A kind of high fluidity, scratch-resistant TPV material and its preparation method and application

A high-fluidity and scratch-resistant technology, applied in the field of thermoplastic vulcanizates, can solve the problems of poor fluidity and scratch resistance, and achieve the effect of improving scratch resistance, high fluidity, and good dynamic vulcanization reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

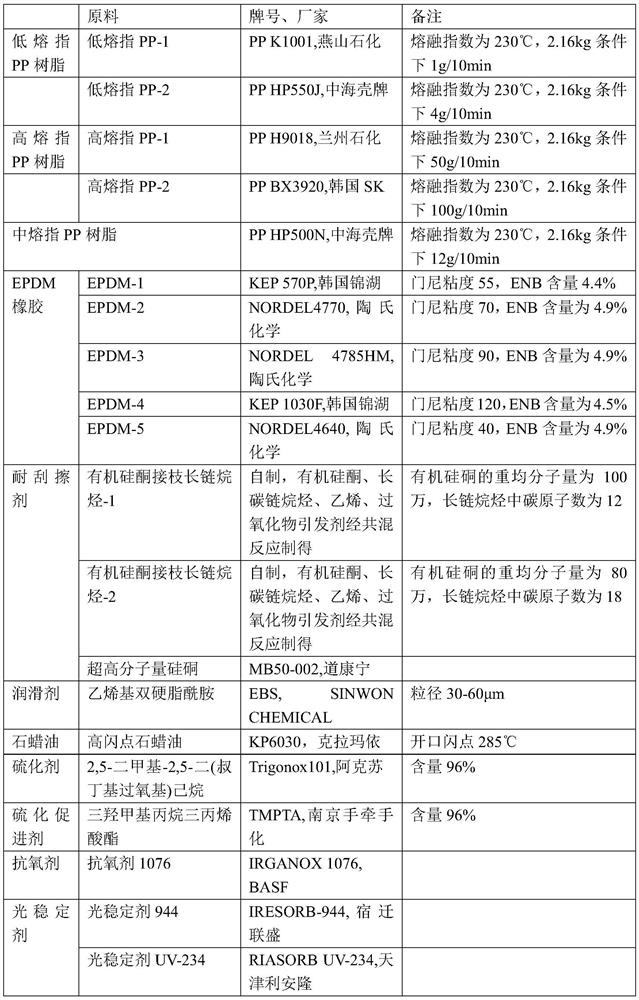

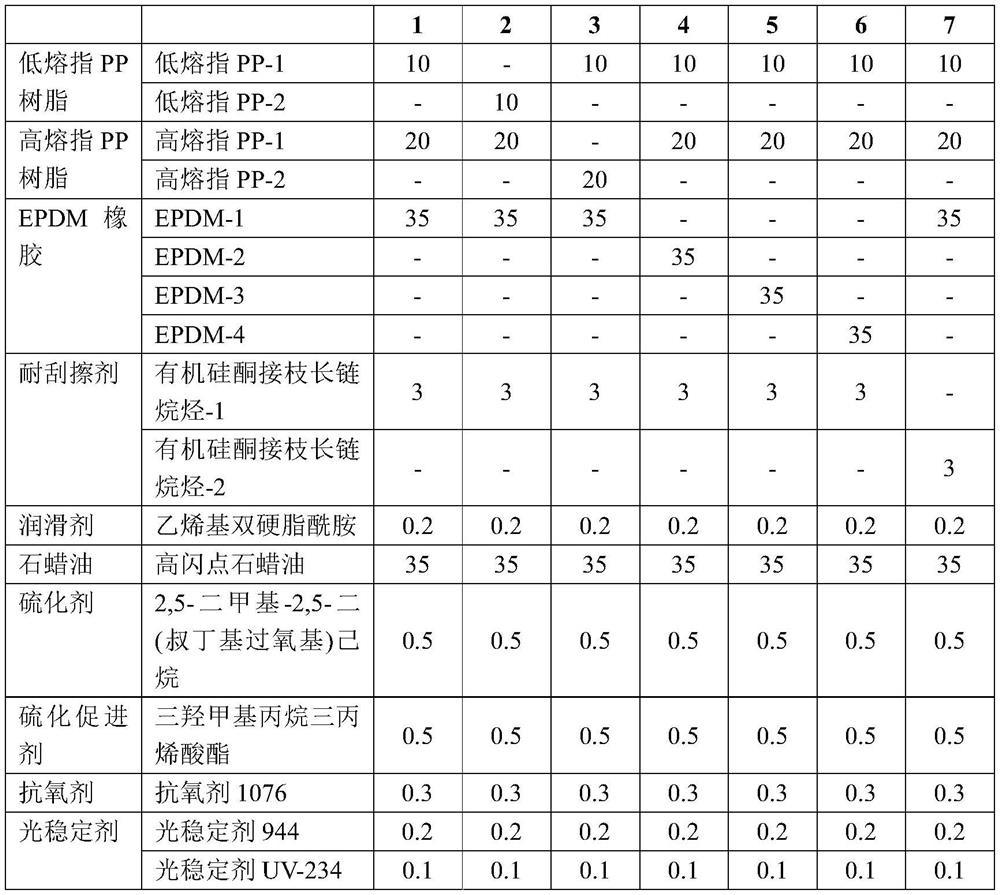

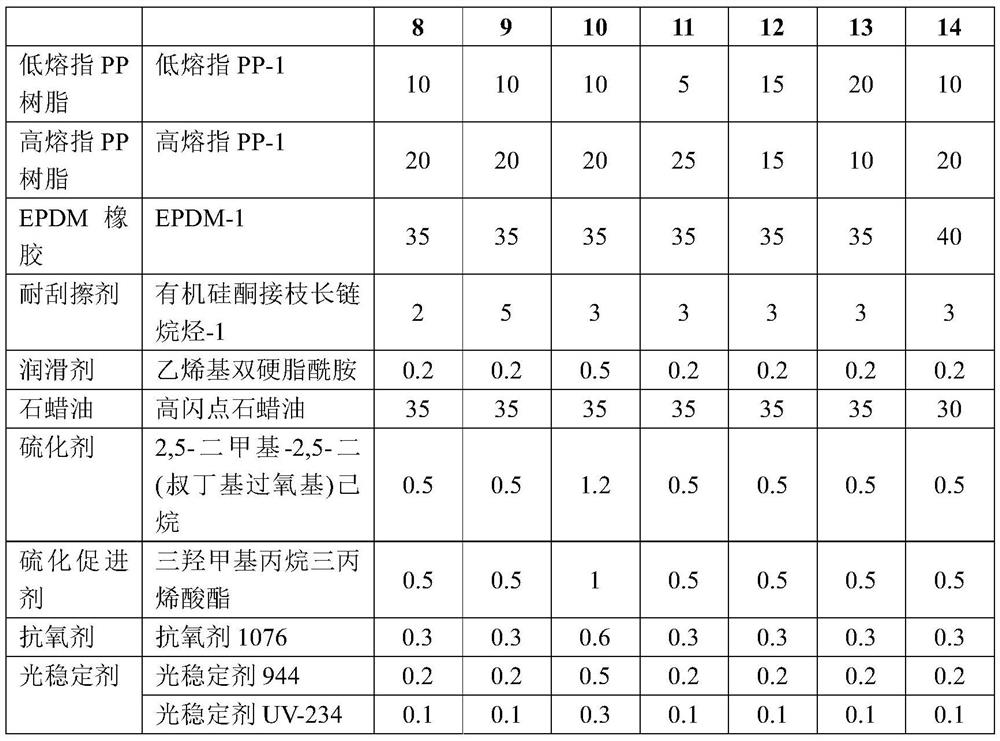

[0063] The content of each component in the TPV materials of Examples 1-14 is shown in Table 1.

[0064] Its preparation method is:

[0065] S1. According to Table 1, mix low-melt index PP resin, high-melt index PP resin, EPDM rubber, vulcanization accelerator, antioxidant, and light stabilizer and add them to the main feed port of the twin-screw extruder. Add paraffin oil to the third screw barrel of the extruder, add vulcanizing agent to the sixth screw barrel of the twin-screw extruder, melt and mix, extrude and granulate to obtain TPV semi-finished products, wherein the screw length of the twin-screw extruder is The diameter ratio is 60:1, the screw speed is 500-650r / min, and the melting and mixing temperature is 160-200°C;

[0066] S2. Add the TPV semi-finished product, anti-scratch agent and lubricant to the twin-screw extruder after mixing, and inject water into the sixth section of the twin-screw extruder. The injection weight of water is 5-20% of the weight of the TP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com