Fine concave-convex surface matte ceramic tile and preparation method thereof

A concave-convex, matte technology, used in the field of ceramic tiles, can solve the problems of unsatisfactory matte performance and insufficient gloss, achieve obvious contrast between low light and matte, excellent flexibility, good color development ability and effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

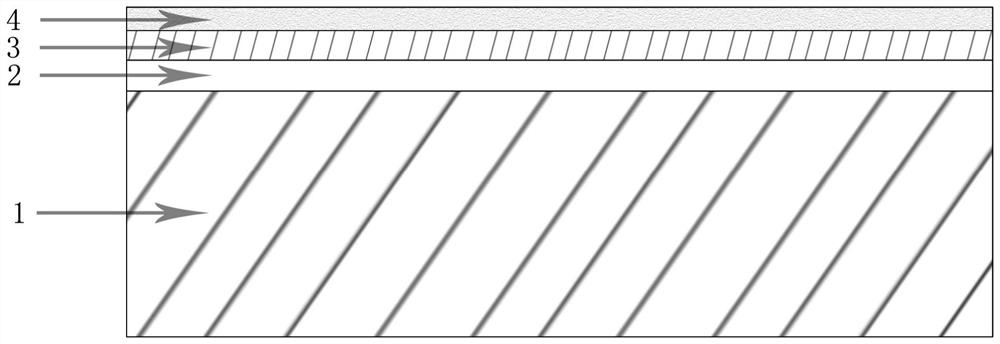

[0041] Provided is a method for preparing fine concave-convex surface matte tiles, comprising:

[0042] Step 1: Preparation of green body powder: ball mill according to the conventional green body formula to obtain mud, and the obtained mud material is granulated in a spray drying tower to obtain a powder with a certain particle size distribution and moisture content;

[0043] Step 2: Pressing and molding the green body with fine concave-convex surface: pressing the powder obtained in step 1 on a press to obtain a green body;

[0044] Step 3: Drying the green body in the drying kiln: send the green body obtained in step 2 into the drying kiln for drying, the drying temperature is 180-230°C, and the drying time is 60-80 minutes to obtain a dried body, and the moisture content of the dried body is controlled at 0.3- 0.6%;

[0045]Step 4: Drizzle the surface glaze: use a bell jar to pour the surface glaze glaze onto the surface of the dry billet obtained in step 3, and the proce...

Embodiment 1

[0054] A method for preparing fine concave-convex surface matt tiles is provided, the process flow of which is as follows:

[0055] Step 1: Preparation of green body powder: ball mill according to the conventional green body formula to obtain mud, and the obtained mud material is granulated in a spray drying tower to obtain a powder with a certain particle size distribution and moisture content;

[0056] Step 2: Press molding of fine concave-convex surface green body: Press the powder obtained in step 1 on a press to obtain a green body. The pressed mold is a PETG material that has been carved with fine concave-convex natural texture by a laser engraving machine;

[0057] Step 3: drying the green body in the drying kiln: send the green body obtained in step 2 into the drying kiln for drying, the drying temperature is 190°C, and the drying time is 70 minutes to obtain a dried body, and the moisture content of the dried body is controlled at 0.4%;

[0058] Step 4: Drizzle the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com