Method for preparing high-impact high-gloss ABS resin by using high-viscosity rubber

An ABS resin, high impact technology, applied in the field of polymer material preparation to reduce production costs and ensure mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

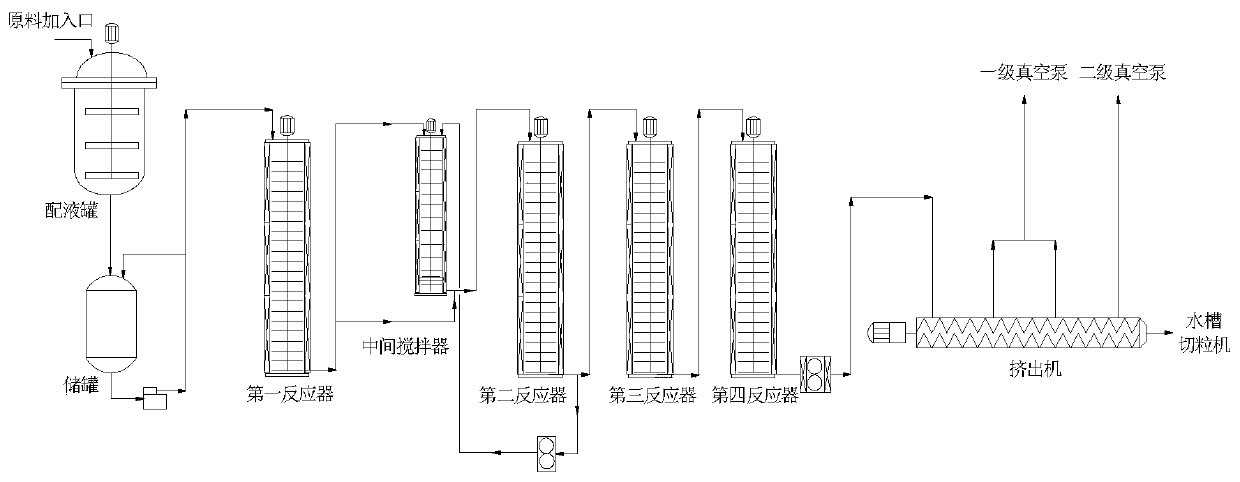

Method used

Image

Examples

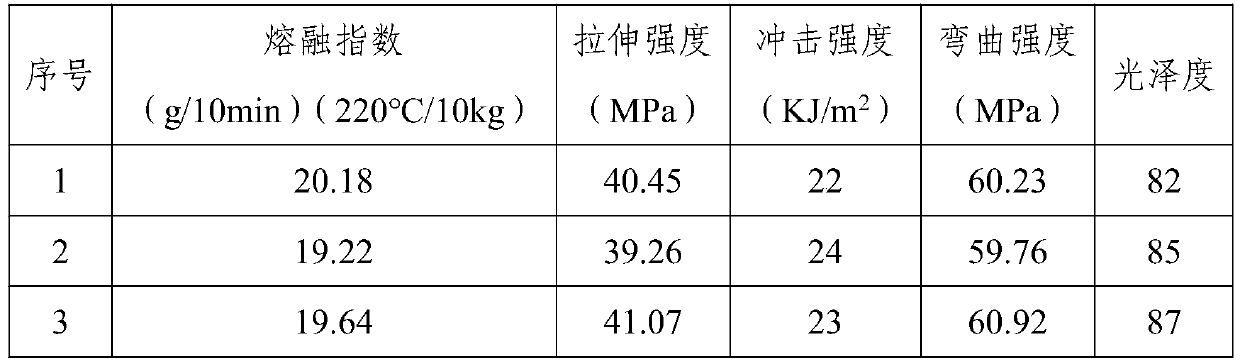

Embodiment 1

[0028] Add 20kg 565T rubber (low cis rubber), 110kg styrene and 18kg ethylbenzene mixture into the solution tank, stir and dissolve at room temperature for 12h, then add 18kg acrylonitrile and continue to stir and disperse for 12h.

[0029] The main feed to the reactor was 4.5 kg / h, and in the first reactor, the reaction was carried out to a polymer product solids content of 20%.

[0030] The material at the outlet of the first reactor is divided into two parts, and the flow rate of one material is 3.6kg / h, and it enters the strong stirring tank (ie the middle agitator) between the first reactor and the second reactor. The stirring speed of the strong stirring tank is At 120 rpm, the average particle size of the rubber is 0.6 μm; the flow rate of another material is 0.9 kg / h, directly entering the second reactor, and the average particle size of the rubber in the material is 3 μm.

[0031] The material at the outlet of the second reactor is divided into two parts, and one part...

Embodiment 2

[0035] Add 23kg of 700A rubber (low cis rubber), 109kg of styrene and 28kg of ethylbenzene mixture into the solution tank, stir and dissolve at room temperature for 12h, then add 31kg of acrylonitrile and continue to stir and disperse for 12h.

[0036] The main feed to the reactor was 4.5 kg / h, and in the first reactor, the reaction was carried out to a polymer product solids content of 20%.

[0037] The material at the outlet of the first reactor is divided into two parts, and the flow rate of one material is 3.8kg / h, and it enters the strong stirring tank between the first reactor and the second reactor. The stirring speed of the strong stirring tank is 130 rpm, and the average particle size of the rubber is is 0.4μm, and the viscosity of the glue solution is 32Pa.s; the flow rate of another material is 0.7kg / h, which directly enters the second reactor, and the average particle size of the rubber in the material is 2μm.

[0038] The material at the outlet of the second react...

Embodiment 3

[0042] Add 25kg of 30AF rubber (low cis rubber), 110kg of styrene and 20kg of ethylbenzene mixture into the solution tank, stir and dissolve at room temperature for 12h, then add 31kg of acrylonitrile and continue to stir and disperse for 12h.

[0043] The main feed rate of the reactor is 4.5 kg / h, and in the first reactor, the reaction is carried out until the solid weight percentage of the polymer product is 20%.

[0044] The material at the outlet of the first reactor is divided into two parts, and the flow rate of one material is 4.0kg / h, and it enters the strong stirring tank between the first reactor and the second reactor. The stirring speed of the strong stirring tank is 120 rpm, and the average particle size of the rubber is is 0.6μm, and the viscosity of the glue solution is 42Pa.s; another material flow rate is 0.5kg / h, which directly enters the second reactor, and the average particle size of the rubber in the material is 3μm.

[0045] The material at the outlet of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com