Ink jet recording method, ink set, and recorded article

An inkjet recording method and ink technology, applied in the field of inkjet recording methods, ink sets and recorded objects, capable of solving problems such as gloss degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

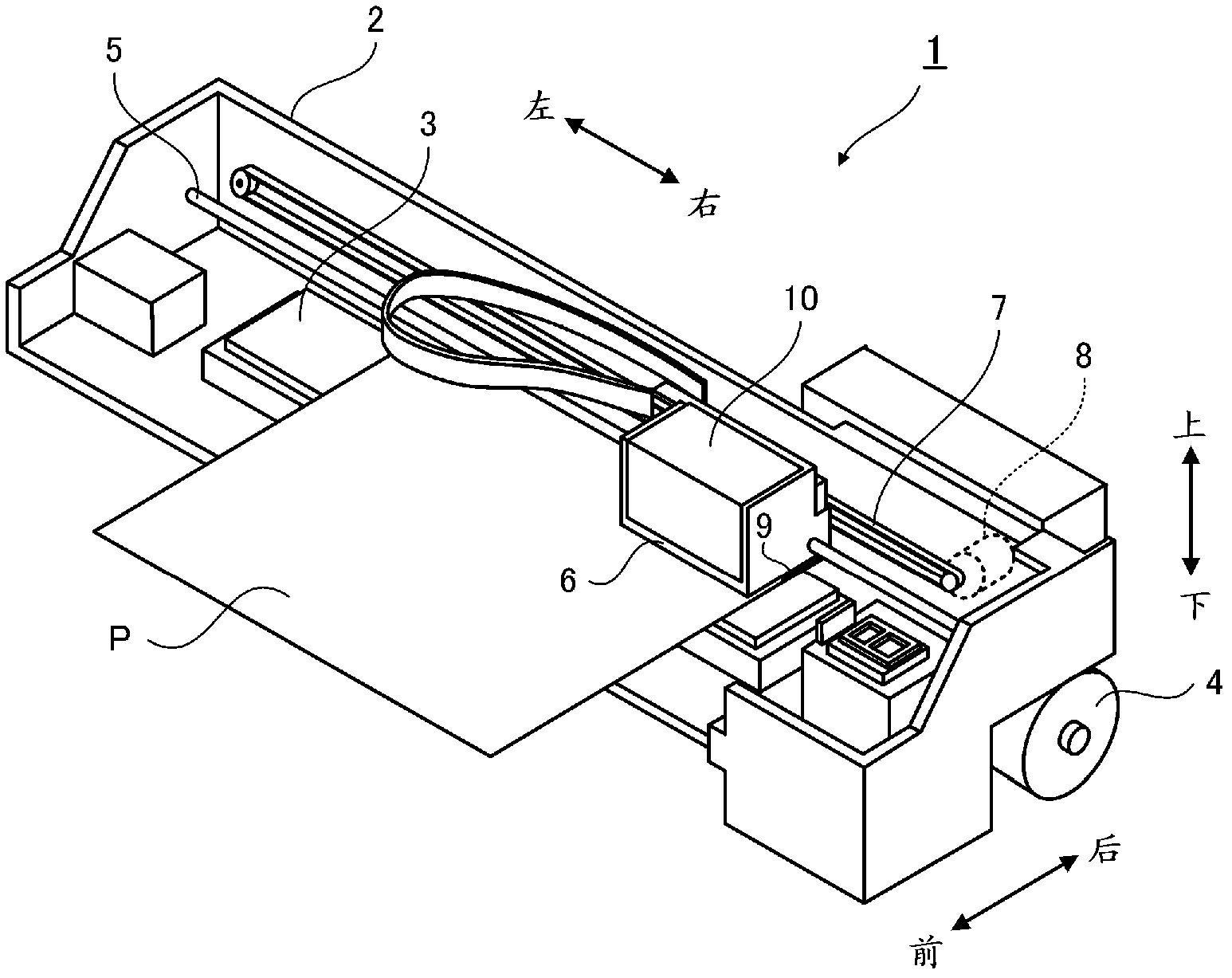

[0143] In the following, the preferred implementation of the present invention is explained.It should be explained that each attached picture is a schematic diagram, and of course it is not limited to that composition.

[0144]

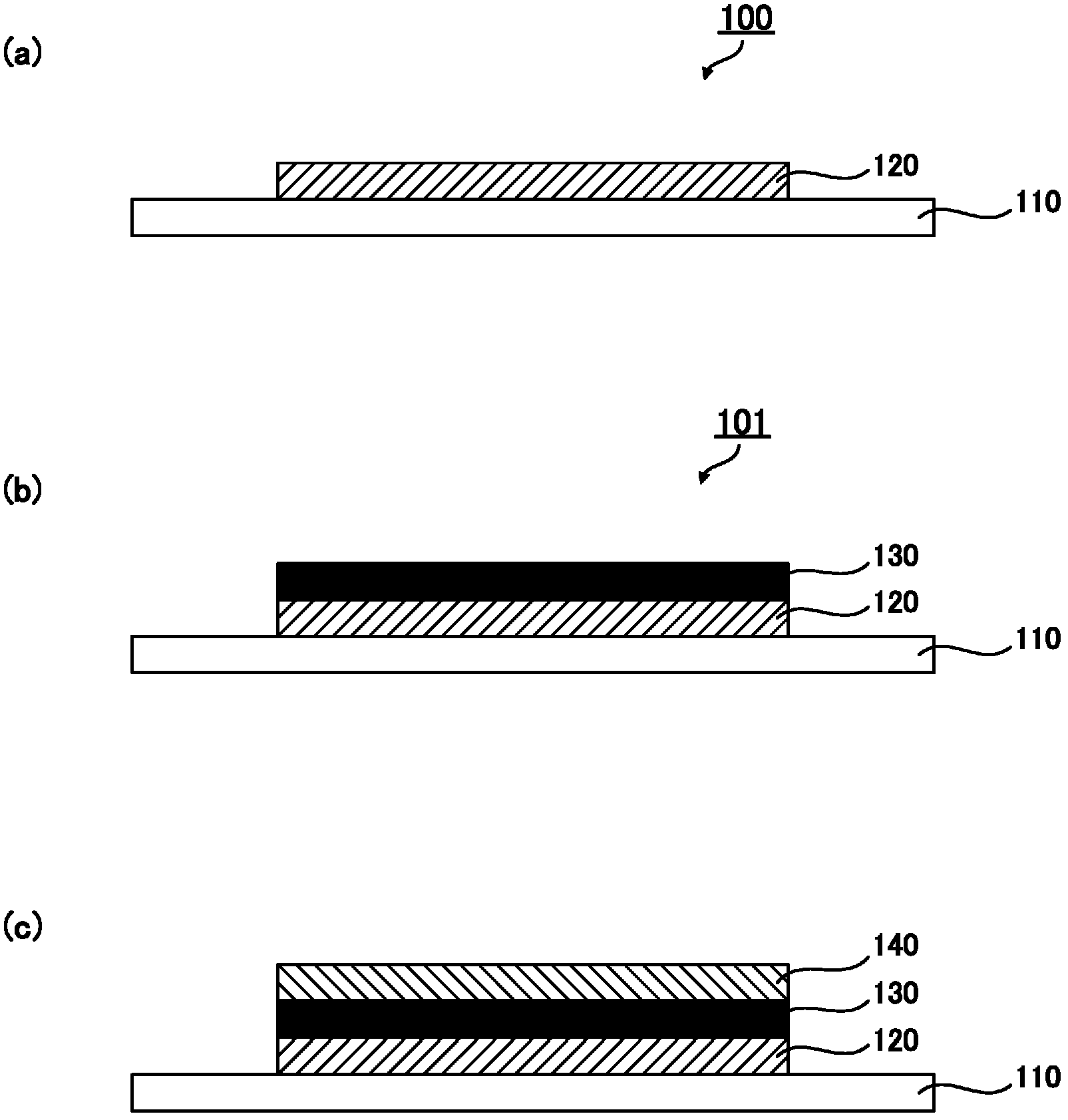

[0145] In this process, prepare the 1st record medium 110, and on the side of the 1st record medium 110, use the above inkjet device to give a bright ink, such as figure 2 (A) Show, the first image 120 is formed on the 1st record medium 110, and the 1st record anterior body 100 is obtained.

[0146]

[0147] In this process, to figure 2 (A) On the 1st image 120 of the front body 100, the above inkjet device is used to give protection ink, such as figure 2 (B) Show, the first record of the 1st image 120 and the protective layer 130 in the upper layer 110 of the 1st record medium 110 are obtained.

[0148]

[0149] In the desk of this worker figure 2 (b) The first record of the pre -body 101 shown in the pre -body 101, the above inkjet device is used to ...

no. 2 Embodiment approach

[0154]

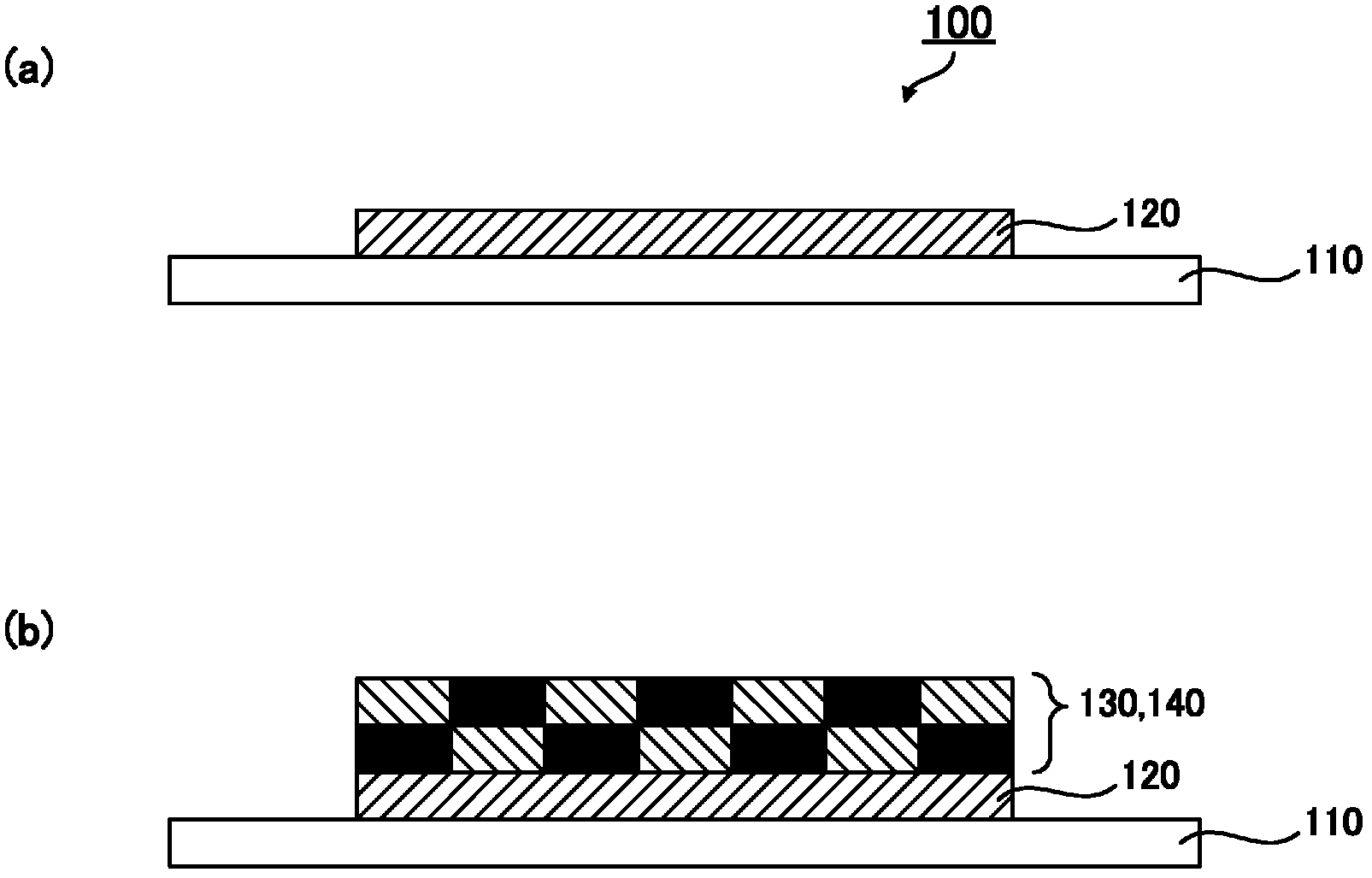

[0155] In this process, prepare the 1st record medium 110 as the first embodiment, and use the above inkjet device to give a bright ink on the side of the 1st record medium 110, such as image 3 (A) Show, the first image 120 is formed on the 1st record medium 110, and the first record front body 110 is obtained.

[0156]

[0157] In this process, to image 3 (A) On the 1st image 120 of the front body 100, the above inkjet device is used to protect the protection of ink and color ink, such as image 3 (B) Show, a record of the protective layer 130 and the 2nd image 140 on the first image 120.

[0158] It should be explained that for the above -mentioned first image formation process, protection ink attachment, and the second image formation process. In order to perform various processes, the first record medium 110 can be implemented according to each process to the inkjet device; or it can alsoThe nozzle of the inkjet head used in the inkjet inkjet device is lined up to th...

no. 3 Embodiment approach

[0162]

[0163] In this process, prepare the 1st record medium 110 as the first embodiment, and use the above inkjet device to give the light bright ink and protect the ink on the side of the 1st record medium 110, such as Figure 4 (A) Show, the first image 120 and protective layer 130 are formed on the first record medium 110, and the first record front body 100 is obtained.

[0164]

[0165] In this process, in Figure 4 (A) On the first image 120 of the front body 100 and the protective layer 130, the above inkjet device is used to give color ink with the above inkjet devices. Figure 4 (B) Show, obtain a record of the second image 140 on the first image 120 and the protective layer 130 at the same time.

[0166] It should be explained that for the above -mentioned first image formation and protection of ink attachment processes, and second image formation processes. In order to perform various processes, the first record medium 110 can be implemented according to each process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com