a nitrogen atmosphere, and then sinter at a constant temperature for 2 hours. After the powder is naturally cooled to room temperature, use a jet mill to pulverize the particles to obtain iron phosphate Lithium / amorphous carbon / graphene nanoribbon composite active materials.

[0081] The total carbon content in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com