Capping plug injection mould and capping plug injection moulding method

An injection mold and cap plug technology, applied in the field of cap plug injection mold and cap plug injection, can solve the problems of difficult demoulding, easily damaged threaded parts, complex mold structure, etc., and achieve the effect of smooth demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0029] Such as Picture 11 with Picture 12 As shown, the lid plug includes a lid plug body 100, the cross section of the lid plug body 100 is circular, the lid plug body 100 has a bottom-up blind hole 500, and the top of the lid plug body 100 is provided with the blind hole 500. The four circumferentially distributed small holes 600; the cover plug body 100 includes an upper cover plug body 200 and a lower cover plug body 300, the outer diameter of the lower cover plug body 300 is smaller than the outer diameter of the upper cover plug body 200, in the lower cover plug body 300 An external thread 400 is provided on the outer circumference of the.

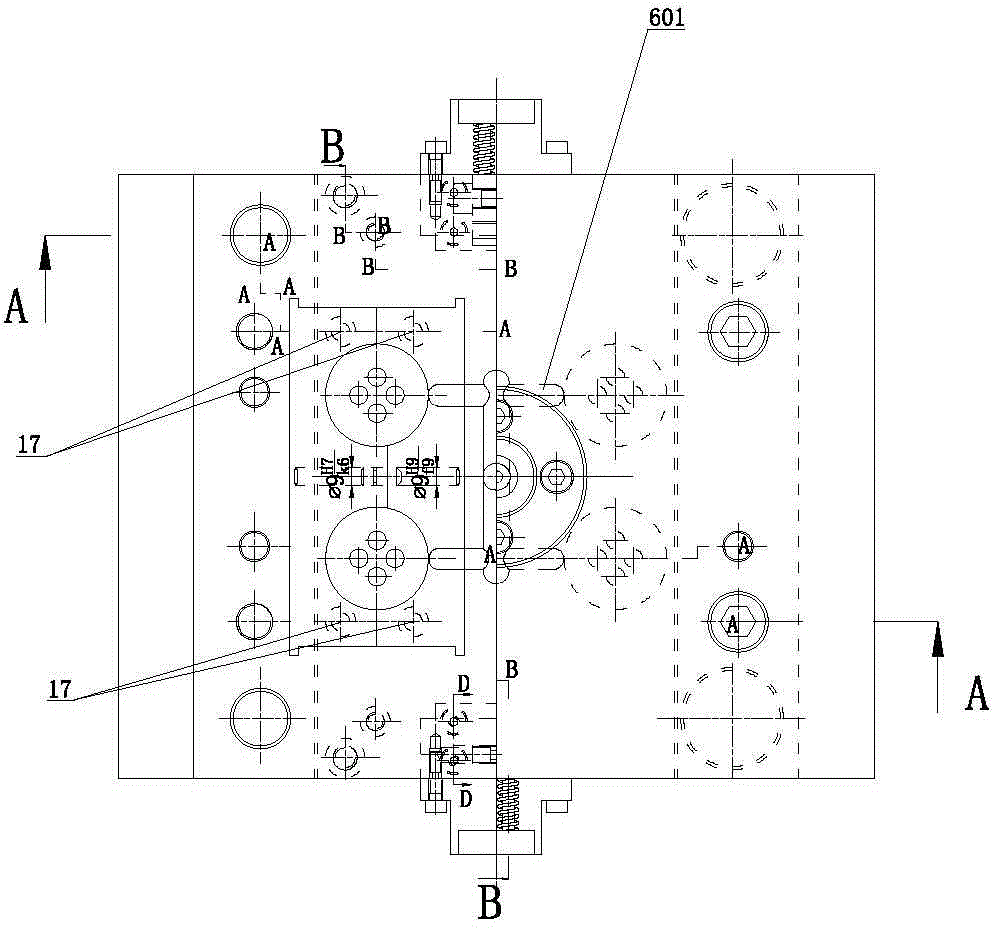

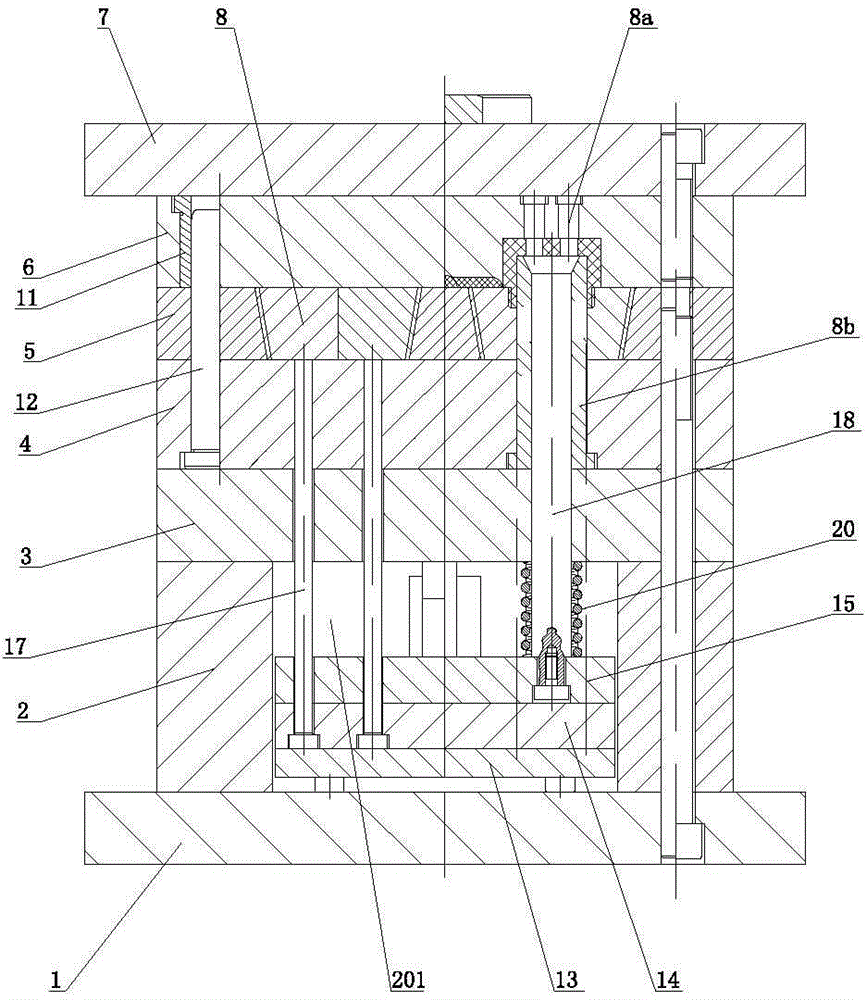

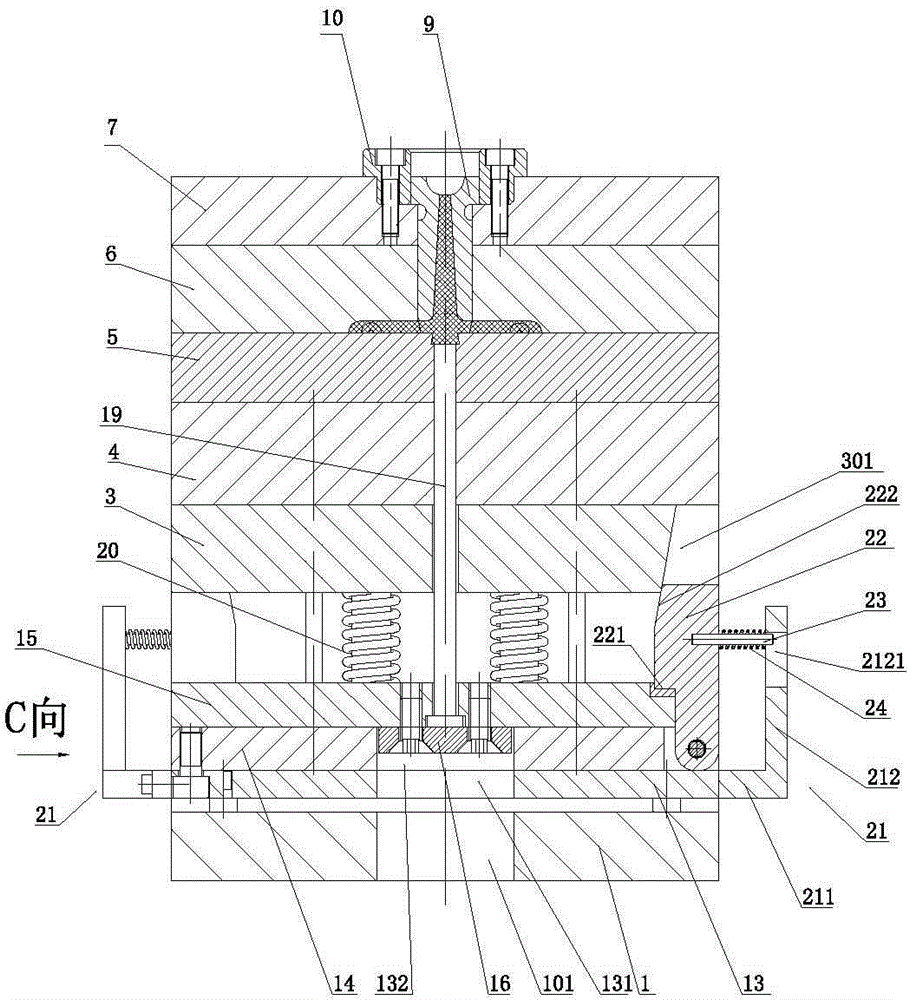

[0030] Such as Figure 1 to Figure 3 As shown, the cap injection mold includes a lower mold base plate 1, two supporting legs 2, a supporting plate 3, a core fixing plate 4, a half fixing plate 5, a small cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com