White glass ink used for ink-jet printing and preparation method thereof

A white glass and inkjet printing technology, which is applied in the field of glass decoration materials, can solve the problems that glass ink has not been recorded in relevant literature, and achieve the effects of not easy flocculation or precipitation, low annealing process temperature, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

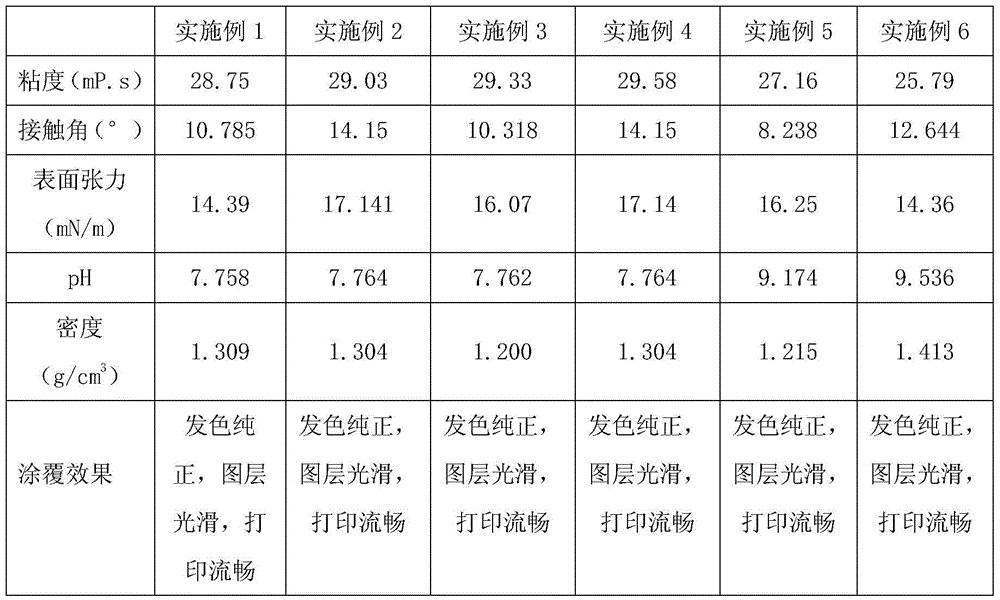

Examples

Embodiment 1

[0020] A kind of white glass ink for inkjet printing is prepared by the following method:

[0021] (1) Bi 2 o 3 -B 2 o 3 -SiO 2 Preparation of system glass powder: weigh 200gBi 2 o 3 , 50gB 2 o 3 (Courtesy of HBO 3 Introduced), 40gAl 2 o 3 , 15gMgO, 75gSiO 2 , 10gZrO 2 , 4gTiO 2 , 30gLi 2 O (by Li 2 CO 3 introduced), 32.5gNa 2 O (by Na 2 CO 3 introduced), 32.5gK 2 O(by K 2 CO 3 introduced), mixed evenly, and melted in a high-temperature environment of 950°C for 2 hours to obtain a uniform molten glass; pour the high-temperature molten glass directly into cold water for quenching, dry and grind the quenched glass to obtain Bi 2 o 3 -B 2 o 3 -SiO 2 System glass powder;

[0022] (2) Preparation of solid phase components: according to Bi 2 o 3 -B 2 o 3 -SiO 2 System glass powder: anatase TiO 2 The mass ratio of the white pigment is 85:15, and the raw materials are weighed, mixed evenly, melted at 600°C, quenched and ground to a particle size of 450...

Embodiment 2

[0026] A kind of white glass ink for inkjet printing is prepared by the following method:

[0027] (1) Bi 2 o 3 -B 2 o 3 -SiO 2 Preparation of system glass powder: weigh 180gBi2 o 3 , 50gB 2 o 3 (Courtesy of HBO 3 Introduced), 50gAl 2 o 3 , 20gCaO, 75gSiO 2 , 10gZrO 2 , 20gLi 2 O (by Li 2 CO 3 introduced), 37.5gNa 2 O (by Na 2 CO 3 introduced), 37.5gK 2 O(by K 2 CO 3 introduced), mixed evenly, and melted in a high-temperature environment of 1100°C for 0.5h to obtain a uniform molten glass. The high-temperature molten glass was directly poured into cold water for quenching, and the quenched glass was dried and ground to obtain Bi 2 o 3 -B 2 o 3 -SiO 2 System glass powder;

[0028] (2) Preparation of solid phase components: according to Bi 2 o 3 -B 2 o 3 -SiO 2 System glass powder: anatase TiO 2 The mass ratio of the white pigment is 88:12, and the raw materials are weighed, mixed evenly, melted at 600°C, quenched and ground to a particle size of 3...

Embodiment 3

[0032] A kind of white glass ink for inkjet printing is prepared by the following method:

[0033] (1) Bi 2 o 3 -B 2 o 3 -SiO 2 Preparation of system glass powder: weigh 220gBi 2 o 3 , 50gB 2 o 3 (Courtesy of HBO 3 Introduced), 50gAl 2 o 3 , 15gMgO, 85gSiO 2 , 5gTiO 2 , 30gLi 2 O (by Li 2 CO 3 introduced), 35gNa 2 O (by Na 2 CO 3 introduced), 35gK 2 O(by K 2 CO 3 introduced), mixed evenly, and melted in a high-temperature environment of 850°C for 2 hours to obtain a uniform molten glass. The high-temperature molten glass was directly poured into cold water for quenching, and the quenched glass was dried and ground to obtain Bi 2 o 3 -B 2 o 3 -SiO 2 System glass powder;

[0034] (2) Preparation of solid phase components: according to Bi 2 o 3 -B 2 o 3 -SiO 2 System glass powder: anatase TiO 2 The mass ratio of the white pigment is 91:9, and the raw materials are weighed, mixed evenly, melted at 600°C, quenched and ground to a particle size of 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com