Scratch-resistant thermal-sensitive paper manufacturing method

A manufacturing method and technology of thermal paper, applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of poor impact resistance, no softness and elasticity, poor scratch resistance of paper, etc., and achieve excellent scratch resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

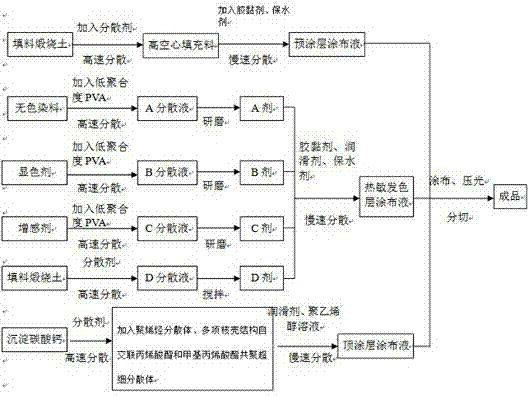

[0056] A method for manufacturing scratch-resistant thermal paper includes the following steps:

[0057] a) Preparation of pre-coating coating liquid:

[0058] Add water to the pre-coated batching tank, open the batching tank and stir, add calcined kaolin with a particle size of 2um, with an oil absorption value of 40~55, add inorganic pigment dispersant, and carry out high-speed dispersion for 40~60 minutes, and the dispersion speed is 1000~1200 revolutions / Then disperse slowly at a speed of 200~300 rpm, then add high hollow fillers (such as plastic pigments), then add adhesive and water-retaining agent in sequence, and disperse for 20 minutes to form a solid content of 40 %~60% pre-coating coating liquid;

[0059] The parts by weight of the calcined kaolin, inorganic pigment dispersant, adhesive, water retention agent and high hollow filler are:

[0060] Calcined kaolin 60~70 parts

[0061] Dispersant 0.5~1 part

[0062] Adhesive 8~12 parts

[0063] Water retaining agent 0.5~1 part

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com