Sealing material and paste material using same

A sealing material and paste technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as lack of heat resistance of organic light-emitting materials, heat damage, and deterioration of display characteristics of organic EL displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0171] Examples of the first embodiment will be described in detail below. In addition, the following Examples are just illustrations. The present invention is not limited by the following examples.

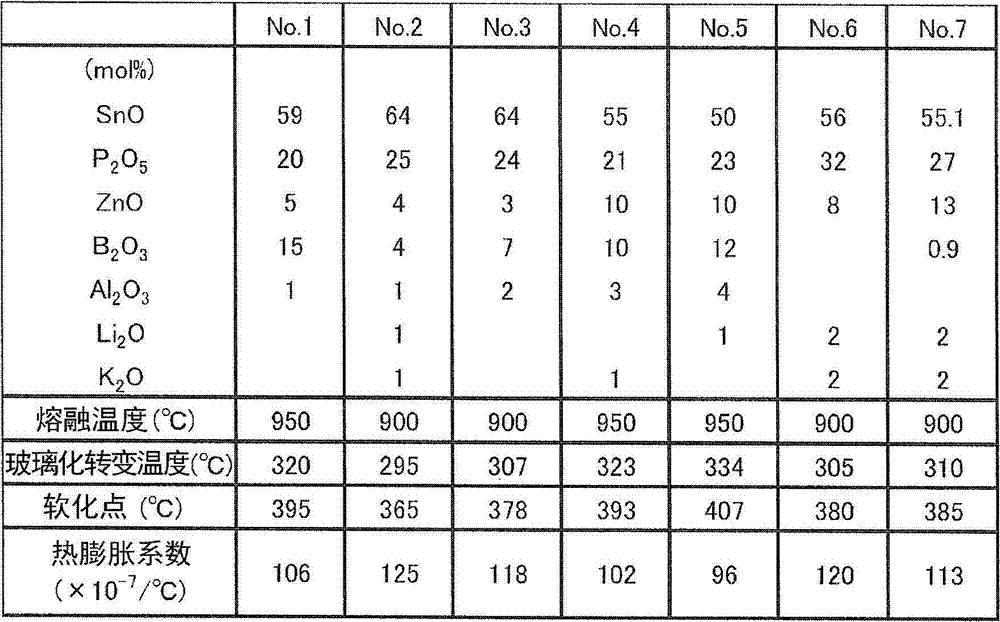

[0172] Table 2 shows SnO-containing glass powders (sample Nos. 1 to 7) related to Examples.

[0173] [Table 2]

[0174]

[0175] Each glass powder was prepared as described below. First, according to the glass composition shown in Table 2, after preparing the raw materials, the prepared raw materials were put into an alumina crucible, and melted at the melting temperature shown in the table under nitrogen atmosphere for 1 to 2 hours. Next, the obtained molten glass is molded into a film form with a water-cooled roll. Next, the glass film is crushed and classified by a ball mill to obtain an average particle size D 50 2.5μm, maximum particle size D 99 7μm glass powder.

[0176] About sample No. 1-7, glass transition temperature, softening point, and thermal expansion coe...

Embodiment 2

[0196] Examples of the second embodiment will be described in detail below. In addition, the following Examples are just illustrations. The present invention is not limited by the following examples.

[0197] Table 4 shows SnO-containing glass powders (sample Nos. 8 to 14) related to Examples.

[0198] [Table 4]

[0199]

[0200] Each glass powder was prepared as described below. Firstly, according to the glass composition shown in Table 4, after preparing raw materials, the prepared raw materials were put into alumina crucibles, and melted at the melting temperatures shown in the table under a nitrogen atmosphere for 1 to 2 hours. Next, the obtained molten glass was molded into a film form by water-cooled rolls. Next, the glass film is crushed by a ball mill and then classified to obtain the average particle size D 50 2.5μm, maximum particle size D 99 10μm glass powder.

[0201] Regarding sample Nos. 8 to 14, glass transition temperature, softening point, and therma...

Embodiment 3

[0214] For sample H in Table 5, only the average particle diameter D of the primary particle of the pigment was changed and adjusted 50 , making sealing materials (sample O ~ U). Using this sealing material, investigate the average particle diameter D of primary particles of the pigment 50 Effect on softening flow characteristics. The results are shown in Table 6.

[0215] [Table 6]

[0216]

[0217] The softening flow properties were evaluated as described below. That is, for the softening flow characteristics, by irradiating a laser beam under the same conditions as the laser sealing characteristics of Example 2 to the glass substrate with a glaze film produced under the same conditions as the laser sealing characteristics of Example 2, and finally observing In the joined portion, the evaluation of moderately softened flow was "O", the evaluation of a position where a small amount of unsoftened flow was confirmed was "Δ", and the evaluation of a position where much un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com