Ink composition, recording method using it and recording image, ink group and ink jet head

A technology of ink composition and recording method, applied in the direction of ink, application, household utensils, etc., can solve the problem of not determining the dynamic surface tension of the slow moving state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

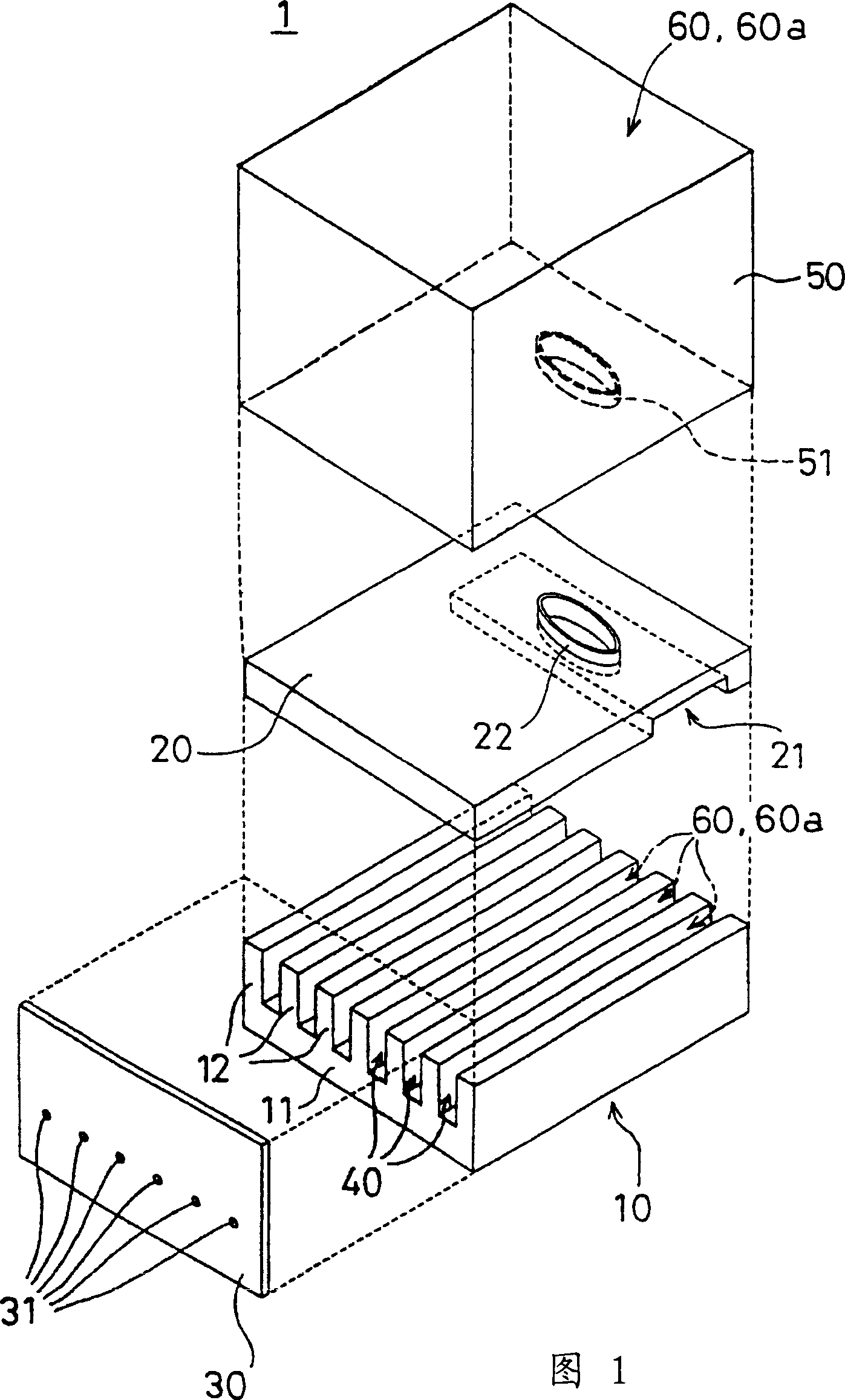

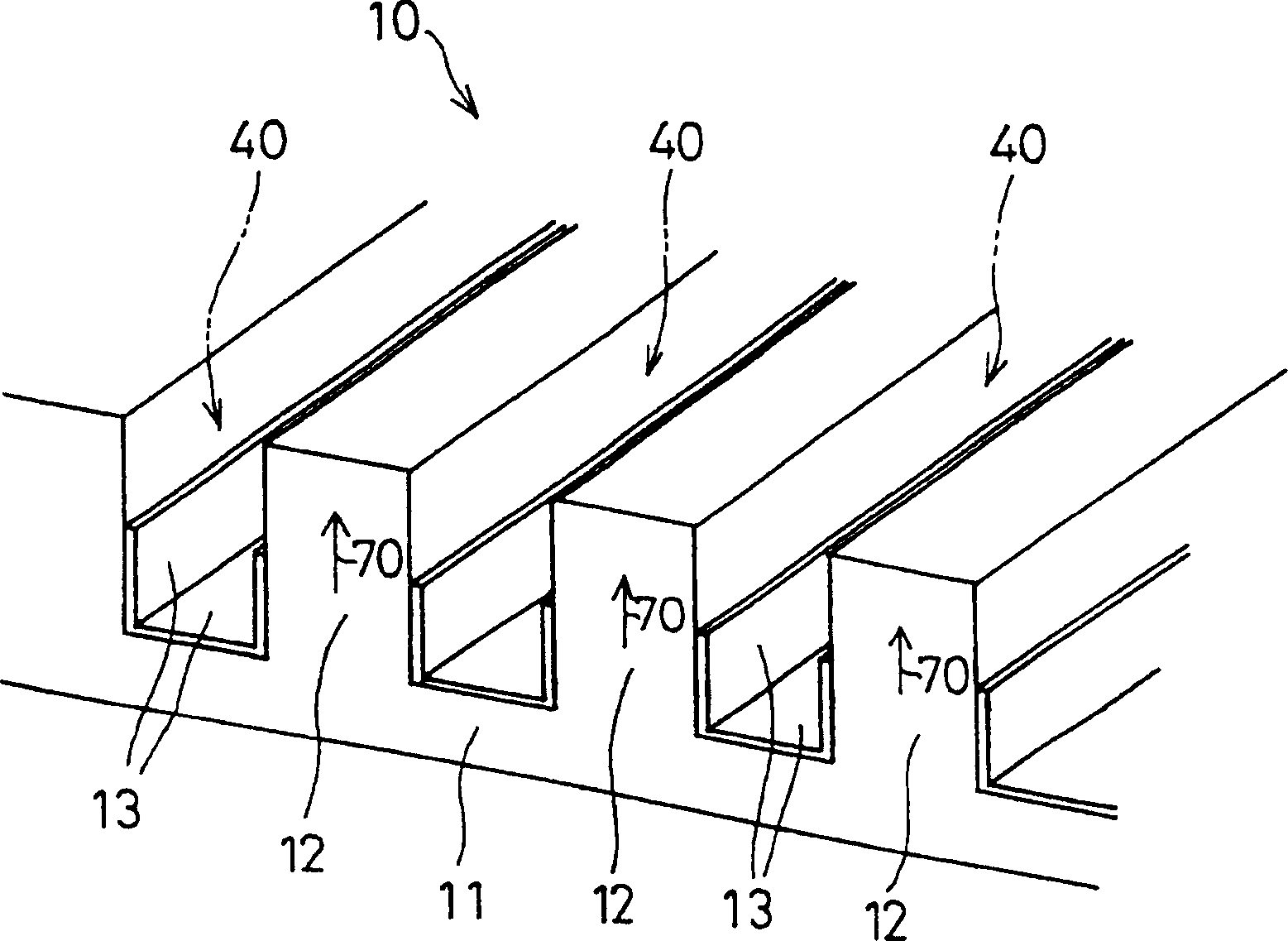

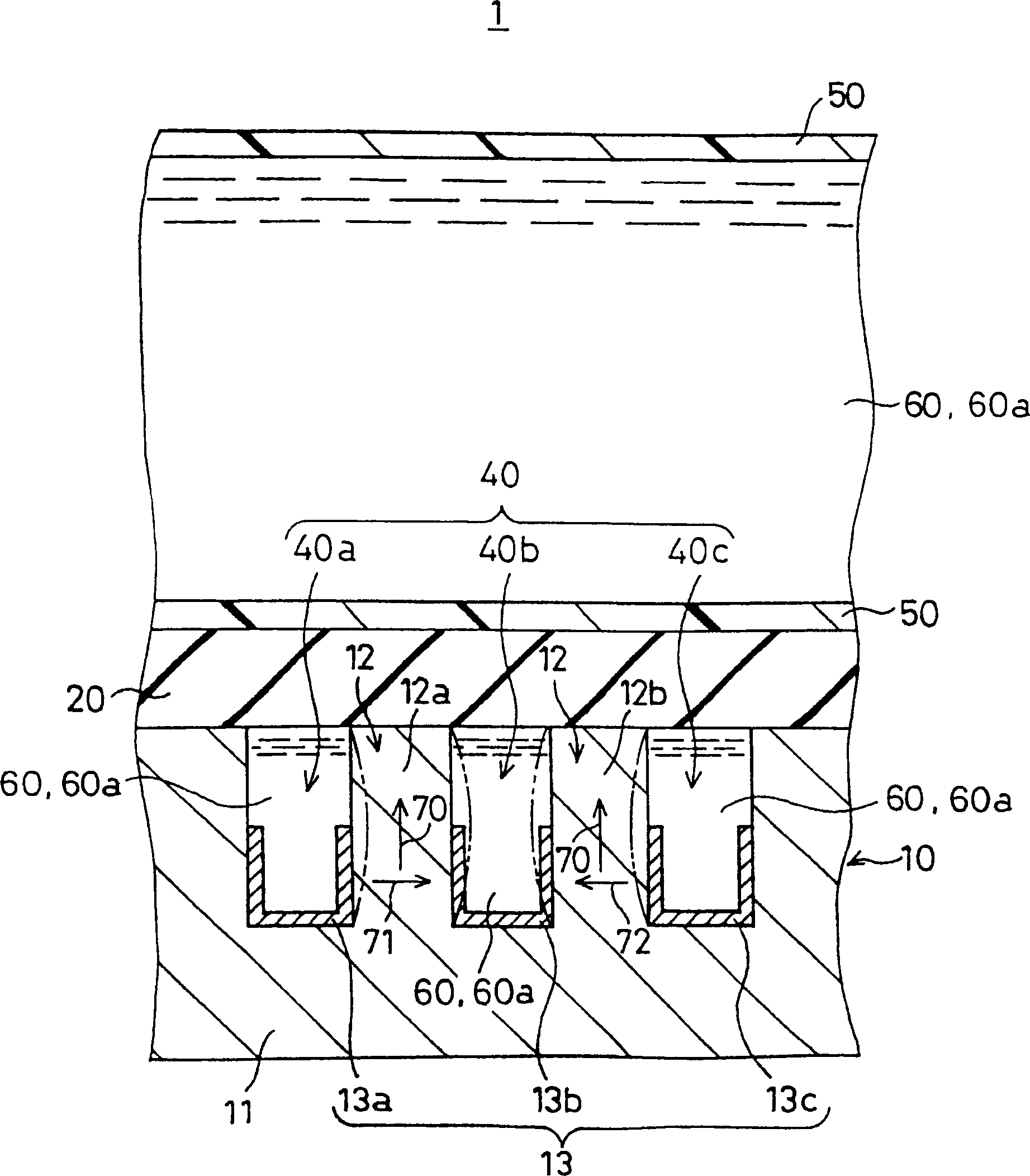

Image

Examples

Embodiment

[0233] The present invention will be further illustrated below by examples, but the present invention is not limited by these examples. In these embodiments, image recording is also referred to as printing or printing.

[0234]

[0235] In the process of preparing the ink composition, the kind and quantity of the coloring agent, organic solvent and surfactant and the content of binder resin and water are changed as shown in Table 1 to obtain the relational expression satisfying the important conditions of the present invention (1) The ink compositions of Examples 1 to 7 and the ink compositions of Comparative Examples 1 to 4 that do not satisfy the relational expression (1) of the present invention. In Table 1, the units of values in each column are expressed in parts by weight, and the total amount of each ink composition in Examples 1 to 7 and Comparative Examples 1 to 4 is 100 parts by weight. Furthermore, in Table 1, TEGBE represents triethylene glycol monobutyl ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com