Nozzle arrangement for an edge strip applying device for supplying hot air to an edge strip or workpiece which is adhesive-free and can be activated by heat or which is coated with a hot-melt adhesive, and edge strip applying device comprising a nozzle arrangement

An adhesive-free, edge-banding technology, applied in adhesive-heated bonding methods, other plywood/plywood appliances, manufacturing tools, etc., can solve process technical difficulties, damage visual image, and work speed is not impressive Satisfaction and other issues, to achieve high heat release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

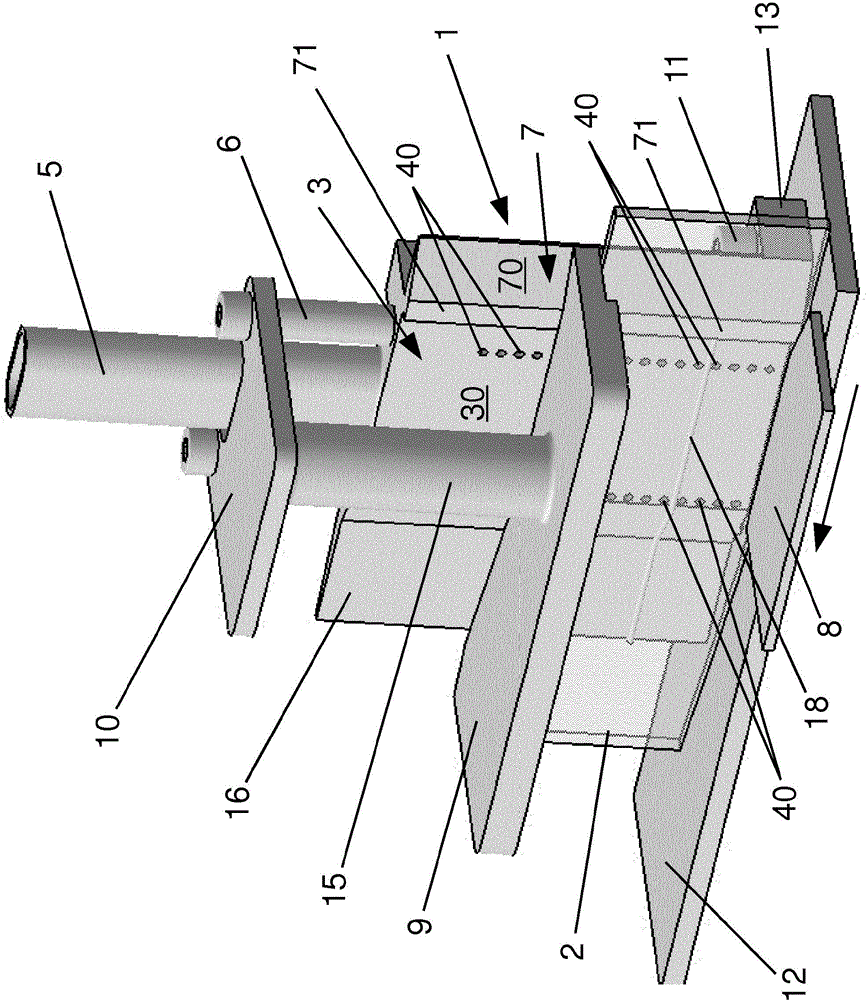

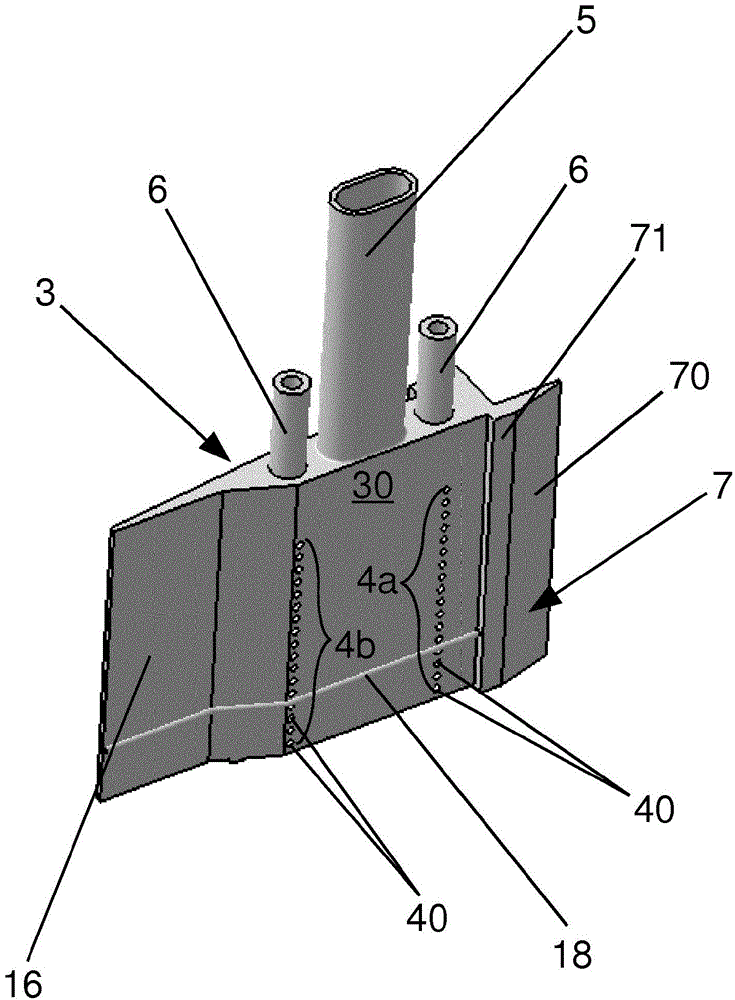

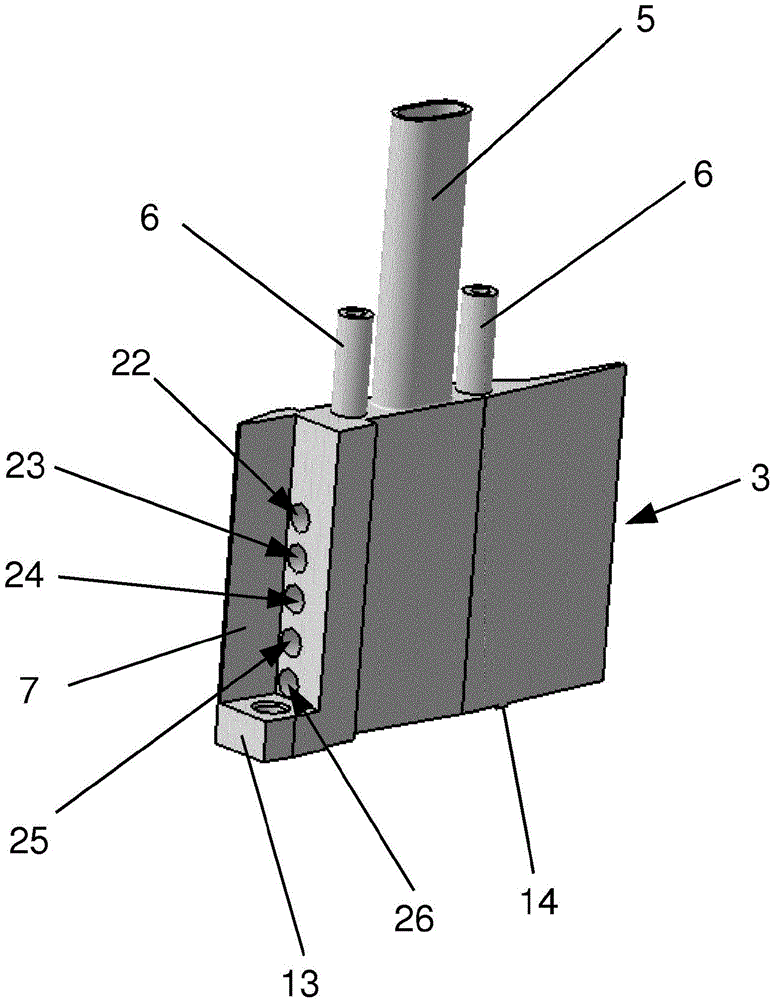

[0031] The following should refer to figure 1 The basic configuration of the nozzle system 1 according to a preferred exemplary embodiment of the invention is explained in more detail for the hot-air impingement application of an adhesive-free, heat-activatable edge strip 2 equipment. The nozzle system 1 comprises a nozzle body 3 which, in this exemplary embodiment, is produced in one piece from heat-resistant steel. The nozzle body 3 is shaped such that it is transverse to the figure 1 The feed direction of the edge strip 2 indicated by the arrow in , is designed to be relatively narrow, since the space available for positioning the nozzle system 1 in edge strip application plants is usually relatively small. The nozzle system 1 is arranged in the edgeband processing plant in such a way that it is positioned in the direction of feed of the edgeband 2 directly in front of the first edgeband pressure roller by means of which the edgeband 2 Edge strip pressure rollers can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com