Patents

Literature

49results about How to "Reliable ejection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pretreatment agent for ink jet textile printing, ink jet textile printing ink set, and method of ink jet textile printing

ActiveUS20130249996A1Increase in whitenessHigh whitenessDuplicating/marking methodsInksComposite materialPolymer chemistry

Owner:SEIKO EPSON CORP

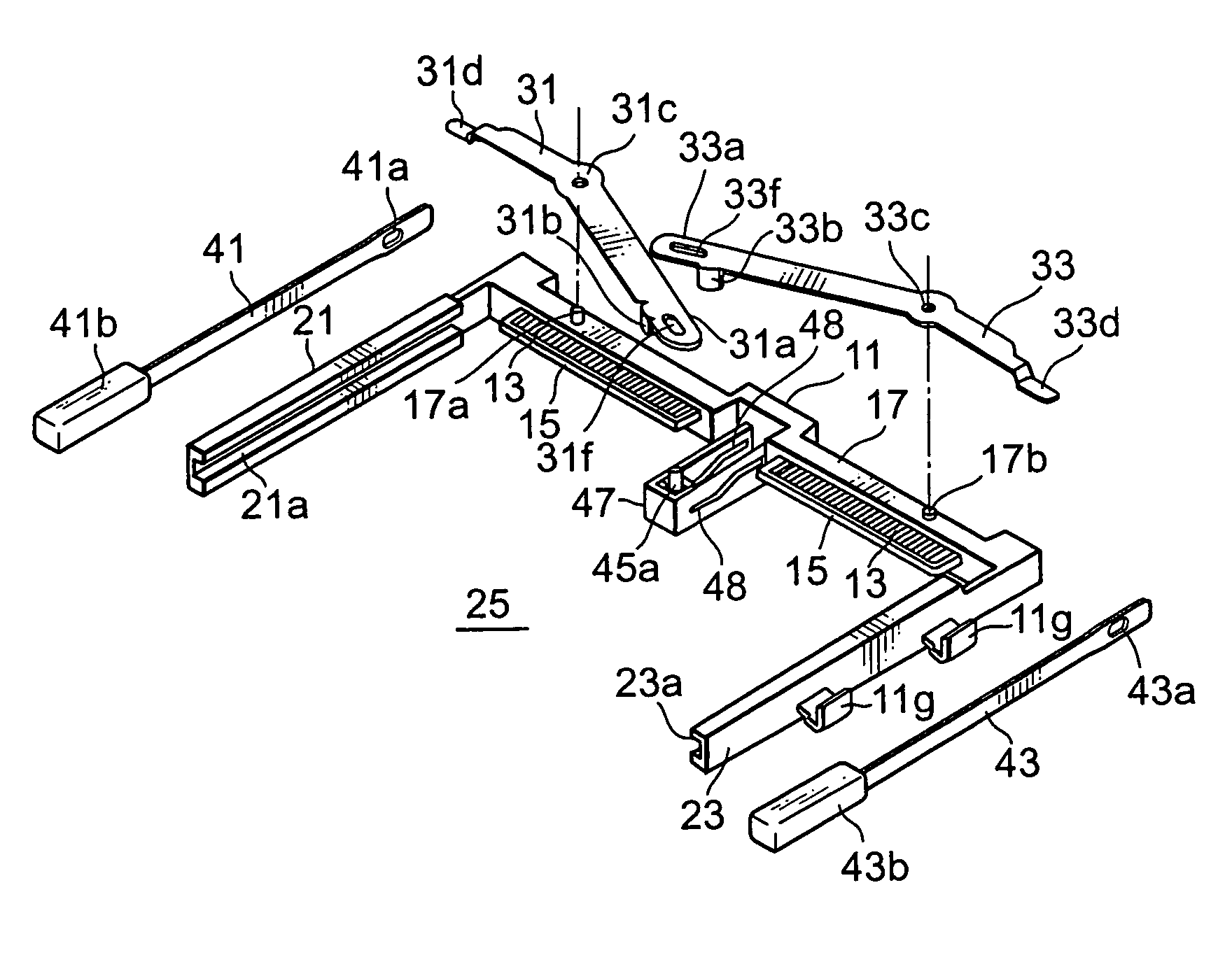

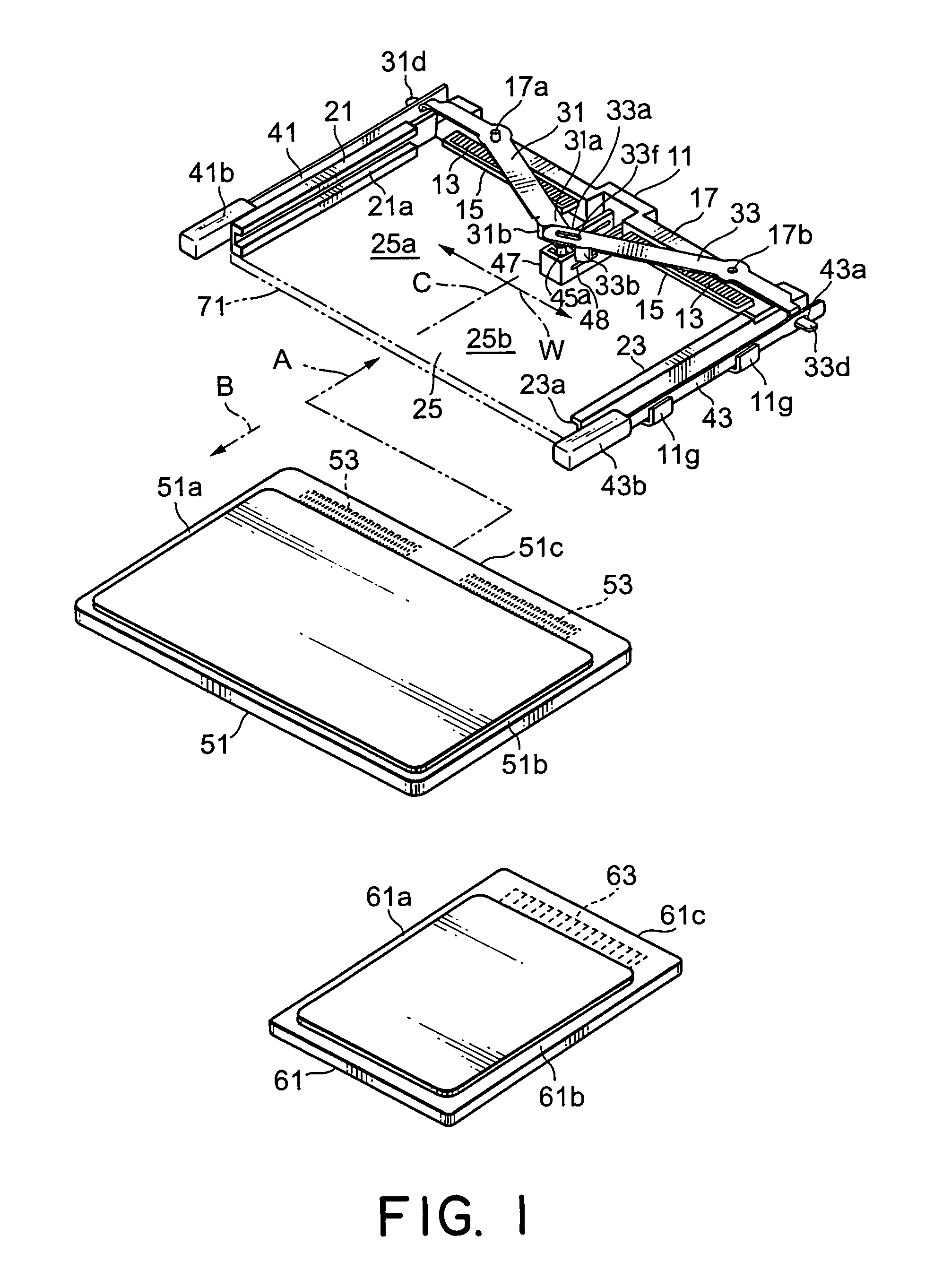

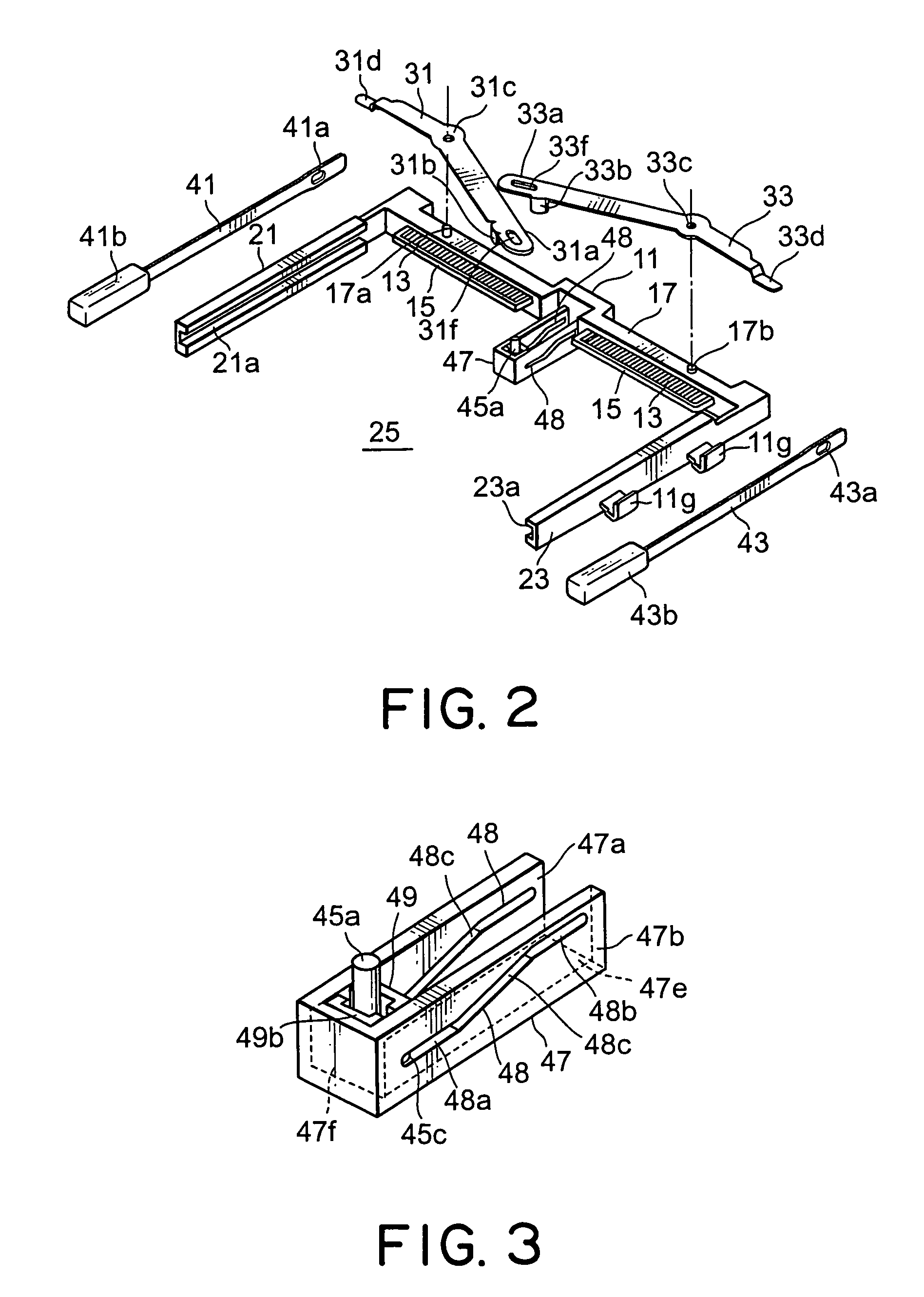

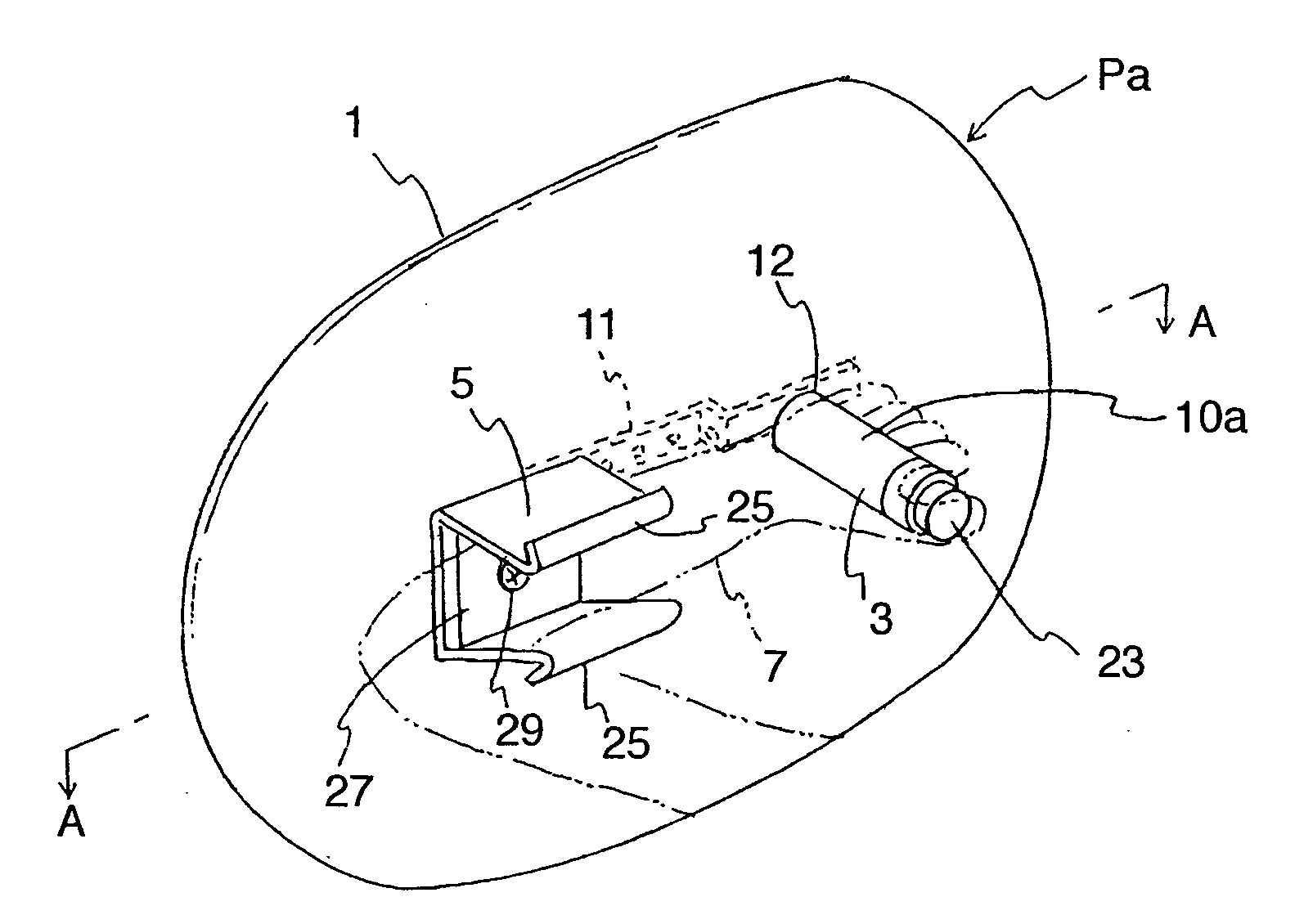

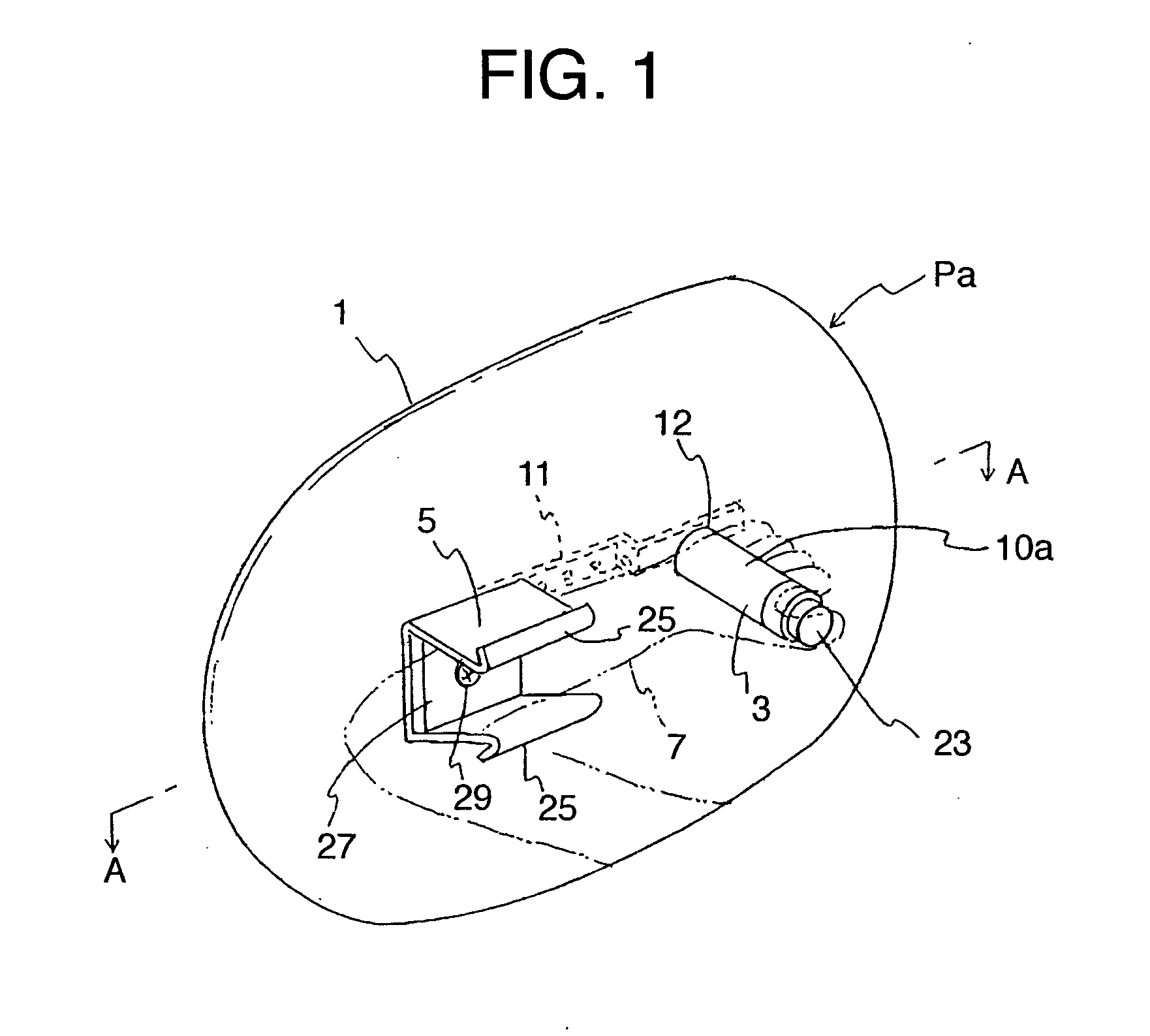

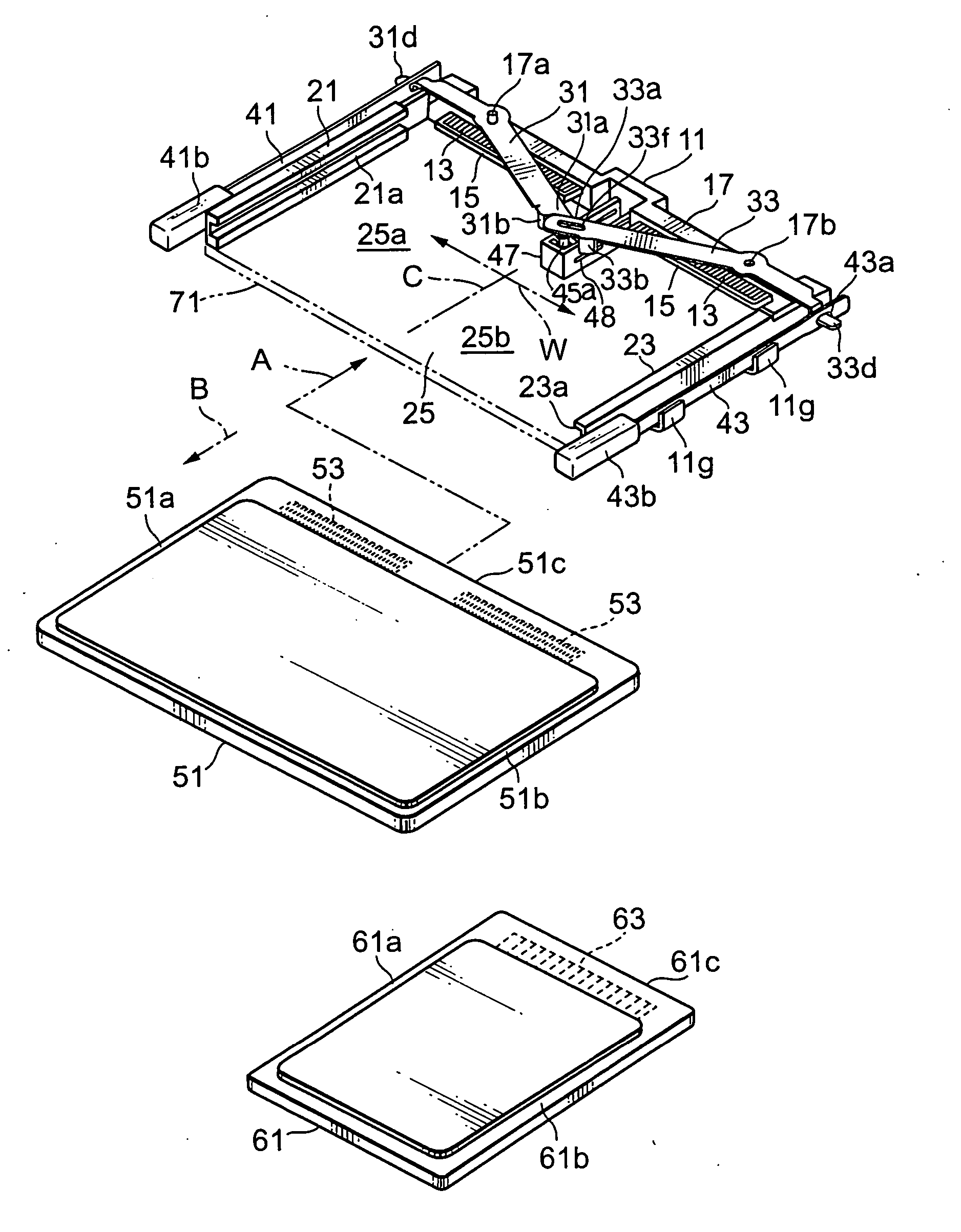

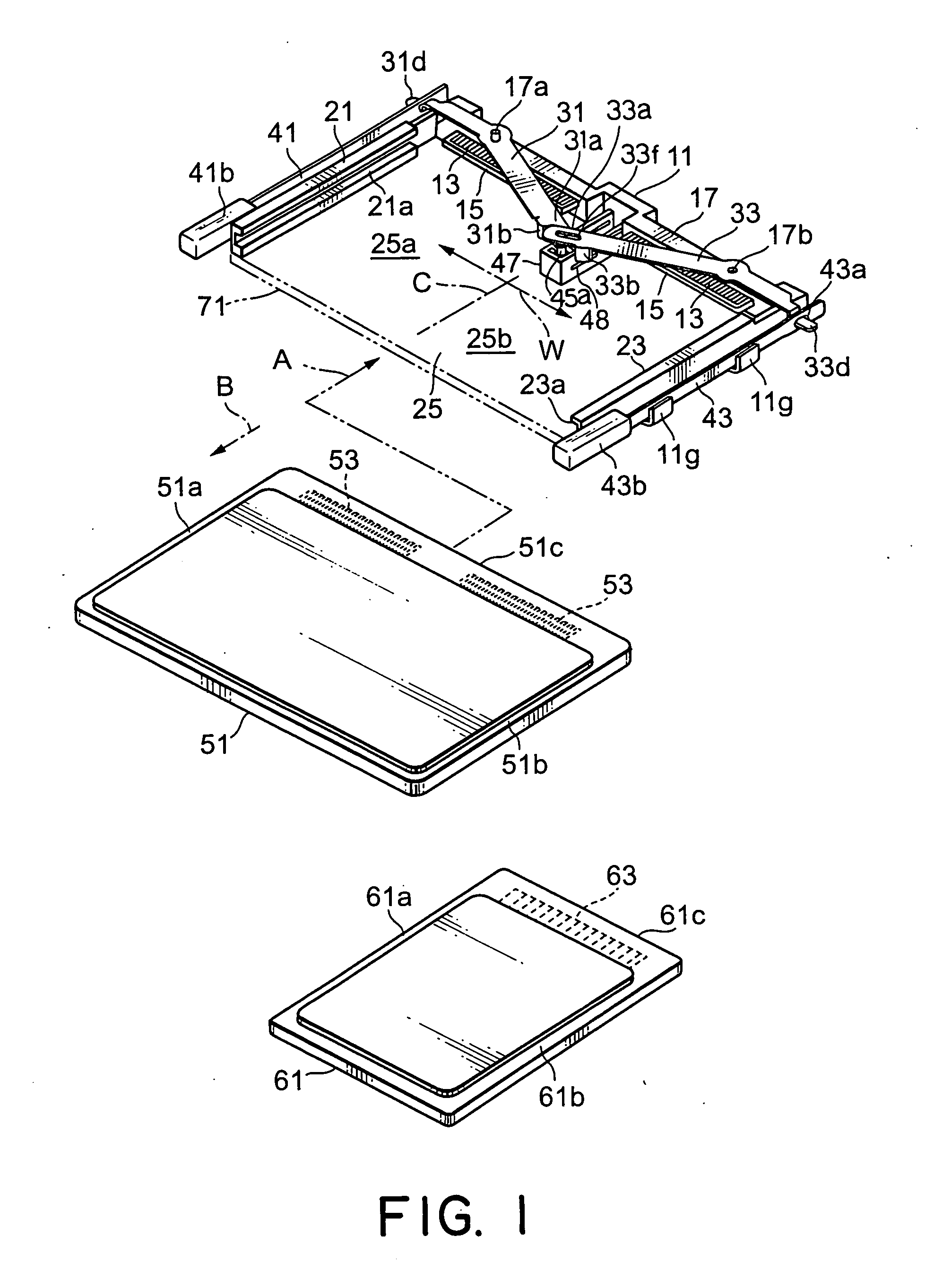

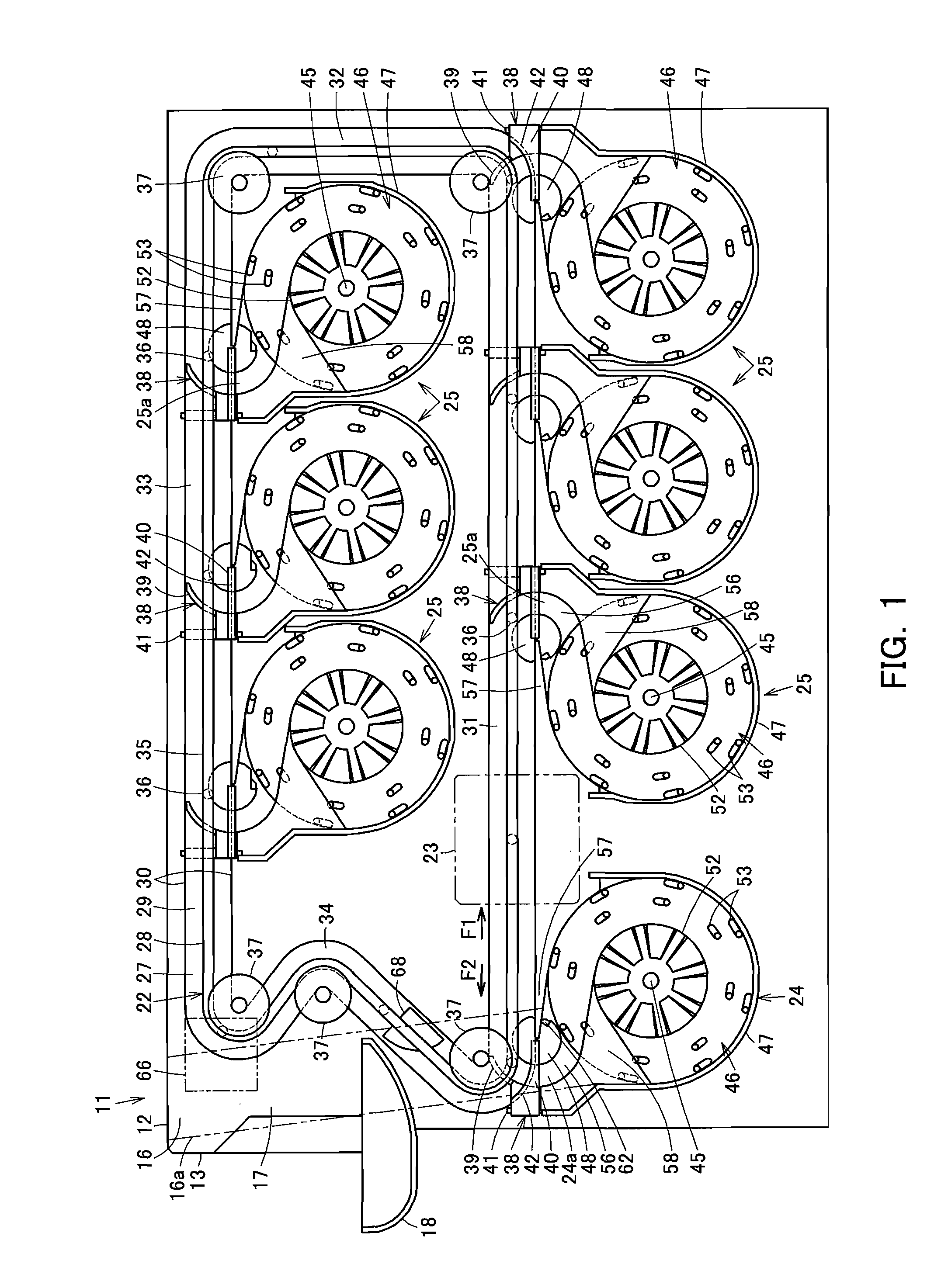

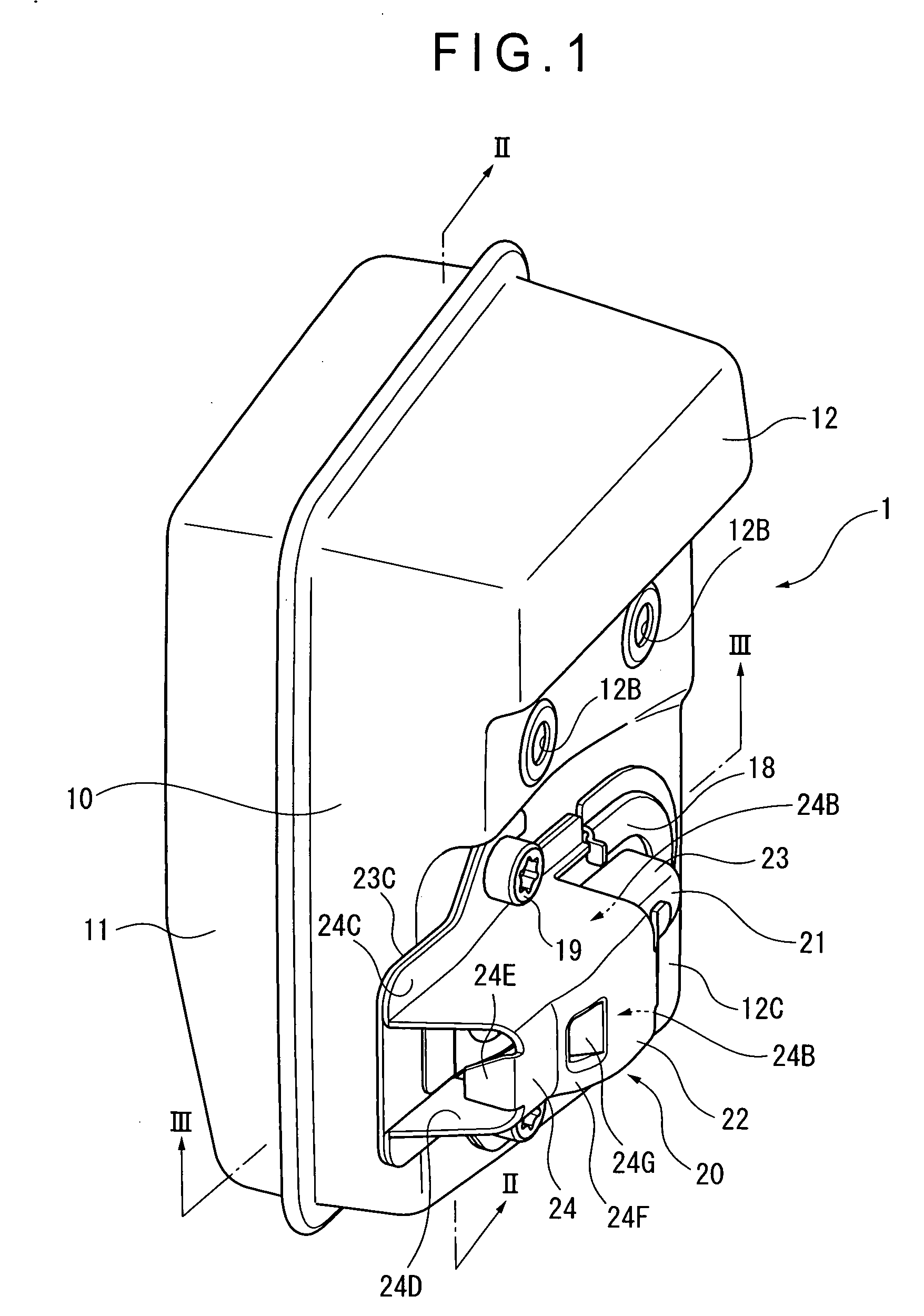

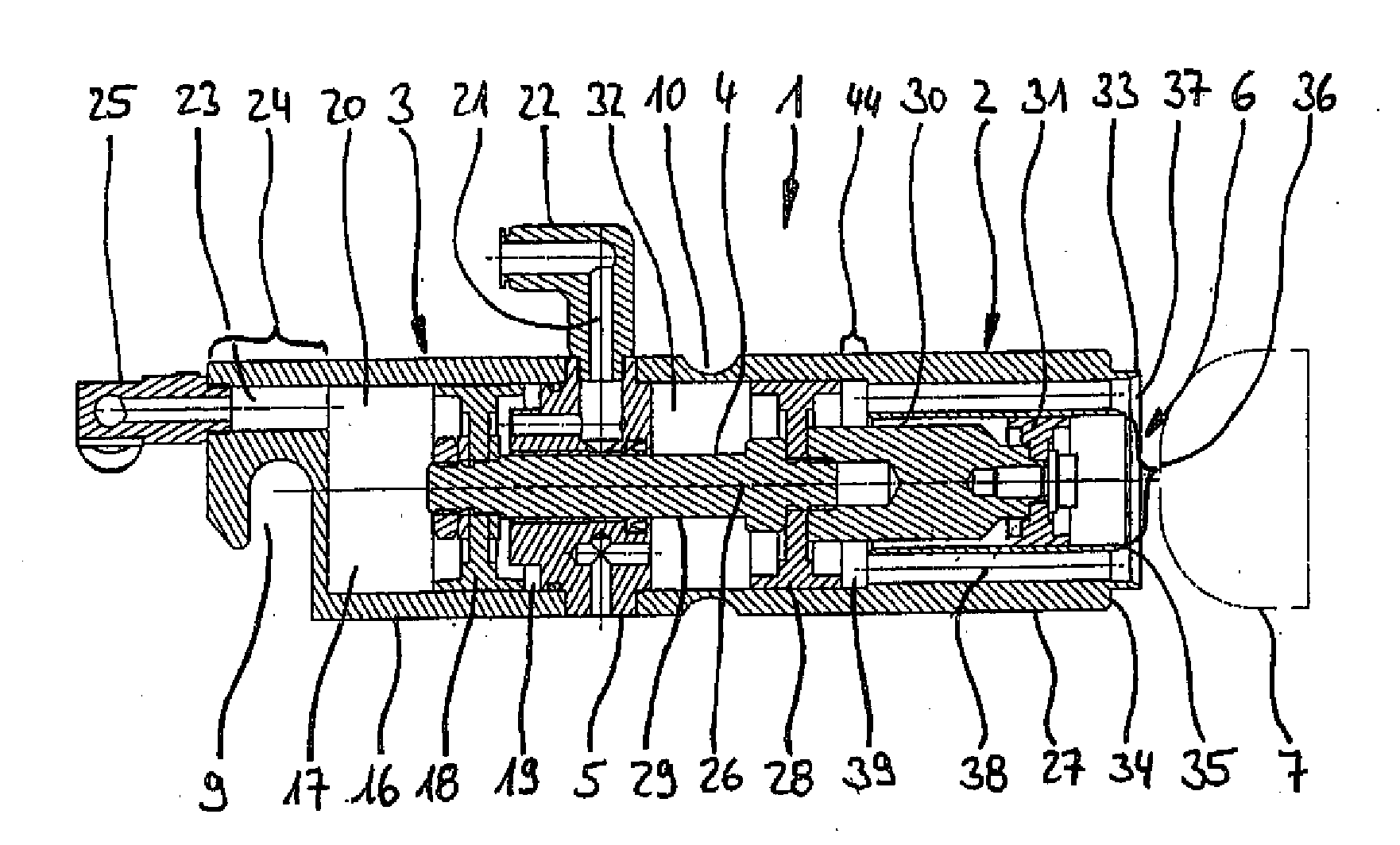

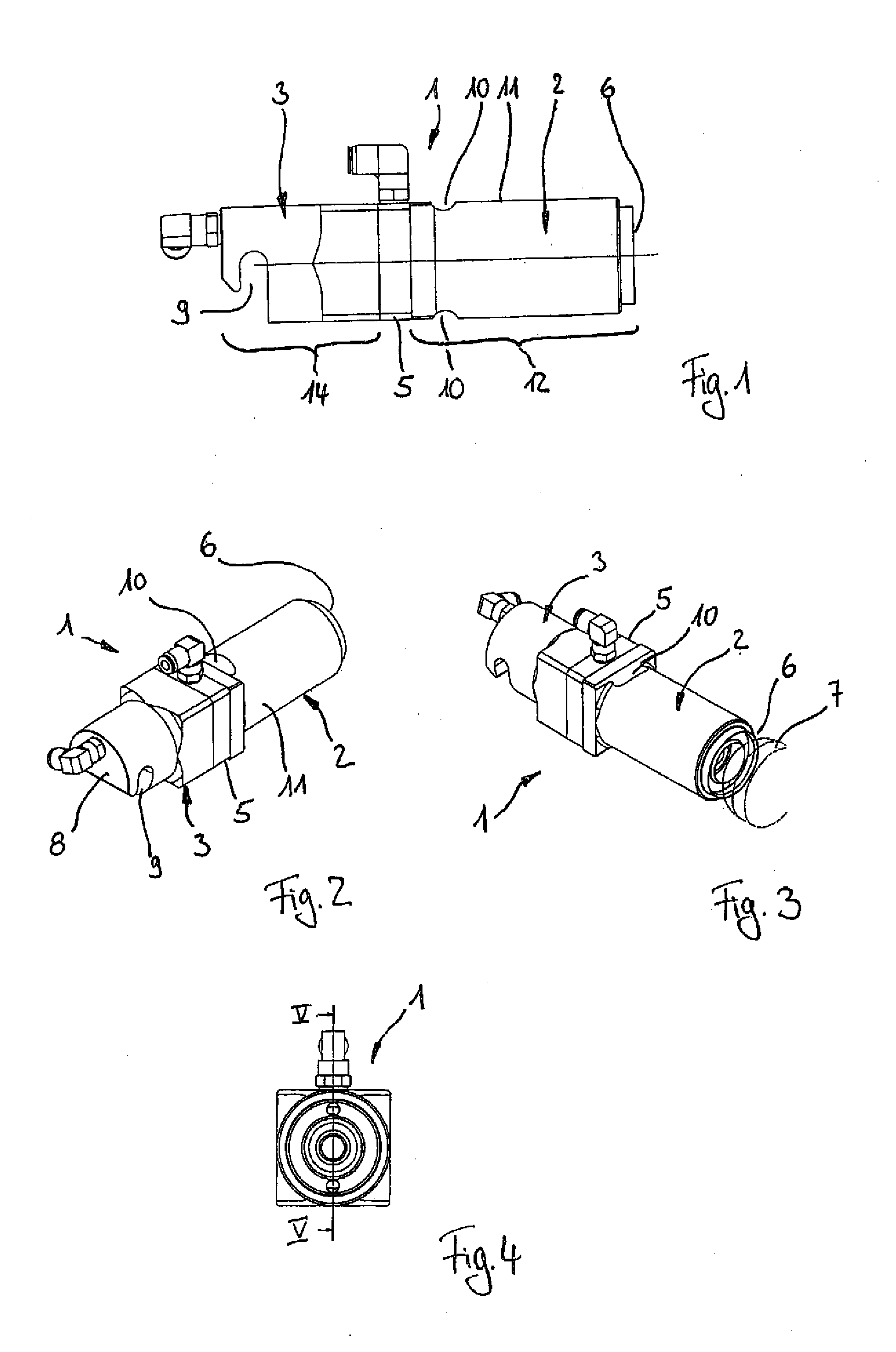

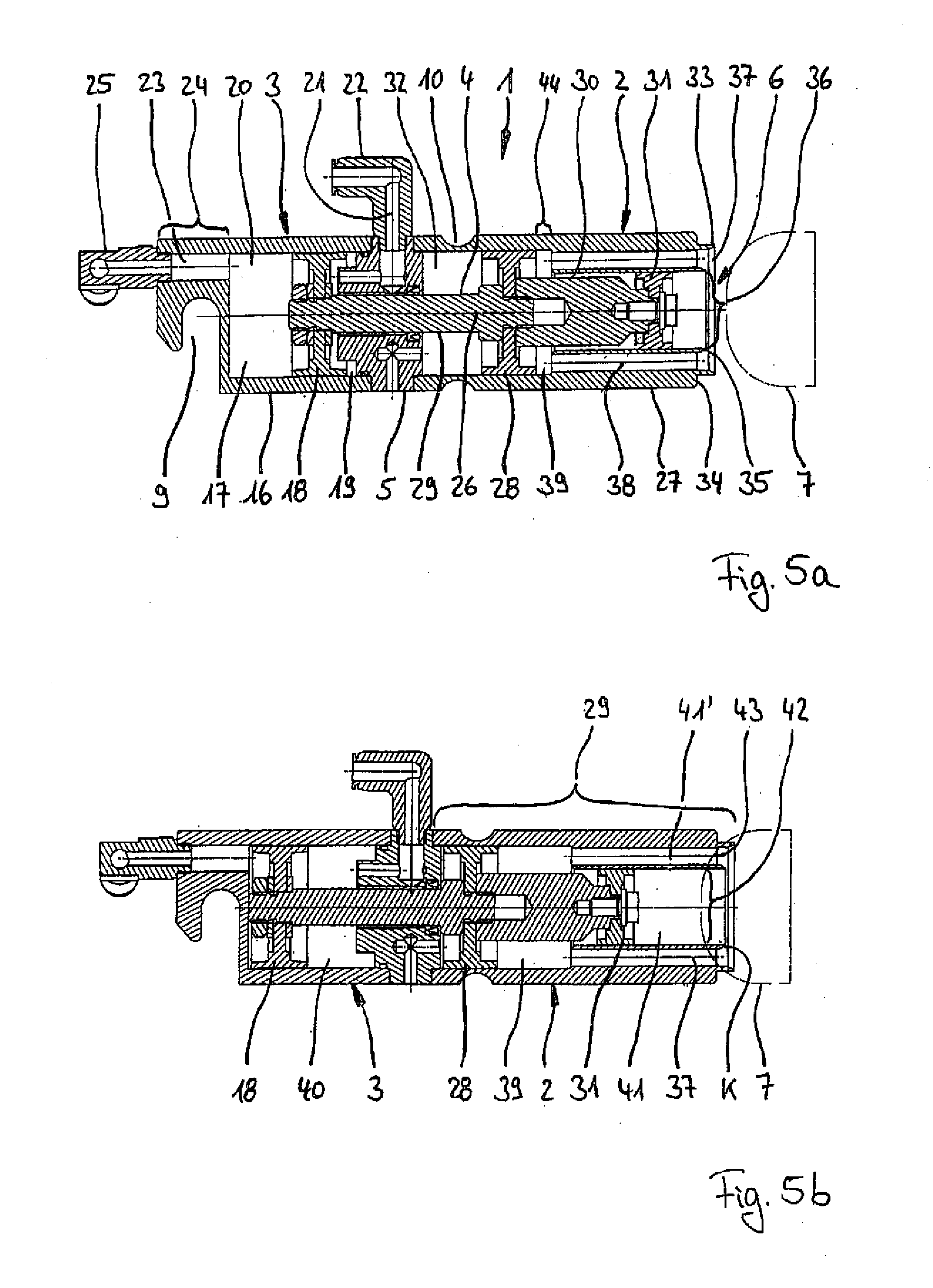

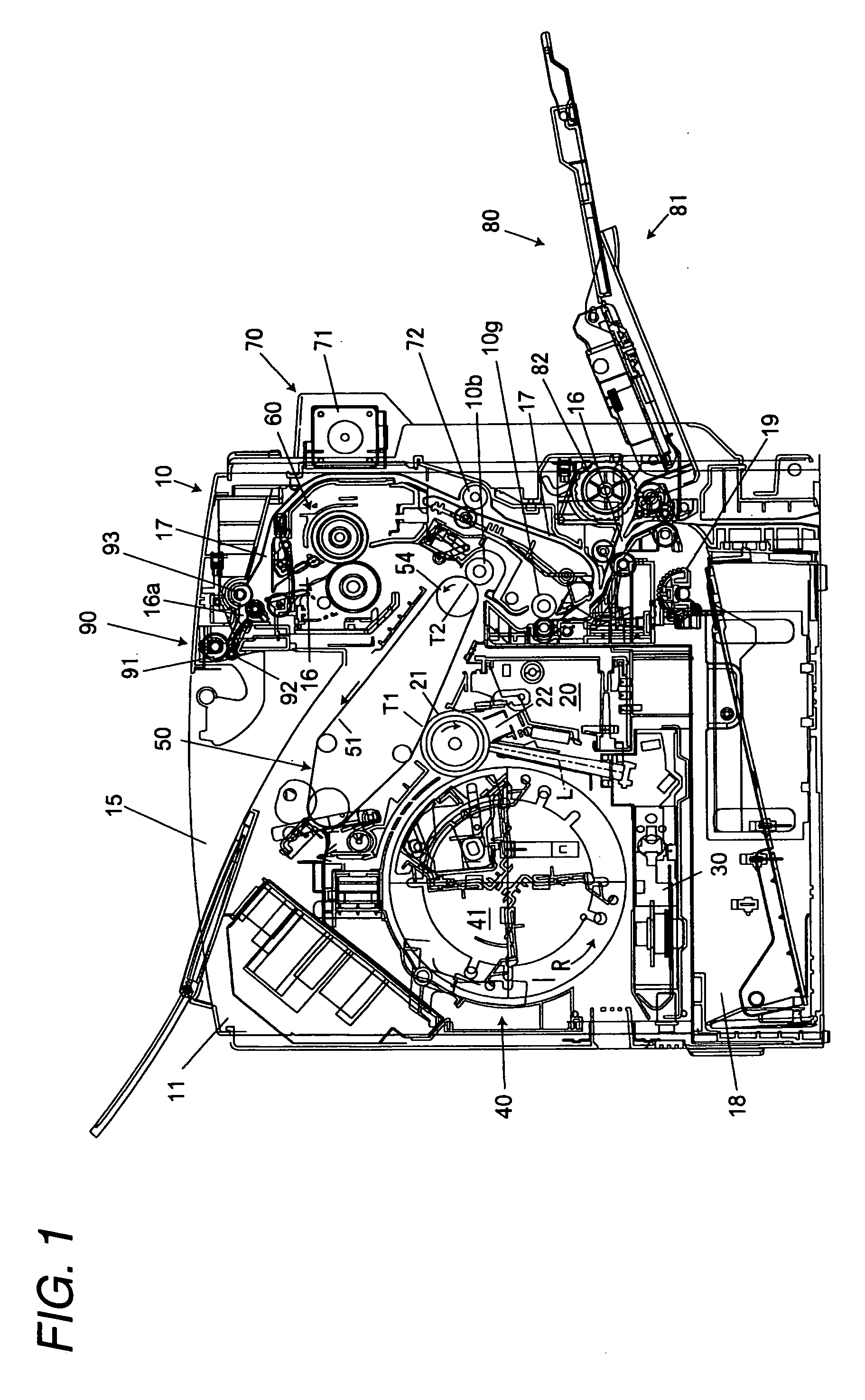

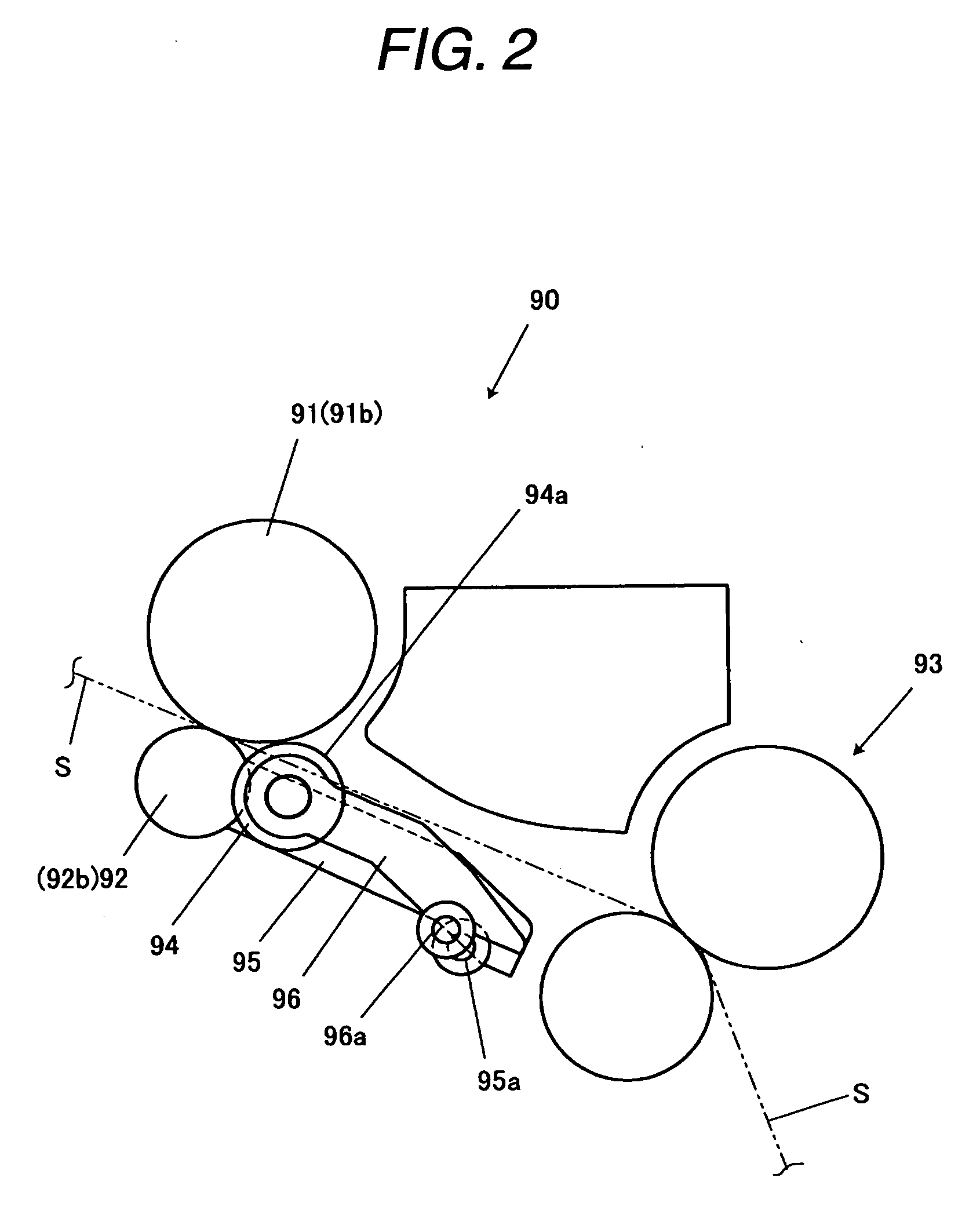

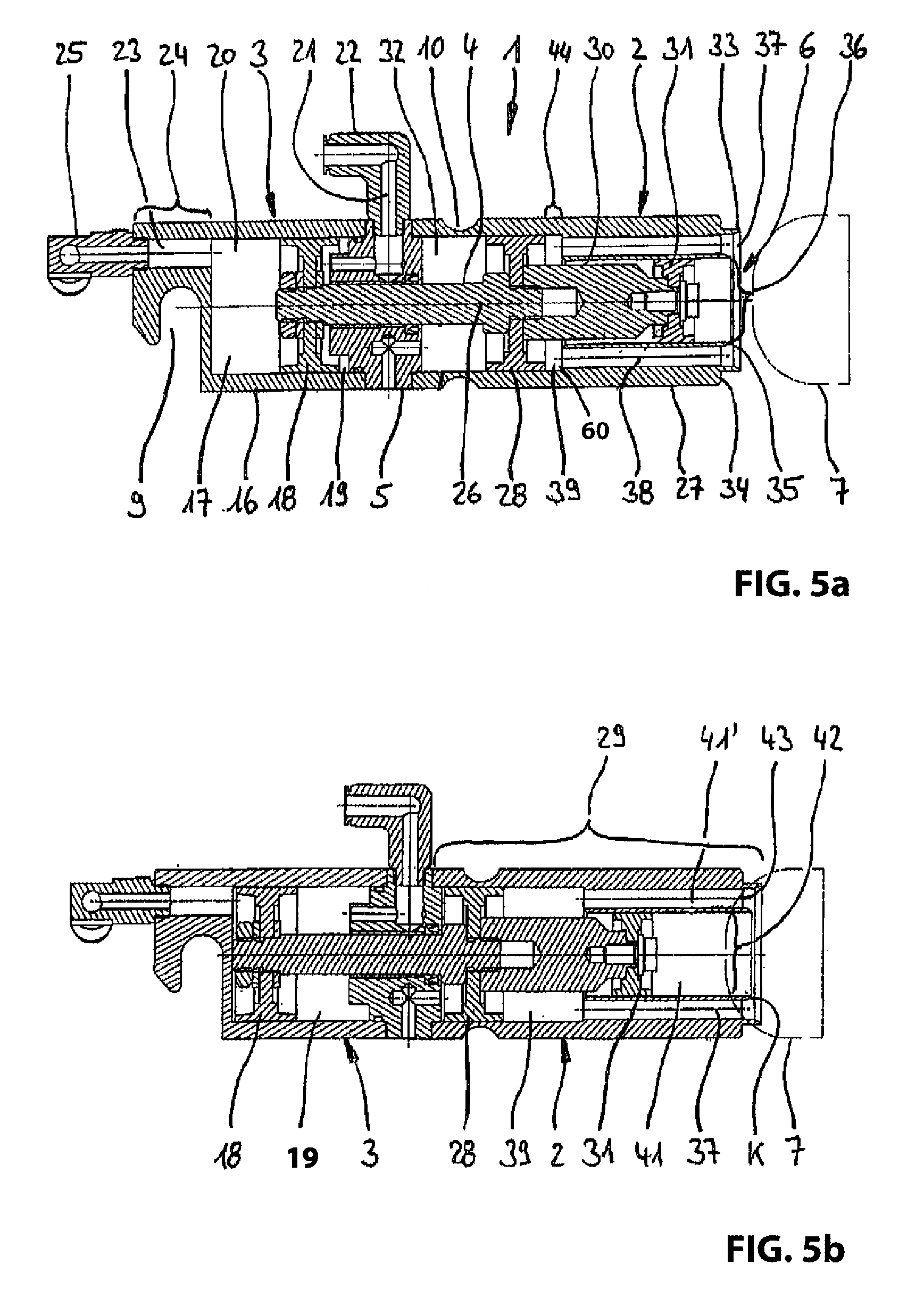

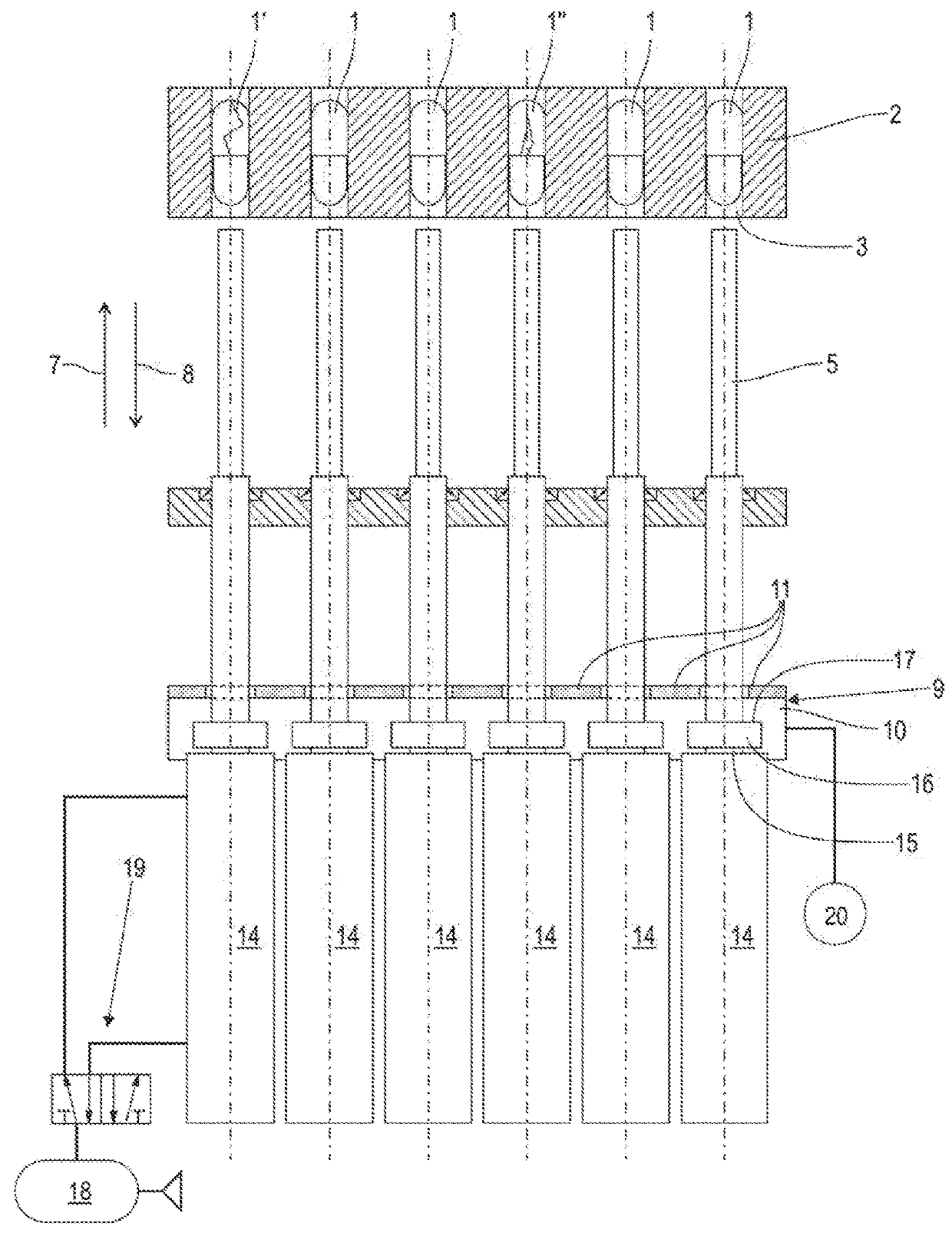

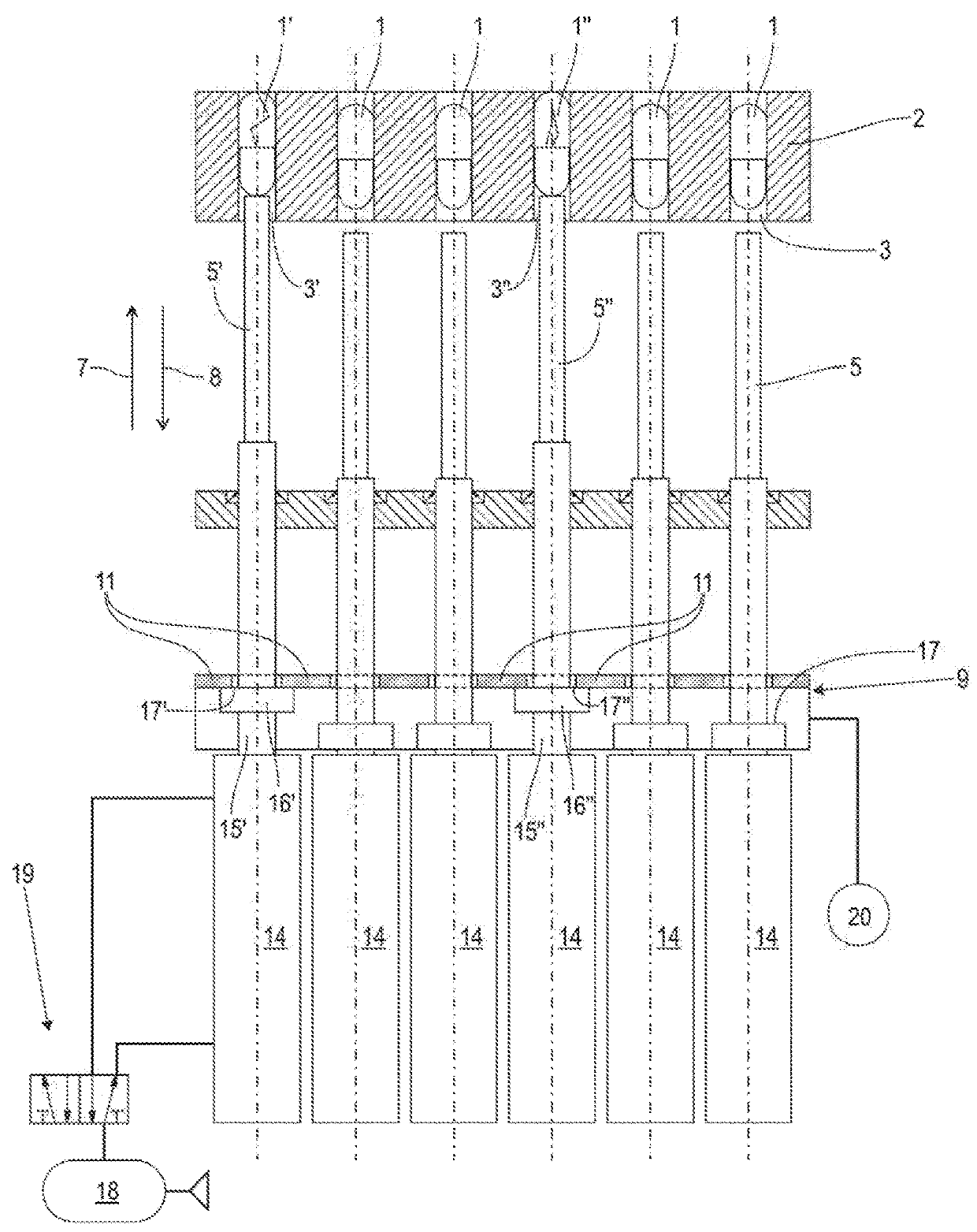

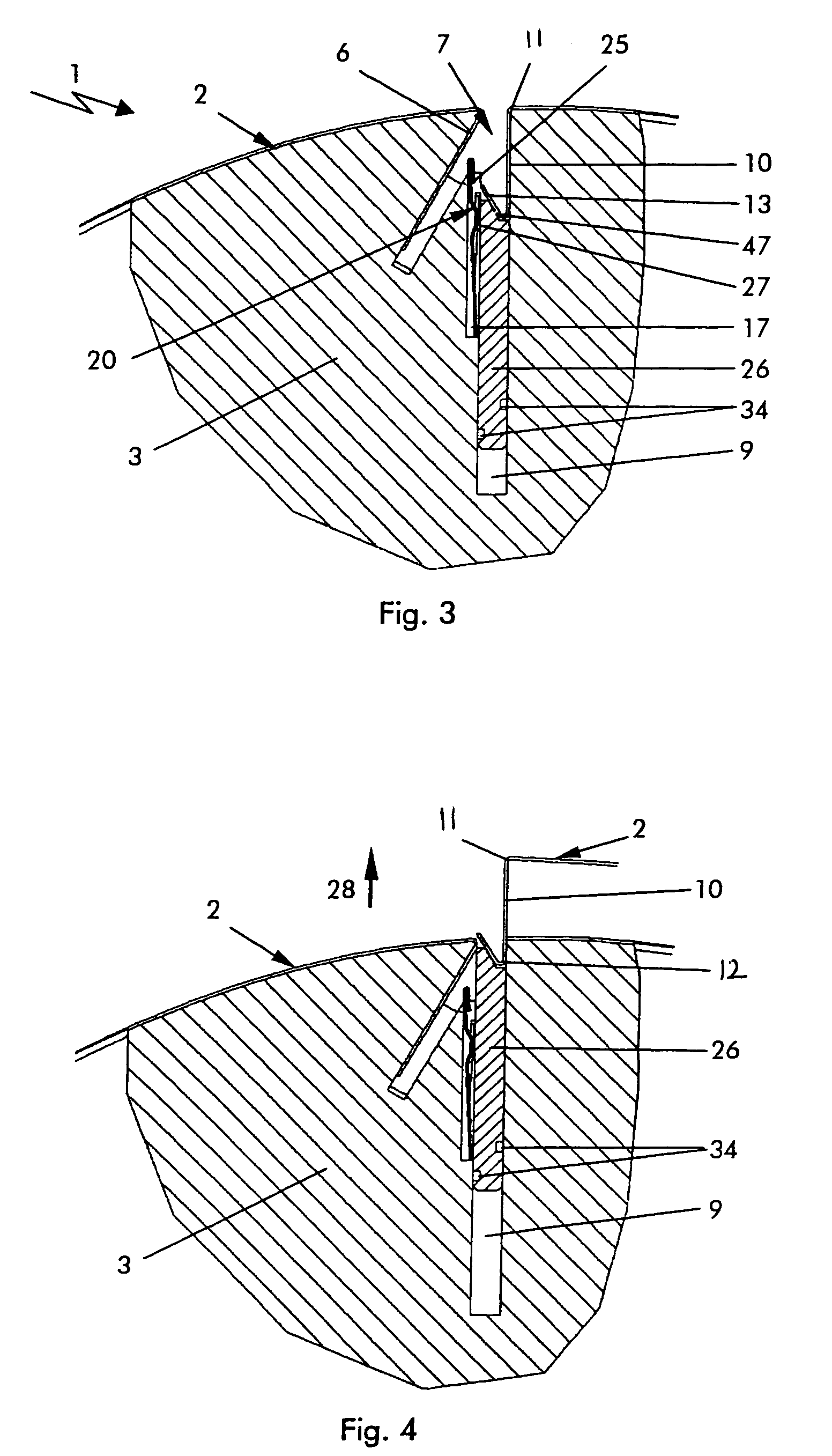

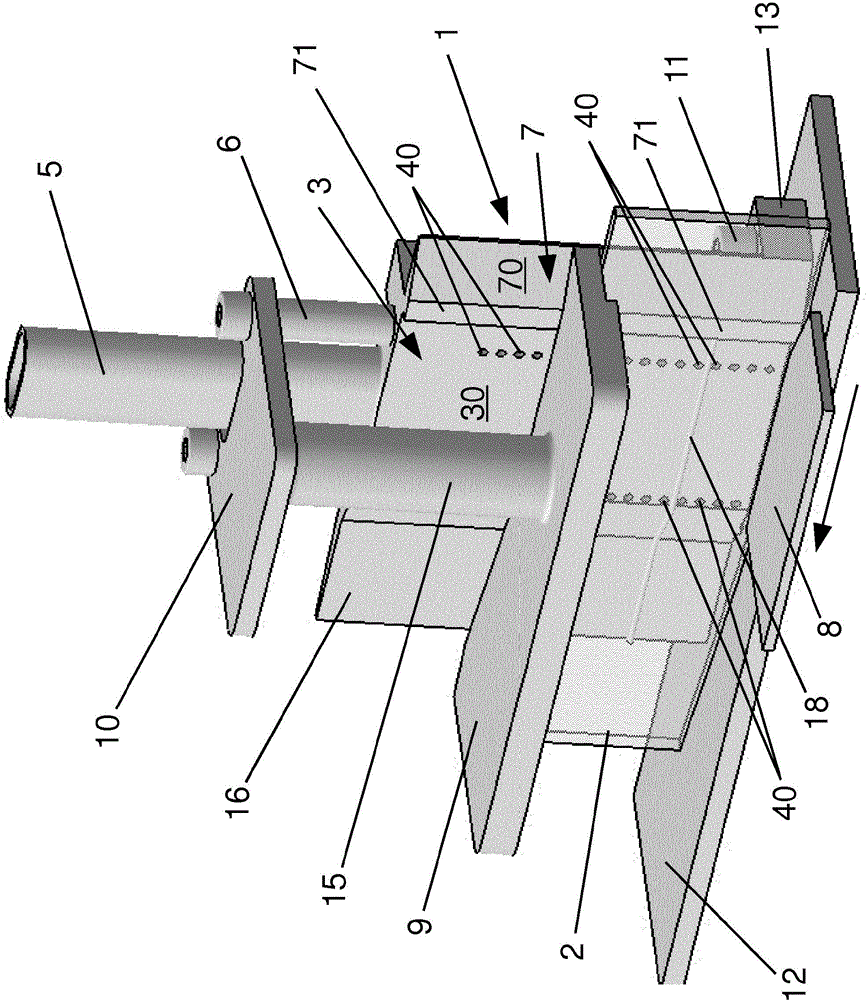

Card connector having an eject mechanism adaptable to a plurality of kinds of cards different in size

InactiveUS6991480B2Eliminate the problemReliable ejectionEngagement/disengagement of coupling partsConveying record carriersEngineering

In a card connector to be connected to a card, a defining member defines an inserting region for receiving the card inserted in an inserting direction. The card connector includes an eject mechanism for ejecting the card from the inserting region in an ejecting direction opposite to the inserting direction. A plurality of ejecting members are adapted to be engaged with the card in the inserting region in the inserting and the ejecting directions and movable with respect to the defining member independently of one another. A linking mechanism selectively links the ejecting members to each other in response to insertion of the card in the inserting region.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

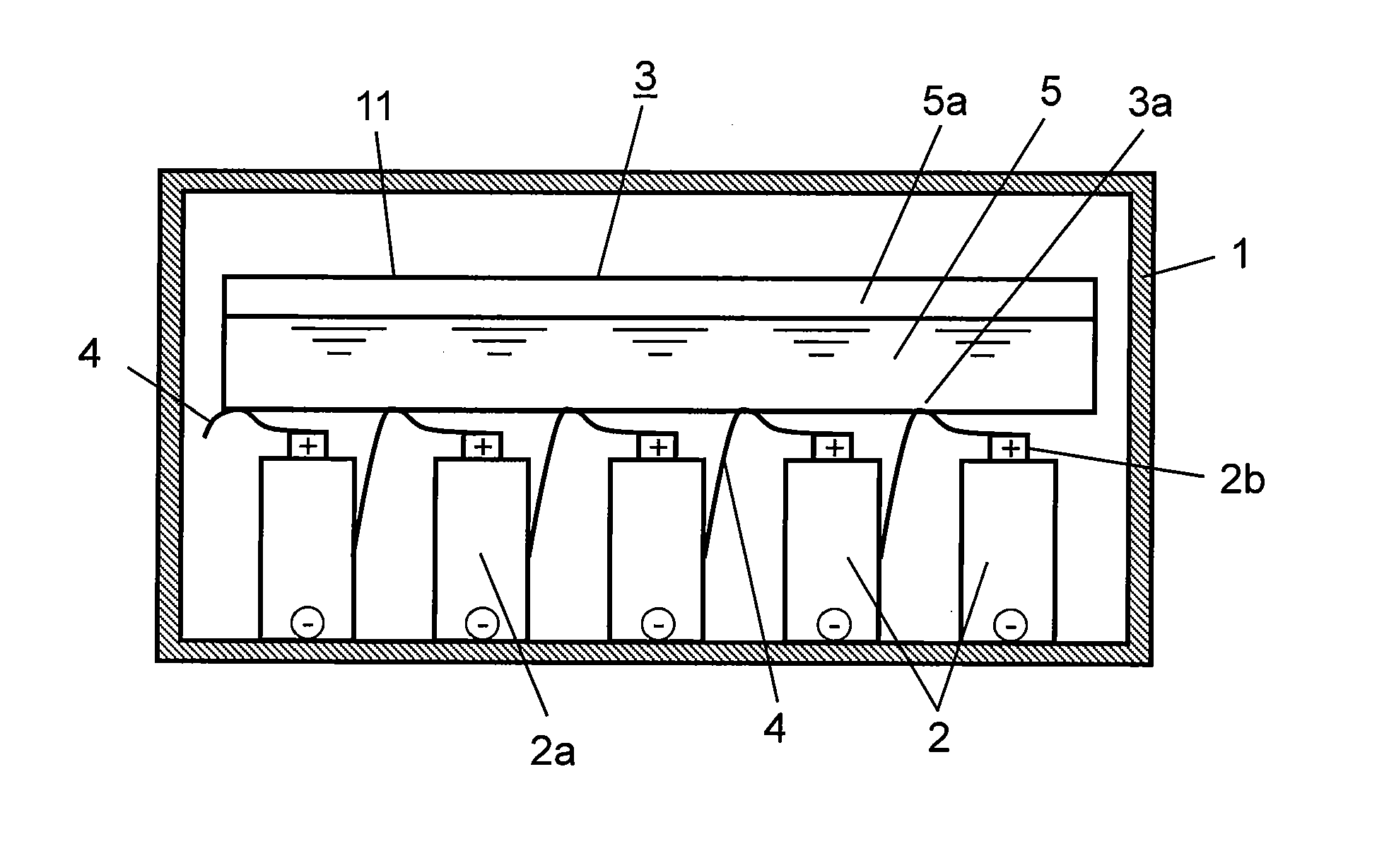

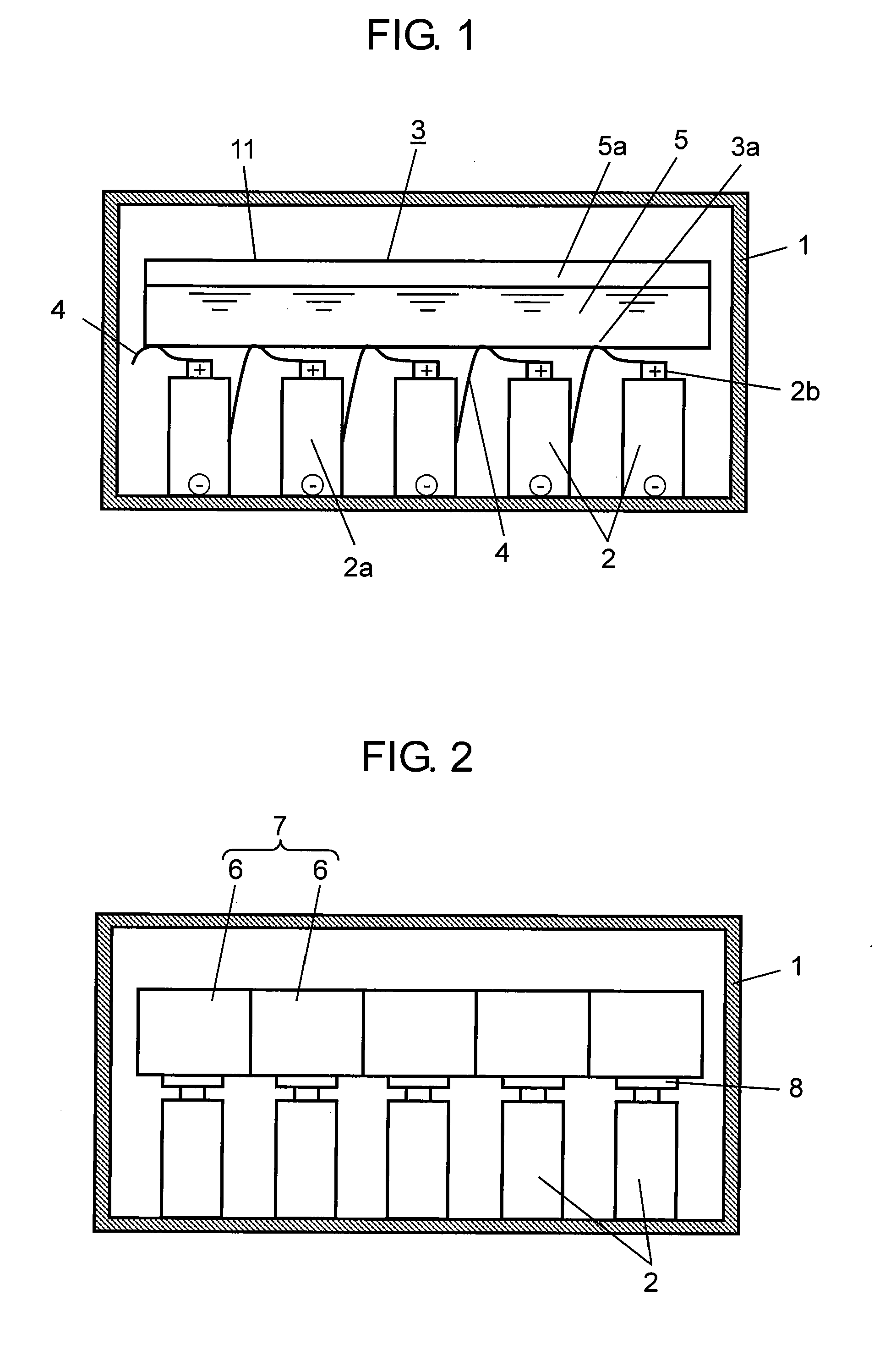

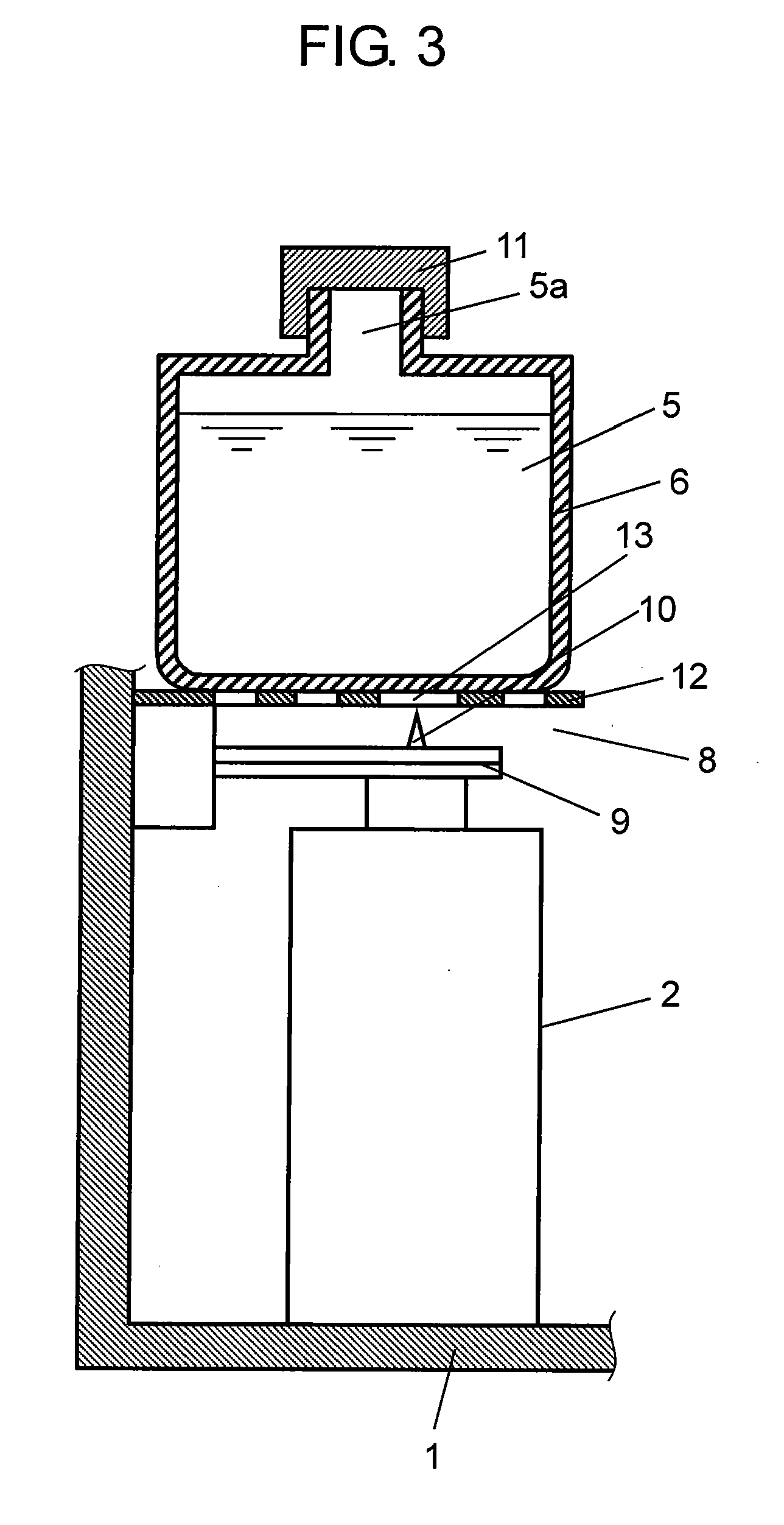

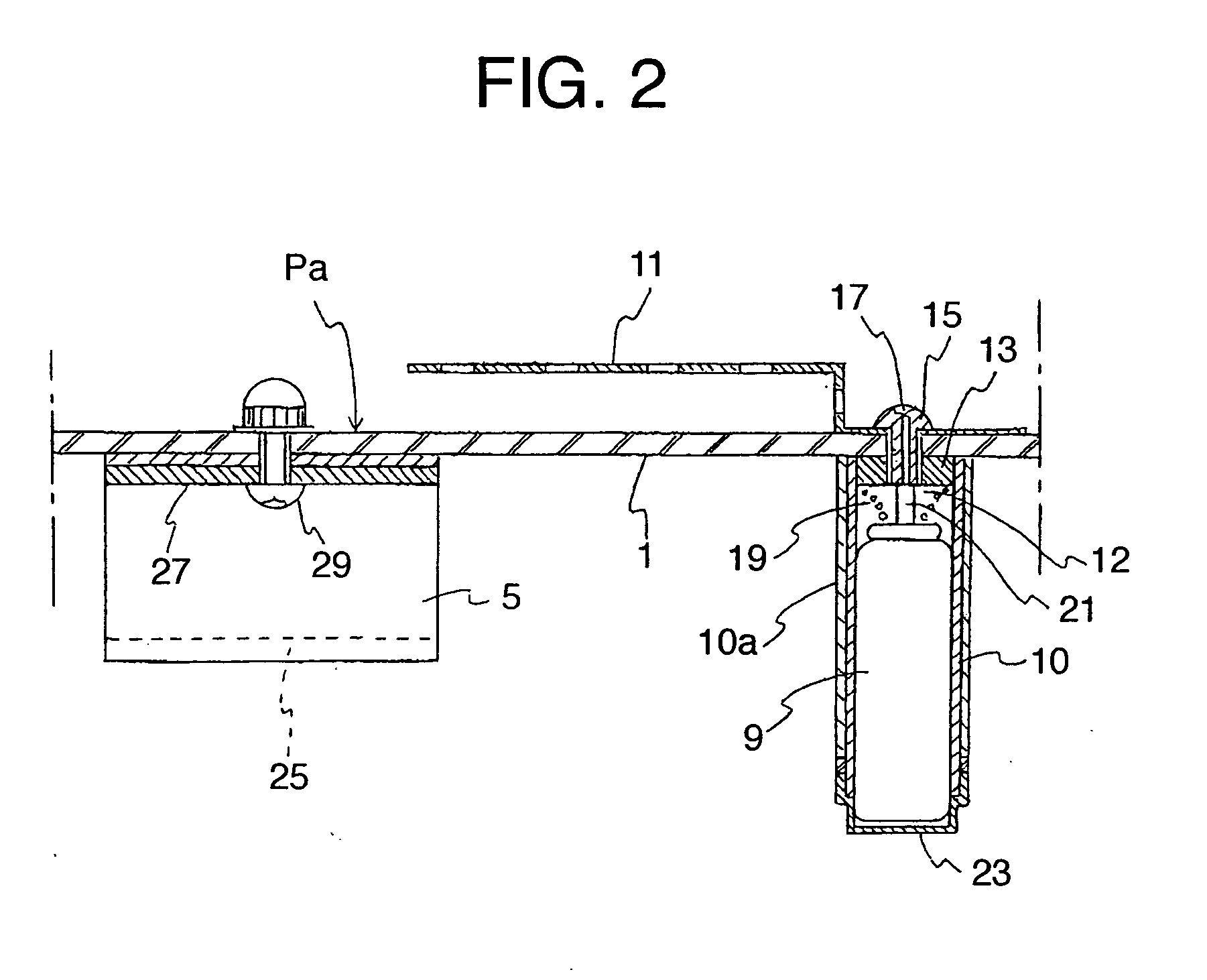

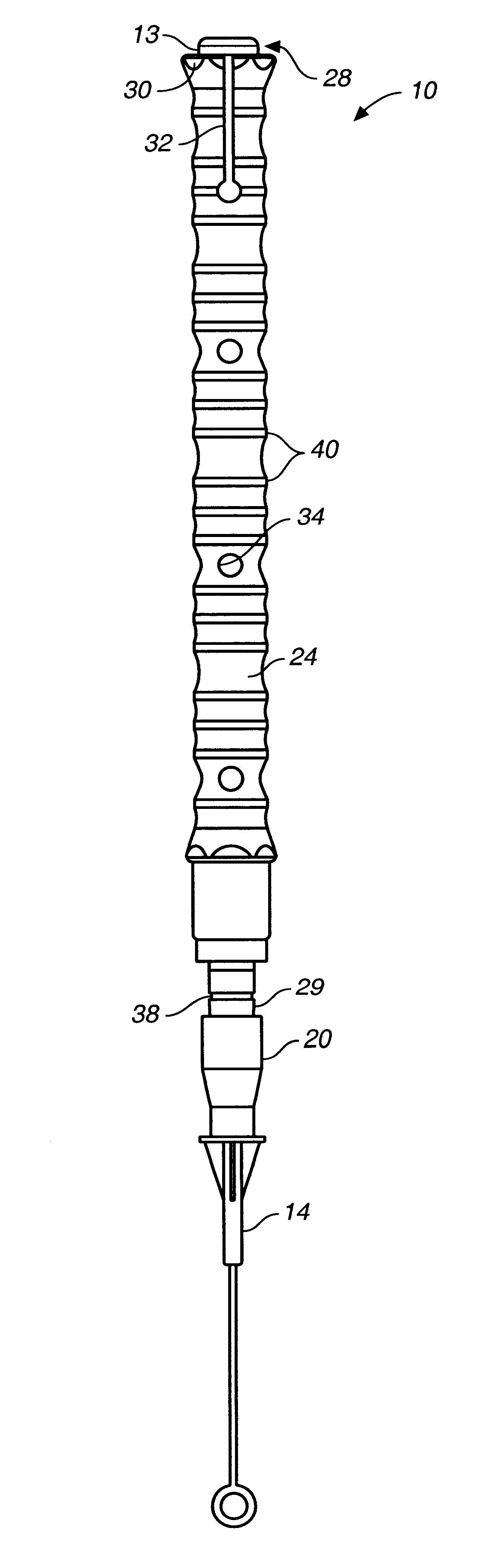

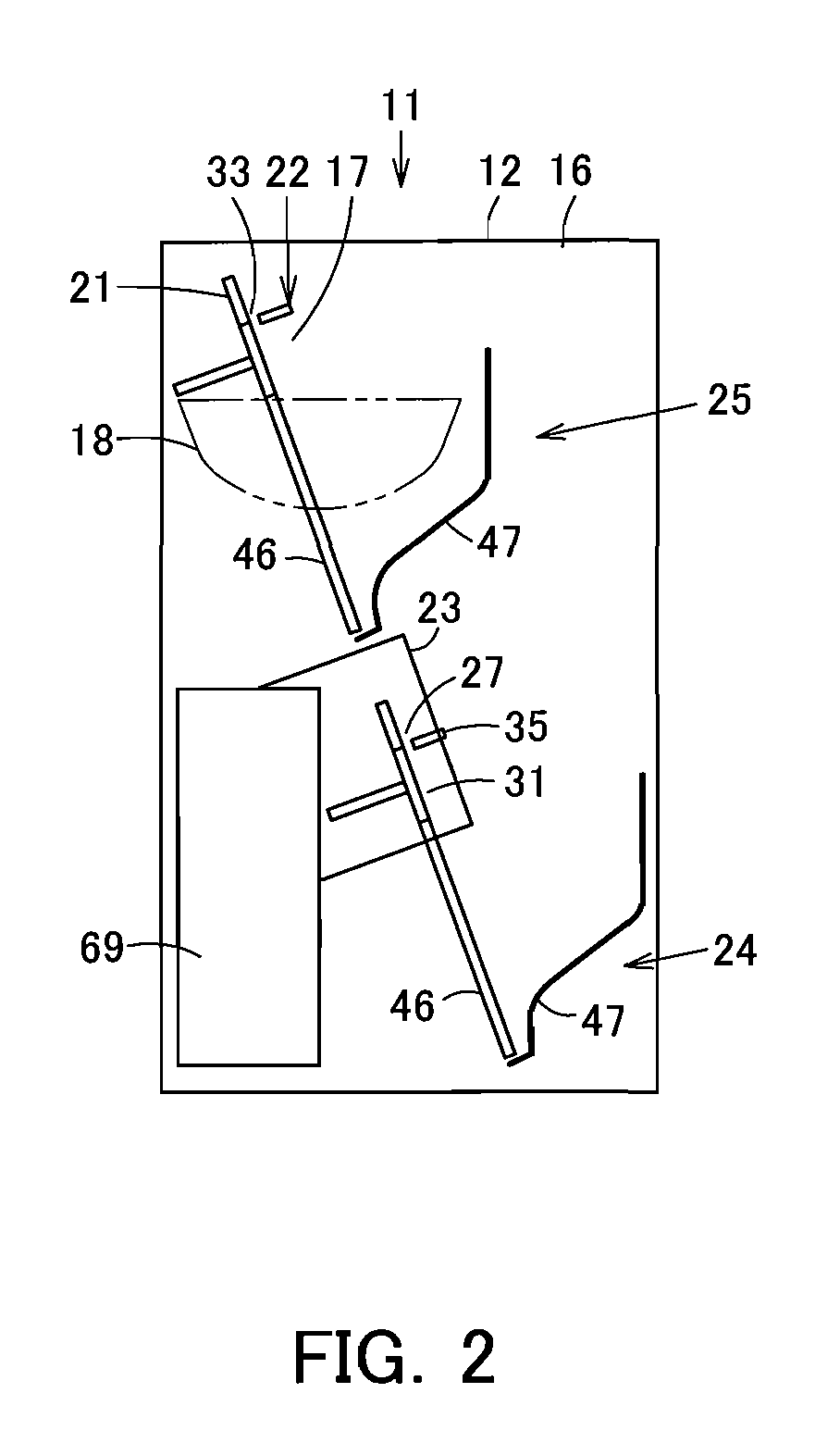

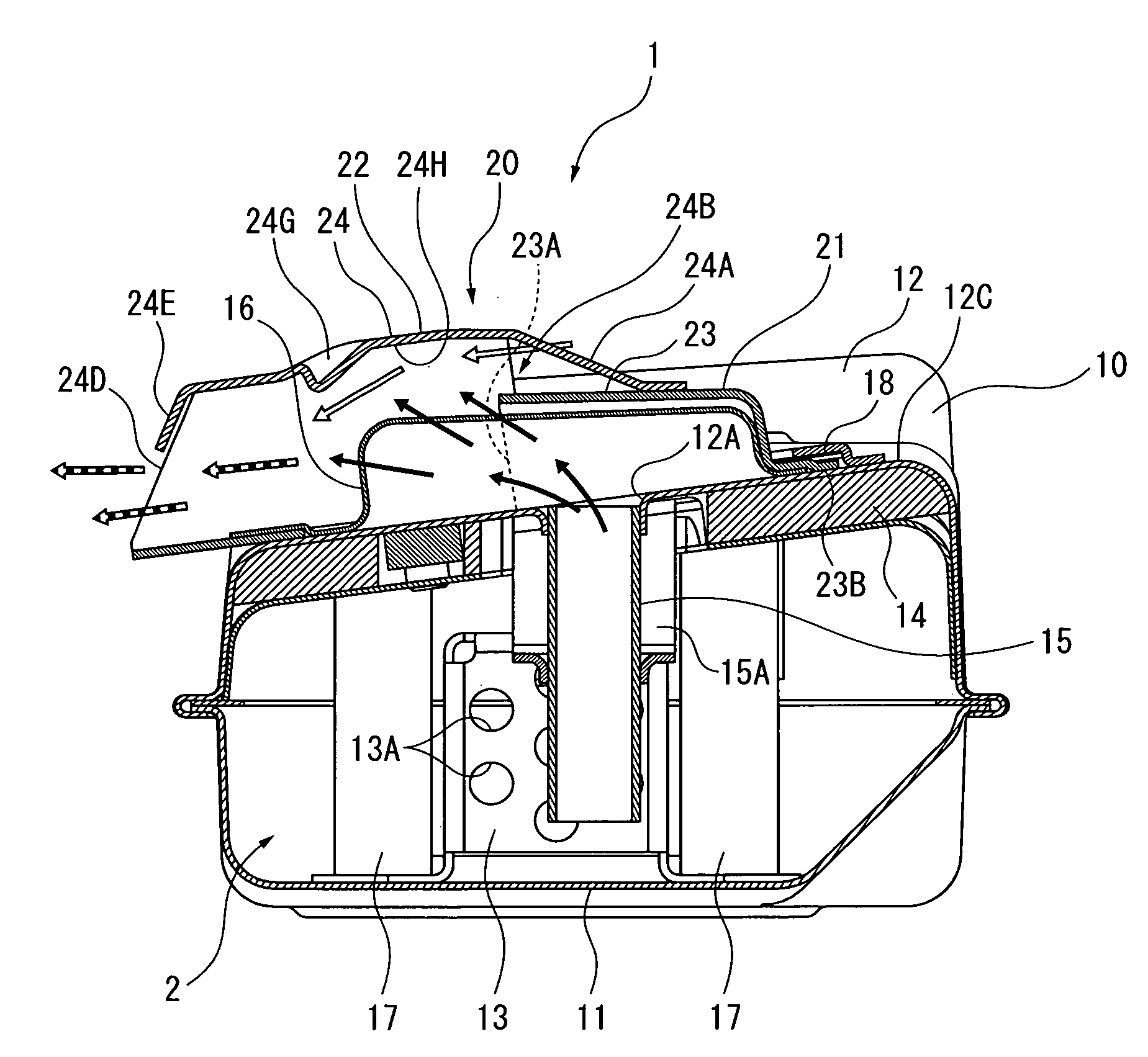

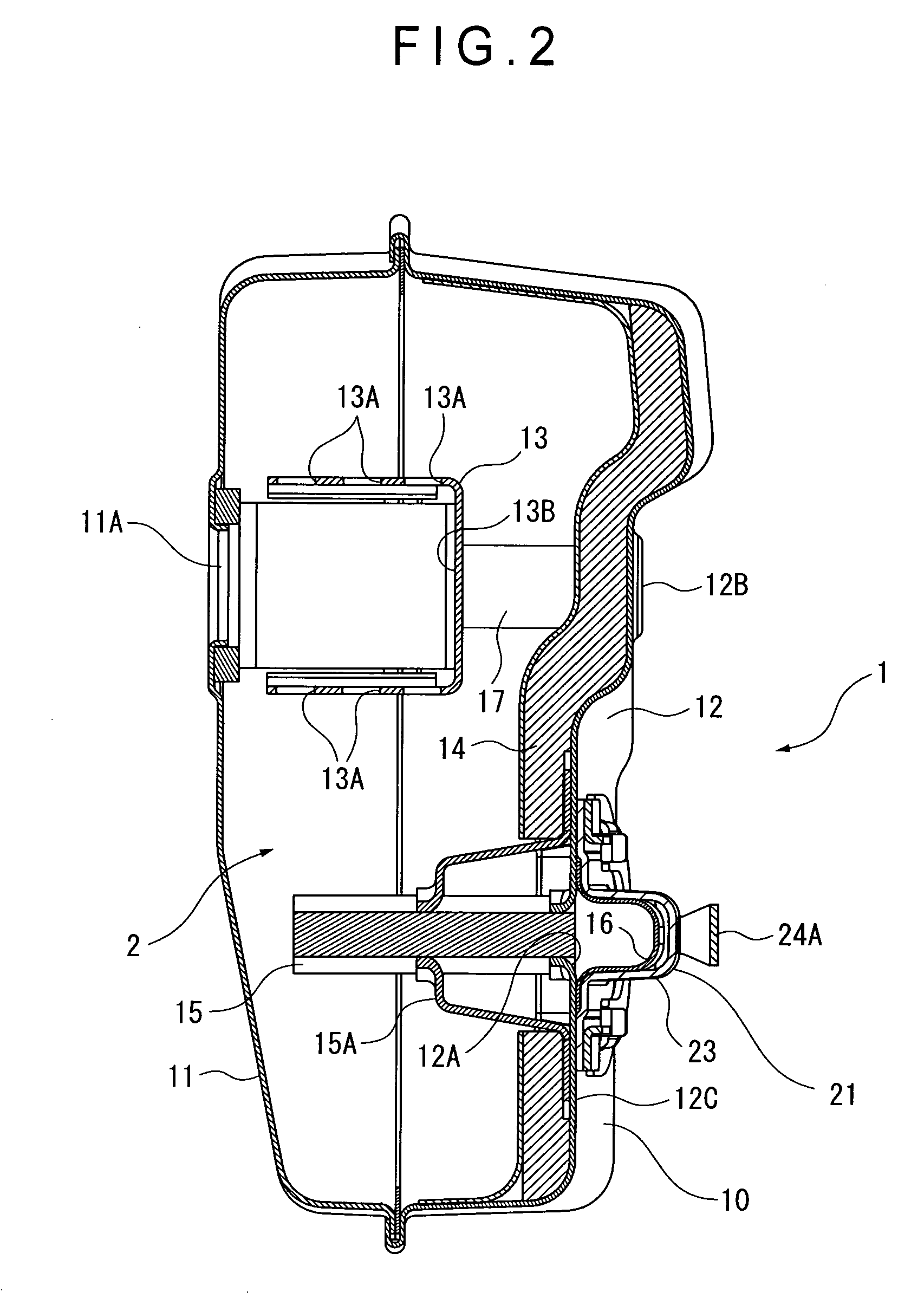

Power apparatus and electronic apparatus using the same

InactiveUS20110005781A1Reduce in sizeReduce amountElectric devicesSecondary cellsEngineeringPower apparatus

A power apparatus of the present invention includes a main body case, a plurality of power supply elements provided inside the main body case, and a fire-extinguishing agent tank facing each of the plurality of power supply elements. An opening part for sensing heat of the power supply elements and substantially opening the fire-extinguishing agent tank is provided between the power supply elements and the fire-extinguishing agent tank facing the power supply elements, thus enabling the size to be reduced.

Owner:PANASONIC CORP

Shield for self-defense provided with a spray device

InactiveUS20080087684A1Easy to operateReliable supportArmoured vehiclesSpray nozzlesEngineeringMechanical engineering

There is provided a shield for self-defense provided with a spray device capable of securing safety by always and reliably supporting the shield so as to eject a spray with a simple operation while using the a hand gripping the shield. The shield for self-defense provided with a spray device comprises a shield body, a longitudinal handle serving as a spray device standing upright from a back face of the shield body so as to be gripped while laying an elbow on the back face of the shield body, an arm holder for fixing the elbow thereon, wherein the longitudinal handle and the arm holder are protruded from and disposed at the left and right sides on the central portion between the upper and lower portions of the shield body, and wherein the longitudinal handle is shaped in a cylindrical form so as to house a spray can therein, and the spray can is covered with a cap provided at the upper end of the cylindrical form, and when the spray can is pushed by the cap, a spray for threat and defense can be ejected toward a front face of the shield body.

Owner:KOSHIMOTO MASAYA

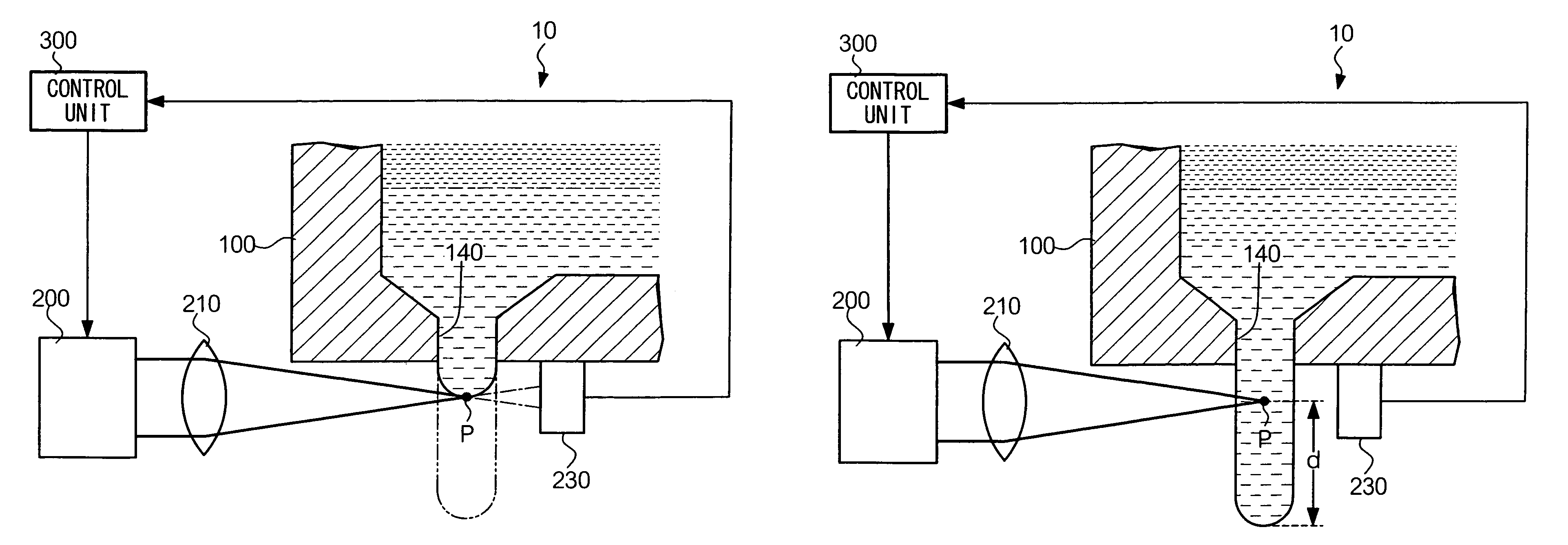

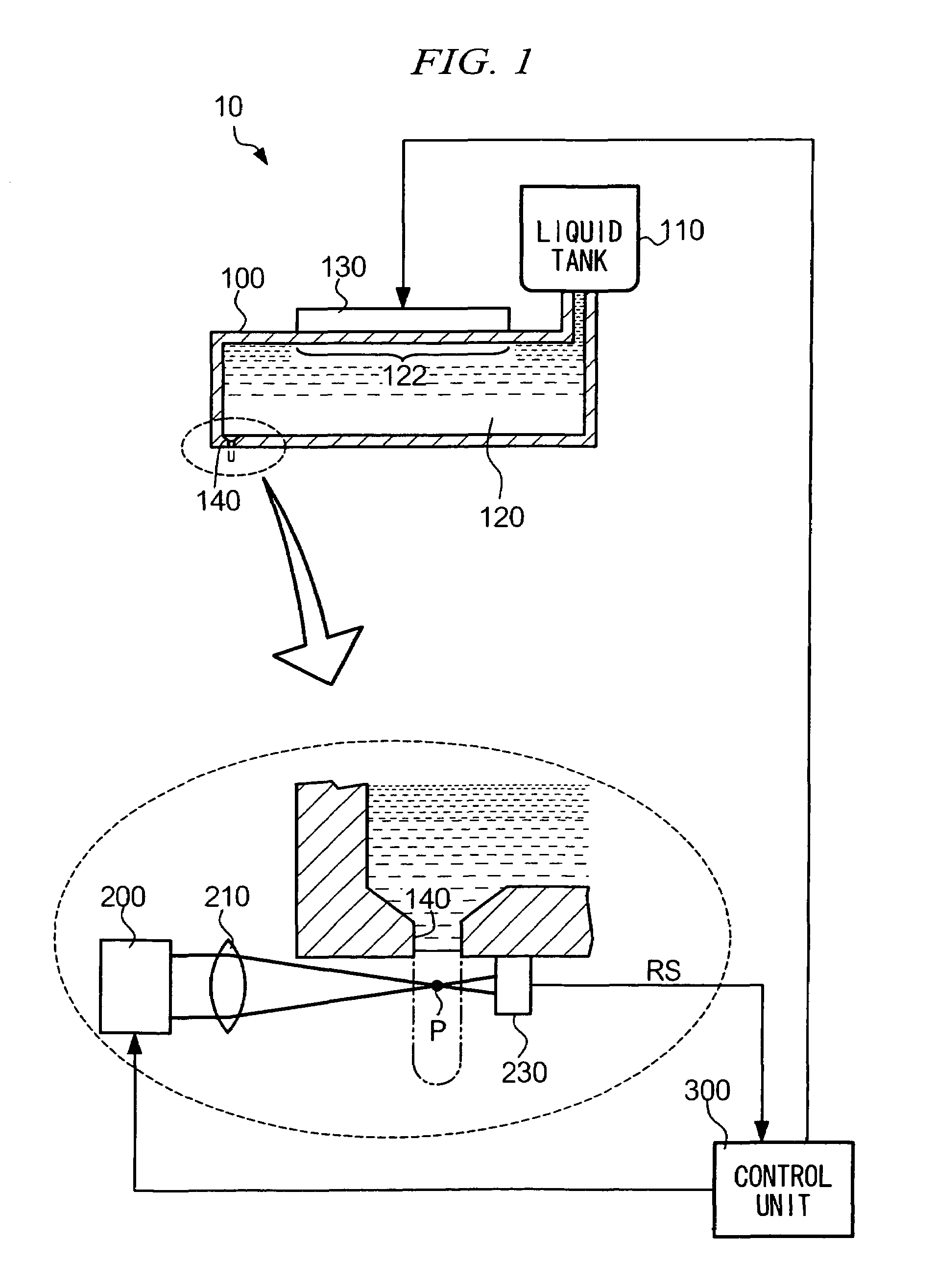

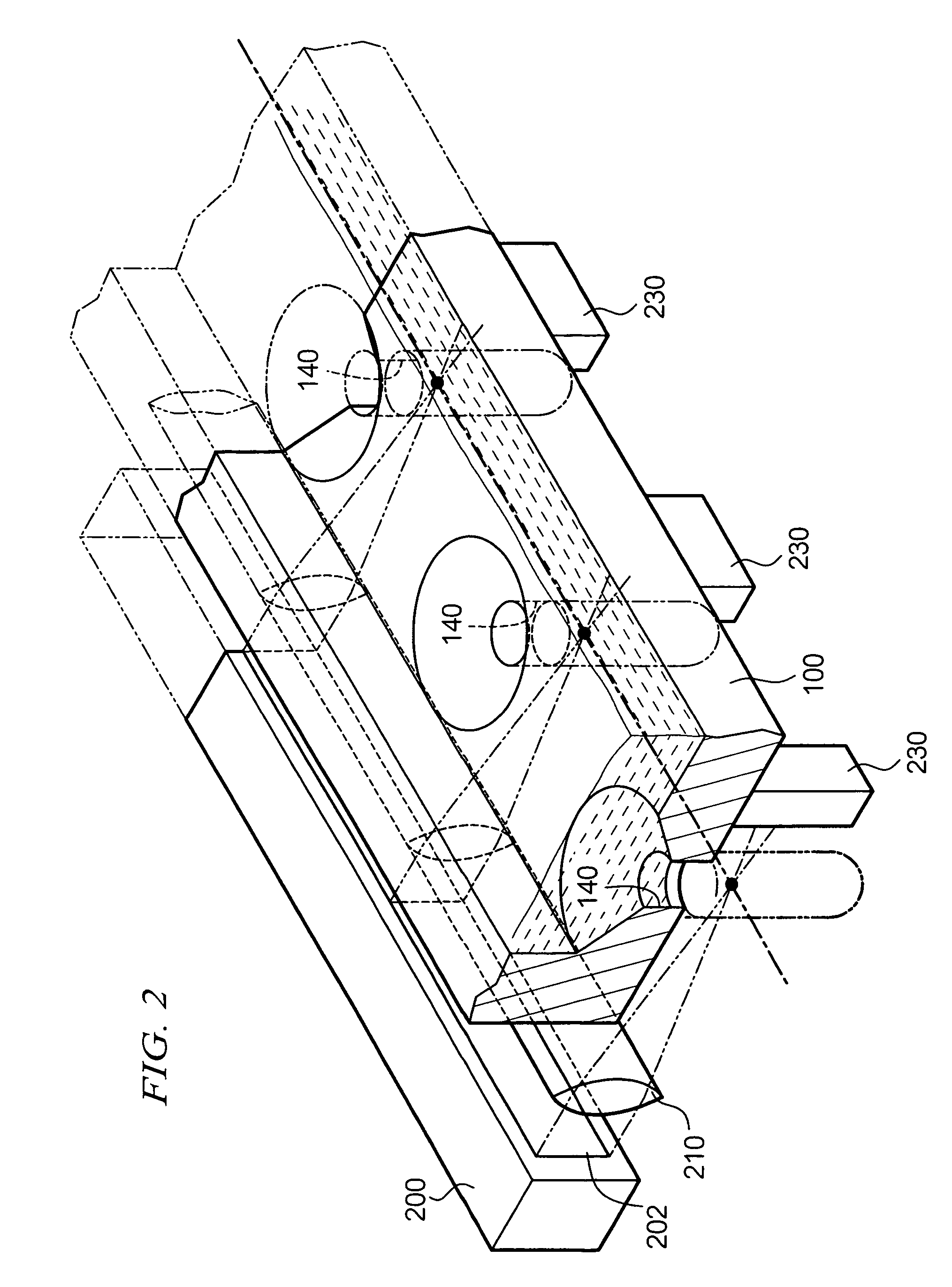

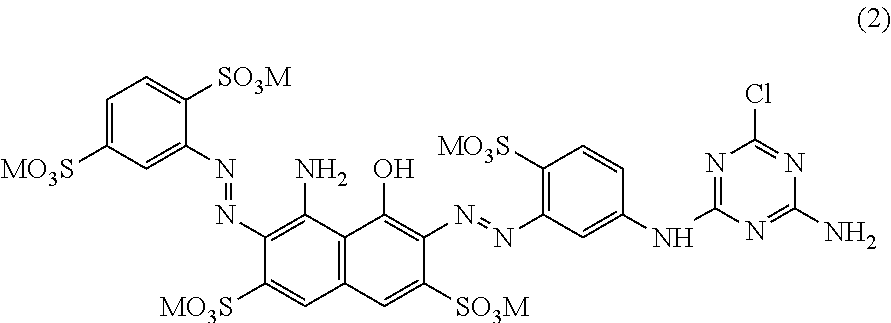

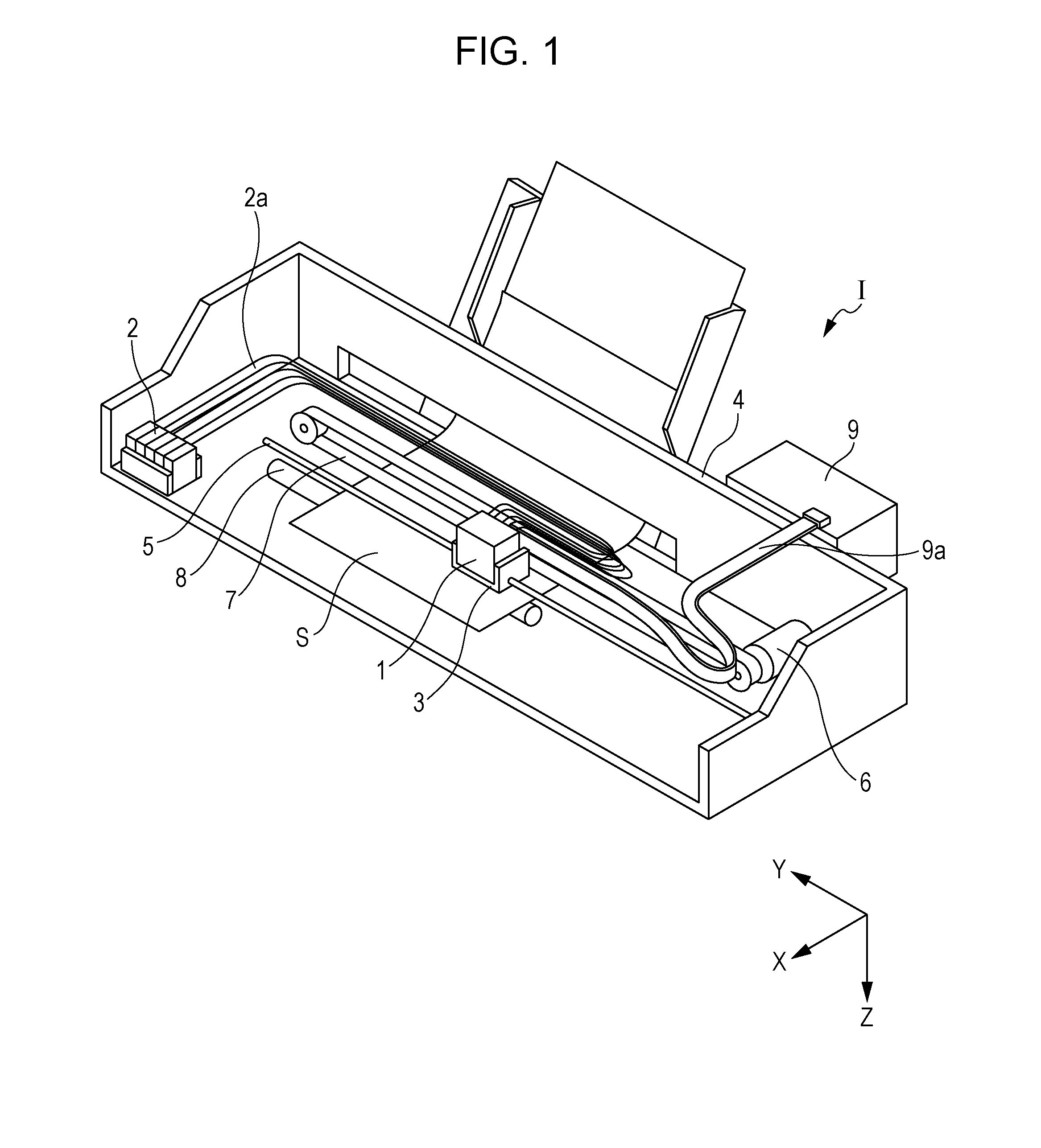

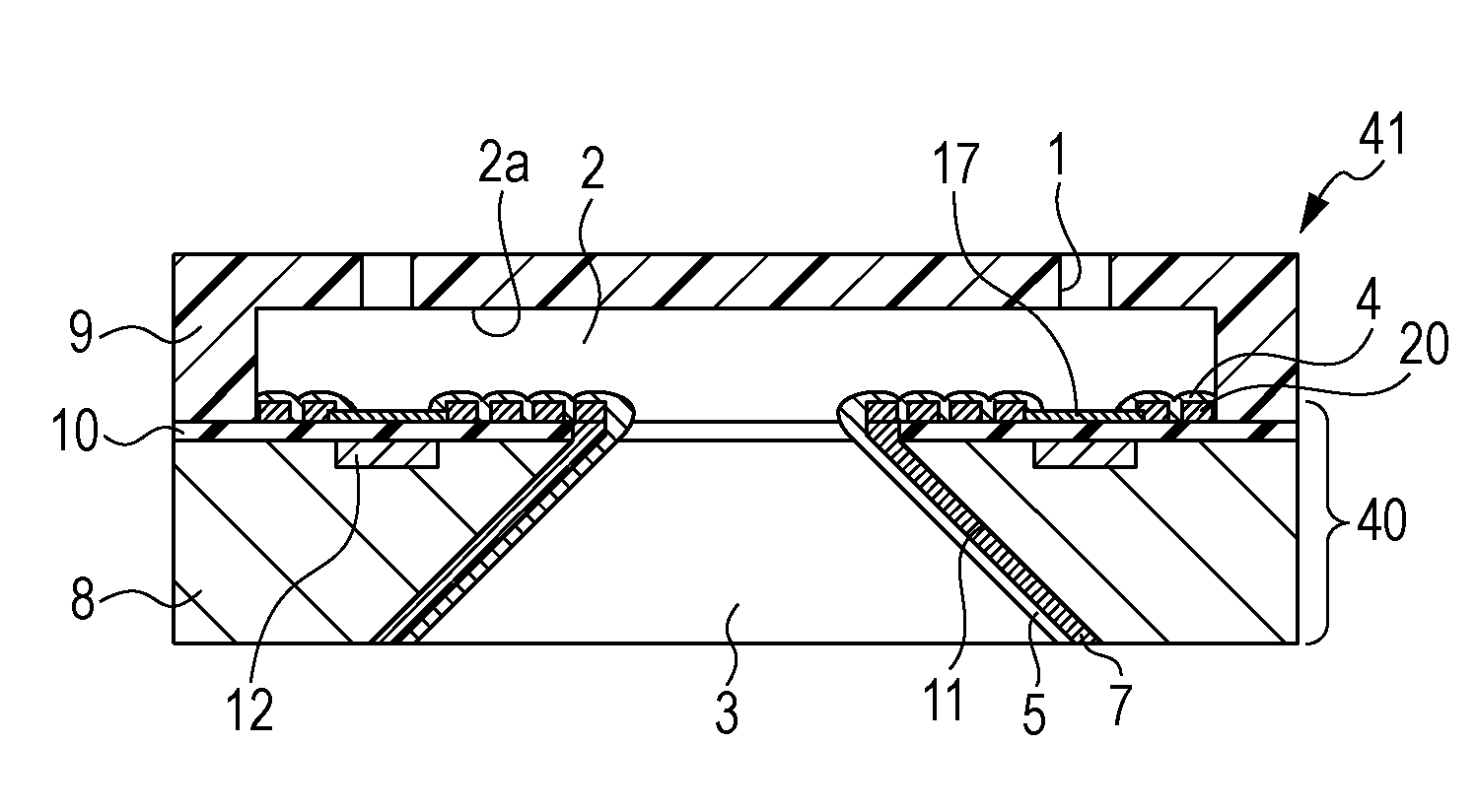

Droplet ejecting device, droplet ejecting method, and electronic optical device

InactiveUS7374273B2Reliable ejectionHigh viscosityElectroluminescent light sourcesSolid-state devicesTime segmentEngineering

A droplet ejecting device includes an ejector that is adapted to eject a liquid stored in a pressure chamber from an ejecting nozzle, by applying pressure to the pressure chamber; an ejection timing detector that is adapted to detect a start timing at which a liquid column starts being ejected from the ejecting nozzle; a droplet separator that is adapted to give, to the liquid column, an energy that separates the liquid column from the liquid stored in the pressure chamber; and a controller that is adapted to control the droplet separator to give an energy at a timing when a predetermined time period has elapsed since the start timing detected by the ejection timing detector.

Owner:SEIKO EPSON CORP

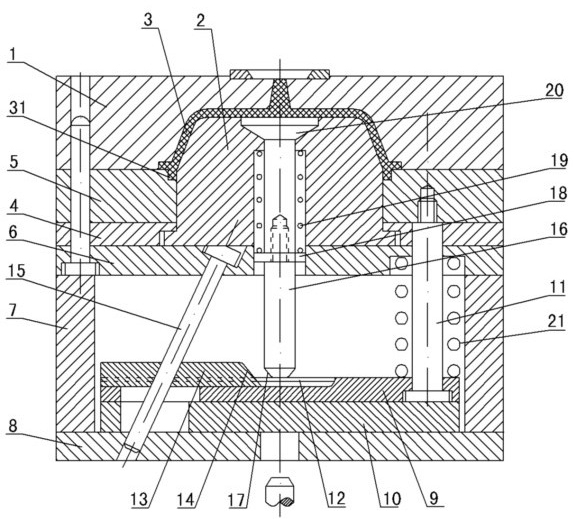

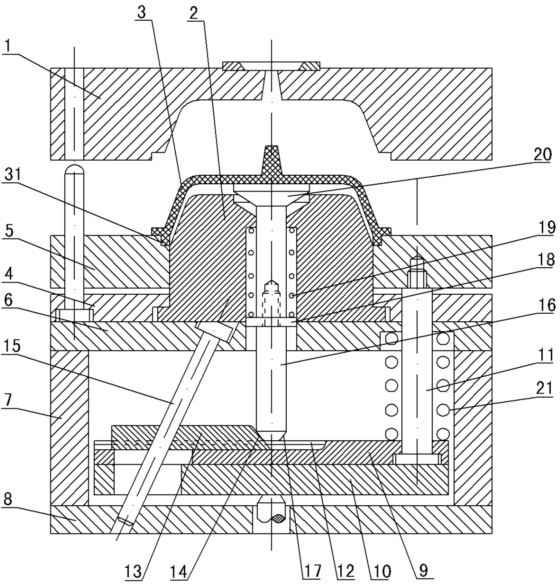

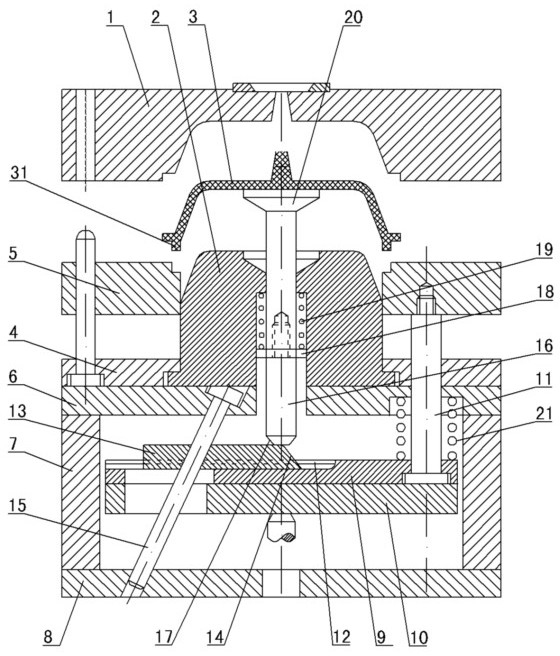

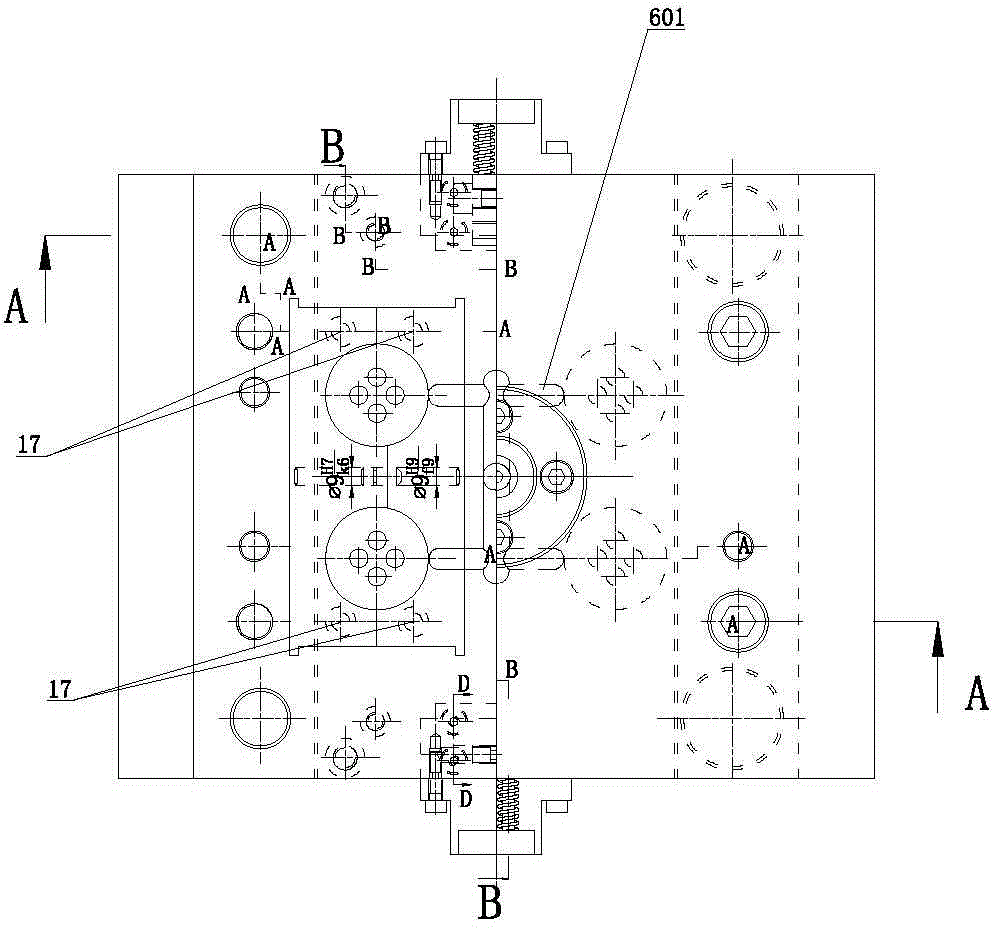

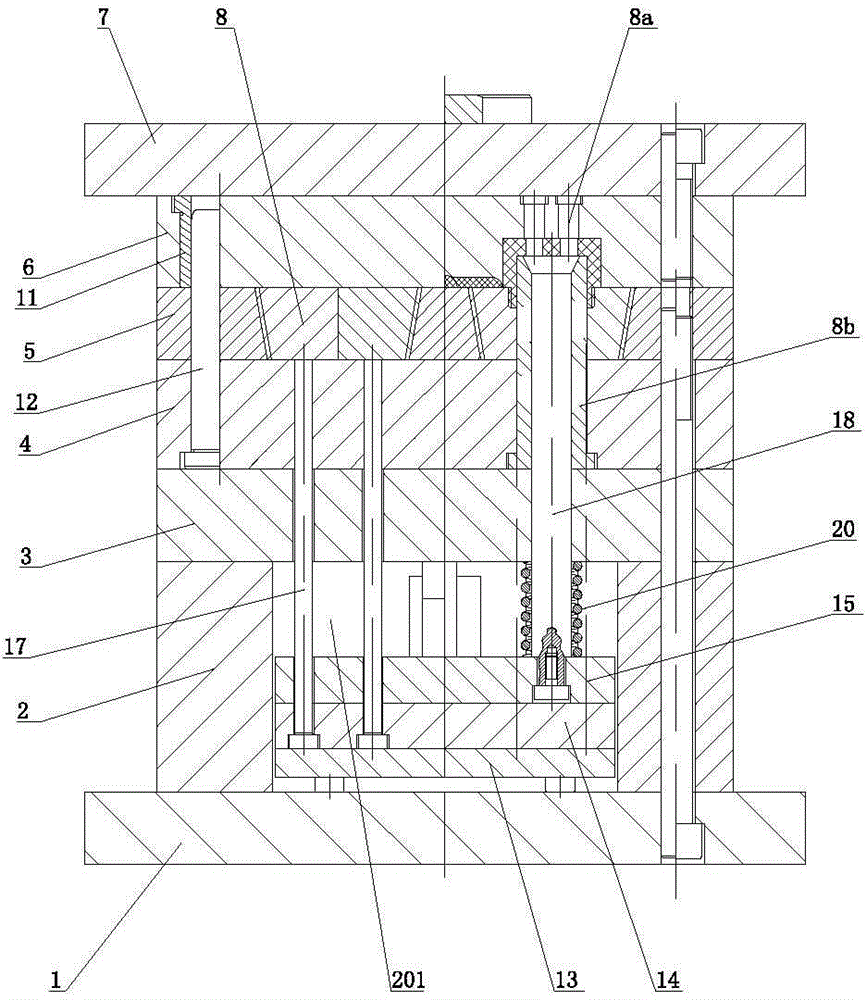

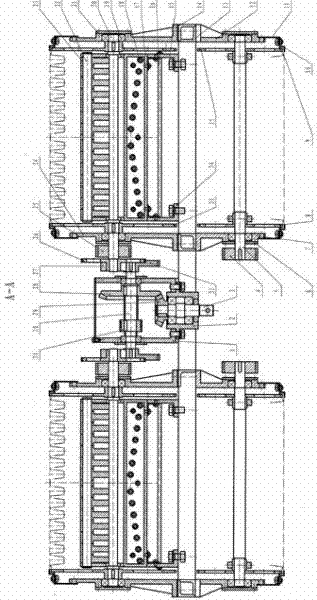

Inclined guide pillar slide block type secondary demolding mechanism of injection mold

The invention relates to an inclined guide pillar slide block type secondary demolding mechanism of an injection mold. The secondary demolding mechanism mainly comprises a mold cavity and a core insert, wherein a core plate is mounted outside the core insert; a stripper plate is arranged on the core plate; a molded product is formed among the mold cavity, the core insert and the stripper plate; convex ribs are arranged at the bottom surface of the product; the stripper plate matches the convex ribs of the product; the core insert and the core plate are mounted on a core fixing plate; a mold feet are mounted below the core fixing plate; lower templates are mounted below the mold foot; an upper ejector plate and a lower ejector plate are arranged between the mold feet; the upper ejector plate is connected with an ejecting pillar, which is connected with the stripper plate after penetrating through the core fixing plate and the core plate; the demolding mechanism is characterized in that an I-shaped groove is formed in the upper ejector plate, a slide block is arranged in the I-shaped groove, the head part of the slide block is made as an inclined surface, an inclined guide rod is connected below the core fixing plate and penetrates through the slide block, an ejector rod is mounted in the core insert, the head part of the ejector rod is in contact with the bottom surface of the product, and an arc surface is made at the bottom of the ejector rod, and the arc surface matches with the inclined surface of the slide block.

Owner:ZHEJIANG KAIHUA MOLDS

Card connector having an eject mechanism adaptable to a plurality of kinds of cards different in size

InactiveUS20050136712A1Eliminate the problemReliable ejectionEngagement/disengagement of coupling partsConveying record carriersEngineering

In a card connector to be connected to a card, a defining member defines an inserting region for receiving the card inserted in an inserting direction. The card connector includes an eject mechanism for ejecting the card from the inserting region in an ejecting direction opposite to the inserting direction. A plurality of ejecting members are adapted to be engaged with the card in the inserting region in the inserting and the ejecting directions and movable with respect to the defining member independently of one another. A linking mechanism selectively links the ejecting members to each other in response to insertion of the card in the inserting region.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

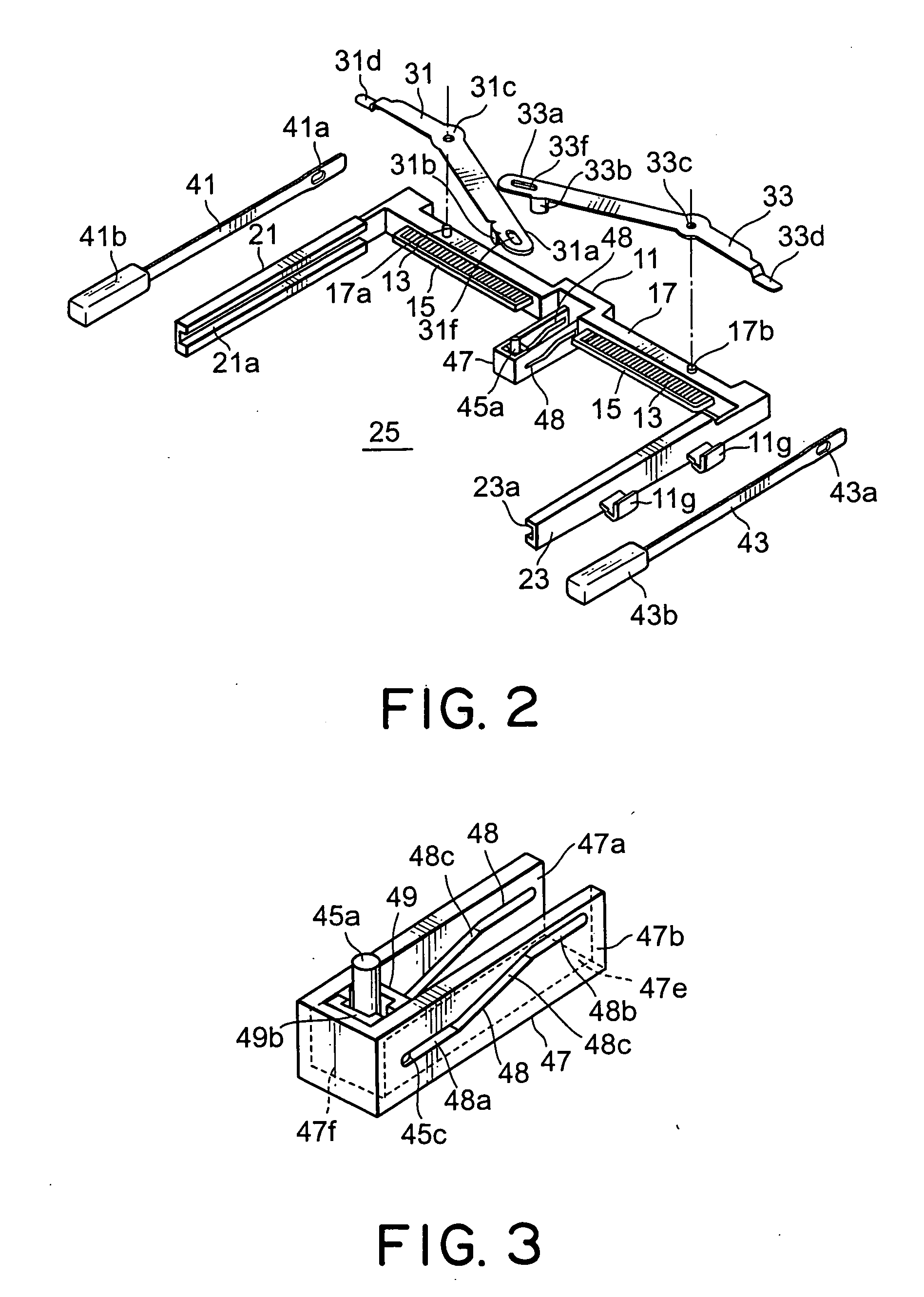

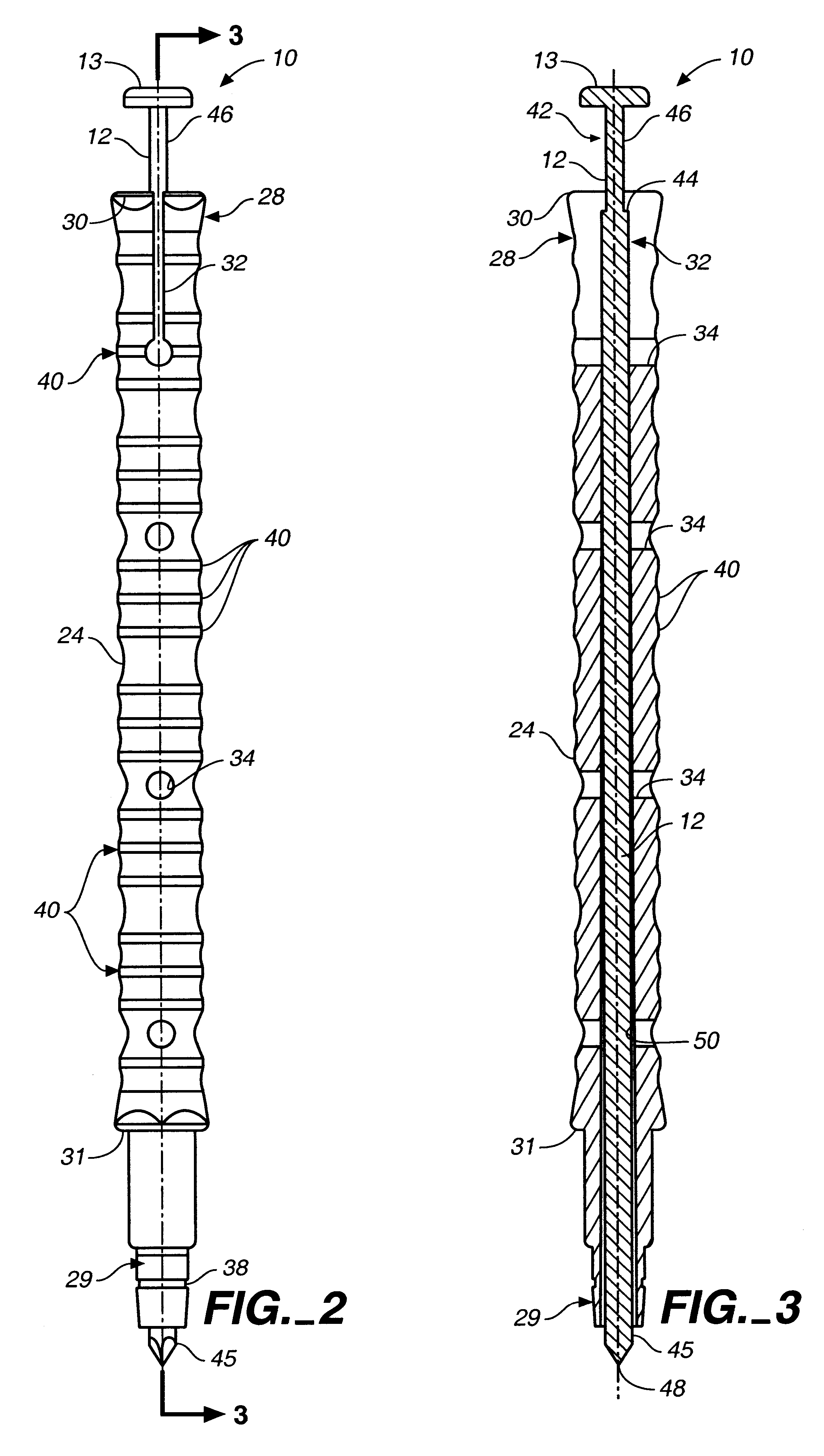

Handle for inoculating loop

InactiveUS6245559B1Save mold costEasy to assembleBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringPlunger

A two-piece handle assembly (10, 10a) including a plunger (12, 12a) and a body (24, 24a) having an axial bore (50, 50a) in which plunger (12, 12a) can move between retracted and extended positions. The upper end (28) of body (24, 24a) includes a pair of opposed longitudinal slots (32) that permit radially outward resilient movement of the upper end (28) to enlarge a bore (52), defined by a neck portion (54) of the body, to permit insertion of plunger (12) into body (24, 24a). A plunger shoulder (44) is designed to engage a body shoulder (55) to limit movement of the plunger in the direction of retraction, and a finger pad (13) is provided to limit movement of the plunger in the direction of extension.

Owner:BIO PLAS

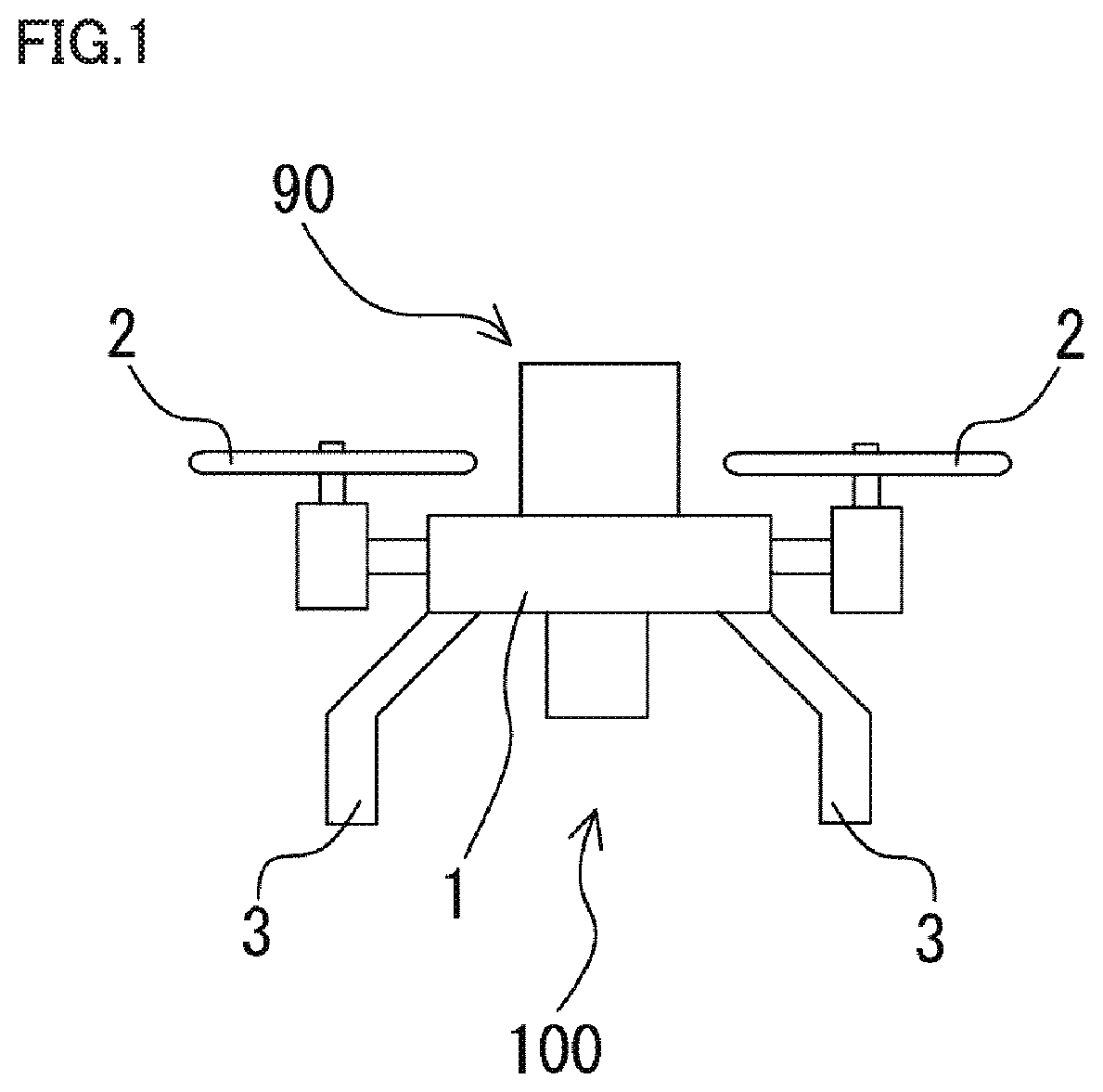

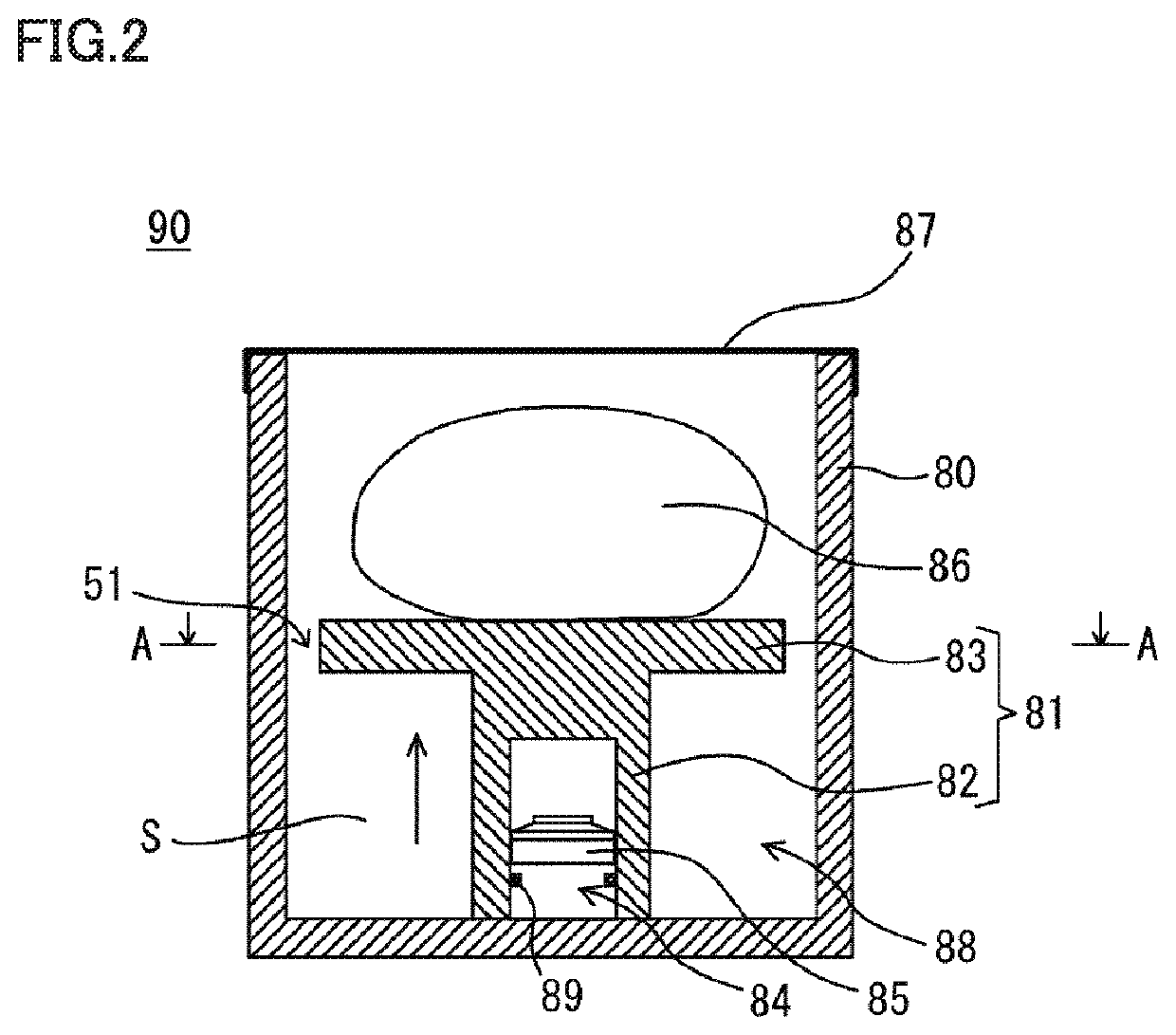

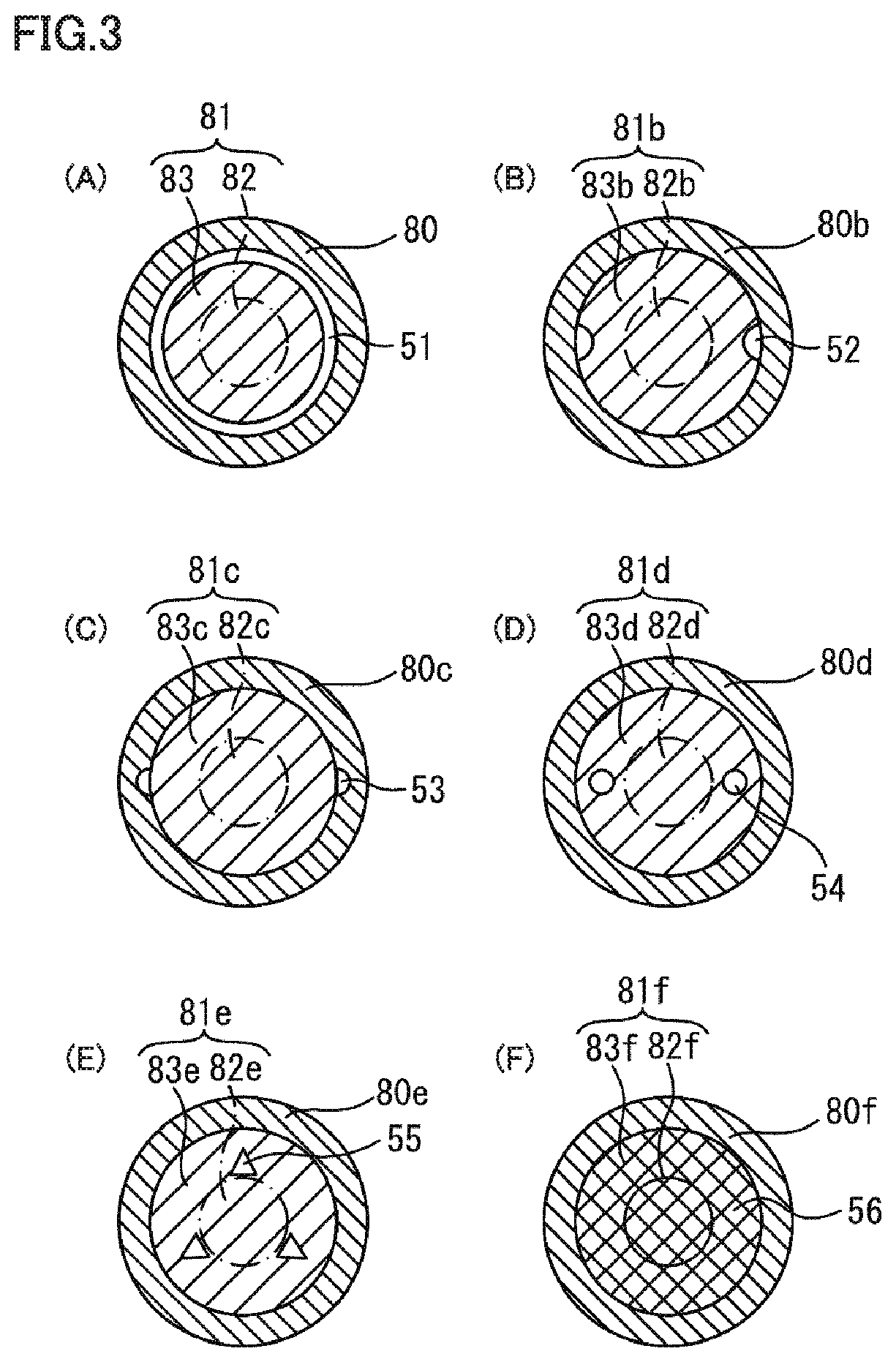

Aerial vehicle safety apparatus and aerial vehicle

ActiveUS20200339278A1Reliable ejectionUnmanned aerial vehiclesParachutesFlight vehicleMechanical engineering

An aerial vehicle safety apparatus includes an expandable object and an ejection apparatus. The ejection apparatus includes a container that accommodates the expandable object and has an opening provided on one end side, a moving member provided in the container, the moving member including an emission base carrying the expandable object on a side of the opening, the moving member being movable along an inner wall of the container, and a driver that ejects the expandable object by moving the moving member toward the opening. A space located opposite to the opening when viewed from the emission base and surrounded by the container and the moving member communicates with a space located outside the space through a communication portion.

Owner:NIPPON KAYAKU CO LTD

Ink jet textile printing ink composition, ink set, and printing method

ActiveUS20170275485A1Excellent color developmentReliable ejectionDisazo dyesReactive dyesPrinting inkPolymer chemistry

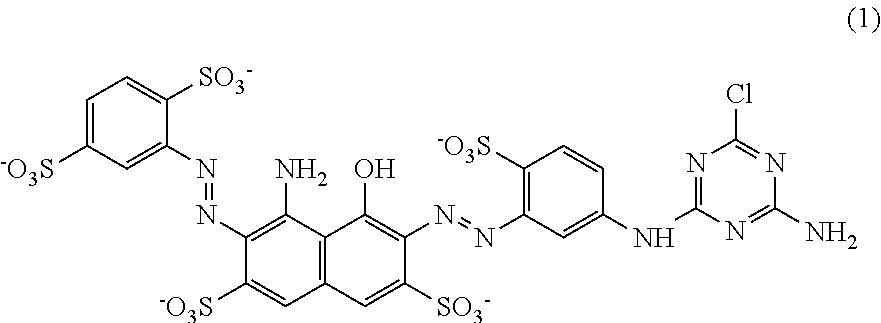

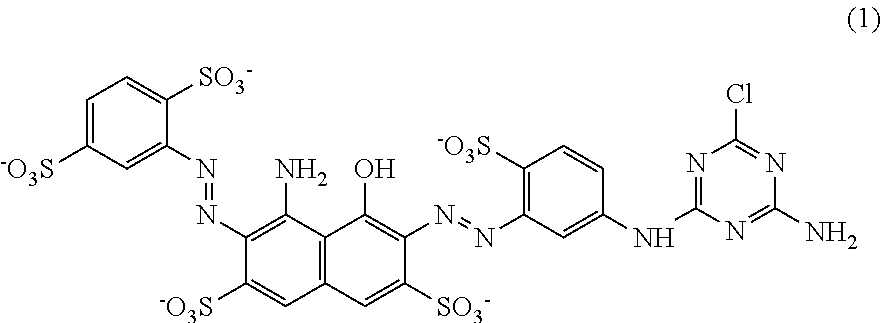

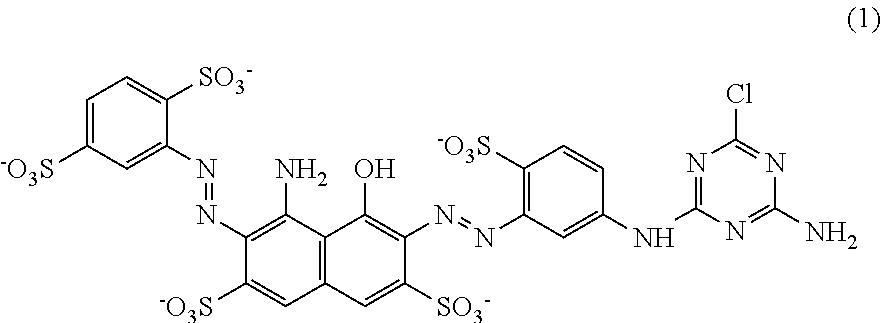

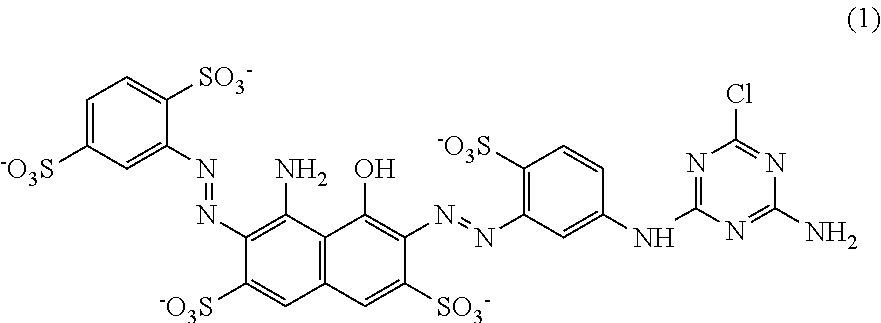

An ink jet textile printing ink composition according to the invention contains Li+, Na+, and a compound represented by the following formula (1):

Owner:SEIKO EPSON CORP

Coin depositing and dispensing machine

ActiveUS8210336B2Convenient to accommodateFast feedingPaper-money testing devicesCoin countersEngineeringCommon path

Owner:GLORY KOGYO KK

Deep hole punching method and deep hole punch head thereof for large forging

The invention discloses a deep hole punching method, which comprises the following steps of (1) heating a steel ingot; (2) discharging a forging blank, wherein the cutting amount of the head end is equal to the 16-20% of the weight of the steel ingot, and the cutting amount of the tail end is equal to the 8-12% of the weight of the steel ingot; (3) upsetting and drawing the forging blank, wherein the forging blank is upset and drawn to form a forging; (4) performing primary punching, wherein the press-down amount of a punch head is equal to 30% of the depth of a finished hole; (5) performing secondary punching, wherein the end of the punch head is applied with combustible matter and then is pressed down; (6) performing third punching, wherein the end of the punch head is applied with the combustible matter and then is pressed down; (7) trimming a hole; (8) performing heat treatment after forging. A deep hole punch head comprises a punch rod, wherein the punch rod is a cylindrical rod, the front end of the punch rod is a semispherical end, and a finishing ring is arranged on the punch rod, and is separated from the semispherical end. The deep hole punching method has the advantages that the production efficiency is high, the internal tissues are uniform and dense, and the utilization rate of materials is high. The deep hole punch head has the advantages that the structure design is skillful, the hole forming accuracy is high, and the quality is high.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

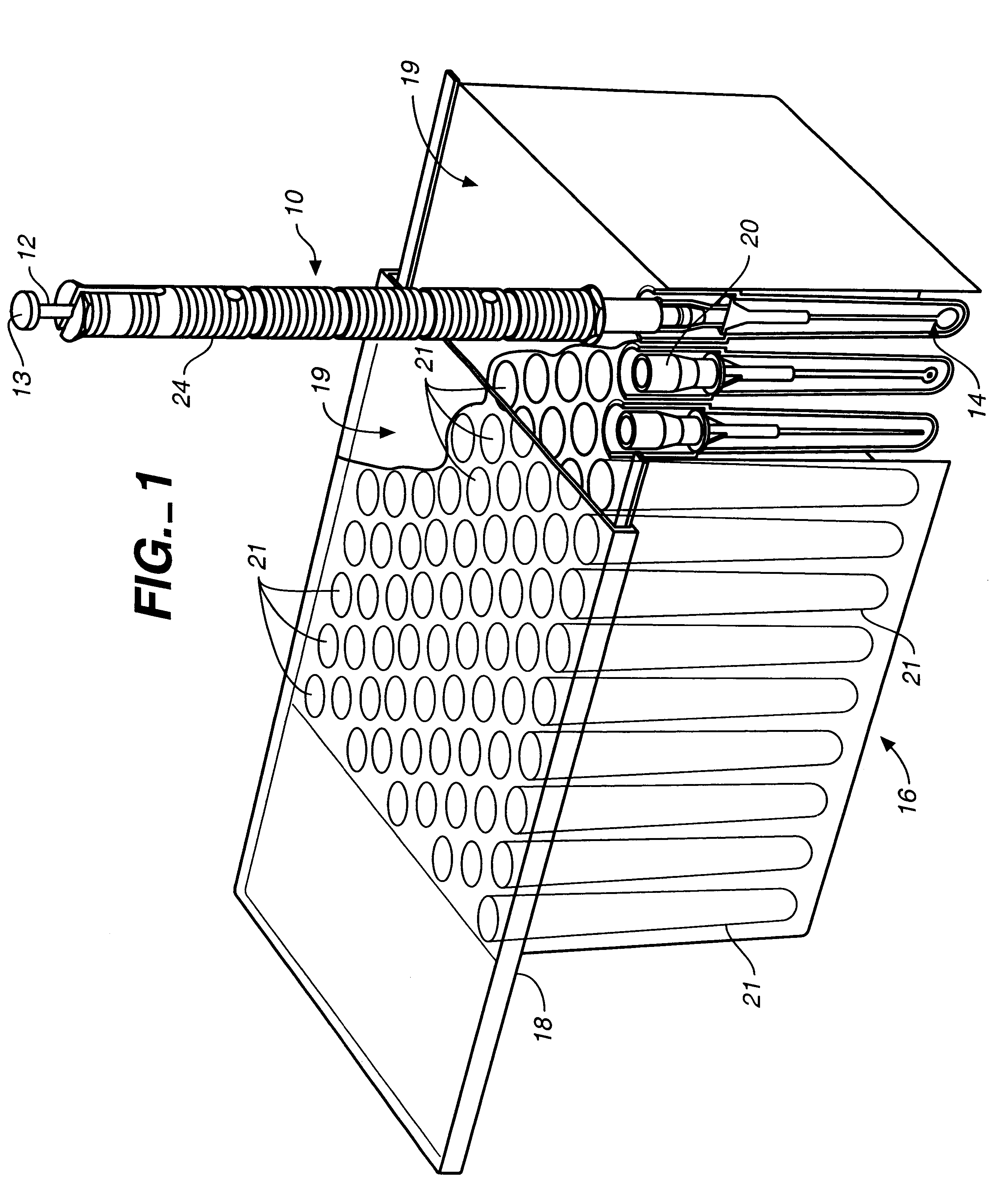

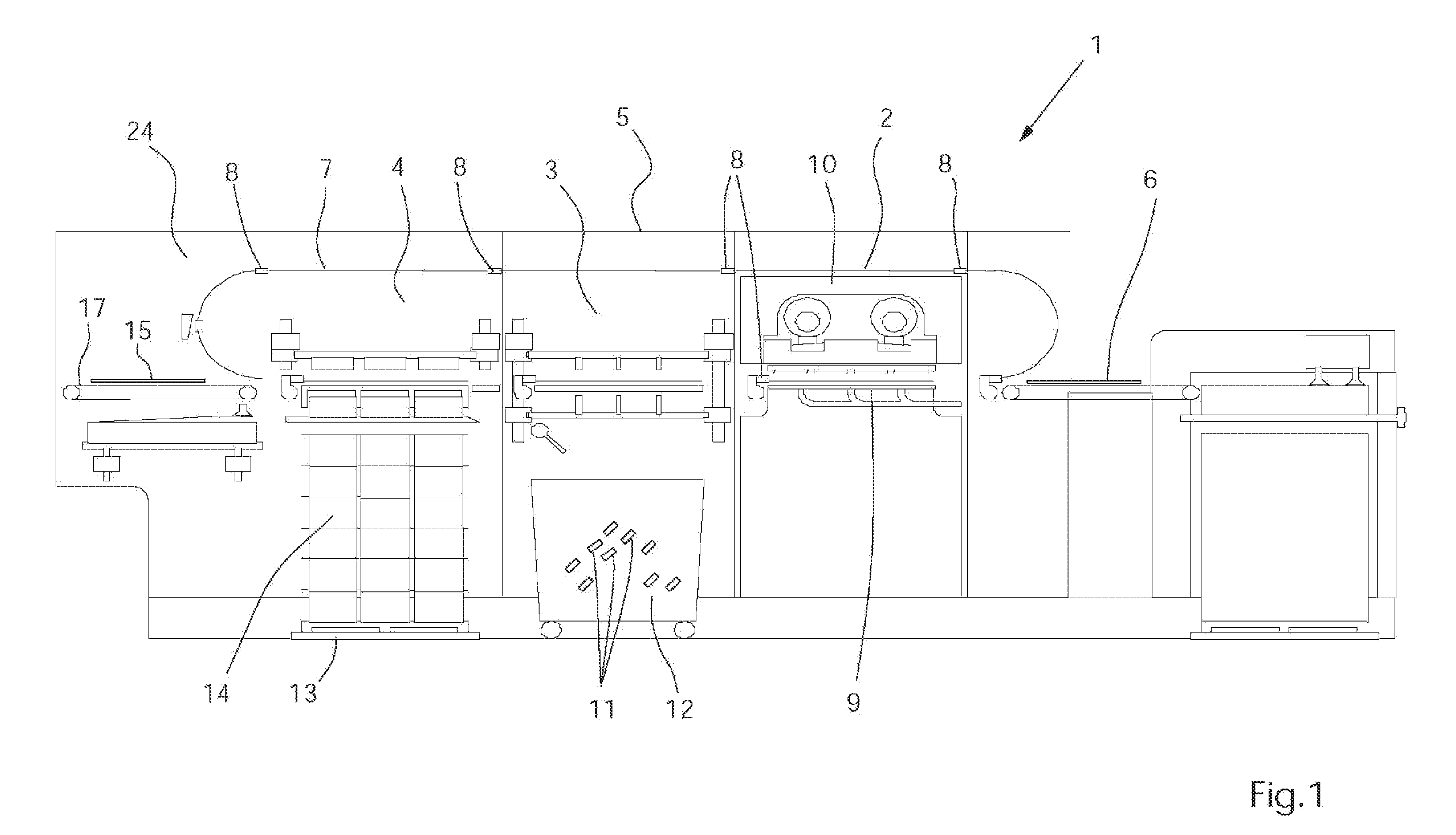

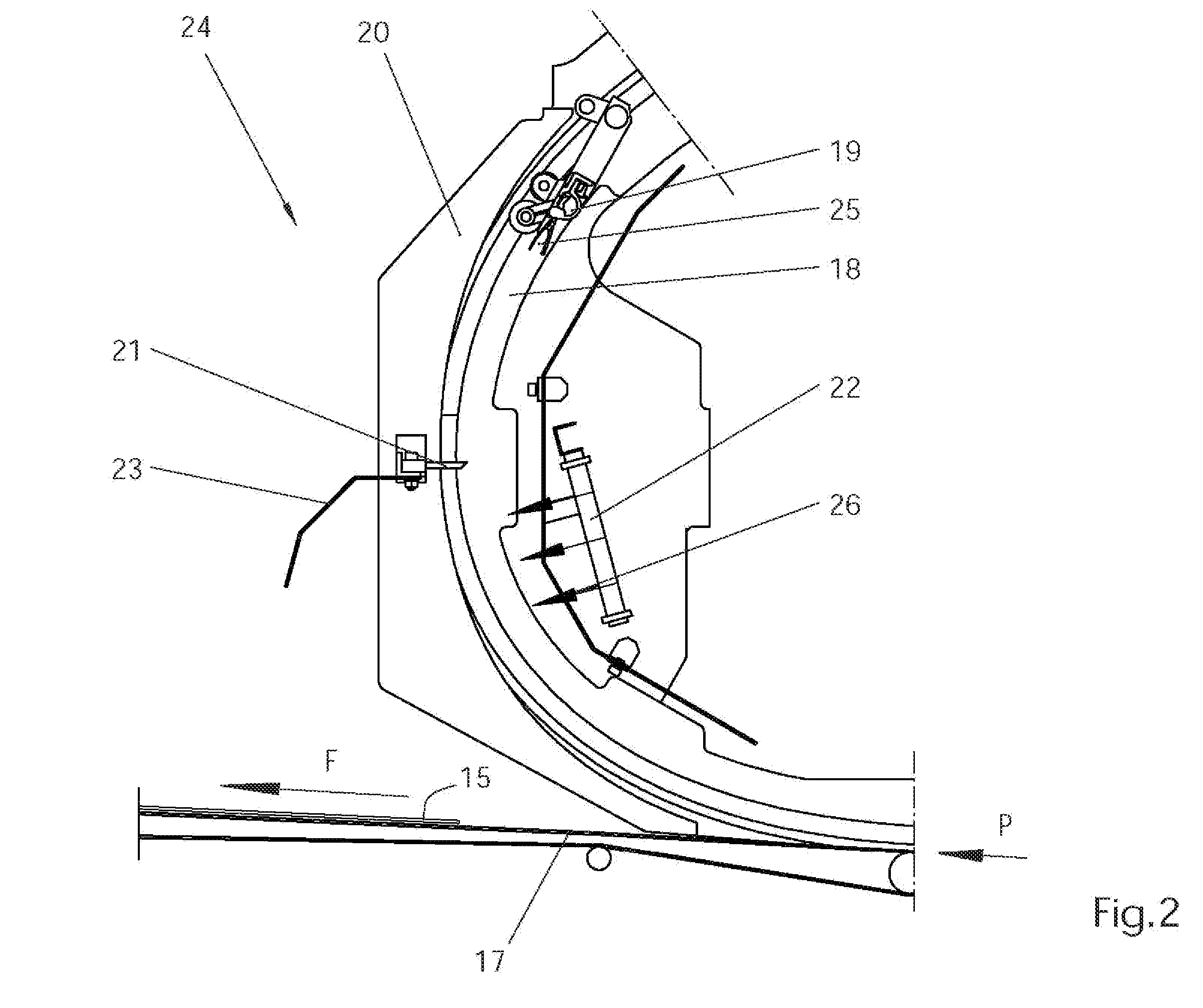

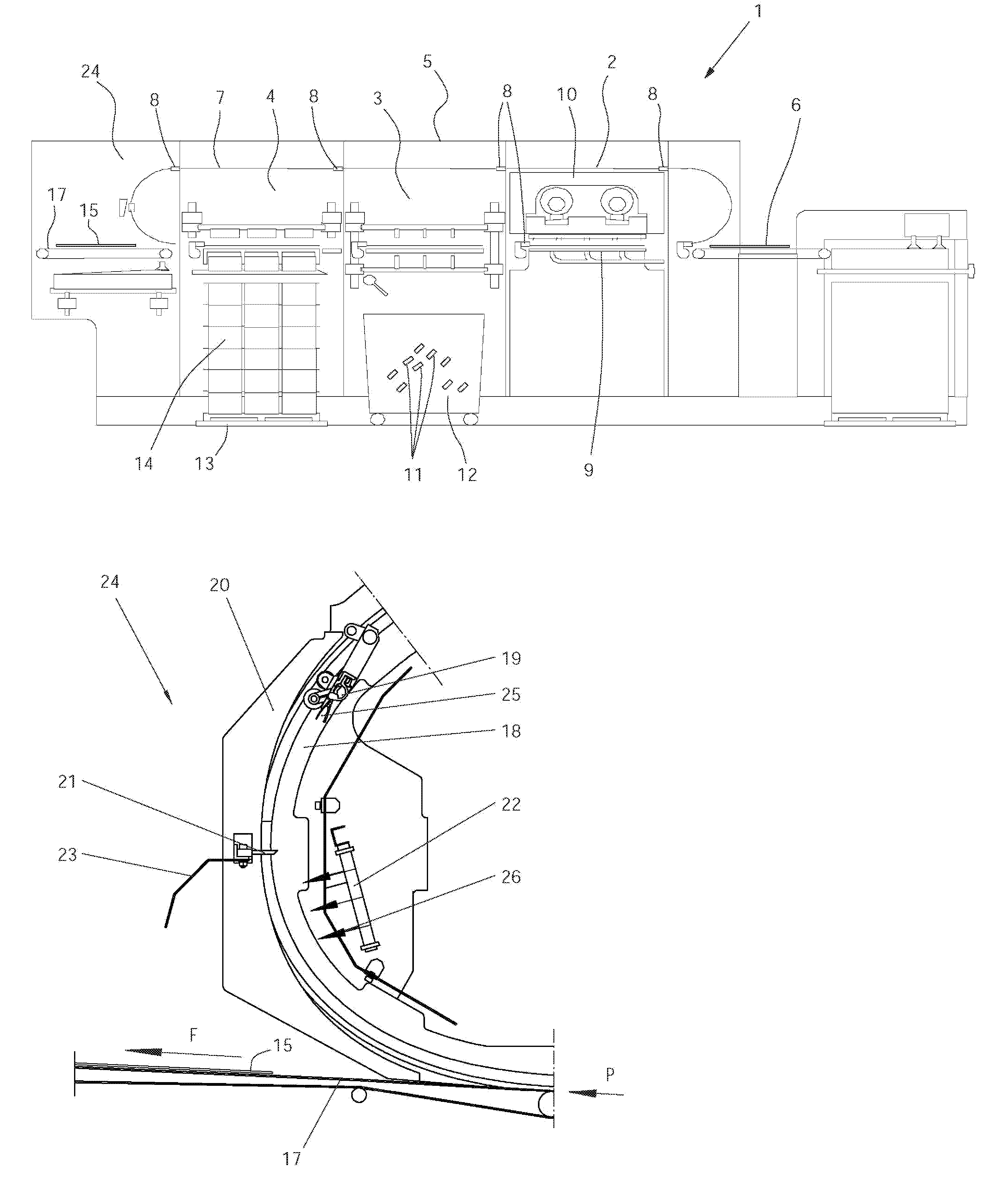

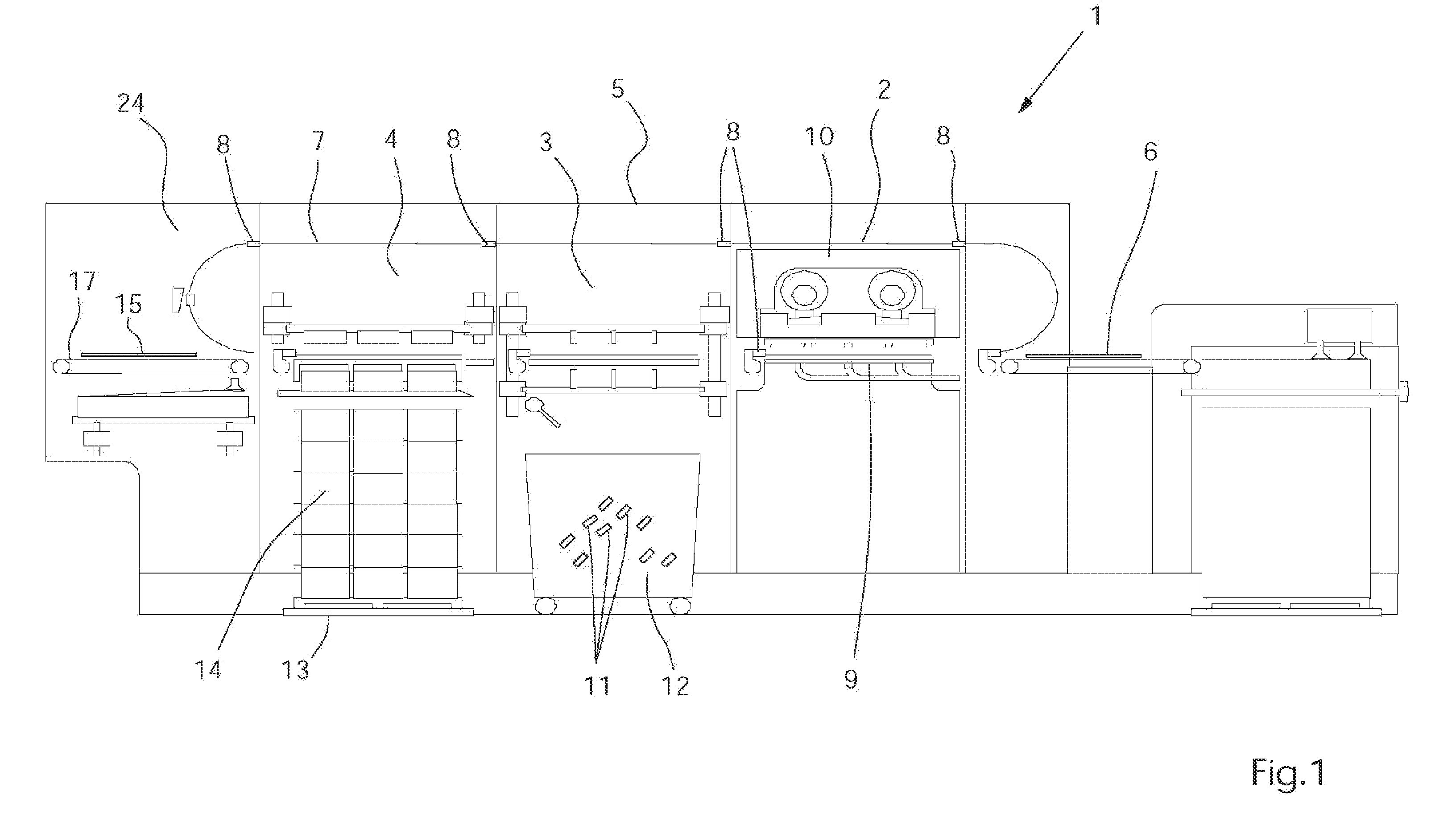

Waste blower for a paper sheet punching and embossing machine

ActiveUS20070296142A1Low costSimple structural elementMetal working apparatusArticle feedersPaper sheetScrap

A sheet punching and embossing machine includes revolving gripper cars with which a gripping margin of a sheet is grasped by grippers disposed on the gripper car so as to move the sheet through the machine, a punching station in which the gripping margin can be separated from the sheet, a delivery station in which the gripping margin can be further separated from the sheet, and an ejection station in which the gripping margin can be ejected from the gripper. The ejection station includes a blower which directs a current of air at the gripping margin.

Owner:MASTERWORK GROUP CO LTD

Muffler

InactiveUS20100230205A1Lower temperature of exhaust gasAvoid downsizingExhaust apparatusSilencing apparatusExhaust gasExhaust fumes

Owner:HUSQVARNA ZENOAH

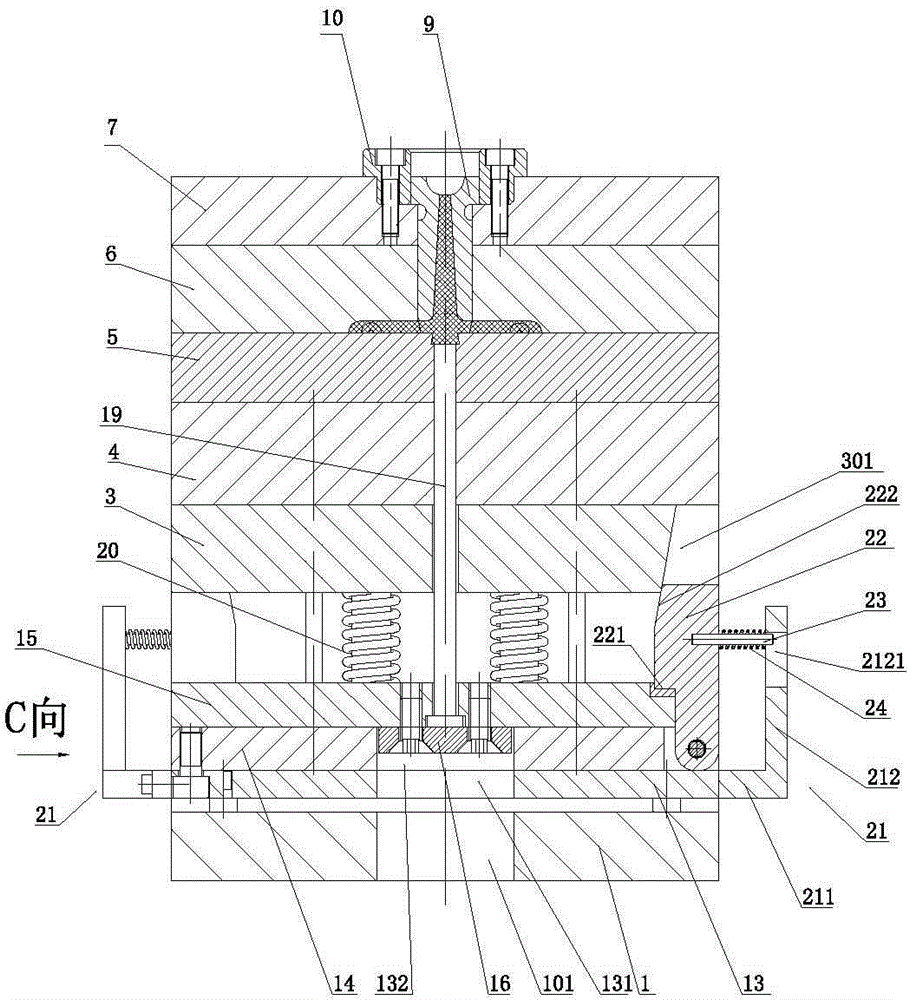

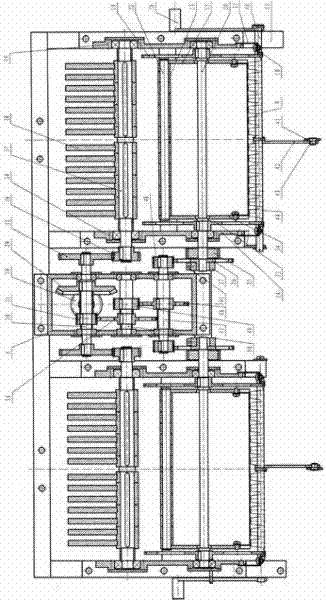

Capping plug injection mould and capping plug injection moulding method

The invention discloses a capping plug injection mould and a capping plug injection moulding method. The capping plug injection mould comprises a lower mould base plate, bearing feet, a bearing plate, a mould core fixed plate, a Haff fixed plate, a small mould core fixed plate and an upper mould base plate from bottom to top. A Haff structure with a thread forming cavity is arranged in the Haff fixed plate and is composed of two pieces of Haff, and a mould core and a small mould core are correspondingly arranged. The mould further comprises a secondary push-off device composed of a first pushing rod fixed plate, a second pushing rod fixed plate, a third pushing rod fixed plate, a pushing rod, a conical pushing rod and a sprue puller, and a swing hook mechanism composed of a swing hook reset plate, a swing hook, a guide rod and a spring is arranged on the secondary push-off device. The injection moulding method comprises mould assembling, injection moulding, cooling, and mould opening ejection. According to the mould opening ejection step, secondary ejection is achieved under matching of the swing hook mechanism. According to the injection mould and the injection moulding method, the mould is simple, demoulding is easy, and injection moulding and mould opening can be achieved without a dedicated injection molding machine.

Owner:林章辉

Method for cutting a loaf-shaped food and cutting machine

ActiveUS20100050834A1Constructive expenditure can be minimizedReduce maintenanceMetal working apparatusEngineeringContact element

In a method for cutting a loaf-shaped food, a loaf of the food is advanced toward a cutting device by means of a feed apparatus and the loaf is cut into slices, strips or cubes by means of said cutting device, which includes that the loaf is fixed during the feed movement by means of a vacuum gripper that is advanced together with the loaf; a negative pressure is generated within an interior of a contact element of the vacuum gripper and acts upon a fixing region of the surface of the loaf in a suction region of the contact element, in order to prevent hygienic problems associated with vacuum pumps, the negative pressure is generated by means of a piston-cylinder unit, the piston of which defines the interior of the contact element.

Owner:REIFENHAEUSER UWE

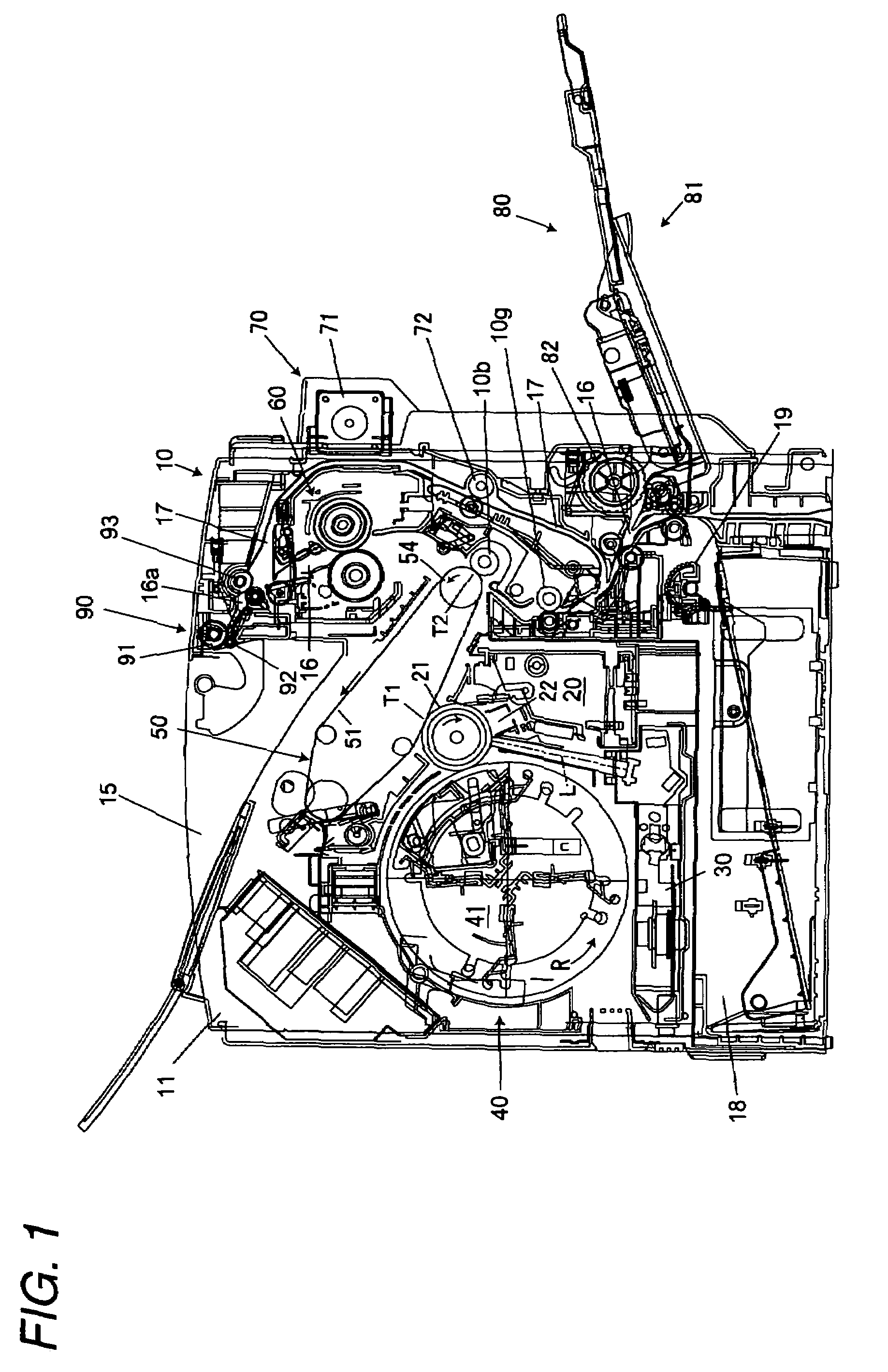

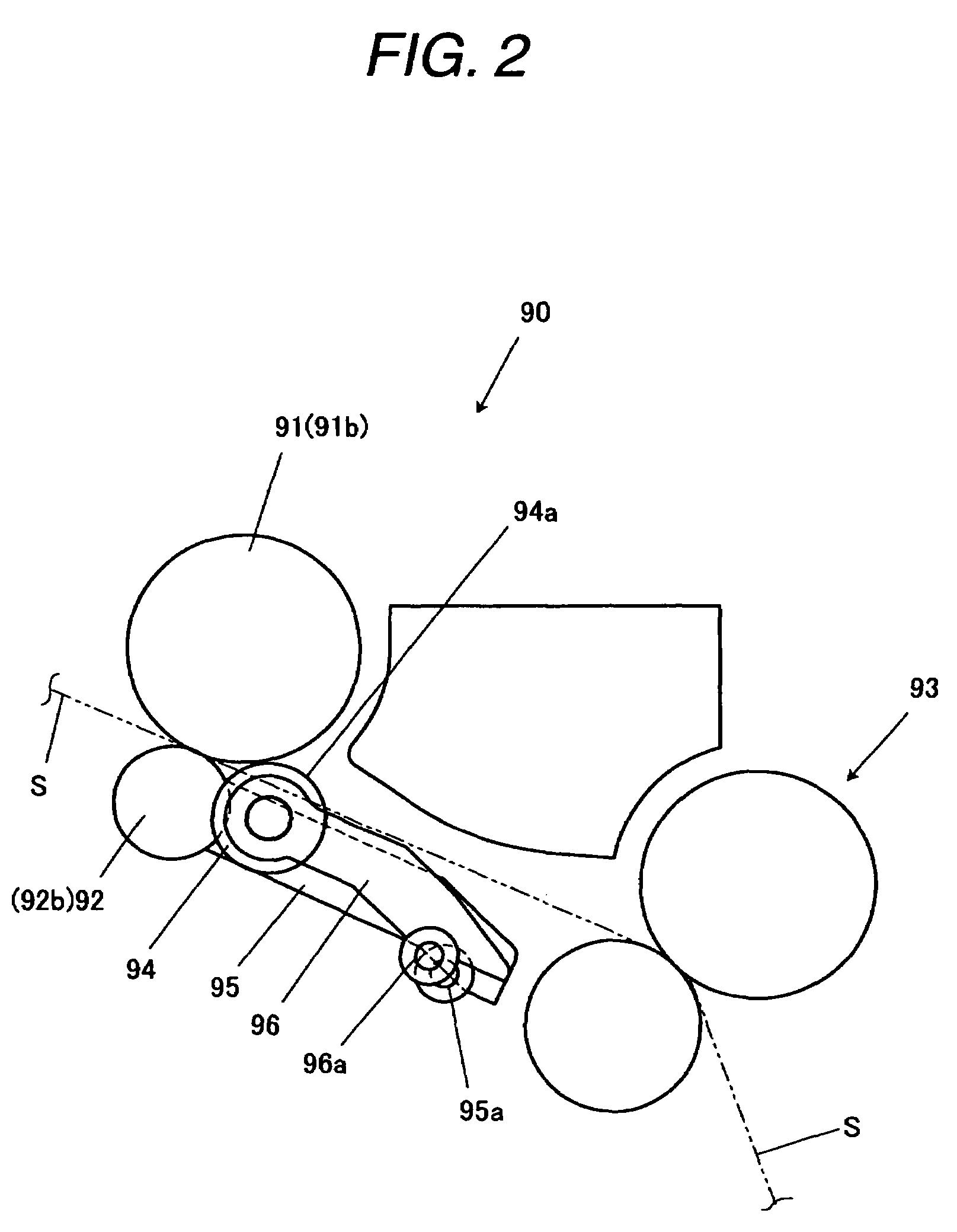

Image forming apparatus

InactiveUS20060198678A1High positioning accuracyBlocking phenomenonElectrographic process apparatusImage formationEngineering

Owner:SEIKO EPSON CORP

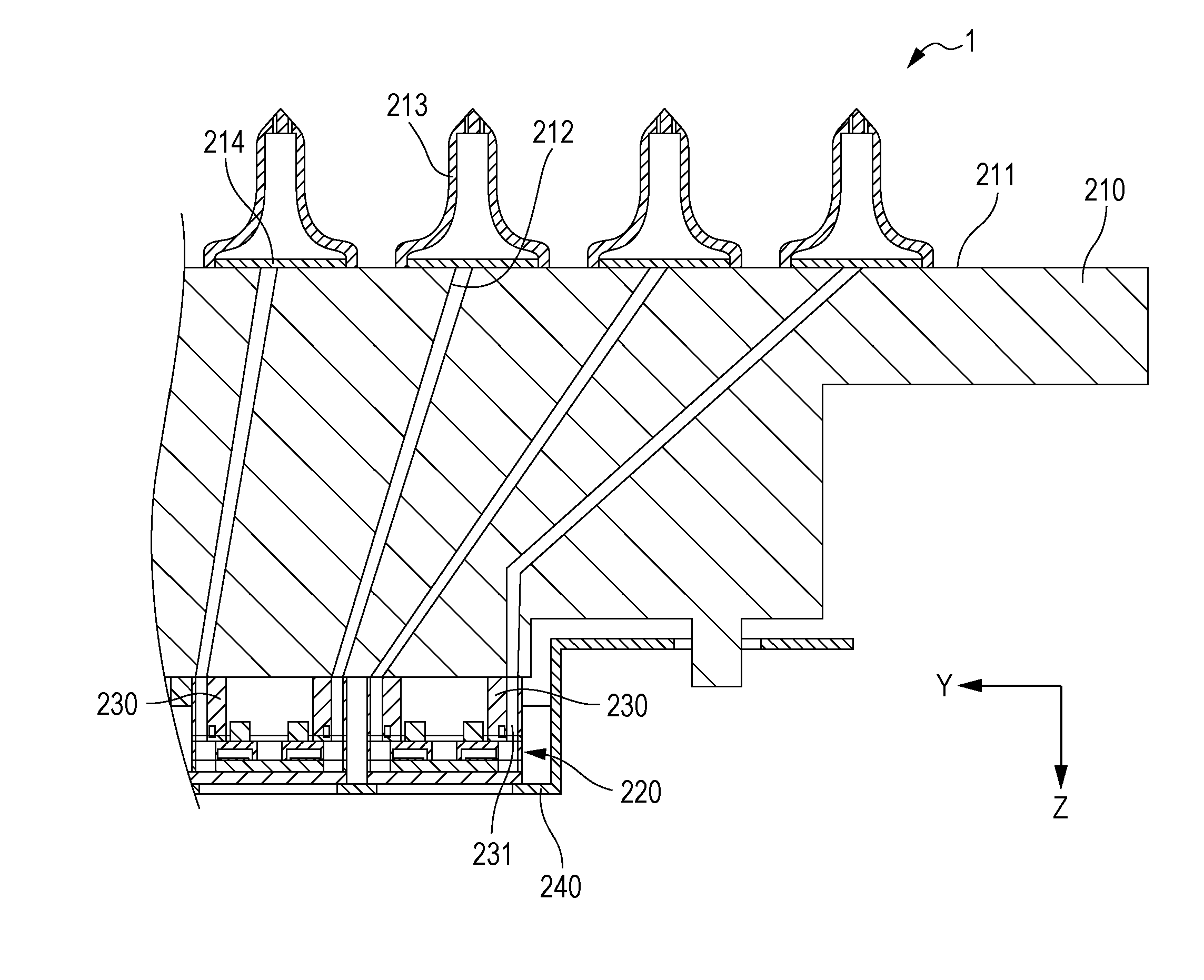

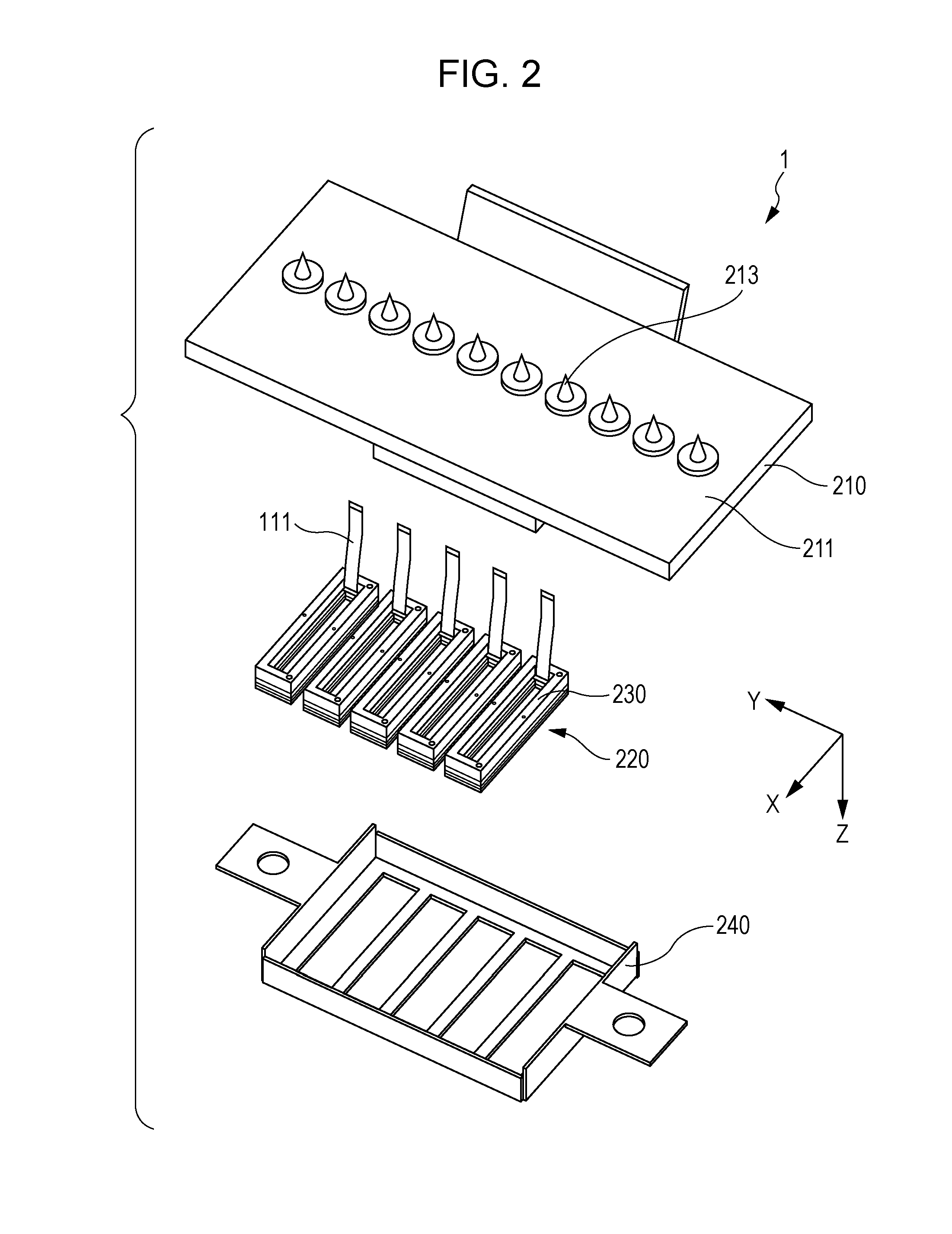

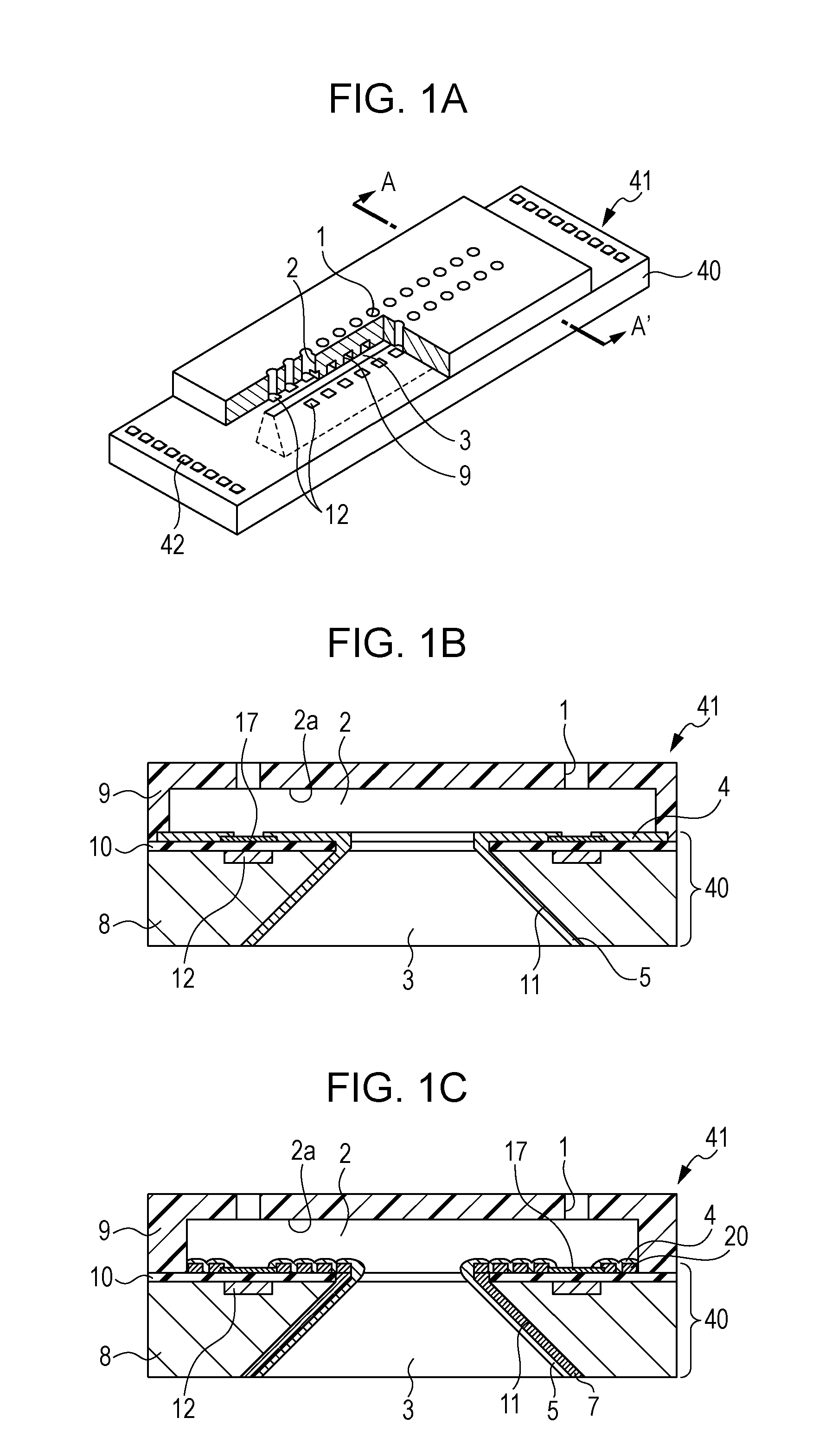

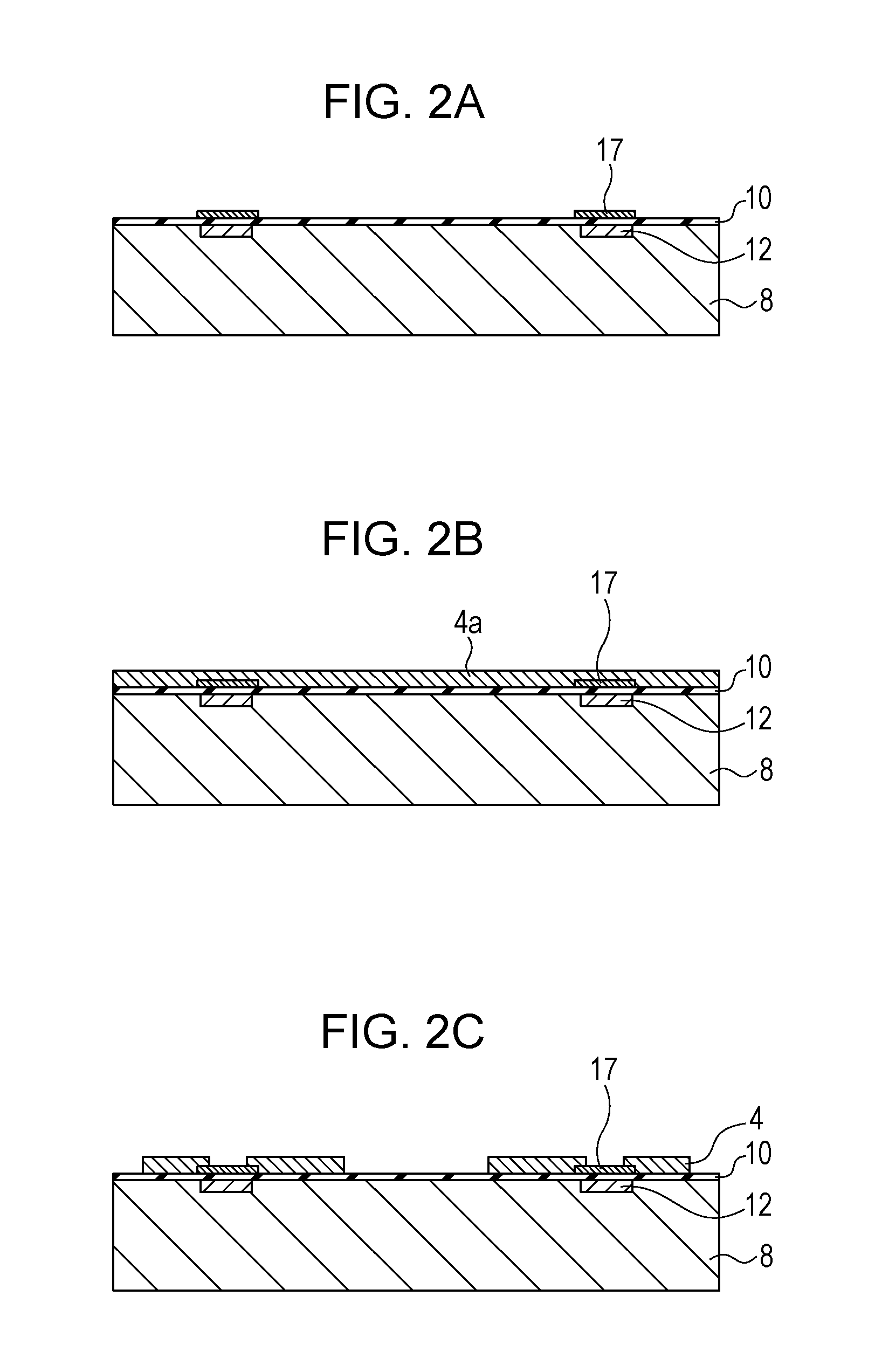

MEMS device, liquid ejecting head, and liquid ejecting apparatus

A MEMS device includes a protective substrate on which is mounted a driving circuit that drives a piezoelectric actuator and on which is formed an interconnect pattern electrically connected to the driving circuit, and a sealing substrate that includes a first opening and that is bonded to the protective substrate using an adhesive so that part of the interconnect pattern is located between the protective substrate and the sealing substrate. The interconnect pattern includes a connection portion that extends from a bonding region where the protective substrate and the sealing substrate are bonded by the adhesive to the first opening, and that has a connection region electrically connected to the driving circuit. A groove is formed in the connection portion between the connection region and a border between the bonding region and the connection portion.

Owner:SEIKO EPSON CORP

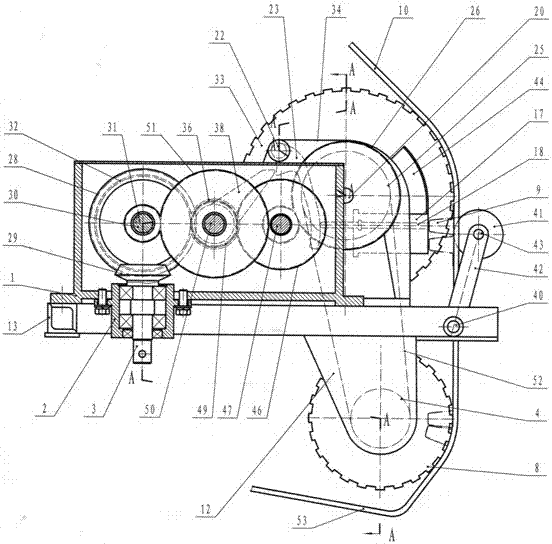

Pot seedling ordered seedling separating device

The invention discloses a pot seedling ordered seedling separating device, which comprises a transmission mechanism, a fluted disc driving type seedling disc conveying mechanism, a seedling disc compression mechanism and a pot seedling propping mechanism, wherein the transmission mechanism respectively transmits motive power to the seedling disc conveying mechanism and the pot seedling propping mechanism through a group of bevel gear transmission devices and several groups of cylindrical gear transmission devices, the fluted disc driving type seedling disc automatic conveying mechanism consists of an upper seedling disc driving wheel, a lower seedling disc driving wheel and a guide rail, the upper seedling disc driving wheel and the lower seedling disc driving wheel are driven by a synchronous belt and are both fluted discs with rectangular teeth, wheel teeth are rightly embedded into tooth grooves arranged at two sides of a seedling disc, and the seedling disc is driven to feed; and the guide rail realizes the compression and guide effects on the seedling disc. The seedling disc compression mechanism mainly consists of a regulating handle and a disc pressing wheel. The pot seedling propping mechanism consisting of a cam, a lever and a propping rod props out rice pot seedlings fed into a seedling disc pot bowl by the seedling disc driving wheels and the guide rail. The pot seedlings fall into the field along with a seedling guide pipe, and the seedling disc is continuously driven by the lower seedling disc driving fluted disc to be conveyed and disengaged into a recovery frame arranged on a machine frame.

Owner:ZHEJIANG SCI-TECH UNIV

Ink jet textile printing ink composition, ink set, and printing method

An ink jet textile printing ink composition according to the invention contains Li+, Na+, and a compound represented by the following formula (1):

Owner:SEIKO EPSON CORP

Pretreatment agent for ink jet textile printing, ink jet textile printing ink set, and method of ink jet textile printing

InactiveUS9156993B2High whitenessReliable ejectionDuplicating/marking methodsInksTextile printerEmulsion

Owner:SEIKO EPSON CORP

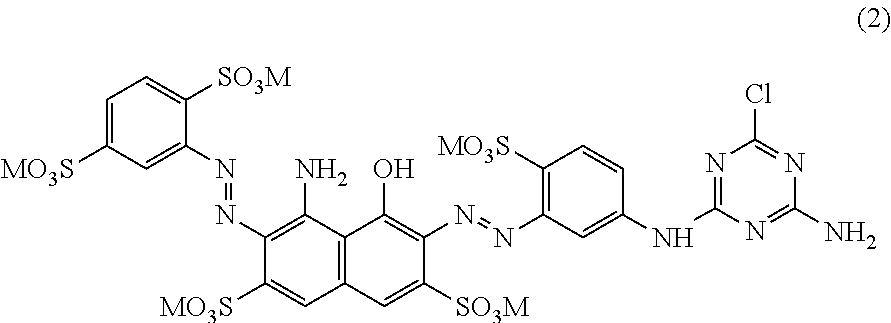

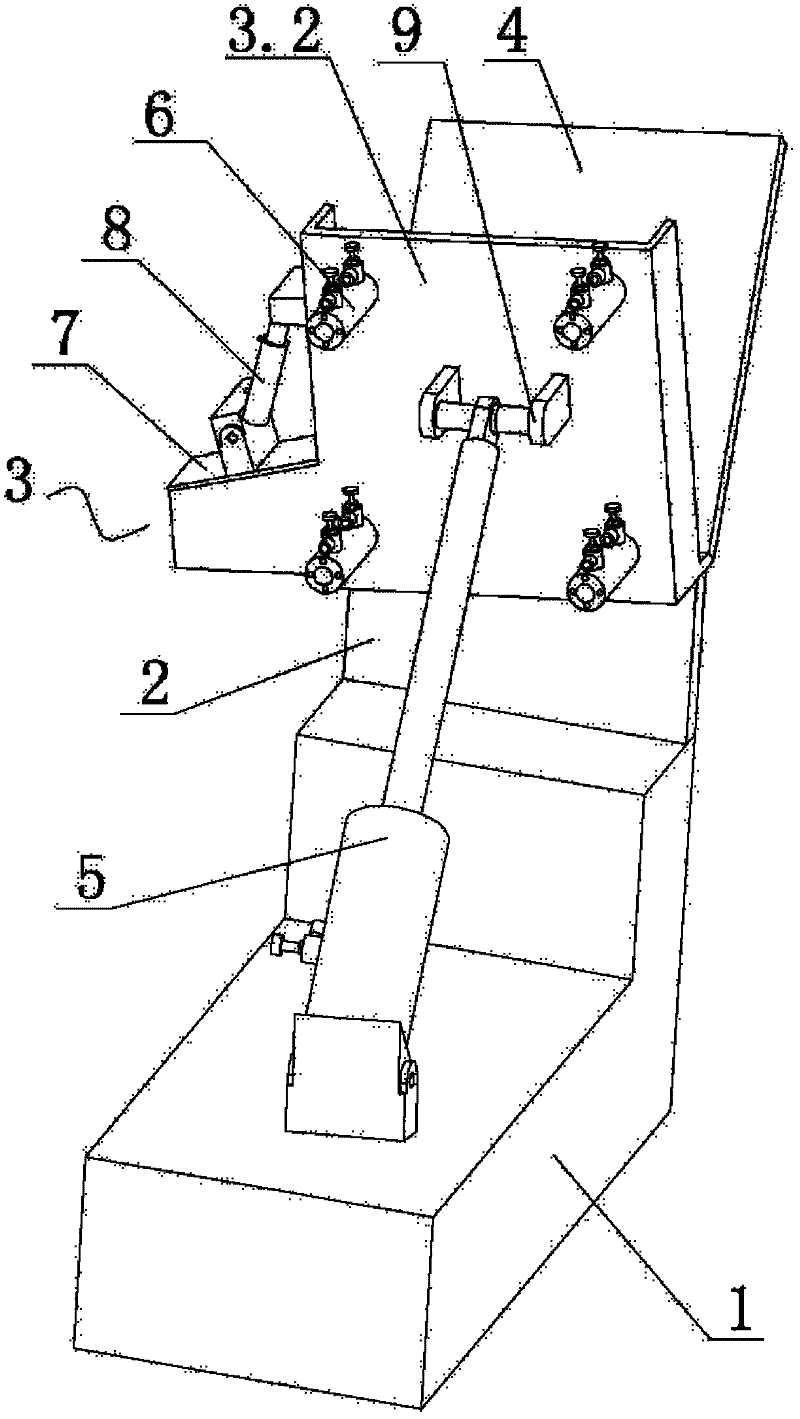

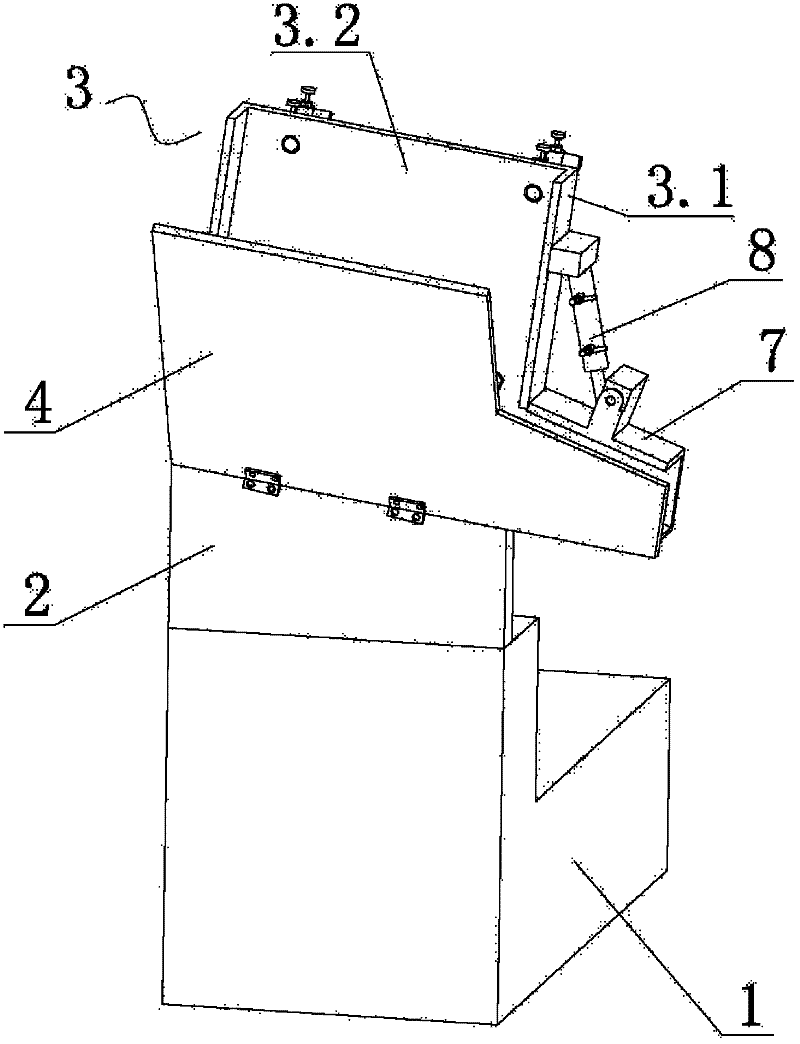

Battery dumping tray machine

ActiveCN102530572ARealize subsequent packagingImprove work efficiencyBottle emptyingEngineeringMechanical engineering

The invention discloses a battery dumping tray machine, which comprises a base (1), a support plate (2) arranged on the base (1), a dumping tray (3) rotationally connected on the support plate (2) by a shaft and adapted to a plastic plate tray of a battery in size, a dumping tray panel (4) hinged on the support plate (2) and used by being matched with the dumping tray (3), and a main cylinder (5)with a cylinder body and a piston rod hinged with the base (1) and the dumping tray (3), respectively, wherein ejector pins (6) used for ejecting out the plastic plate tray of the battery are arranged on the dumping tray (3), a movable baffle (7) is hinged with the lower end of a side plate (3.1) of the dumping tray (3) close to one side of the inlet end of a trough, an auxiliary cylinder (8) is arranged on the outer wall of the side plate (3.1), and the piston rod of the auxiliary cylinder (8) is hinged with the movable baffle (7). The battery dumping tray machine can effectively save the bulk battery placing time and does not need a special personnel for watching.

Owner:NINGBO FUBANG BATTERY

Method for cutting a loaf-shaped food using a cutting machine

InactiveUS9132564B2Reliable ejectionConstructive expenditure can be minimizedMetal working apparatusEngineeringContact element

In a method for cutting a loaf-shaped food, a loaf of the food is advanced toward a cutting device by a feed apparatus and the loaf is cut into slices, strips or cubes by said cutting device, which includes that the loaf is fixed during the feed movement by a vacuum gripper that is advanced together with the loaf; a negative pressure is generated within an interior of a contact element of the vacuum gripper and acts upon a fixing region of the surface of the loaf in a suction region of the contact element, in order to prevent hygienic problems associated with vacuum pumps, the negative pressure is generated by a piston-cylinder unit, the piston of which defines the interior of the contact element.

Owner:REIFENHAEUSER UWE

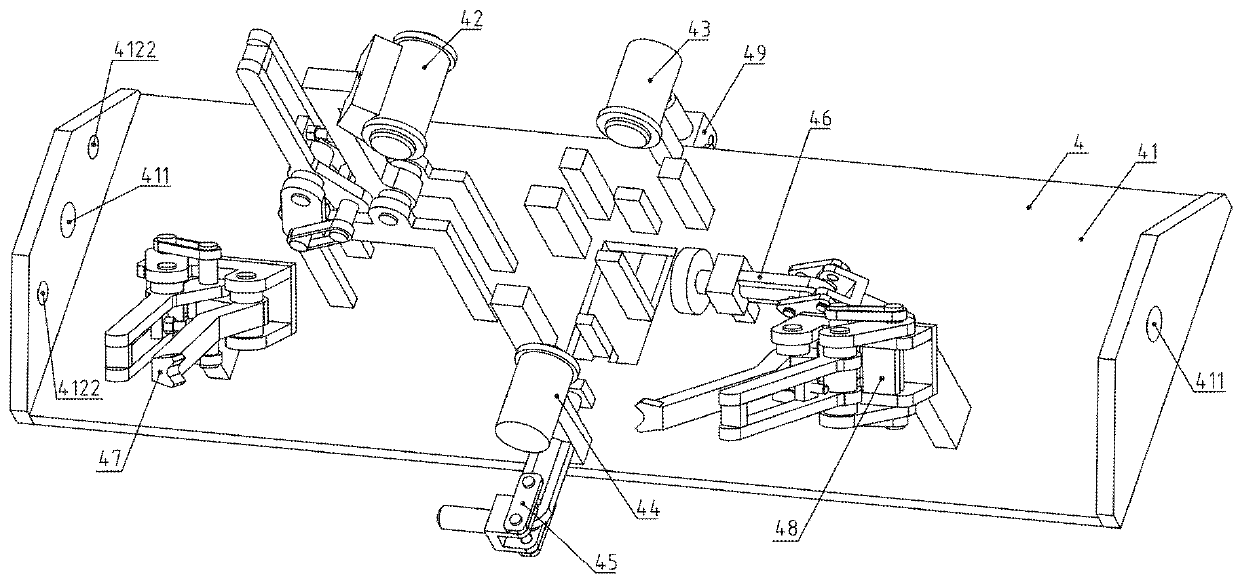

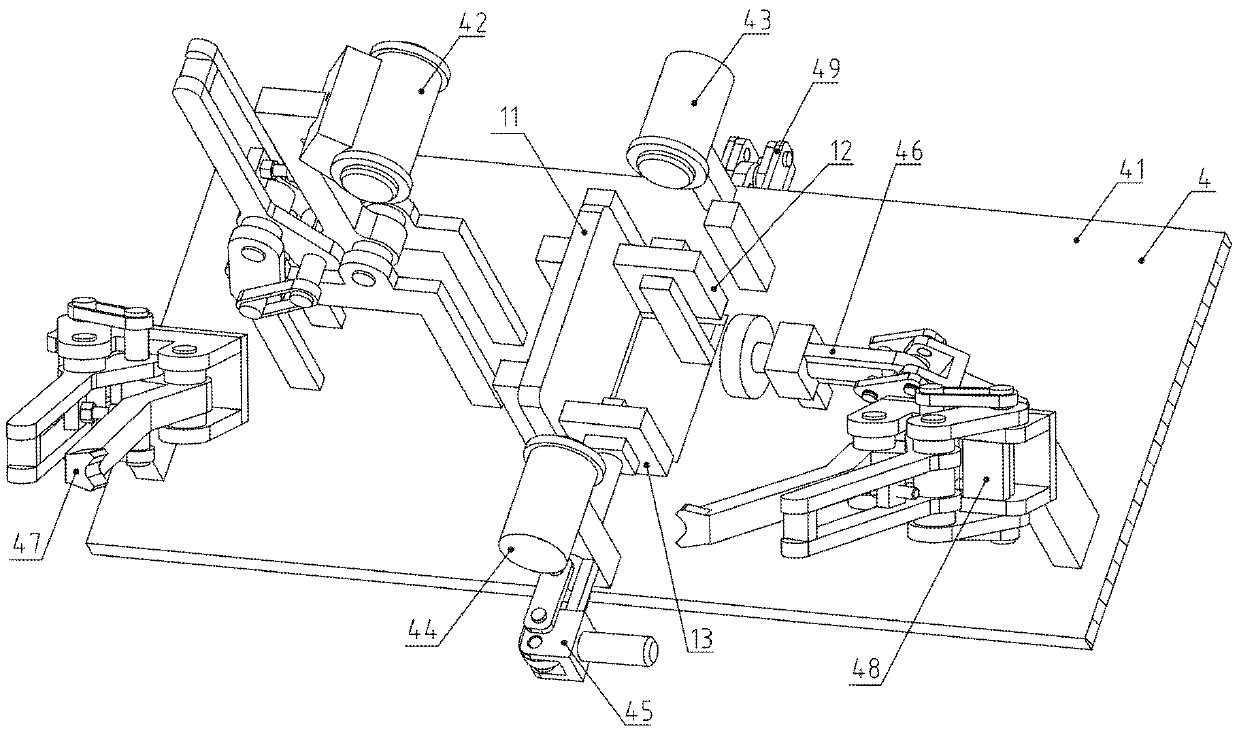

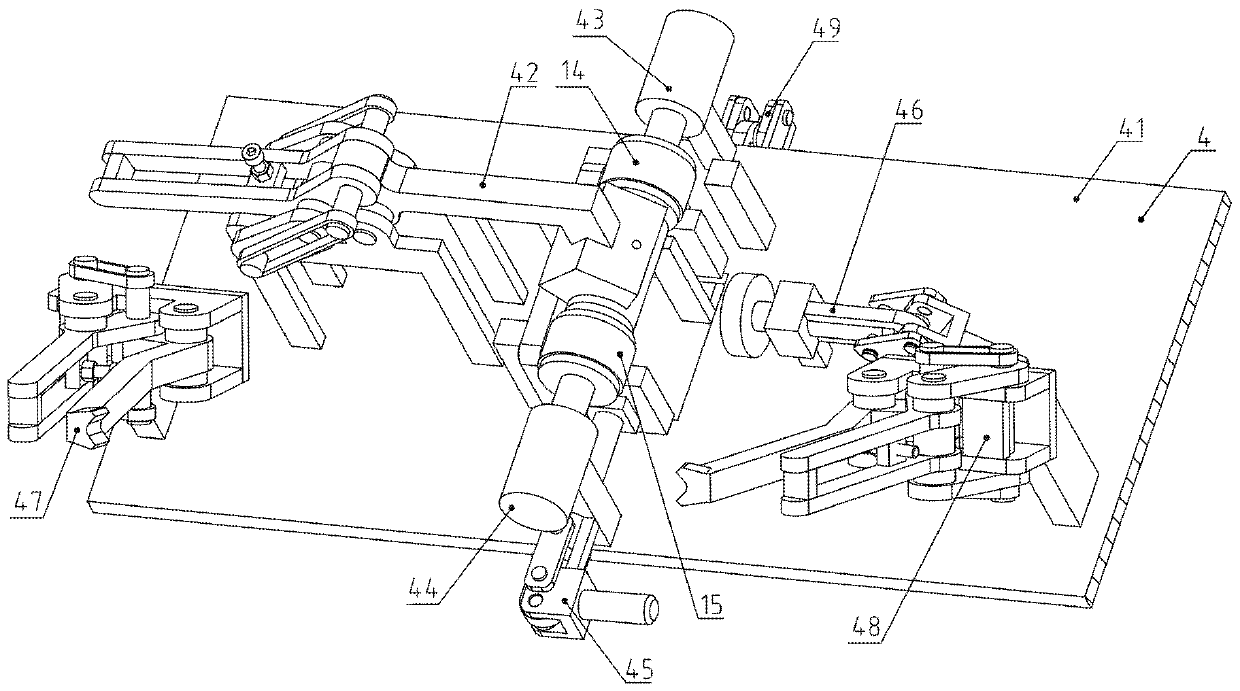

Spot welding assembly tool clamp for roller cage shoe base lug ring assembly

ActiveCN110434445ASmall sizeUniform sizeWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

The invention belongs to the technical field of mine mechanical making equipment, and relates to a spot welding assembly tool clamp for a roller cage shoe base lug ring assembly. Three hydraulic cylinders on a sleeve middle positioning pin assembly, a sleeve rear positioning pin assembly and a sleeve front positioning pin assembly precisely position a lug ring rear single ring and a lug ring frontsingle ring, a front side plate rapid clamp, a left side plate rapid clamp, a right side plate inclined pressing rapid clamp, a left side plate inclined pressing rapid clamp and a rear side plate rear hook rapid clamp use dead points of a plane four-rod mechanism or a guide rod mechanism for pressing and positioning all side plates, and a turnover disc rotates by half circle to facilitate weldingof the inner side welding line. Compared with giant manual hydraulic pressure, it can be ensured that the lug ring rear single ring and the lug ring front single ring can be precisely positioned, andmold retreating can be facilitated; the tool is used for determining the relative size of the workpiece, compared with marking line scribing, the size determining is more precise, the produced part is unified in size, labor force is reduced, work efficiency is improved, the work principle of the dead points of the rapid clamps is used, use is convenient, the pressing force can be increased, and work efficiency is improved.

Owner:HEFEI LONGTUTEM INFORMATION TECH CO LTD

Waste blower for a paper sheet punching and embossing machine

A sheet punching and embossing machine includes revolving gripper cars with which a gripping margin of a sheet is grasped by grippers disposed on the gripper car so as to move the sheet through the machine, a punching station in which the gripping margin can be separated from the sheet, a delivery station in which the gripping margin can be further separated from the sheet, and an ejection station in which the gripping margin can be ejected from the gripper. The ejection station includes a blower which directs a current of air at the gripping margin.

Owner:MASTERWORK GROUP CO LTD

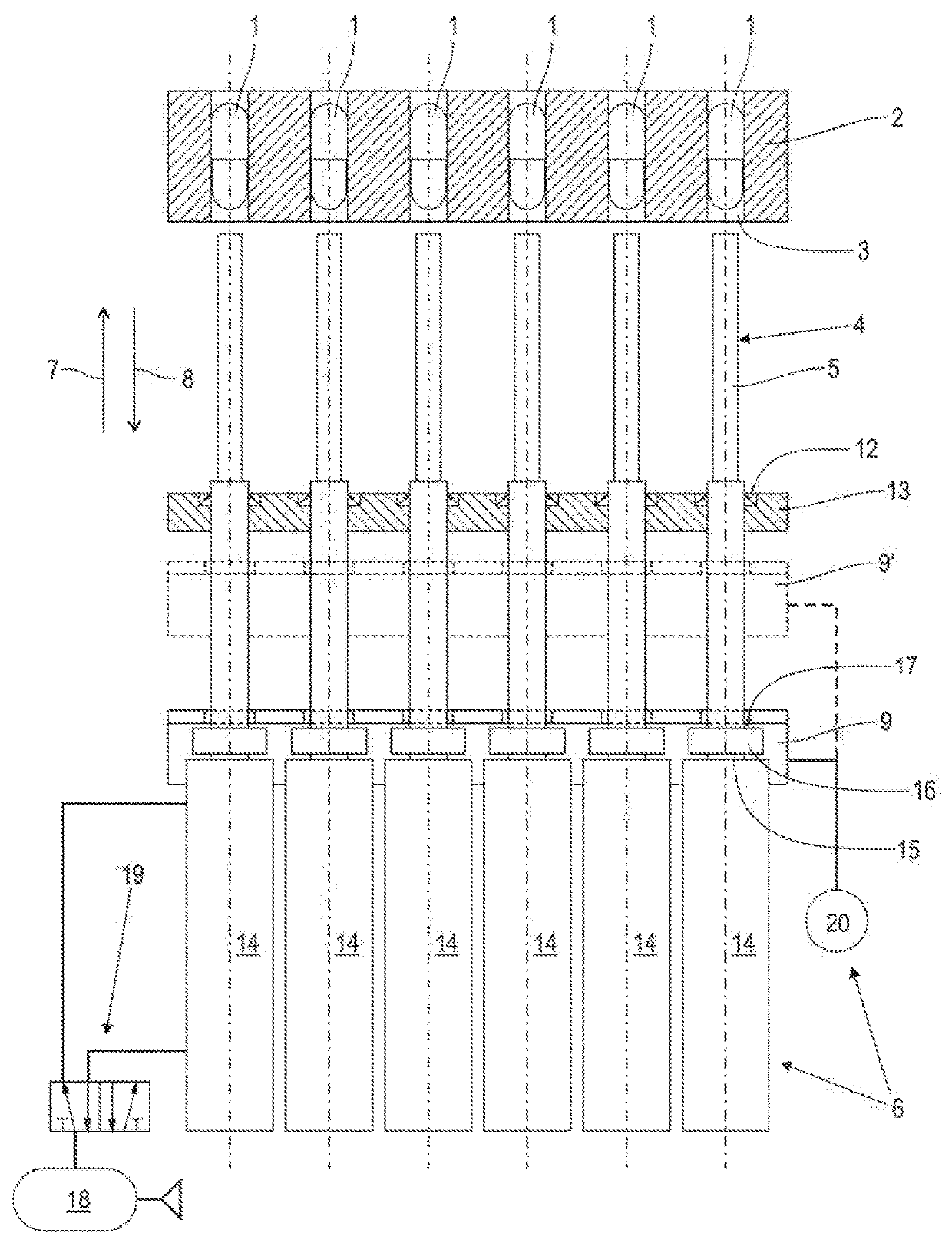

Device and method for ejecting at least one capsule from a capsule holder

ActiveUS20180271750A1Save spaceSimple structurePackaging automatic controlCapsule deliveryBiomedical engineeringInjector

A device for ejecting at least one capsule from a capsule holder. The capsule holder has at least two capsule receptacles for, in each case, one capsule. The device comprises: at least two ejectors, each of the ejectors being configured to eject a respective one of the capsules from the corresponding one of the receptacles; a drive unit configured to actuate the at least two ejectors independently of each other in an ejection direction and in an opposite return direction; the drive unit having a pneumatic actuating cylinder for each ejector; the pneumatic actuating cylinders being individually actuatable as a drive for respective ones of the at least two ejectors; a limiter element which is provided jointly for a plurality of the at least two ejectors and which has a cyclical lifting drive; and, each ejector being assigned a stop acting in the return direction for the limiter element.

Owner:HARRO HOFLIGER VERPACKUNGSMASCHEN

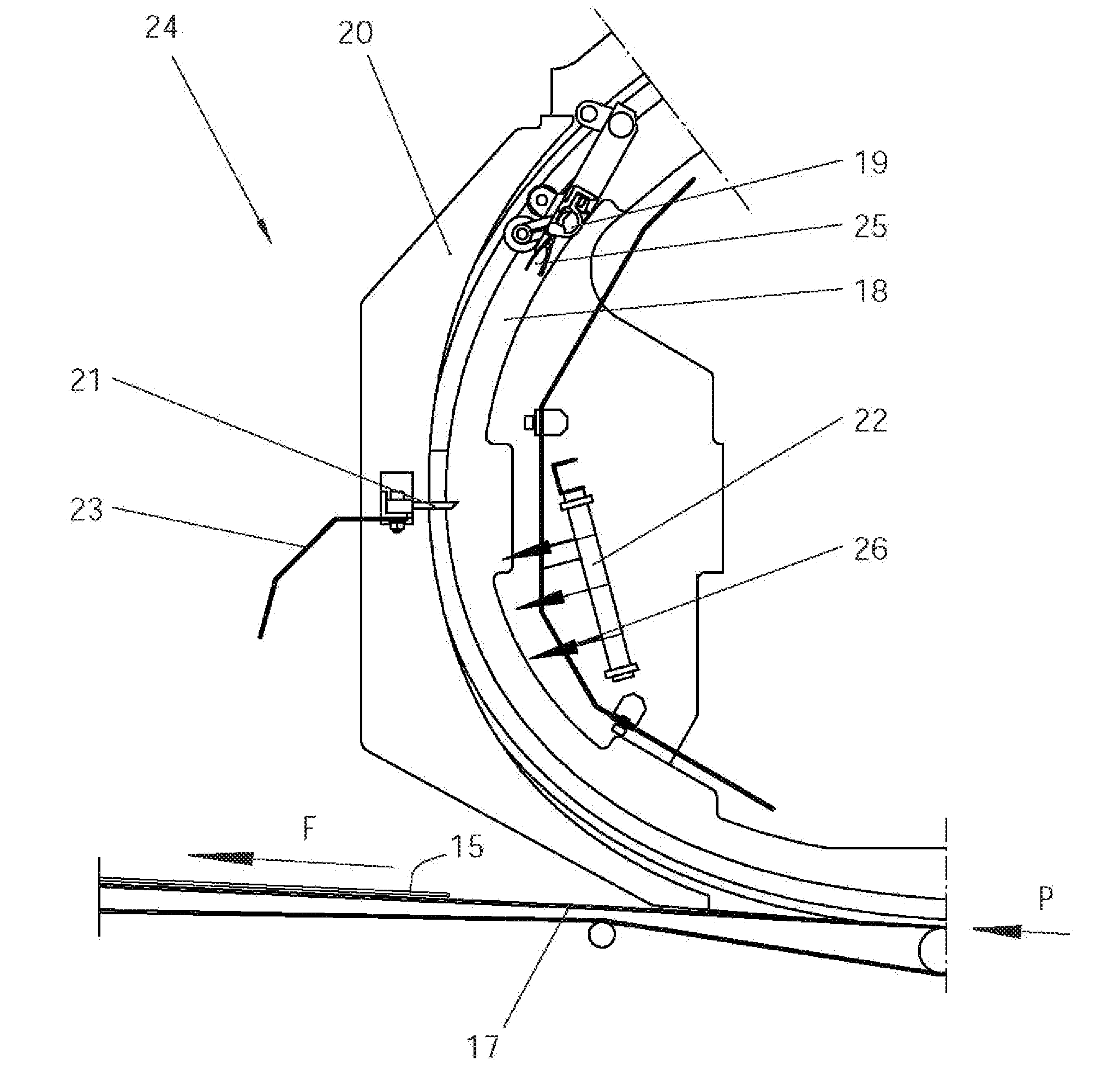

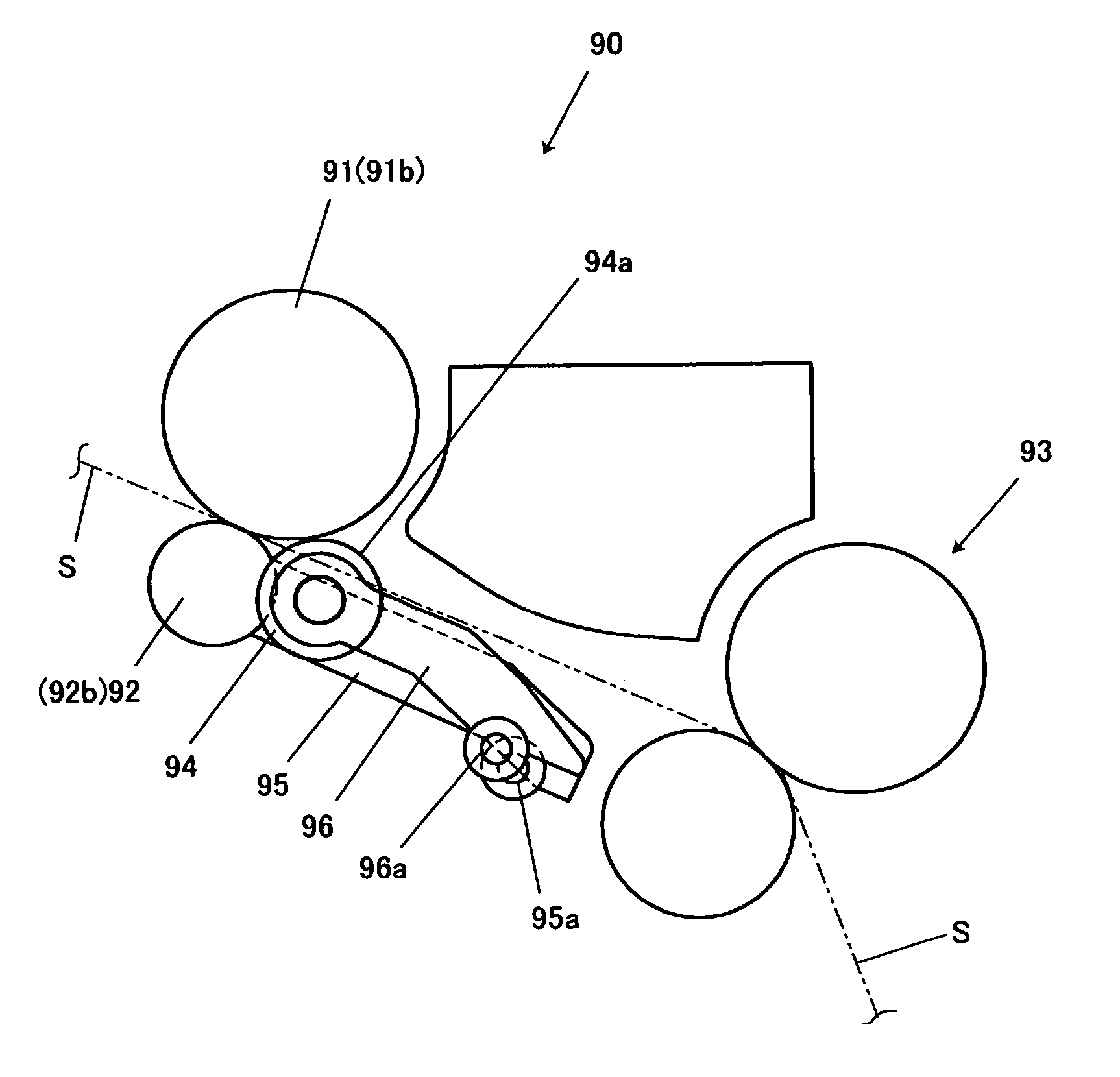

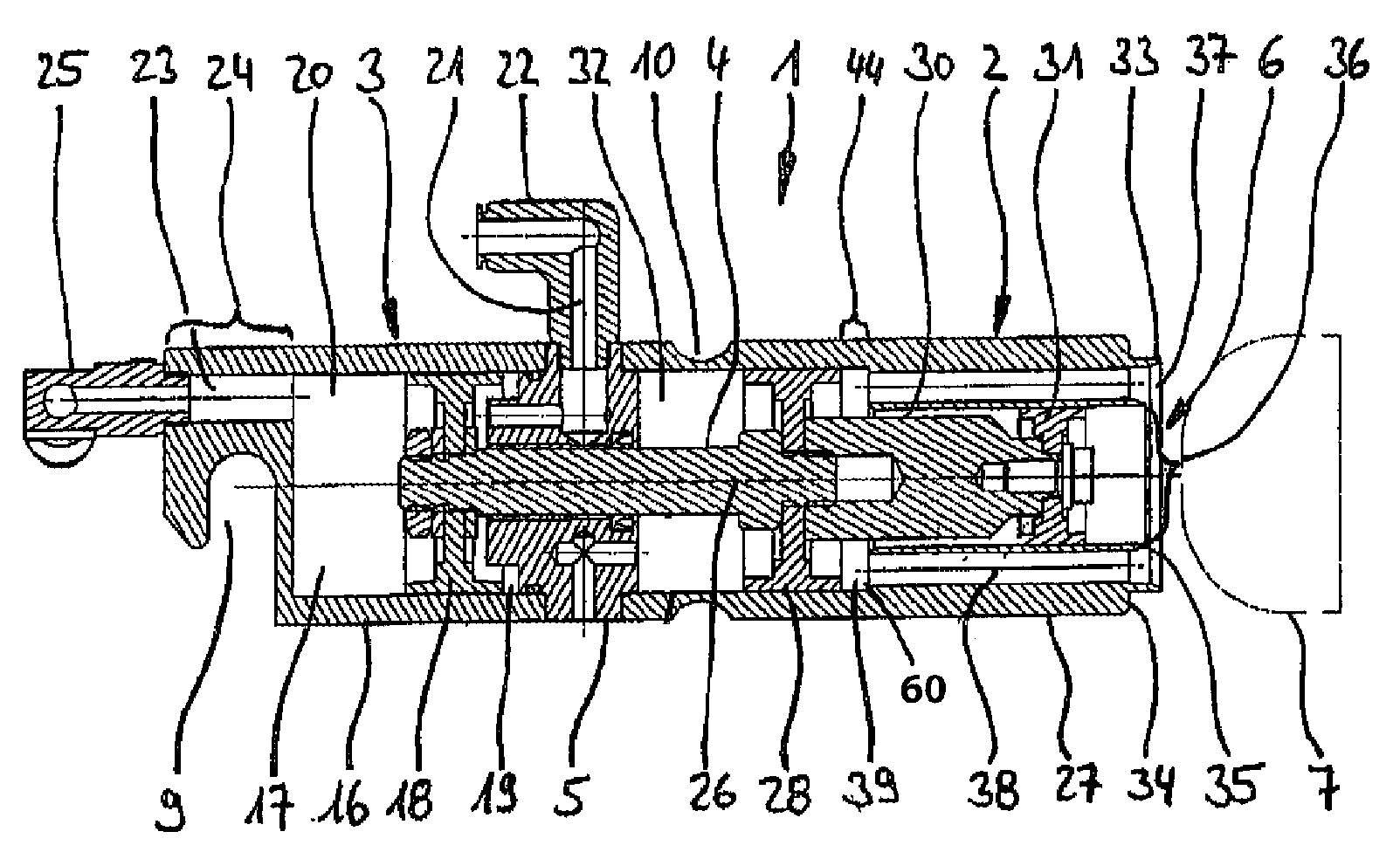

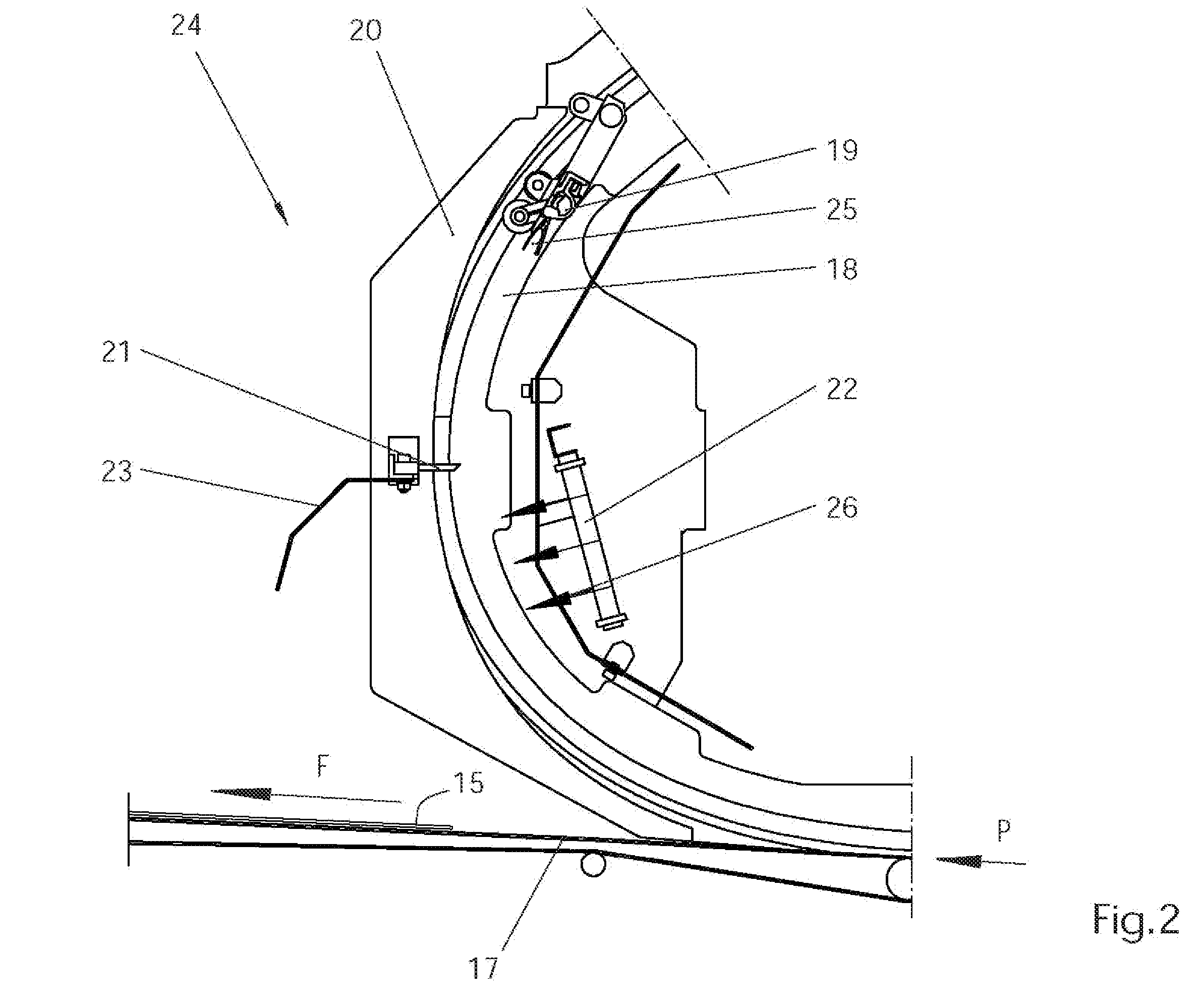

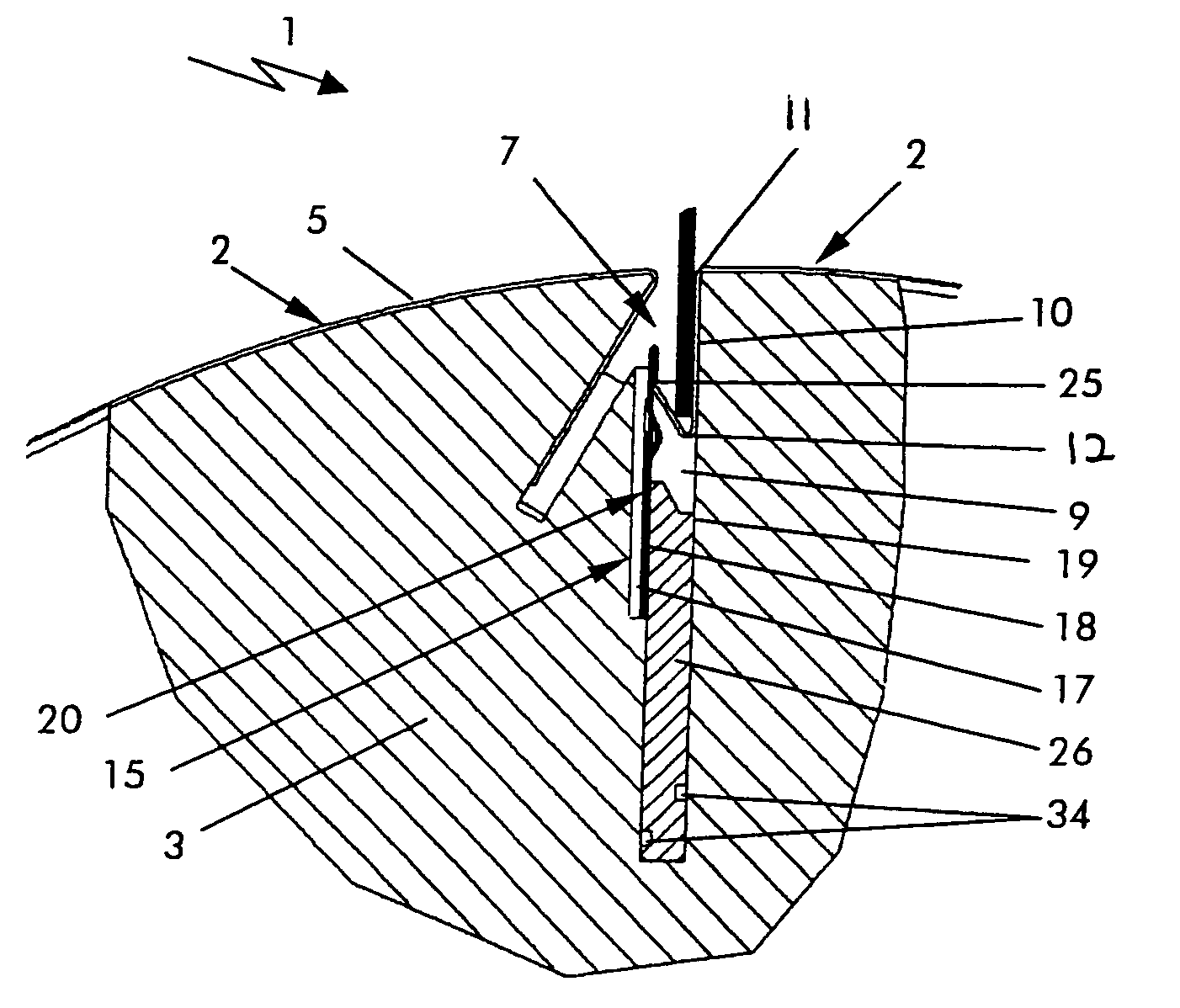

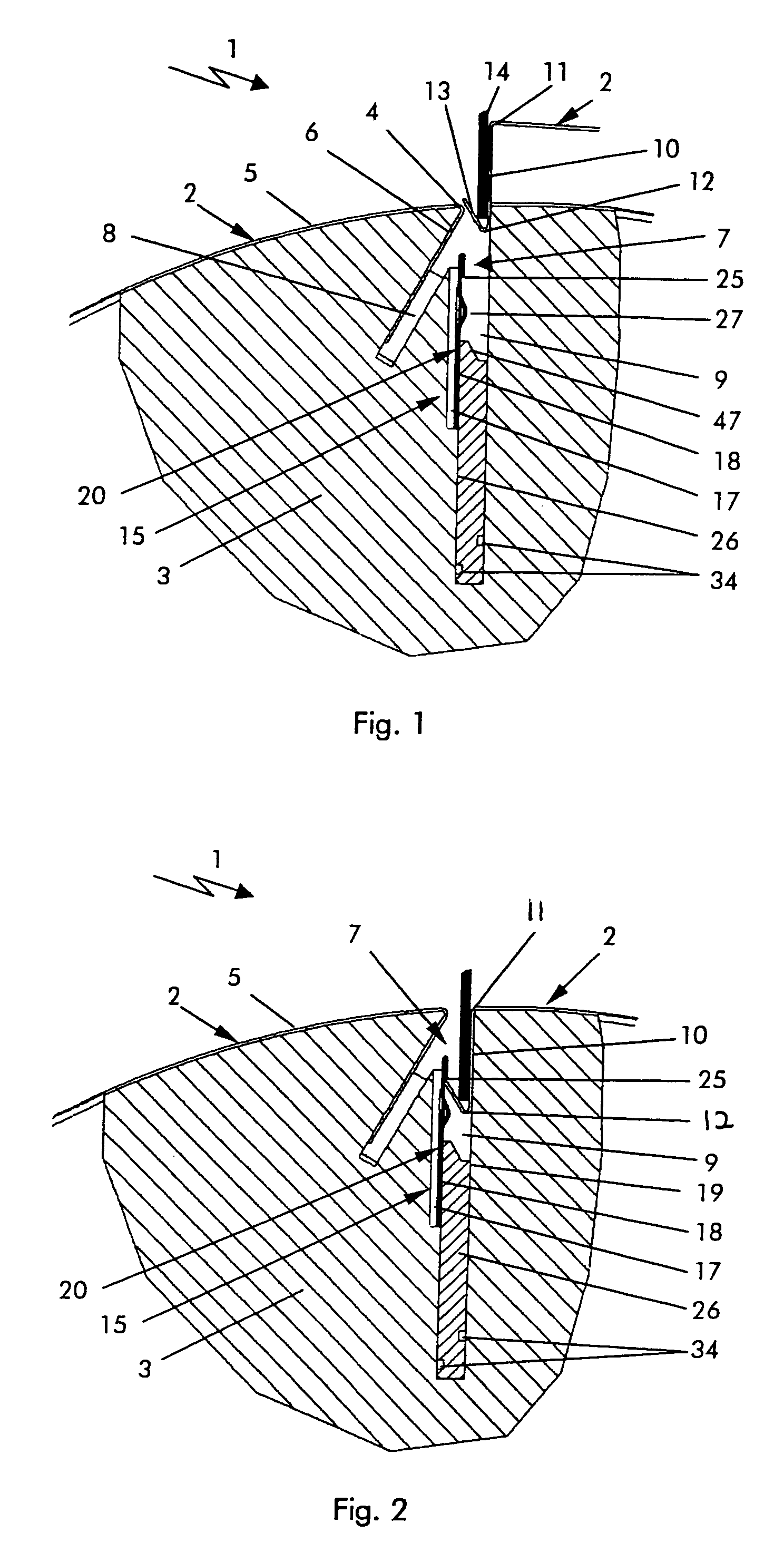

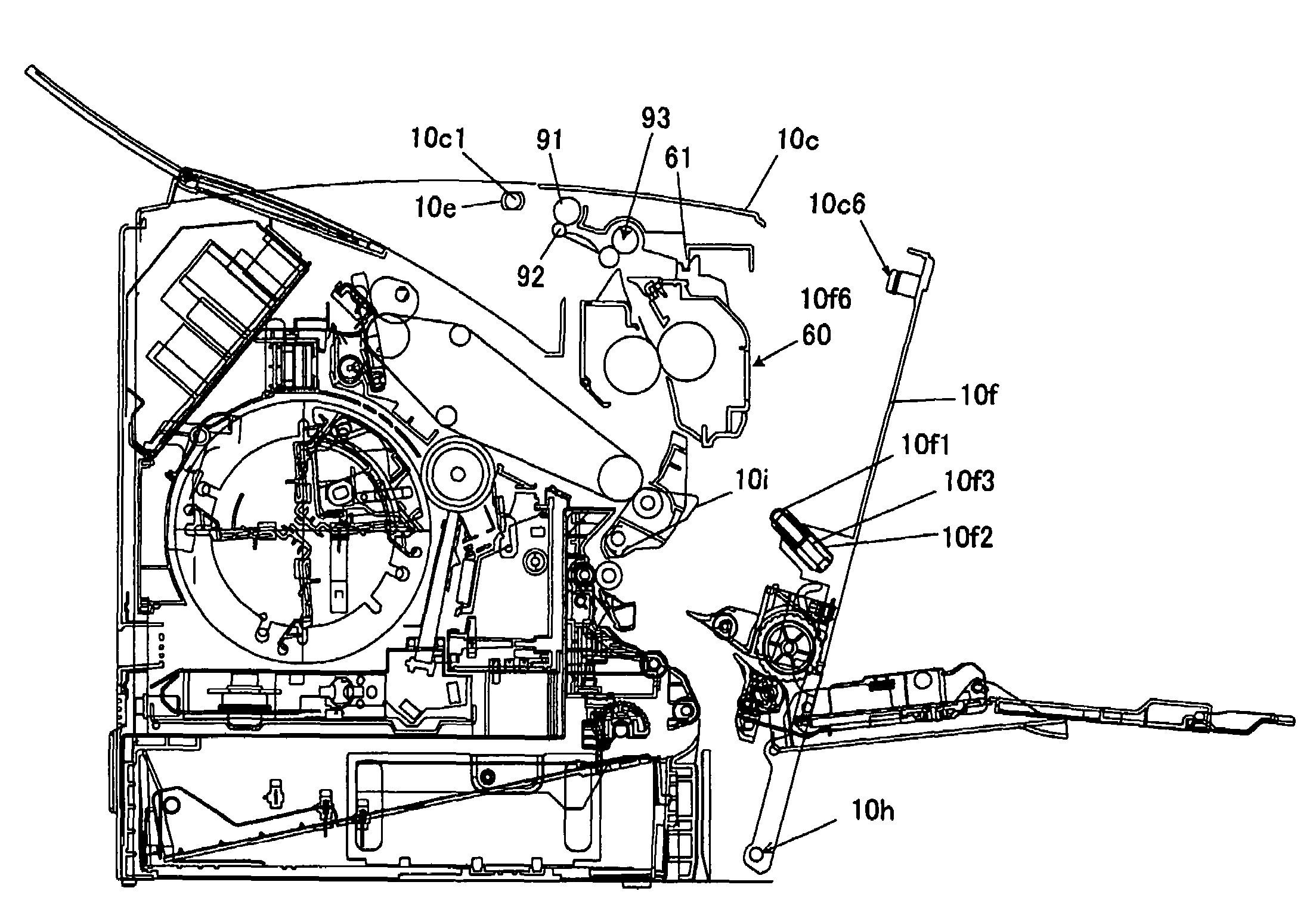

Device for mounting a printing plate on a plate cylinder for a rotary printing press

InactiveUS7096788B2Reliable ejectionBetter securingPlaten pressesRotary pressesRotational axisEngineering

A plate cylinder adapted for a rotary printing press has a cylinder jacket and a recess followed by a clamping channel which extend at least approximately parallel to the rotational axis of the plate cylinder inside the cylinder jacket. The printing plate has a leading end and a trailing end which are both secured inside the recess. A trailing end region of the printing plate includes two parallel bent edges extending transverse to the rotational direction of the plate cylinder. One bent edge is formed by a section of printing plate fitting against the cylinder jacket and another section of the printing plate that projects into the clamping channel which together enclose approximately a right angle. The other bent edge is formed by the section of printing plate projecting into the clamping channel and an end section of the printing plate extending through the clamping channel.

Owner:MULLER MARTINI HLDG

Substrate for liquid-ejection head, liquid ejection head, method for manufacturing substrate for liquid-ejection head, and method for manufacturing liquid ejection head

ActiveUS20110141197A1Improve reliabilityImprove protectionSemiconductor/solid-state device manufacturingPrintingEngineeringProtection layer

When an insulating layer is provided in order to protect an energy generating element, there arises a possibility that the layer dissolves in a contacting liquid. Therefore, in order to eject liquid, a first protection layer containing metal is provided on the insulating layer facing a substrate for a liquid-ejection head and a second protection layer containing metal is provided on the surface of a liquid supply port to which a base containing silicon is exposed.

Owner:CANON KK

Image forming apparatus

InactiveUS7418233B2High positioning accuracyBlocking phenomenonElectrographic process apparatusImage formationEngineering

Owner:SEIKO EPSON CORP

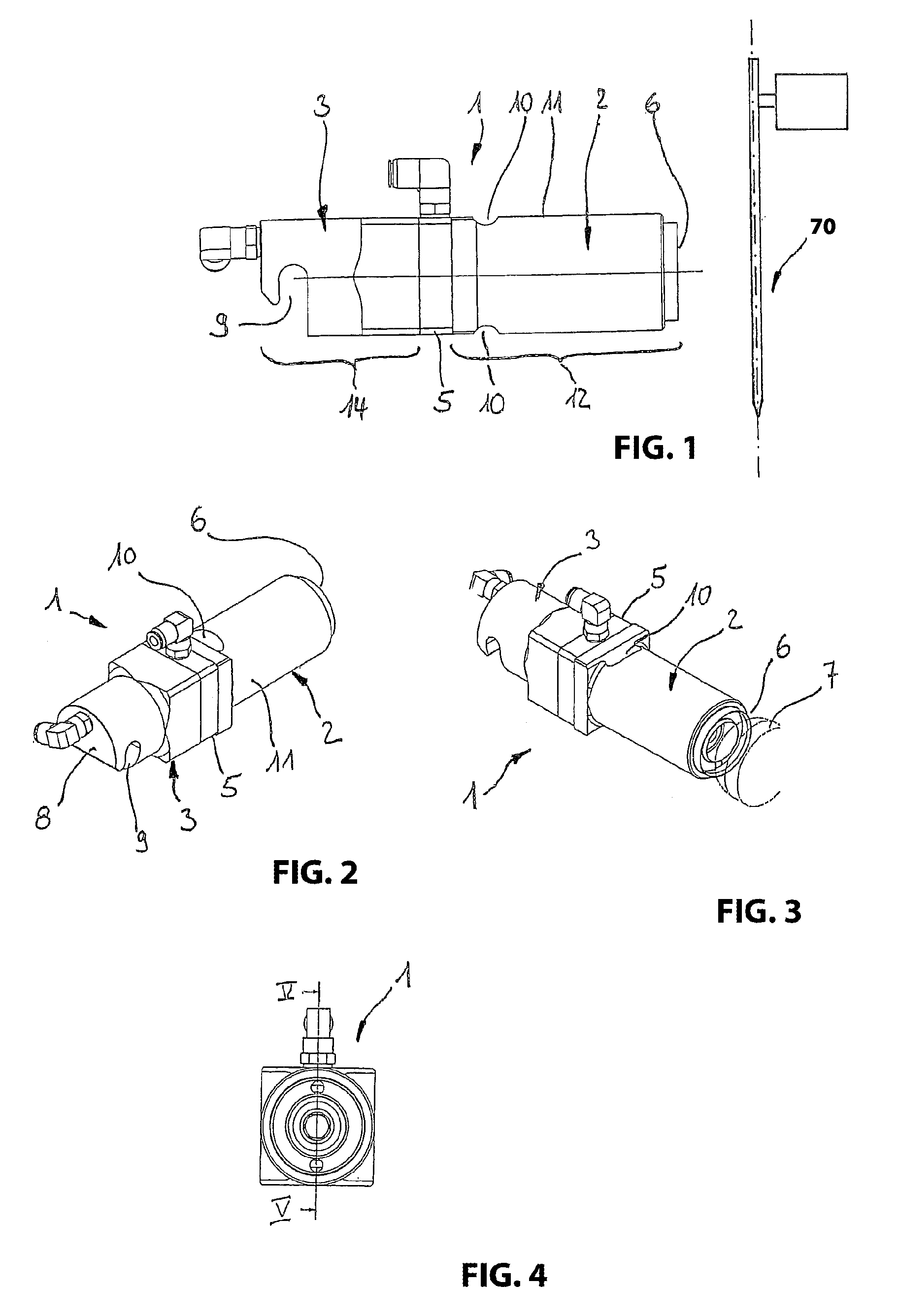

Nozzle arrangement for an edge strip applying device for supplying hot air to an edge strip or workpiece which is adhesive-free and can be activated by heat or which is coated with a hot-melt adhesive, and edge strip applying device comprising a nozzle arrangement

ActiveCN104039517AEfficient heatingFast heat releaseOther plywood/veneer working apparatusSpray nozzlesHot meltHot blast

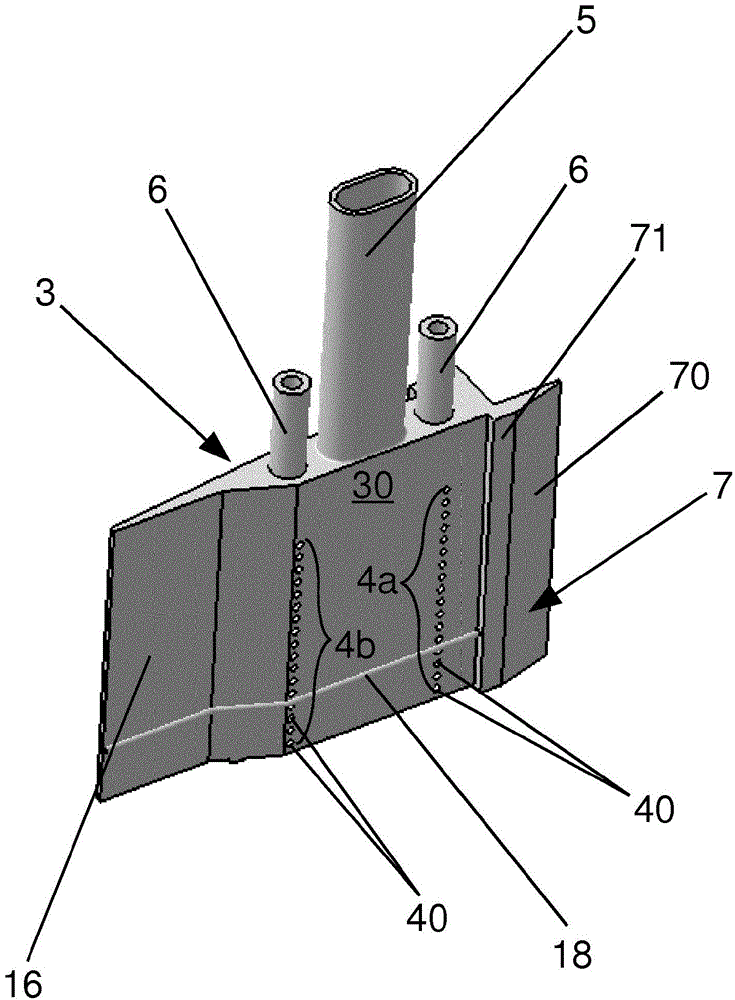

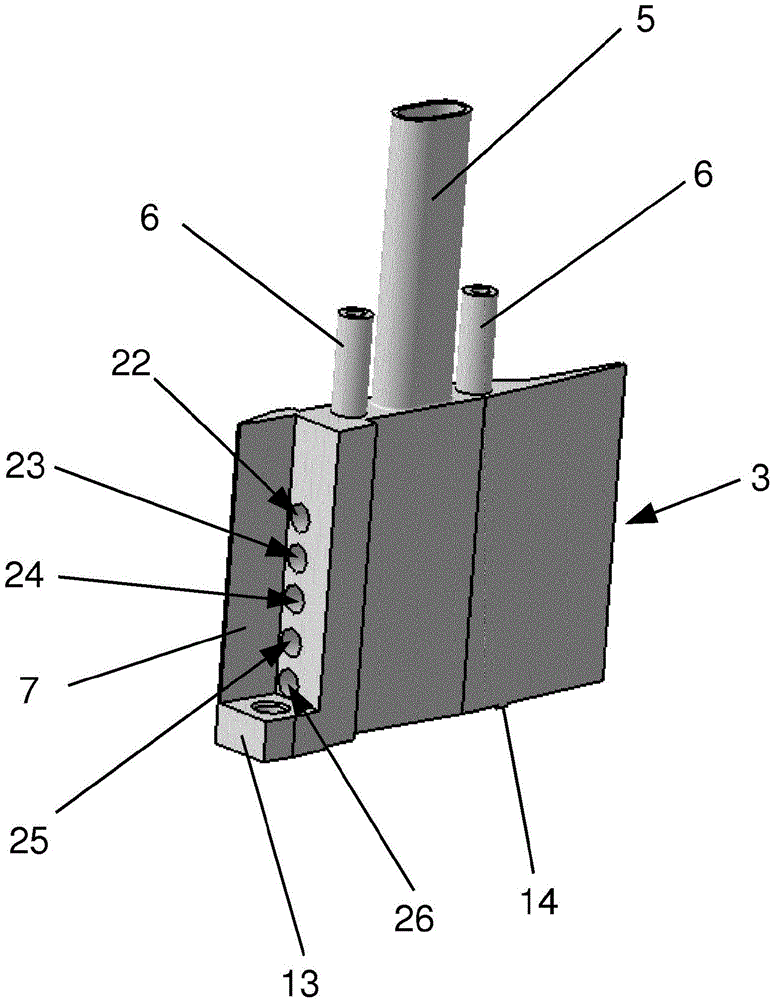

The invention relates to a nozzle arrangement (1) for an edge strip applying device for supplying hot air to an edge strip (2) or workpiece which is adhesive-free and can be activated by heat or which is coated with a hot-melt adhesive, comprising a nozzle body (3) with - at least one air inlet channel (20, 21) which can be connected to a hot air generator such that pressurized hot air can be fed to the nozzle body (3) during the operation of the edge strip applying device, - at least two groups (4a, 4b, 4c) of air outlet openings (40), wherein the air outlet openings (40) are formed on an air outlet surface (30) of the nozzle body (3) at a distance from one another in the vertical direction, said outlet surface facing the edge strip (2), and are fluidically connected to the at least one air inlet channel (20, 21) such that the at least two groups (4a, 4b, 4c) of air outlet openings (40) are spaced from one another in the advancing direction of the edge strip (2) and the hot air fed to the nozzle body (3) can be discharged out of the air outlet openings (40) and supplied to an edge strip (2) functional layer which can be activated by heat, and - a number of closing organs (6, 6') which are designed such that at least some of the air outlet openings (40) can be optionally opened or closed dependent on the width of the fed edge strip (2), said number corresponding to the number of groups (4a, 4b, 4c) of air outlet openings (40).

Owner:霍尔根·克卢格

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com