High performance lithium ion secondary battery and manufacture method

A secondary battery, lithium ion technology, used in secondary batteries, electrode manufacturing, battery electrodes, etc., can solve problems such as impact, physical and mental harm of production workers and surrounding environment, gas leakage, etc., to achieve abundant resources and controllable production cycle , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] For the positive electrode, take modified lithium ferrous phosphate (LiFe 0.75 Ni 0.25 PO4)+organic silica gel crosslinking additive, modified polyethylene oxide+conductive carbon black=100:30:1 (by weight), add 25% water of the total weight, mix in the mixer, stir, then filter, evenly Coated on aluminum foil and dried at 55°C to make positive electrode sheet.

[0034] For the negative electrode, take artificial graphite + conductive carbon black + styrene-butadiene rubber + sodium carboxymethyl cellulose = 90%: 1%: 2%: 2%, mix with 52% water, stir, filter, and evenly coat on copper Foil, after drying at 70 ℃, made of negative electrode sheet.

[0035] The positive and negative pole pieces are rolled, riveted with lugs, wound with the separator to form a pole assembly and put into a 16340 (CR123A) battery case, and 2-4g of electrolyte is added to each battery case.

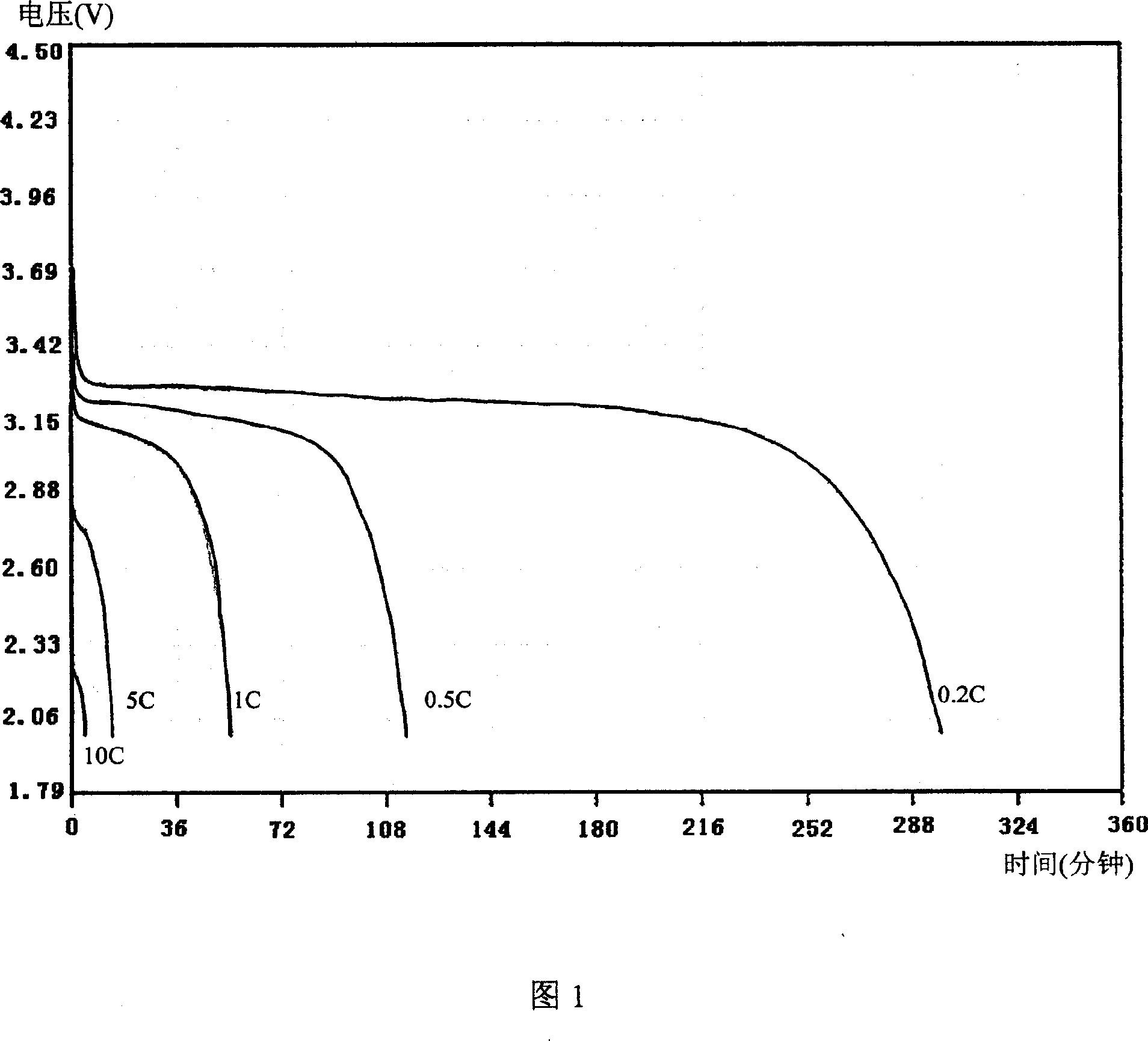

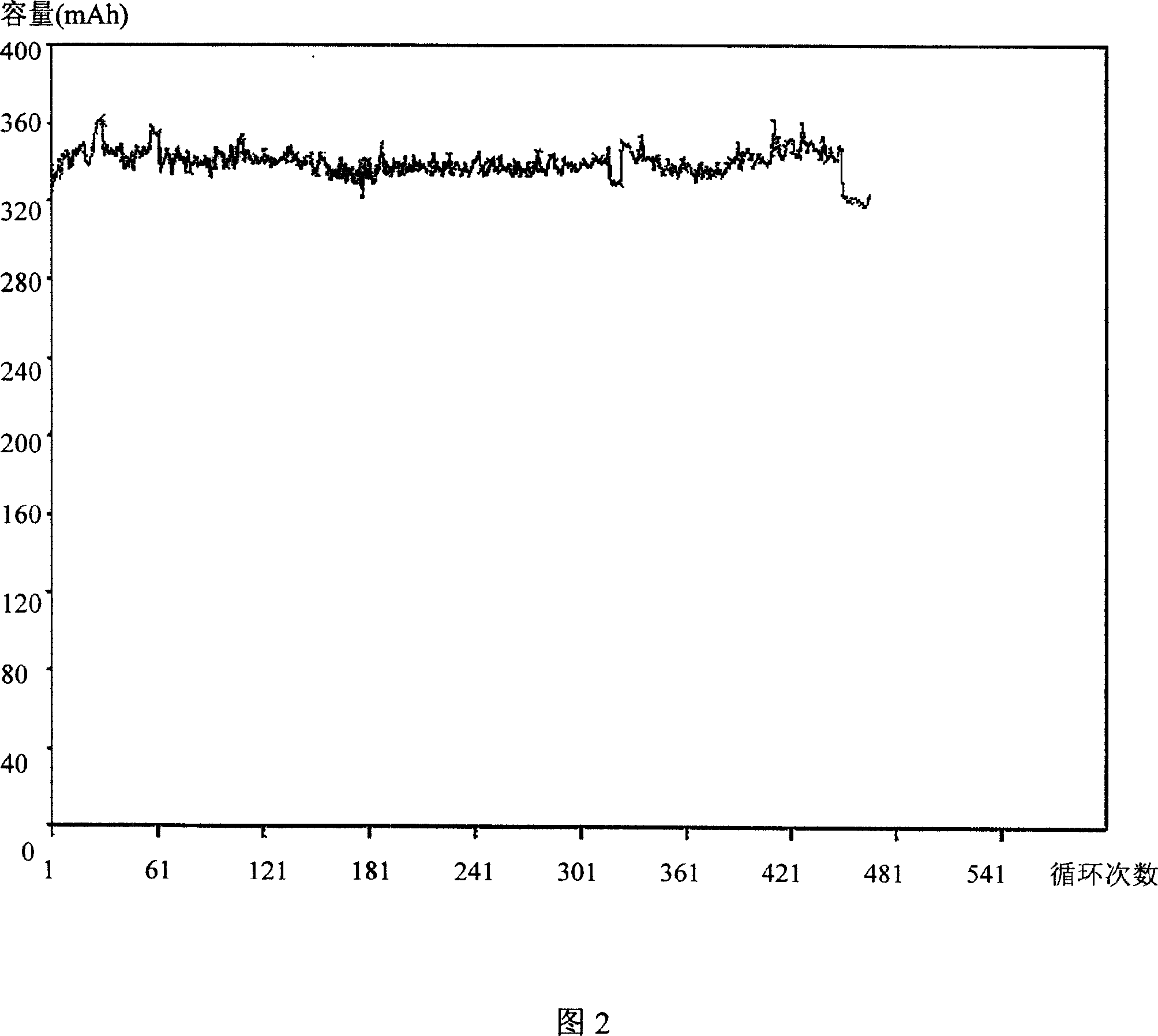

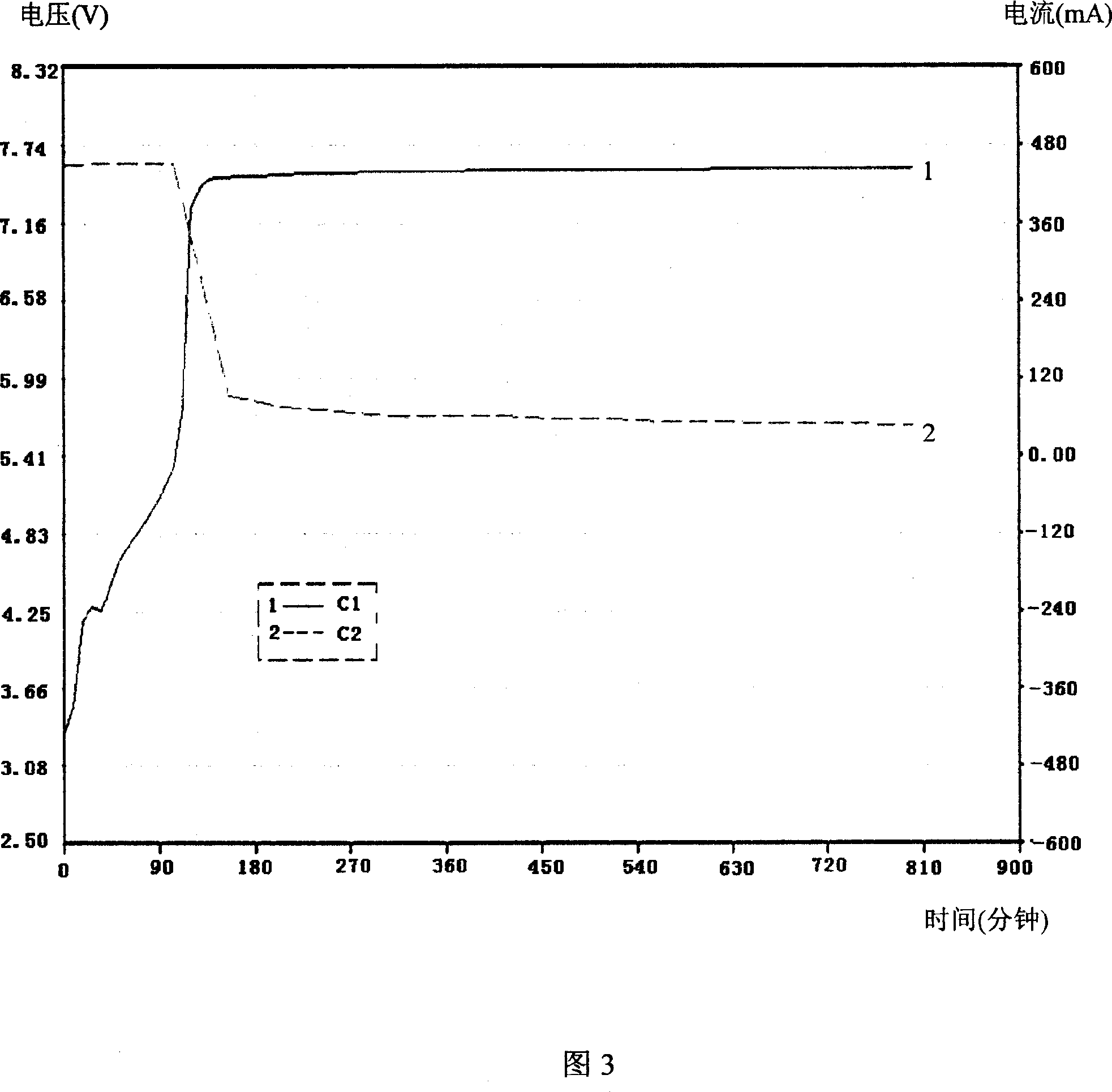

[0036] After sealing, let it stand at 60°C for 3 days, pre-charge it with a small current of 0.01C, s...

Embodiment 2

[0038] Take modified lithium ferrous phosphate (LiFe 0.65 mn 0.35 PO4)+polyvinyl alcohol+conductive carbon black=100:15:2 (by weight), add 28% water of the total weight, mix in the mixer, stir, then filter, evenly coated on the aluminum foil, after 85 ℃ drying to make a positive electrode sheet.

[0039] Negative electrode: Take artificial graphite + conductive carbon black + styrene-butadiene rubber + sodium carboxymethyl cellulose = 95%: 0.5%: 2.5%: 2%:, mix with 55% water, stir, filter, and evenly coat on copper Foil, after drying at 70 ℃, made of negative electrode sheet.

[0040]The positive and negative pole pieces are rolled, riveted with lugs, wound with the separator to form a pole assembly and put into a 16340 (CR123A) battery case, and 2-4g of electrolyte is added to each battery case.

[0041] After sealing, let stand at 15°C for 5 days, pre-charge with a small current of 0.1C, stand at 70°C for 18 days, divide the capacity, and pass 1C discharge test. The batte...

Embodiment 3

[0043] Take modified lithium ferrous phosphate (LiFe 0.55 Ca 0.45 PO4) + polyacrylamide + conductive carbon black = 120: 10: 1 (by weight), add 25% of the total weight of water, mix in the mixer, stir, then filter, evenly coated on aluminum foil, after 150 ℃ drying to make a positive electrode sheet.

[0044] Negative electrode: Take artificial graphite + conductive carbon black + styrene-butadiene rubber + sodium carboxymethyl cellulose = 94.5%: 0.5%: 3%: 2%:, mix with 58% water, filter, and evenly coat on copper foil After drying at 70°C, the negative electrode sheet was made.

[0045] The positive and negative pole pieces are rolled, riveted with lugs, wound with the separator to form a pole assembly and put into a 16340 (CR123A) battery case, and 2-4g of electrolyte is added to each battery case.

[0046] After sealing, let it stand at 70°C for 1 day, pre-charge it with a small current of 0.65C, stand at 60°C for 15 days, divide the capacity, and pass 1C discharge test....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com