Spot welding assembly tool clamp for roller cage shoe base lug ring assembly

A technology of roller can ears and earrings, which is applied in the direction of manufacturing tools, auxiliary devices, welding equipment, etc., and can solve problems such as errors, pin difficulties, workpiece deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Example: see Figure 1 to Figure 20 .

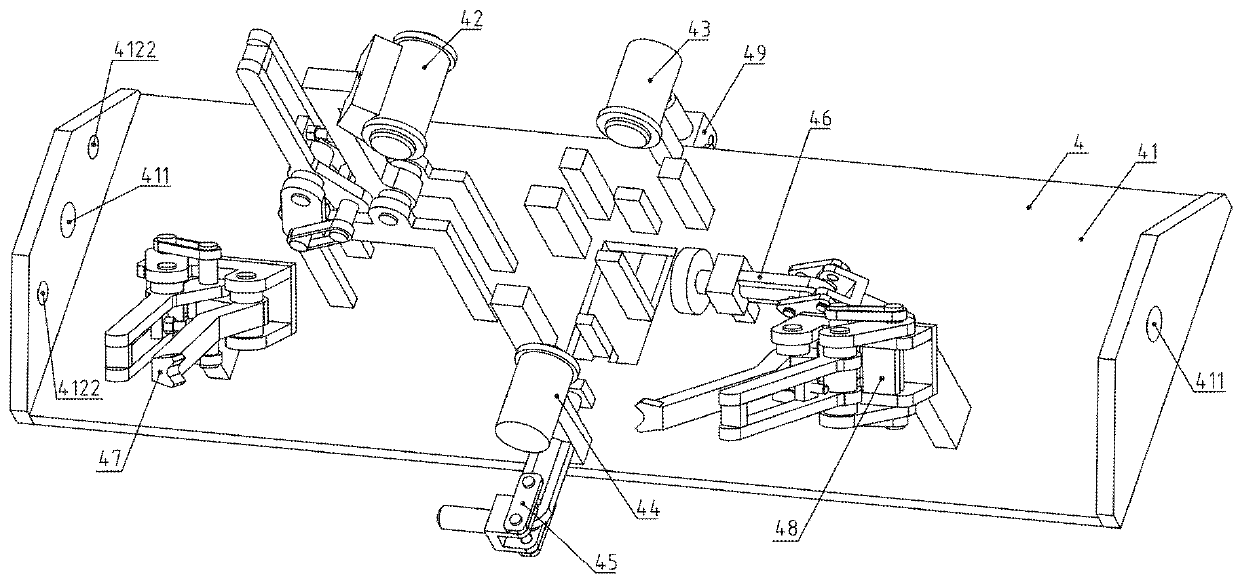

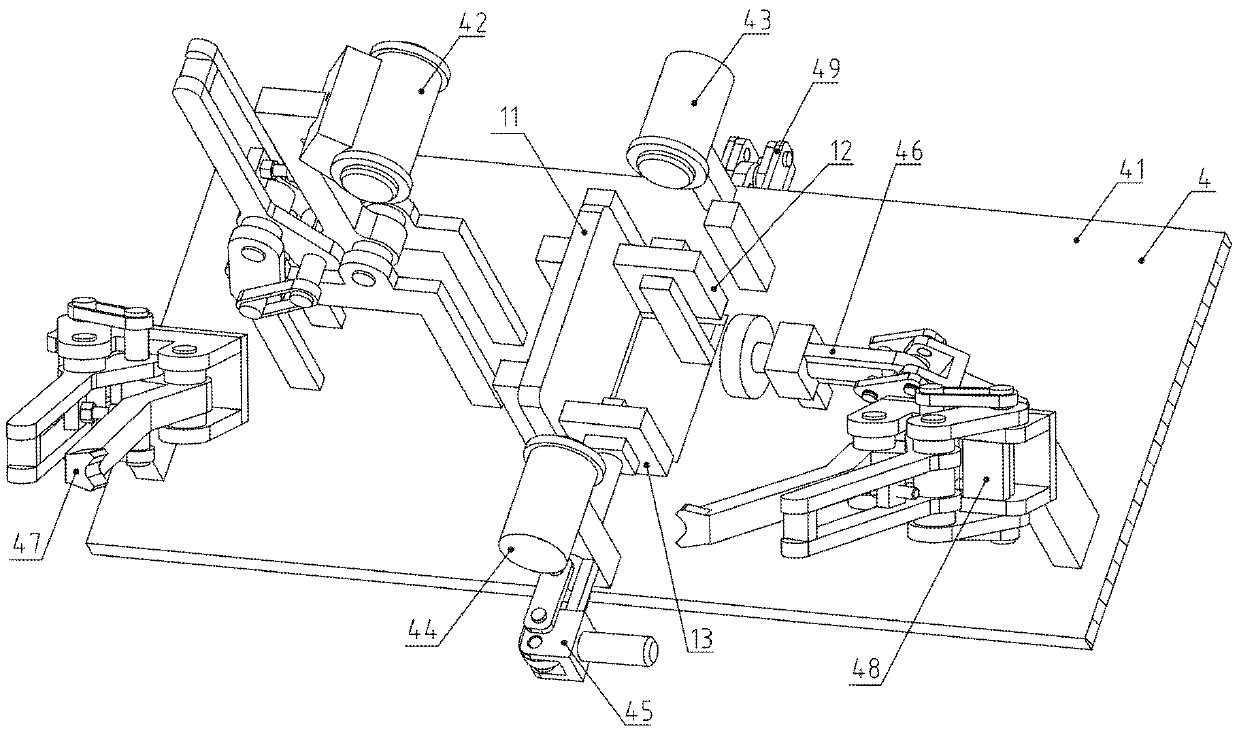

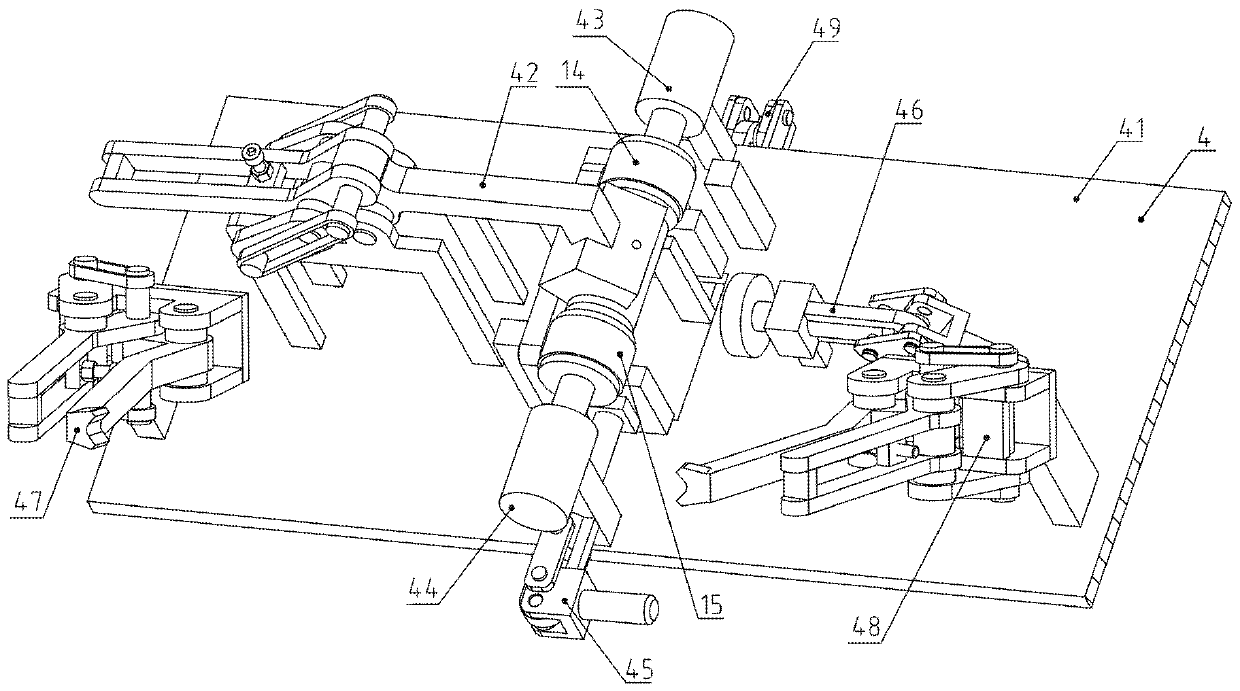

[0055] A spot-welding assembly jig for roller can ear base earring assembly, including a frame 2, a rotation limiting pin 3 and a turning assembly 4;

[0056] The overturn assembly 4 includes an overturn disc 41, a locating pin assembly 42 in the sleeve, a locating pin assembly 43 behind the sleeve, a locating pin assembly 44 before the sleeve, a front side plate quick clamp 45, a left side plate quick clamp 46, a right Plate oblique pressure quick clamp 47, left side plate oblique pressure quick clamp 48 and rear side plate rear hook quick clamp 49;

[0057]The two ends of overturning disk 41 are provided with overturning installation hole 411, and the axis line of overturning installation hole 411 is horizontally arranged; Just behind the installation hole 411 is provided with a rear limiting rotation hole 4122; by making the overturn installation hole 411 cooperate with the pin shaft on the frame 2, the overturn disc 41 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com