Smell-free styrene-acrylic emulsion and clean-smell coating with emulsion as film forming matter

A styrene-acrylic emulsion and emulsion technology, which is applied to coatings, separation methods, evaporator accessories, etc., can solve the problems of reducing odor, high residual monomer content, and irritating odor, and achieve the effect of reducing odor.

Active Publication Date: 2016-08-24

HENGSHUI XINGUANG CHEM

View PDF7 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

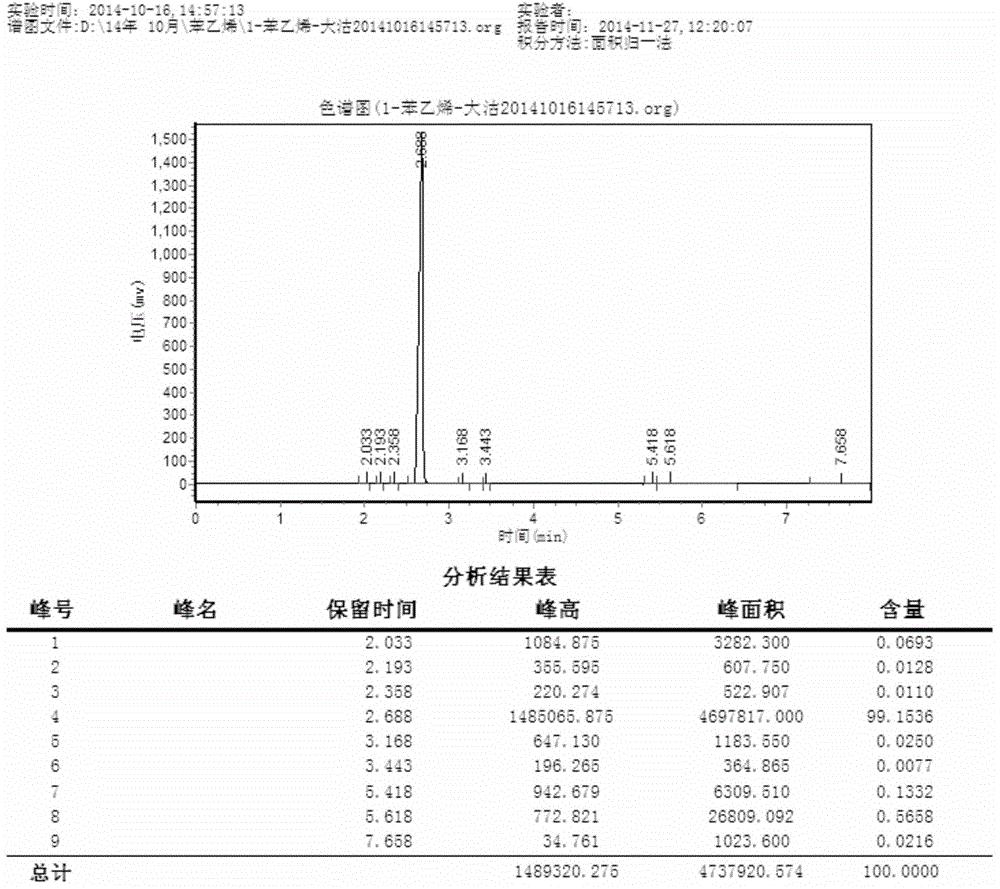

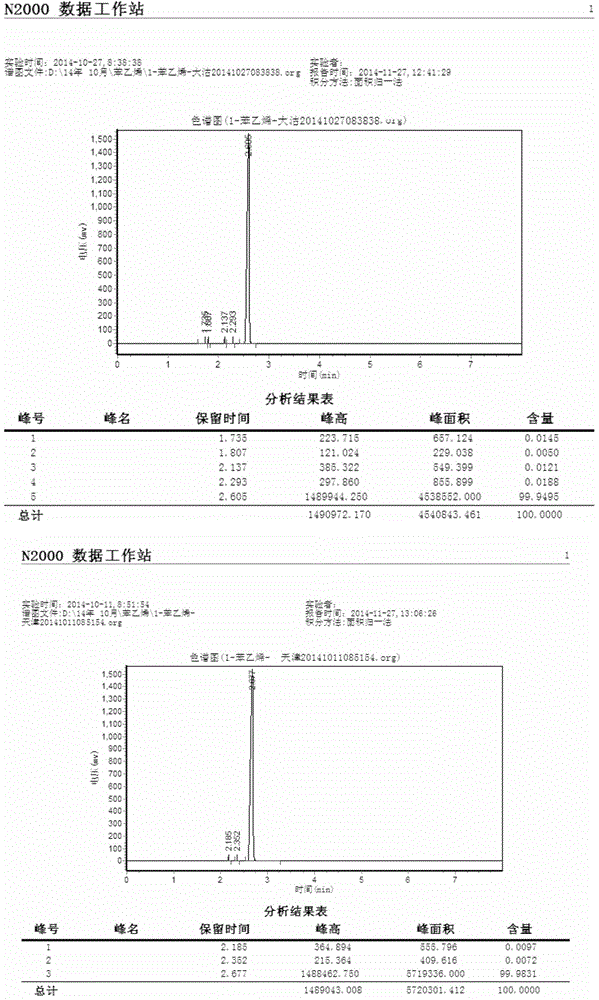

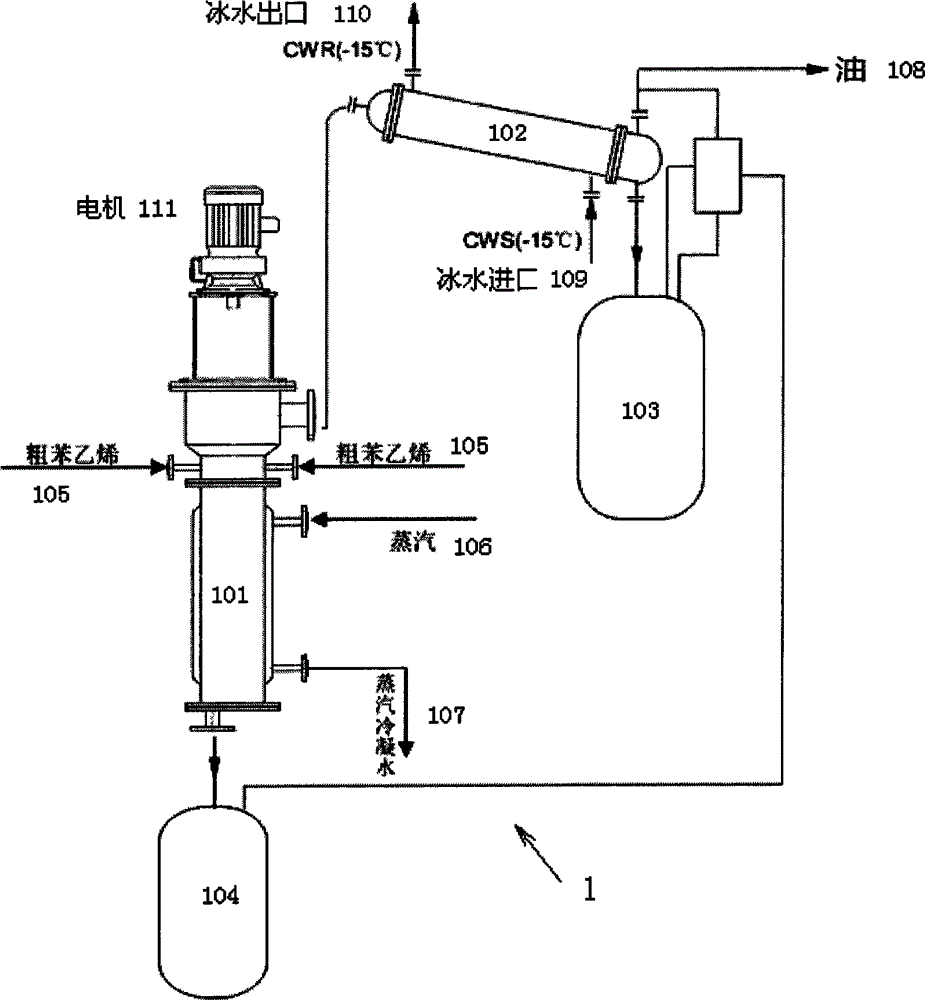

[0003] The present inventor has carried out in-depth research for the purpose of solving the problems of high residual monomer content and large pungent odor in the styrene-acrylic copolymer emulsion used in domestic architectural coatings, thereby further improving the competitiveness of domestic coating emulsions, and found that Through: (1) selection of specific monomers and cross-linking monomers; (2) strict control of impurities in the raw materials used in emulsion polymerization, such as the impurity content of monomers, such as xylene and ethylbenzene content in styrene; (3) Using reactive emulsifiers for emulsion polymerization to synthesize styrene-acrylic emulsions, reducing the odor brought by conventional small molecule non-reactive emulsifiers; (4) After the emulsion is added dropwise and polymerized, an odorless initiator before and after decomposition is used as a post-elimination process (5) After the emulsion is synthesized, high-temperature nitrogen and falling film evaporation technology are used to extract and distill the residual monomer and other organic impurities in the monomer raw material; the VOC of the final emulsion can be controlled at less than 100ppm Within, architectural coating emulsion with excellent color development, mechanical stability, paint film water resistance, alkali resistance and scrub resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0085] Preparation of paint

[0086] table 5

[0087]

[0088] The above dosage unit is kg.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a preparation method of a styrene-acrylic emulsion with VOC lower than 100 ppm and a coating containing the emulsion. The VOC of the final emulsion coating can be controlled to be lower than 100 ppm. The emulsion has excellent color contrast properties, mechanical stability and water resistance, alkali resistance and scrubbing resistance of a paint film, and is suitable for being used as a building coating emulsion.

Description

technical field [0001] The invention relates to a deodorizing styrene-acrylic emulsion and a deodorizing paint using the emulsion as a film-forming substance. Background technique [0002] Latex paint has entered the Chinese home improvement market for more than 30 years. It can be said that in the minds of ordinary Chinese consumers, latex paint is a synonym for "building wall paint". At present, due to the increasing attention to environmental protection issues, paint manufacturers in Europe, America, and Japan have successively launched low-VOC or even zero-VOC latex paints, and the film-forming materials used have developed from early vinyl acetate series to acrylate copolymer emulsion series with better water resistance. , this is because the residual monomer vinyl acetate in the emulsion of vinegar-acrylic paint has high hydrophilicity, which is not only extremely difficult to eliminate chemically, but also difficult to remove even by distillation. Therefore, the odor ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F220/18C08F212/08C08F220/14C08F220/06C08F220/56C08F2/28C08F2/26C09D133/08C09D125/14C09D7/12B01D1/22B01D1/30

Inventor 田海宁田海水周志尚王俊丽

Owner HENGSHUI XINGUANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com