Metal thio compound @ S composite material and preparation and application thereof in lithium-sulfur battery

A technology of metal thio compounds and composite materials, applied in the direction of lithium batteries, battery electrodes, active material electrodes, etc., can solve the problems of poor lithium conduction performance and unsatisfactory electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Preparation of positive electrode material: Weigh 1.6g of elemental S, 3.58g of dimethylammonium dimethyldithiocarbamate and 0.348g of sodium dodecylbenzenesulfonate in 100mL of deionized water for ultrasonic dispersion for 1 hour. After the ultrasound is finished, transfer it to a water bath, set the heating temperature to 70°C, slowly add the prepared 0.05mol / L silver nitrate solution dropwise, react for 12 hours and then cool naturally. The reaction solution was placed in a centrifuge tube and centrifuged at a speed of 8000 r / min, and the centrifuged filter residue was alternately washed three times with deionized water and ethanol and dried at 60° C. for 24 hours to obtain the positive electrode material.

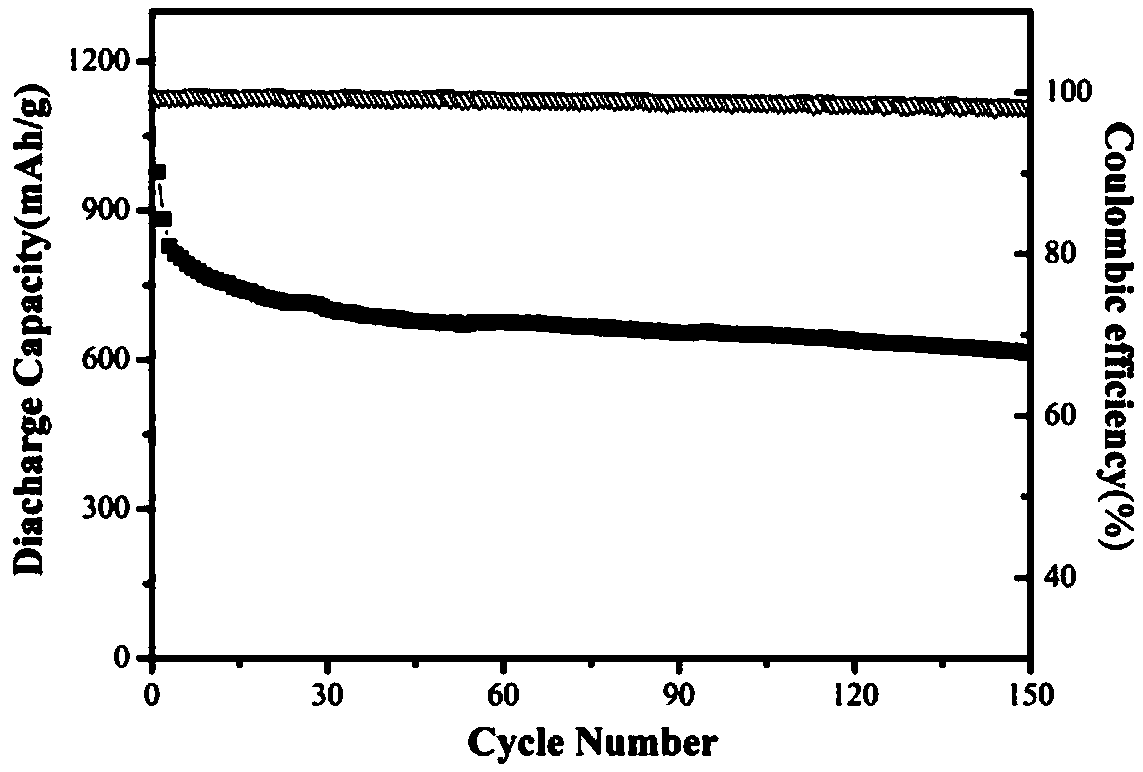

[0074] Lithium-sulfur battery assembly and testing: Slurry prepared with organometallic thio compound-coated sulfur element, acetylene black, and PVDF in a ratio of 6:3:1 was coated on carbon-coated aluminum foil to prepare a positive electrode, and the prepared p...

Embodiment 2

[0076] Preparation of positive electrode material: Weigh 1.6g elemental S, 3.32g sodium dimethyldithiocarbamate and 0.56g N-polyvinylpyrrolidone in 80mL deionized water for ultrasonic dispersion for 1 hour. After the ultrasound is finished, transfer it to a water bath, set the heating temperature to 70°C, slowly add the prepared 0.05mol / L lithium acetate solution dropwise, react for 12 hours and then cool naturally. The reaction solution was placed in a centrifuge tube and centrifuged at a speed of 8000 r / min, and the centrifuged filter residue was alternately washed three times with deionized water and ethanol and dried at 60° C. for 24 hours to obtain the positive electrode material.

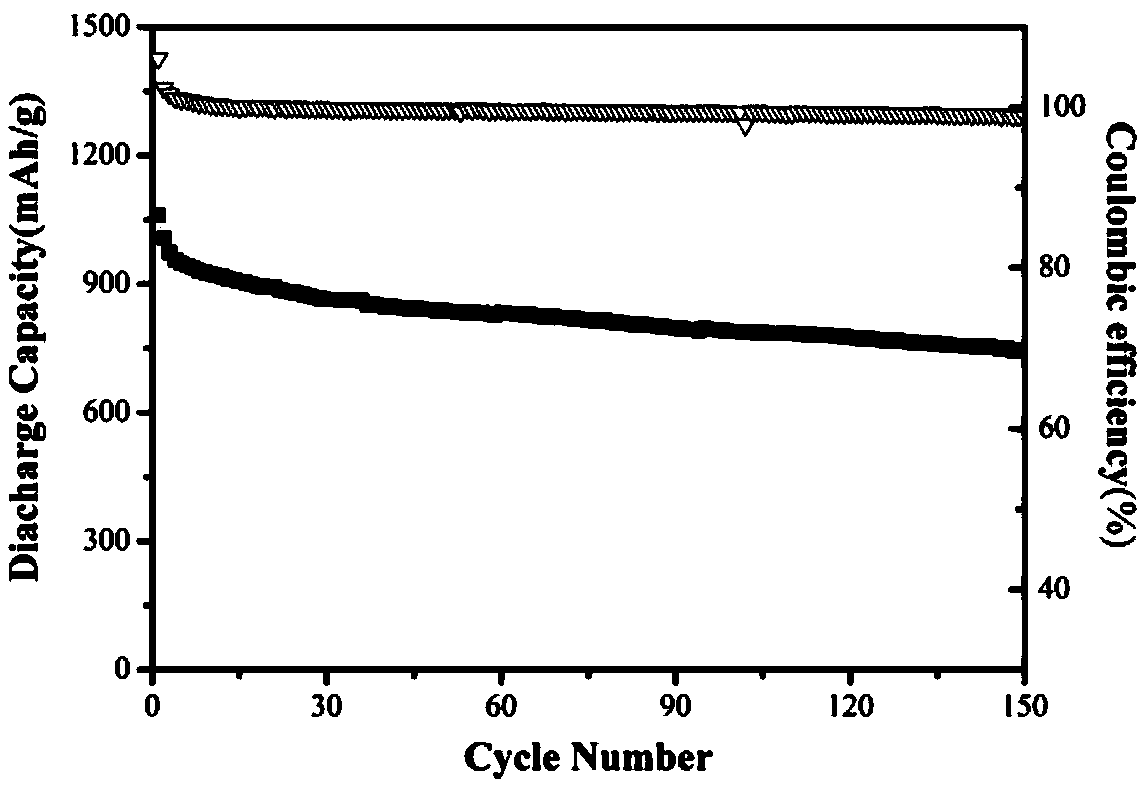

[0077] Lithium-sulfur battery assembly and testing: Slurry prepared with organometallic thio compound-coated sulfur element, acetylene black, and PVDF in a ratio of 6:3:1 was coated on carbon-coated aluminum foil to prepare a positive electrode, and the prepared positive electrode sheet was pun...

Embodiment 3

[0079] Preparation of positive electrode material: Weigh 1.6g of elemental S, 3.32g of sodium dimethyldithiocarbamate and 0.56g of sodium dodecylbenzenesulfonate and place them in 80mL of deionized water for ultrasonic dispersion for 1 hour. After the ultrasound is finished, transfer it to a water bath, set the heating temperature to 70°C, slowly add the prepared 0.02mol / L copper chloride solution dropwise, react for 12 hours and then cool naturally. The reaction liquid was placed in a centrifuge tube and centrifuged at a speed of 8000 r / min. The filter residue obtained by centrifugation was alternately washed three times with deionized water and ethanol and dried at 60° C. for 24 hours to obtain the positive electrode material.

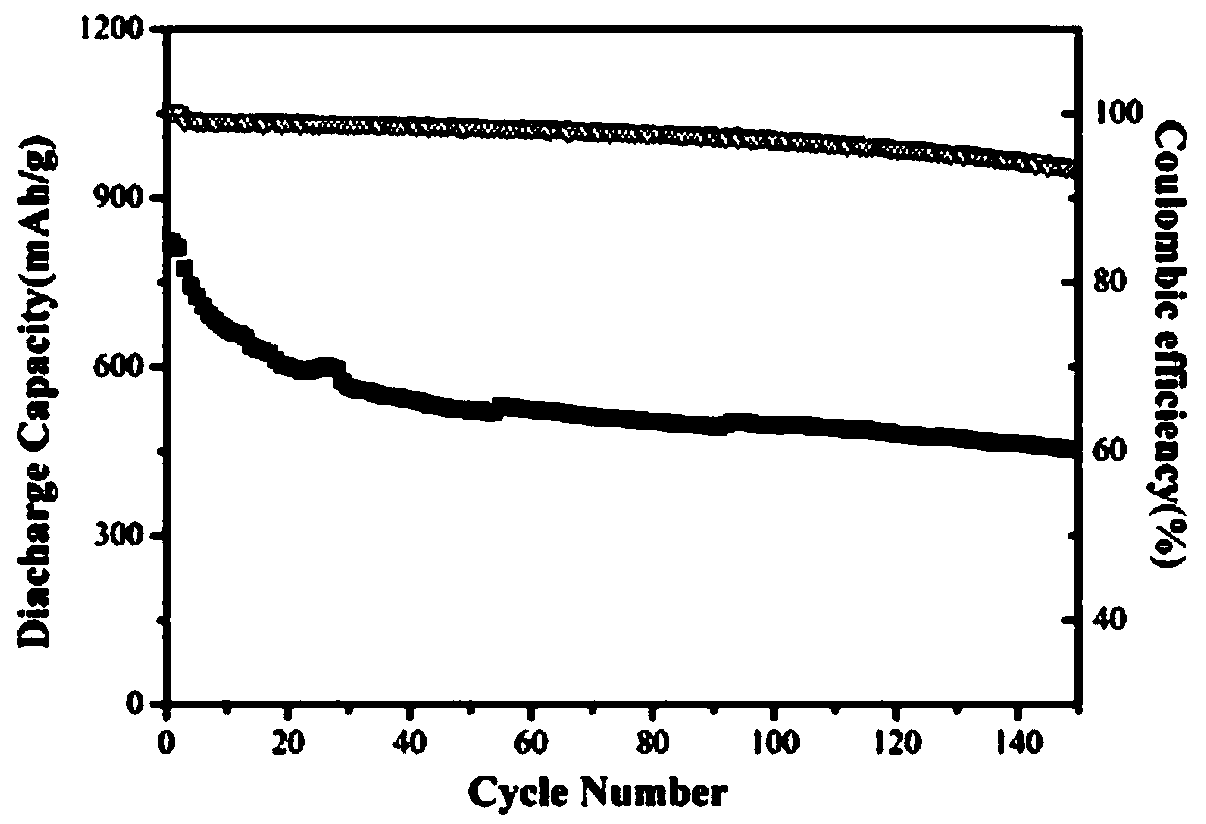

[0080] Lithium-sulfur battery assembly and testing: Slurry prepared by coating organometallic thio compound-coated sulfur element, acetylene black, and PVDF in a ratio of 6:3:1 was coated on carbon-coated aluminum foil to prepare a positive electrode,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com