Composite solid electrolyte membrane, and preparation method and application thereof

A solid electrolyte membrane, sulfide electrolyte technology, applied in non-aqueous electrolyte batteries, circuits, electrical components, etc., can solve the problems of low strength and room temperature ionic conductivity, poor toughness, etc., to achieve high energy density and safety performance, flexibility Good, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

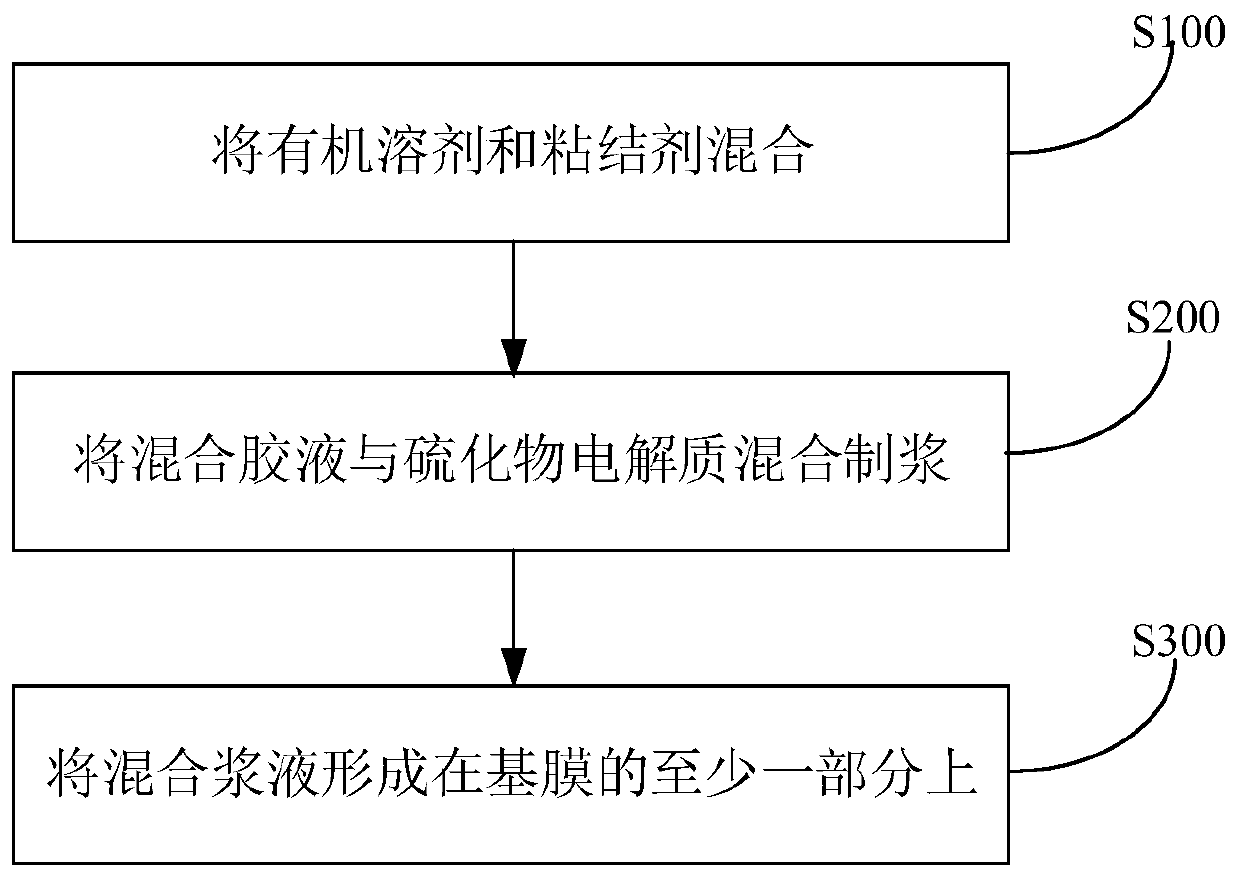

[0038] The method for preparing a composite solid electrolyte membrane according to one aspect of the present invention comprises:

[0039] S100: mixing organic solvent and binder

[0040] According to some embodiments of the present invention, the organic solvent and the binder are mixed to obtain a mixed glue solution, wherein the organic solvent is selected from dichloromethane, tetrahydrofuran, n-hexane, n-heptane, toluene, 2,4-bis At least one of methyl-3-pentanone, monochlorobenzene, xylene, anisole, cyclohexanone, 1,3,5-trimethylbenzene, n-decane, and methylformamide. The inventors have found that the above solvents can dissolve a variety of sulfide-stable binders, these solvents have moderate boiling points, and the residual moisture can be removed to less than 10ppm within 24 hours. After mixing for more than 24 hours, the conductivity remains between 50% and 100%, indicating that it is stable to sulfide electrolytes. These solvents mainly belong to ketones, ethers, ...

Embodiment 1

[0056] (1) Dichloromethane and PVDF5130 (molecular weight: 200,000) are mixed to make glue according to the mass ratio of 25:1 to obtain a mixed glue;

[0057] (2) Combine the mixed glue with Li 10 SnP 2 S 12 According to the mass ratio of 1.2:1, mixing and pulping to obtain mixed slurry;

[0058] (3) The mixed slurry is coated on the PP-PE composite film (its microstructure is as follows) according to the solid-liquid ratio of 130:1 figure 2 Shown) on the surface of the composite solid electrolyte membrane (the SEM image of its cross-section is shown in image 3 As shown, the surface SEM image is shown in Figure 4 As shown, the optical photo is as Figure 5 shown).

Embodiment 2

[0060] (1) tetrahydrofuran and PEO (molecular weight: 550,000) are mixed to make glue according to the mass ratio of 22:1 to obtain mixed glue;

[0061] (2) Combine the mixed glue with Li 10 GeP 2 S 12 According to the mass ratio of 1.2:1 mixed pulping, to obtain mixed slurry;

[0062] (3) The mixed slurry is coated on the surface of the PAN membrane according to the solid-to-liquid ratio of 140:1 to obtain a composite solid electrolyte membrane (the surface structure of which is shown in Figure 6 As shown, the optical photo is as Figure 7 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com