Patents

Literature

33results about How to "The preparation process is compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

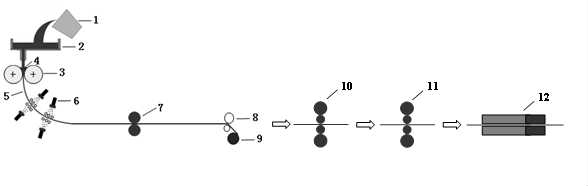

A manufacturing method of non-oriented silicon steel sheet based on twin-roll strip continuous casting technology

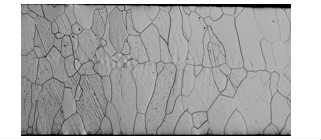

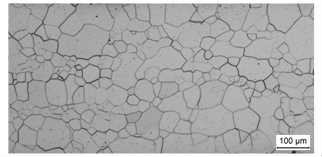

The invention relates to the technical field of metallurgical technology, in particular to a method for manufacturing a non-oriented silicon steel plate based on a twin-roll thin strip continuous casting technology. The method comprises the steps of: smelting molten steel with the silicon content of 2.9-3.5wt% at a temperature of 1610-1720 DEG C; pouring the molten steel in a tundish, wherein themolten steel flows into a cavity formed by two crystallizing rolls which rotate at a linear velocity of 20-60m / min and a side-closing plate through the tundish, and is in contact with the crystallizing rolls to generate a solidified shell, and a cast band is led out of the crystallizing rolls; obtaining a cast band coil after the cast band is subjected to the online side-shearing treatment and coiling; warm-rolling the cast band coil after the cast band coil is cooled down to 200-600 DEG C in air, wherein the amount of deformation in warm-rolling is 5-30 percent; and cold-rolling, annealing and coating the warm-rolled cast band coil to prepare a non-oriented silicon steel plate. The method provided by the invention has the advantages that the process is simple and compact, energy is saved, consumption is reduced, microscopic structures of the cast band can be effectively controlled, the drawability, the plate shape and the surface quality of the cast band can be improved, and the magnetic induction intensity of the non-oriented silicon steel plate can be effectively increased.

Owner:NORTHEASTERN UNIV

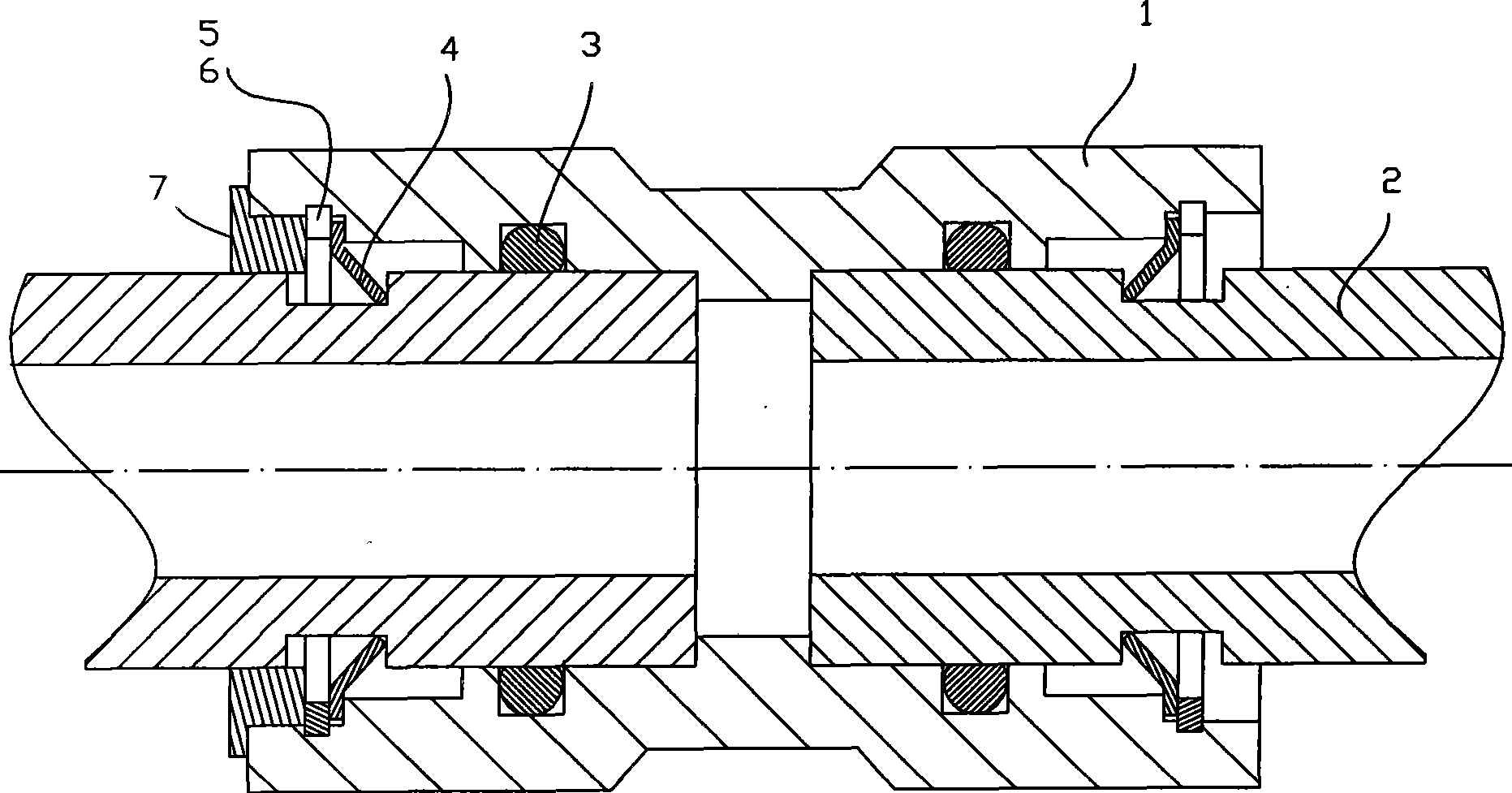

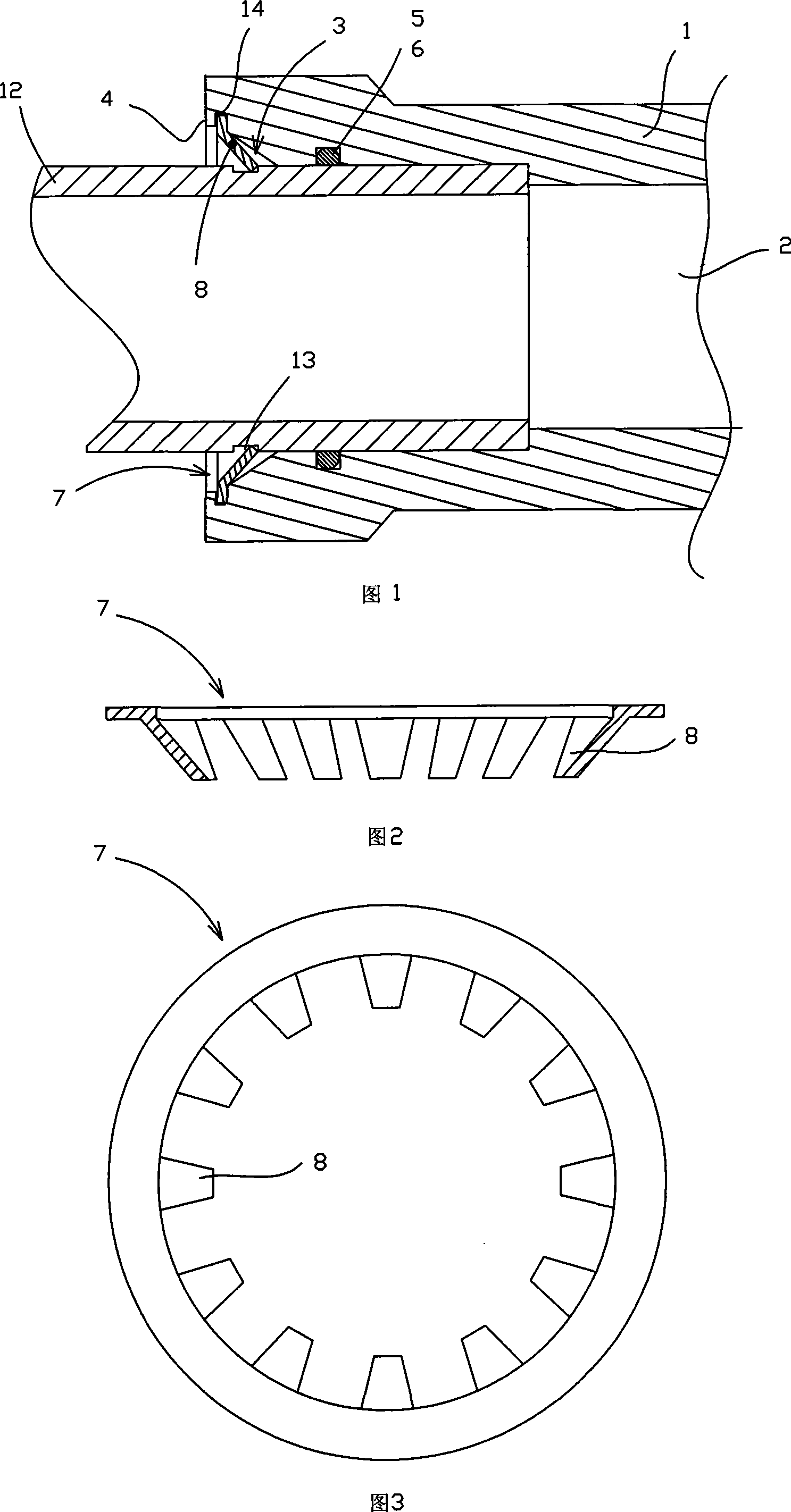

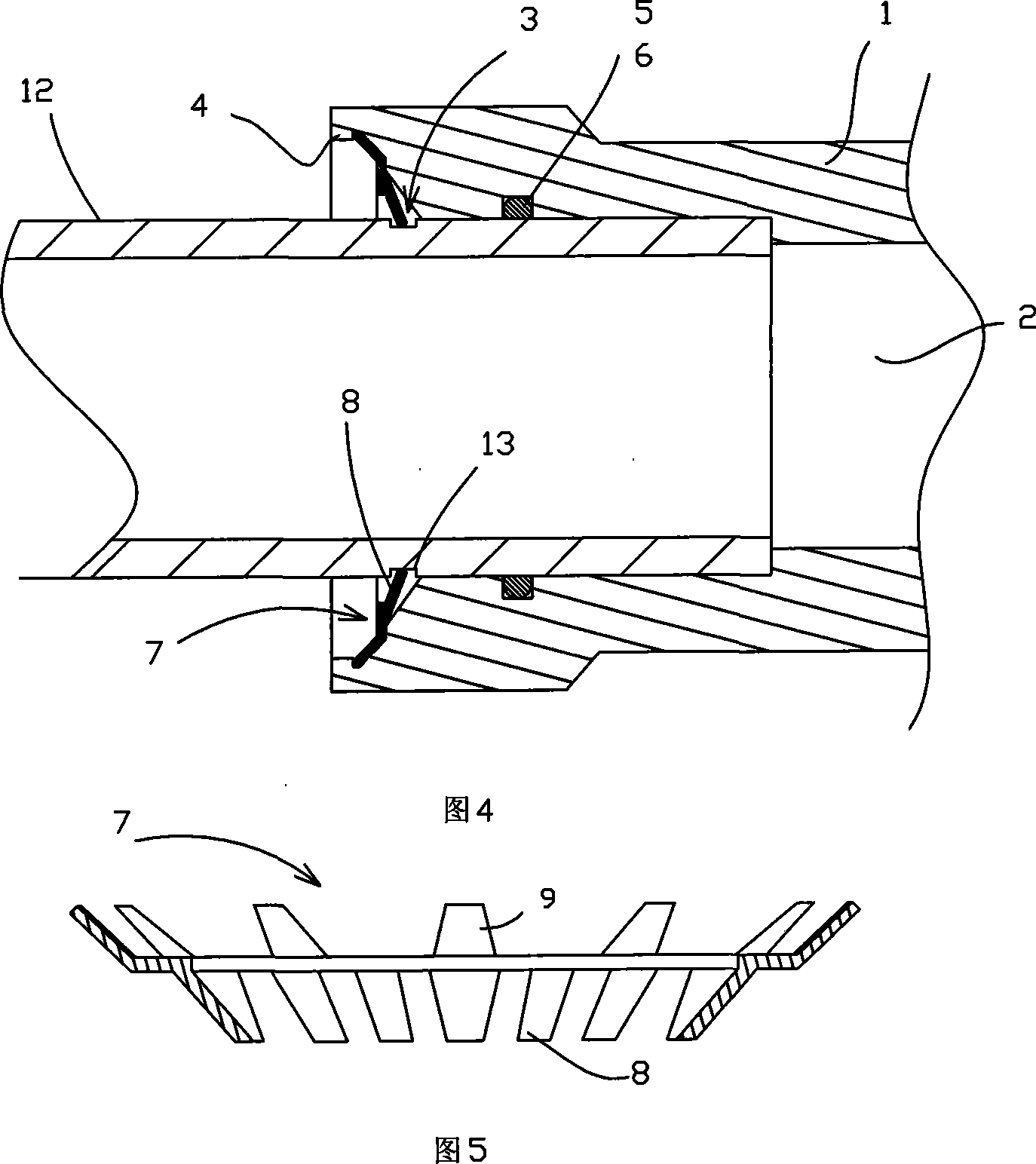

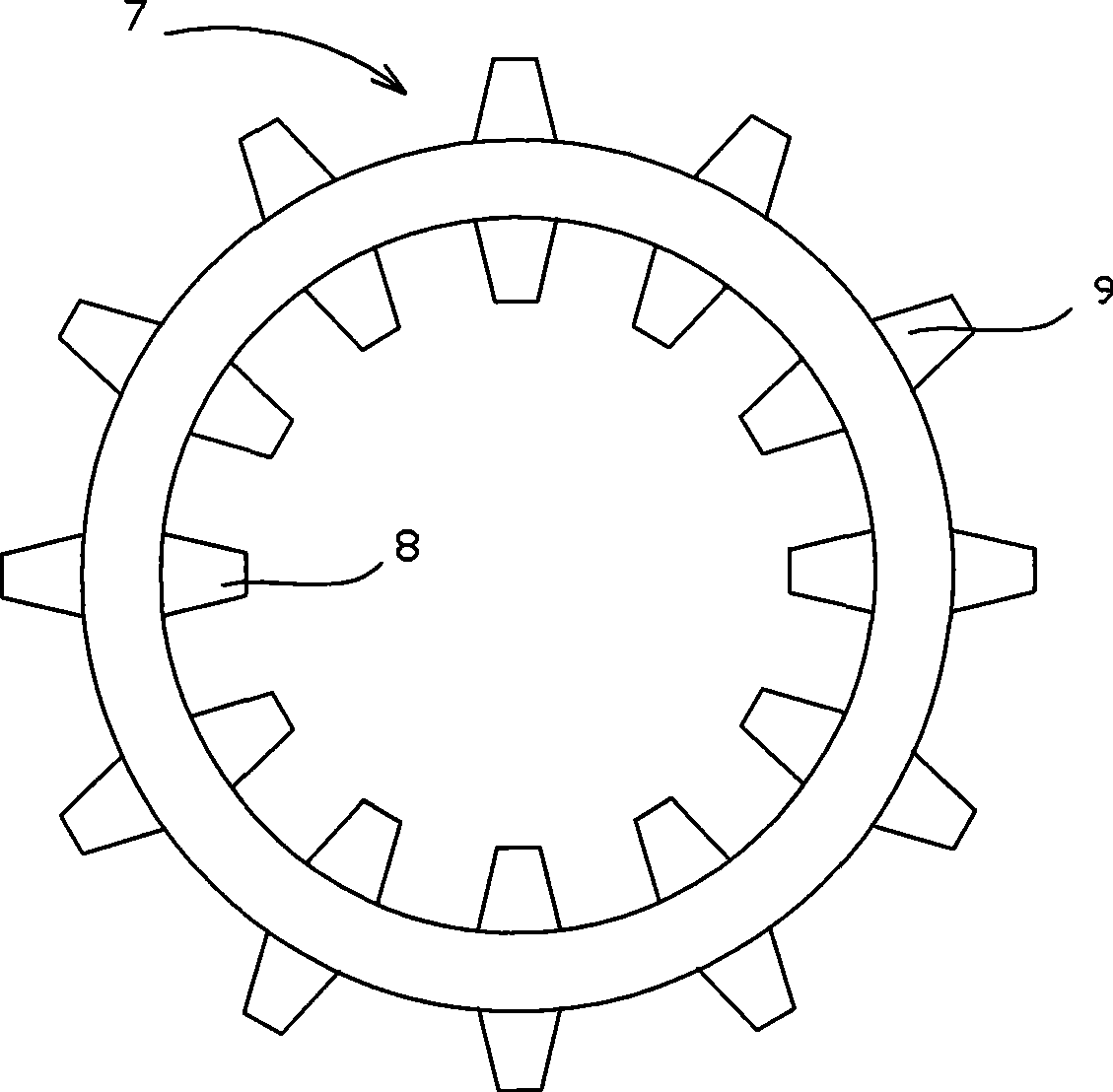

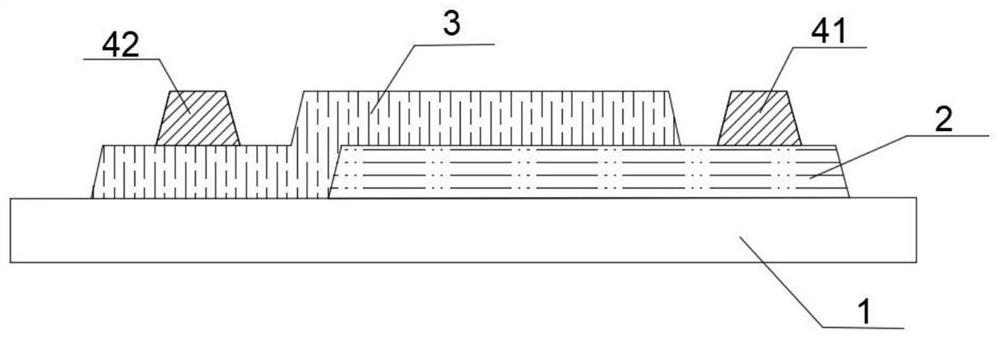

Connector of pipe

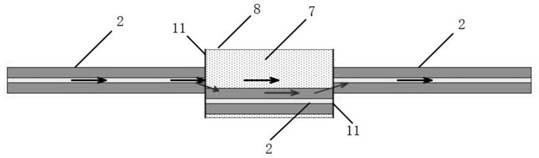

InactiveCN101482209ACompact structureThe preparation process is compactSleeve/socket jointsCouplingsSurface layerLocking mechanism

The invention discloses a pipe joint, comprising a joint body (1) with a through hole; wherein the middle part of the through hole is provided with a locating step used to be located by a connecting pipe; the port of the through hole is a step hole which is small in the inside and large in the outside; a small hole is adaptive to the outer diameter of a connected pipe (2); a rubber gasket circular groove provided with a seal rubber gasket (3) is arranged on the inner wall of the small hole; the inner end of a large hole is provided with an elastic locking gear ring (4); and a locking mechanism and the opening mechanism of the elastic locking gear ring are arranged outside the elastic locking gear ring (4). The pipe joint has less parts, compact structure, simple manufacture technique and low cost, and can be manufactured by the materials like iron or aluminum alloy, plastics, and the like. When being manufactured and assembled, the pipe joint on a surface layer can not be destroyed, is reliably connected, and can be quickly mounted and dismounted.

Owner:伍婧绫

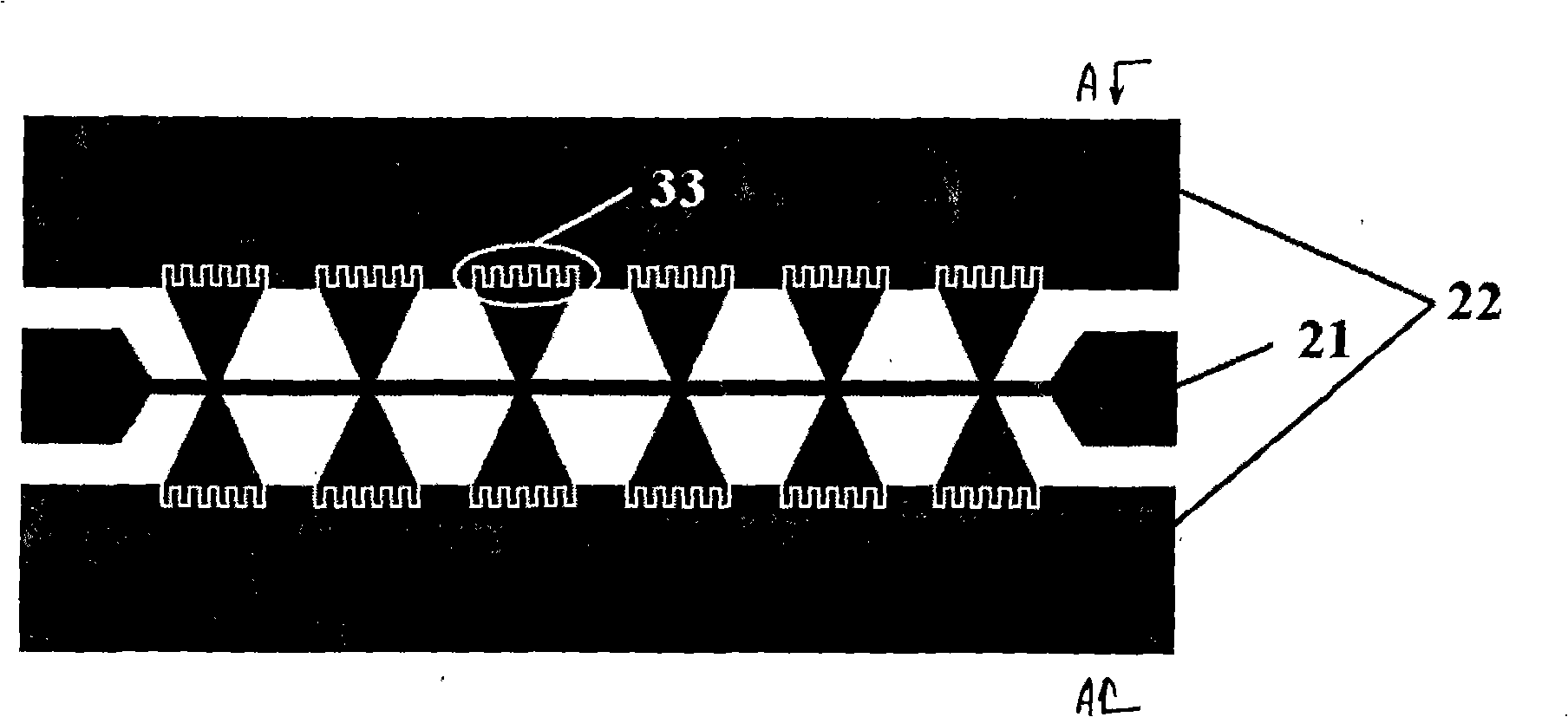

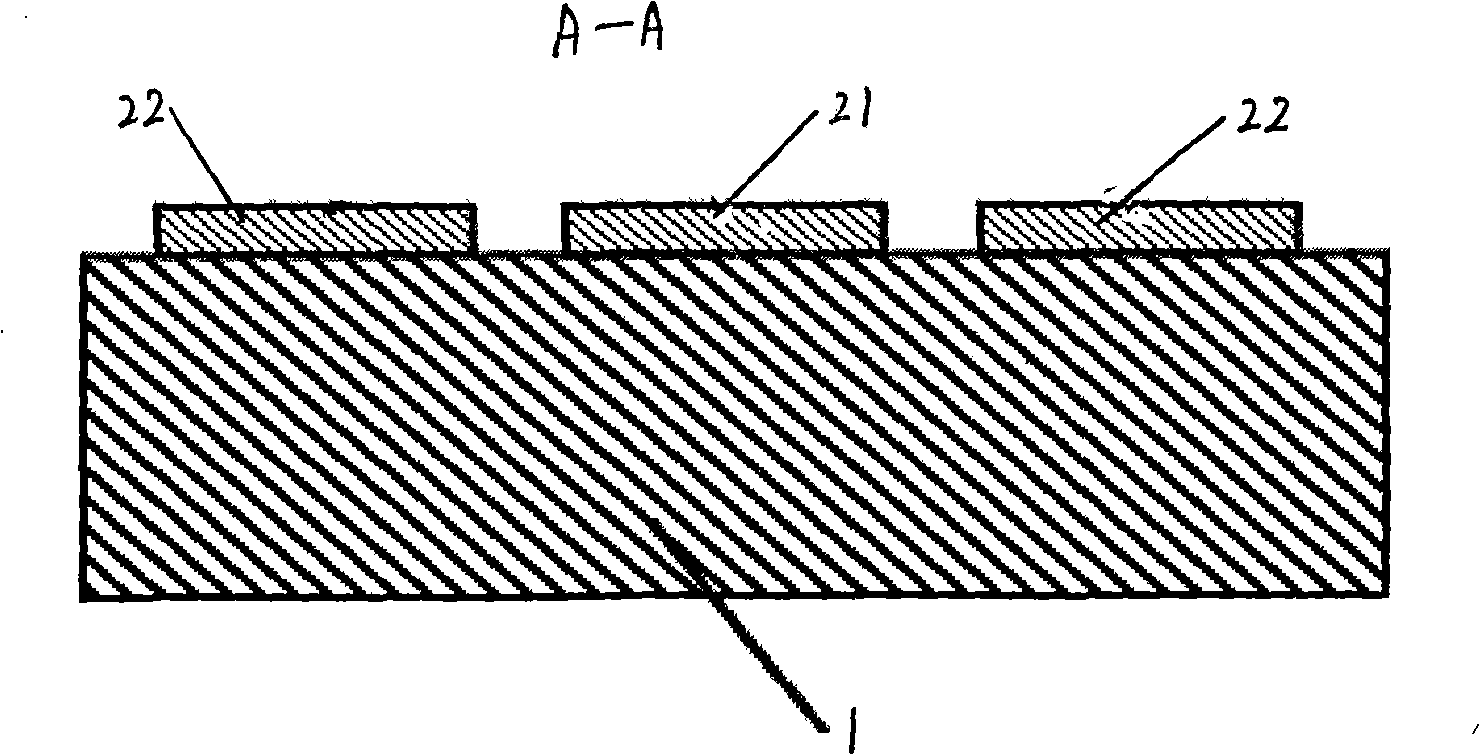

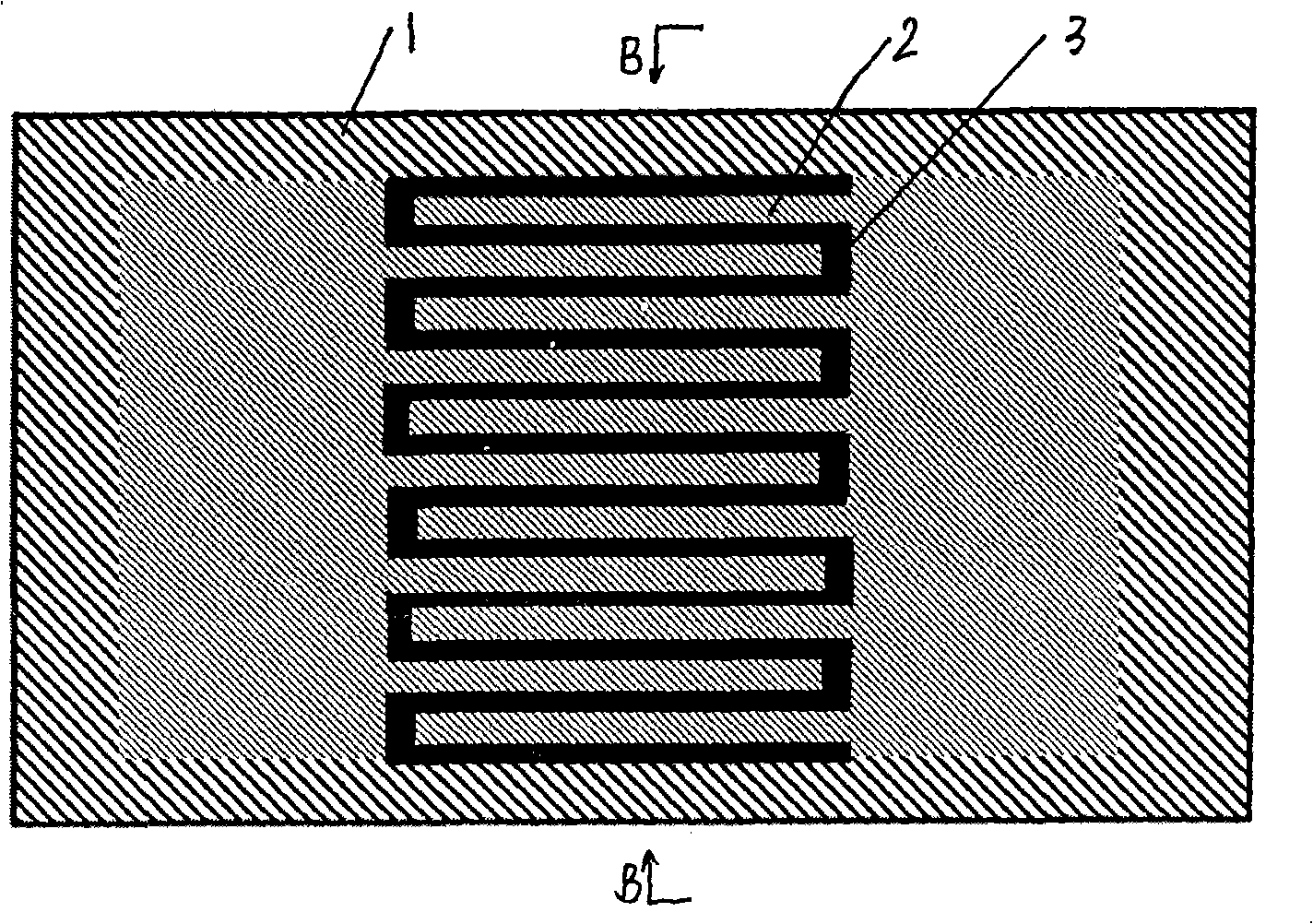

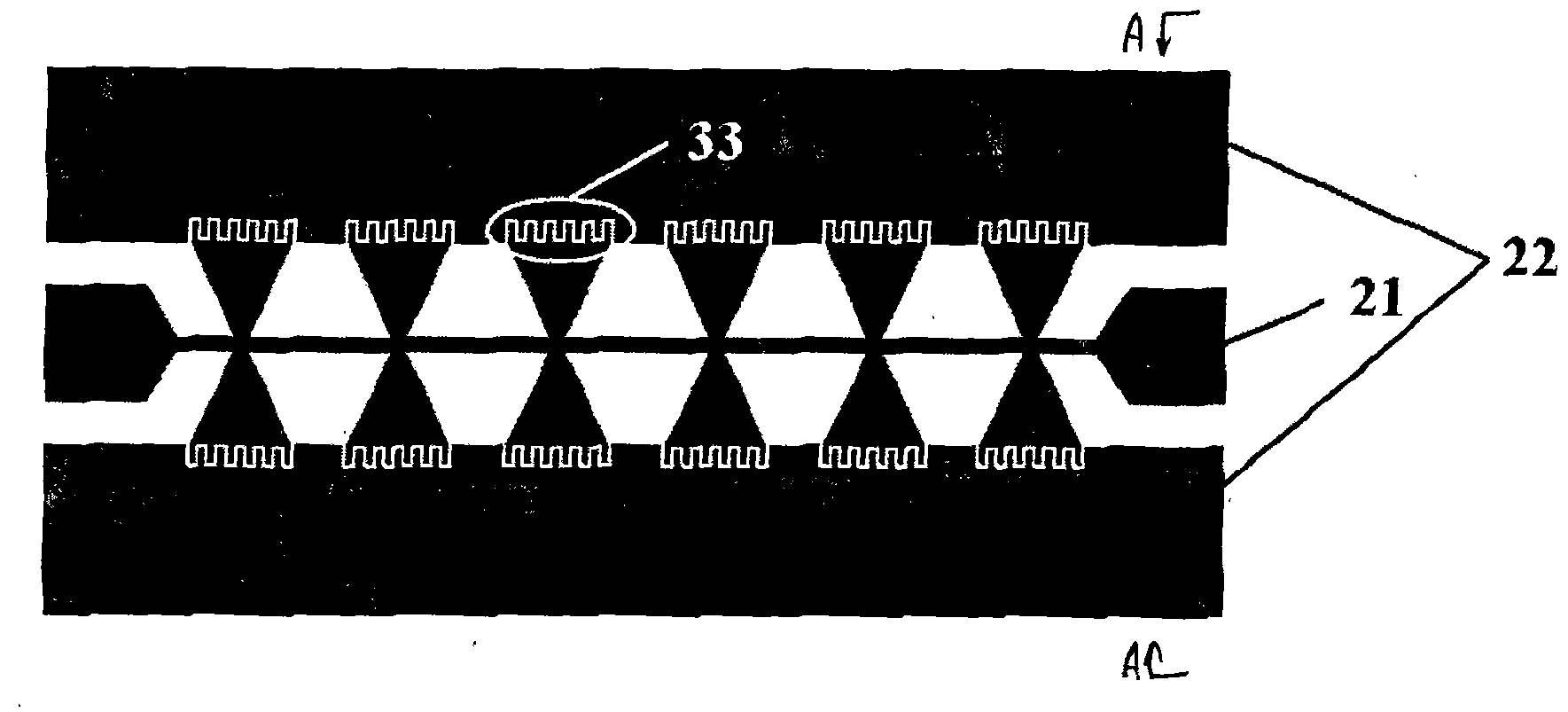

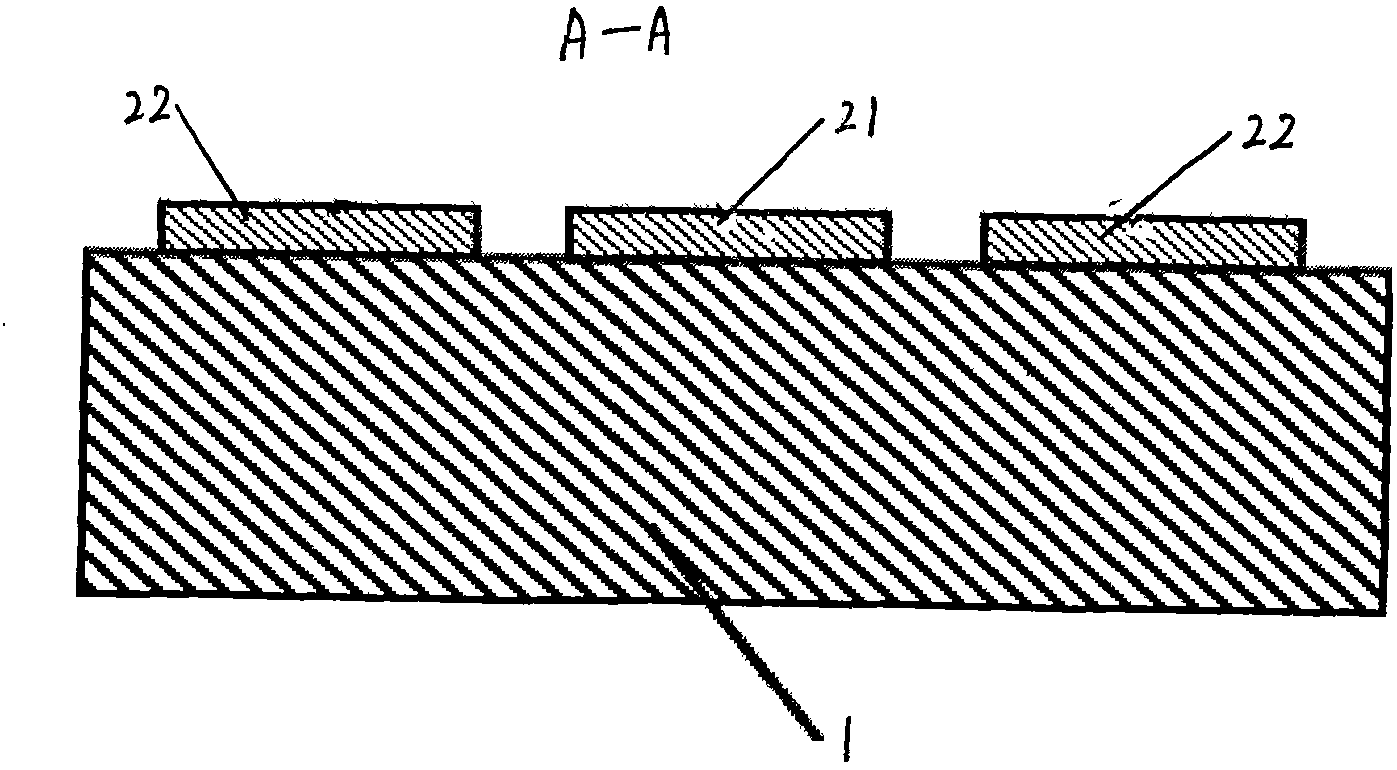

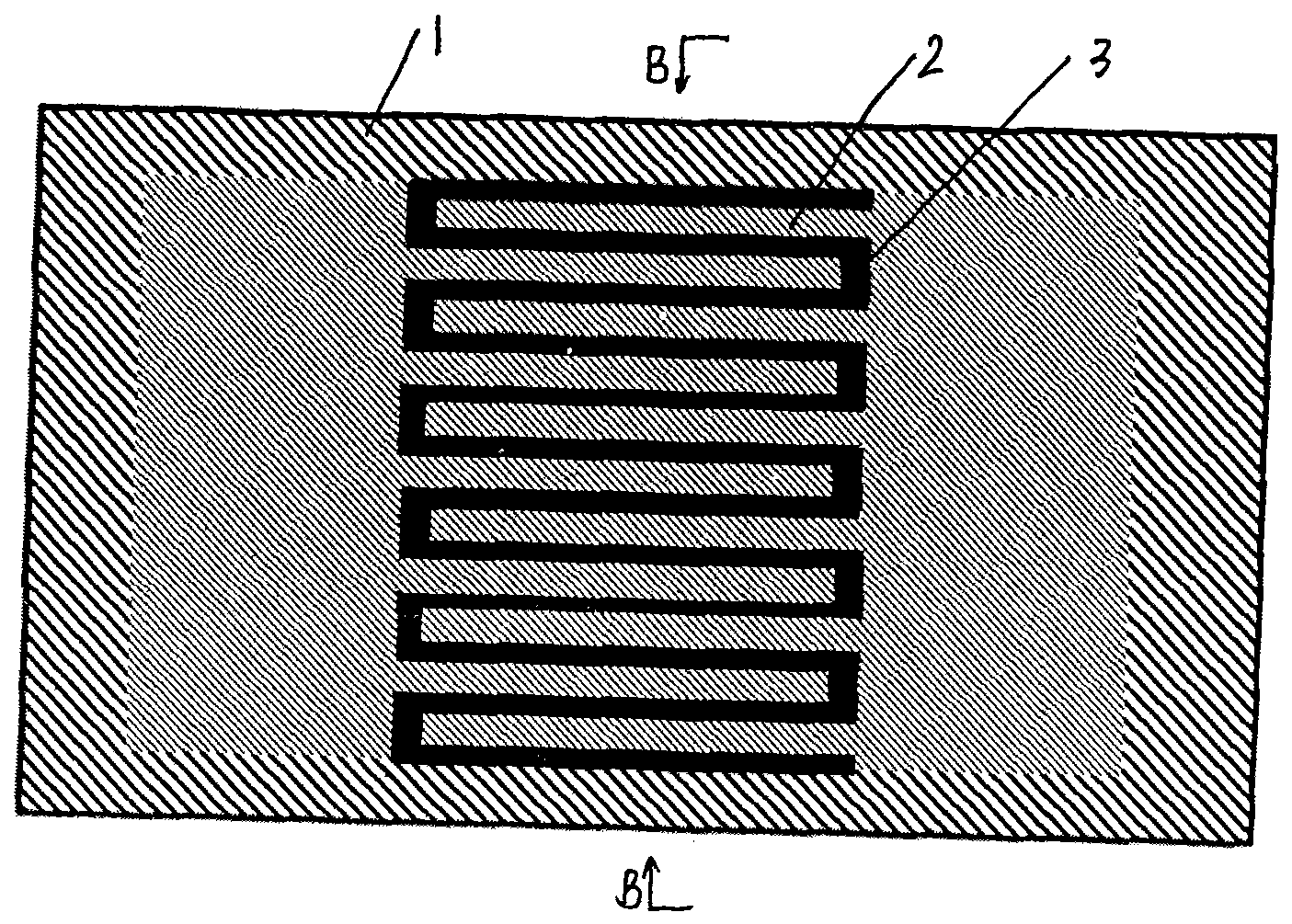

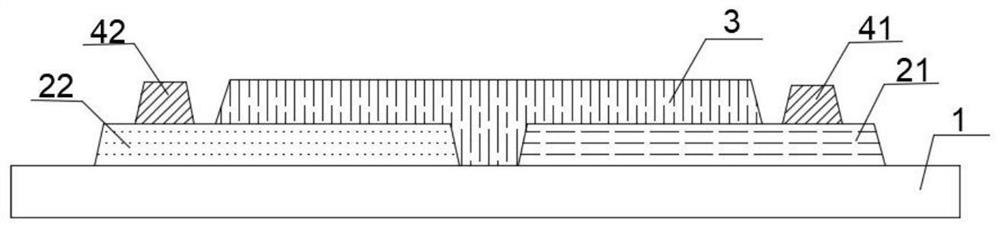

Ferroelectric thin-membrane phase shifter and preparation thereof

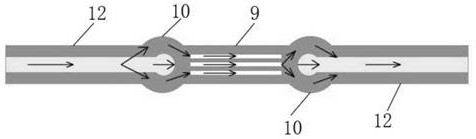

InactiveCN101335371ASimple preparation processImprove Modulation CapabilitiesWaveguide type devicesCapacitanceManufacturing technology

The invention relates to a ferro-electricity film phase shifter, pertaining to the field of microwave engineering technology, which comprises a coplanar line structure that comprises a transmission line constituted by a general conductive film and ground planes on both sides thereof. Aequilate slots are arranged between the ground planes and the transmission line, interdigited capacitor structures are arranged mutually and periodically on the transmission line and the ground planes on both sides thereof, the conductive film is directly fixed on to the substrate of an underlay, and ferro-electricity films are provided in the slots between the mutually interdigited transmission line and the ground planes. The intedigited capacitor structure of the invention places equal attention to advantages of simple manufacturing technology of a general intedigited capacitor and to that a parallel plate capacitor structure can highly concentrate impressed electric field into the ferro-electricity film, thus realizing the advantage of large phase shifting capacity under low voltage and having potential and broad practical prospect.

Owner:HENAN UNIV OF SCI & TECH

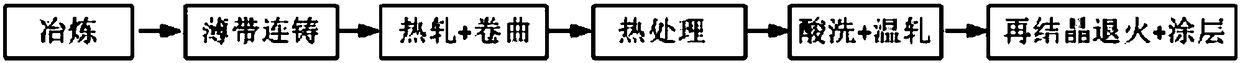

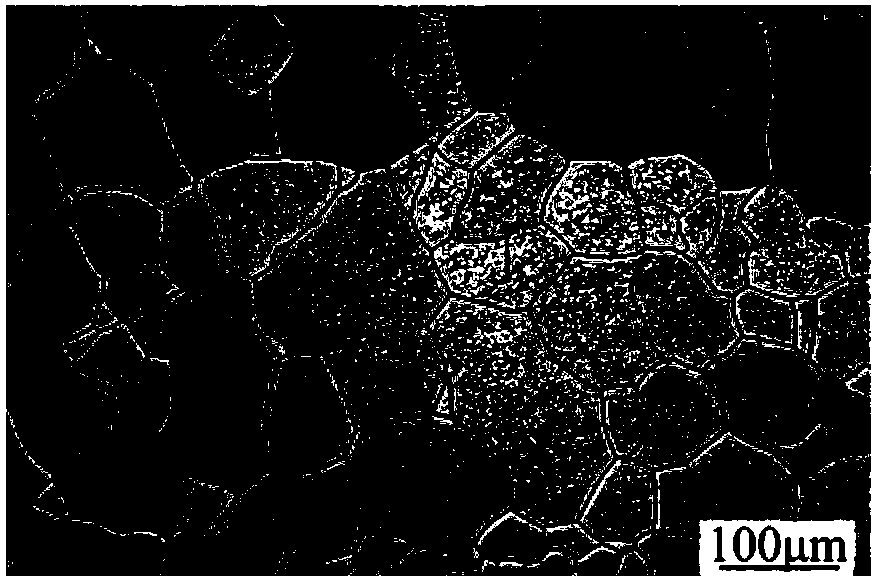

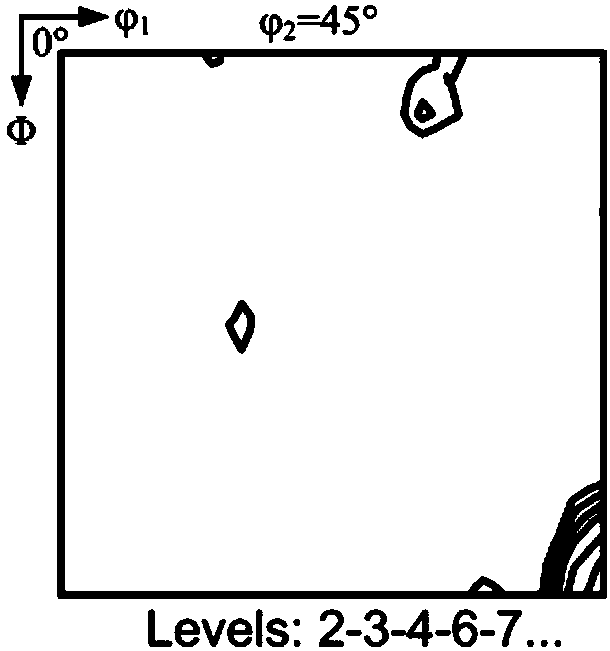

Preparation method of high grade non-oriented silicon steel based on thin-strip casting

The invention belongs to the technical field of metallurgy, and particularly relates to a preparation method of high grade non-oriented silicon steel based on thin-strip casting. The high grade non-oriented silicon steel is prepared from the following chemical components in percentage by weight: less than or equal to 0.004 percent of C, 2.6 to 3.4 percent of Si, 0.1 to 0.4 percent of Mn, 0.4 to 0.8 percent of Al, less than or equal to 0.003 percent of S, less than or equal to 0.003 percent of N and the balance of Fe. The preparation method comprises the following steps: preparing smelted molten steel into a casting strip of 2 to 3 mm through a thin-strip casting machine, and directly rolling at 1000 to 1150 DEG C after 8 to 15 percent of hot rolling; then keeping warm for 10 to 20 minutesat 1000 to 1100 DEG C; carrying out acid pickling and warm rolling, wherein the warm rolling temperature is 200 to 500 DEG C, and the rolling reduction is 70 to 85 percent; carrying out annealing andcoating treatment on a plate coil which is subjected to the warm rolling, thus preparing a non-oriented silicon steel sheet. According to the preparation method disclosed by the invention, the technology is simple, energy consumption and equipment investment are reduced, and meanwhile, an induction value of the high grade non-oriented silicon steel can be remarkably increased.

Owner:NORTHEASTERN UNIV

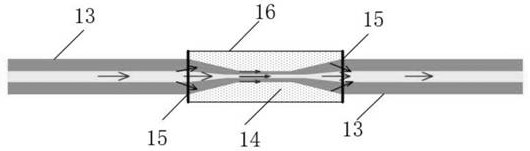

Parallel double M-Z optical fiber magnetic sensing device and manufacturing method thereof

PendingCN112666503AReduce volumeReduce weightMagnetic field measurement using magneto-optic devicesSpectrum analyzerEngineering

The invention discloses a parallel double M-Z optical fiber magnetic sensing device and a manufacturing method thereof. The manufacturing method comprises the following steps of: connecting a port on one side of a first optical fiber coupler with a broadband light source through a single-mode optical fiber, and connecting two ports on the other side with one end of an M-Z magnetic sensing probe and one end of a reference MZ magnetic sensing probe through single-mode optical fibers respectively; the port on one side of the second optical fiber coupler is connected with a spectrum analyzer through the single-mode optical fiber, and two ports on the other side of the second optical fiber coupler are respectively connected with the other end of the M-Z magnetic sensing probe and the other end of the reference M-Z magnetic sensing probe through the single-mode optical fibers; the M-Z magnetic sensing probe is provided with an optical fiber of an interference structure, the optical fiber of the interference structure is sleeved with a closed quartz micro-tube, the closed space between the interior of the quartz micro-tube and the exterior of the optical fiber of the interference structure is filled with magnetic fluid, and an M-Z interferometer is formed in the quartz micro-tube. The magnetofluid is injected into the M-Z optical fiber structure to measure the change of an external magnetic field, and the vernier effect generated by parallel double M-Z interference is utilized to improve the measurement sensitivity and accuracy; the manufacturing process is simple and easy to implement.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

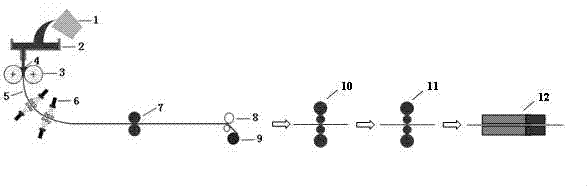

Method for preparing carbon fiber yarns by direct flame carbon deposition

The invention discloses a method for preparing carbon fiber yarns by direct flame carbon deposition and relates to a preparation method of carbon fibers. The method aims to solve the problem that existing method for preparing carbon fibers is complex, relatively high in requirement on production equipment and relatively low in yield of product. The method for preparing the carbon fiber yarns comprises the following steps: I, shearing and moulding a catalyst, washing by anhydrous ethanol and airing to obtained the cleaned catalyst; II, connecting a hydrocarbon fuel gas tank to a combustor by virtue of a breather pipe, fixing a porous bearing part above a nozzle of a combustor, and putting the cleaned catalyst on the porous bearing part to accomplish assembly of the preparation equipment; and III, igniting the combustor, adjusting the flame temperature of the combustor, putting the catalyst on the combusting flame to be combusted and growing the carbon fiber yarns on the catalyst. According to the method disclosed by the invention, the used equipment is simple, and the catalyst is put in the hydrocarbon fuel flame, so that carbon can be quickly deposited on the surface in the flame combustion process under an open system so as to obtain a lot of carbon fibers.

Owner:HARBIN INST OF TECH

Method for preparing high-quality sports rubber running track by utilizing papermaking rubber roller leftover material

InactiveCN106867232AAvoid wastingStable structureGround pavingsBuilding insulationsTO-18Non toxicity

The invention relates to a method for producing a high-quality sports rubber running track by utilizing a papermaking rubber roller leftover material. The rubber running track is prepared from the following effective components in parts by weight: 15 to 20 parts of rubber roller cuttings, 25 to 30 parts of polyurethane prepolymer, 20 to 25 parts of mixed polyether, 10 to 15 parts of polyethylene granules, 8 to 12 parts of pigment, 5 to 8 parts of auxiliary agent, 12 to 18 parts of asphalt and 15 to 20 parts of filler. The rubber running track provided by the invention has the characteristics of turning waste into treasure, aging resistance, exposure resistance, stable structure, good shock absorbing effect, non-toxicity, high elasticity, softness, skid resistance, collision resistance and the like.

Owner:GUANGXI YUEGUI GUANGYE HOLDINGS CO LTD

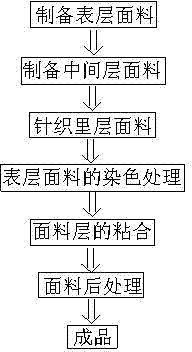

Preparation method for novel insect-resistant fabric

InactiveCN102774059AGood insect repellentImprove breathabilitySynthetic resin layered productsBiotechnologyEngineering

The invention provides a preparation method for a novel insect-resistant fabric. The preparation method includes the following steps: (a) preparation of a surface fabric; (b) preparation of a middle fabric; (c) knitting of an inner fabric; (d) dyeing of the surface fabric; (e) bonding of the layers of the fabric; and (f) aftertreatment of the fabric. The process arrangement of the preparation method for the novel insect-resistant fabric, which is disclosed by the invention, is reasonable, the preparation steps are compact, the cost is moderate, the prepared fabric has excellent insect resistance, and can prevent mosquitoes, mites, fleas and other poisonous insects from harming the human body, moreover, the fabric keeps excellent air permeability and elasticity, the appearance is stylish, and the service performance is excellent.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

Method for manufacturing non-oriented silicon steel plate based on twin-roll thin strip continuous casting technology

Owner:NORTHEASTERN UNIV LIAONING

Preparation process of bamboo floor

InactiveCN107457851AGuarantee processing qualityHigh strengthPlant material mechanical workingWood charring/burningEngineeringBamboo floor

The invention discloses a preparation process of a bamboo floor. The preparation process comprises the following steps of: preparing original bamboo into bamboo chips in same specifications and sizes; planishing the bamboo chips; milling part of bamboo outer skin and tabasheer of the bamboo chips; feeding the bamboo chips into a disinfecting carbon drying machine; carbonizing the bamboo, taking the bamboo out and drying the same; selecting the bamboo chips meeting the splicing conditions; milling the bamboo outer skin and tabasheer of the dried bamboo chips thoroughly; performing hot-press gluing on the plurality of bamboo chips by means of a hot press to form bamboo blank plates; planing the bamboo blank plates, wherein the surfaces of the bamboo blank plates are level; slotting the bamboo blank plates in four surfaces and tenoning the bamboo blank plates at two ends by using a slotting machine to obtain a bamboo floor coarse product; polishing the bamboo floor coarse product by a polishing machine, wherein the bamboo floor coarse product achieves the brightness demand; firstly, spraying paint to the groove and tongue of the bamboo floor coarse product; then successively performing primer coating, photocuring and primer polishing for three times on the surface of the bamboo floor coarse product, separately to obtain a wood floor product.

Owner:蒋红卫

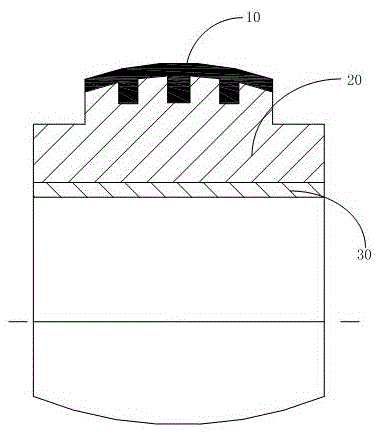

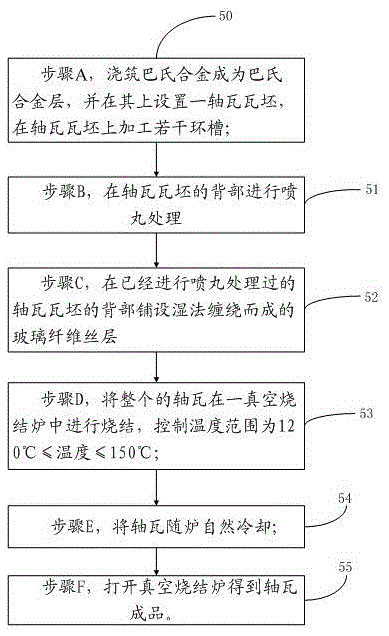

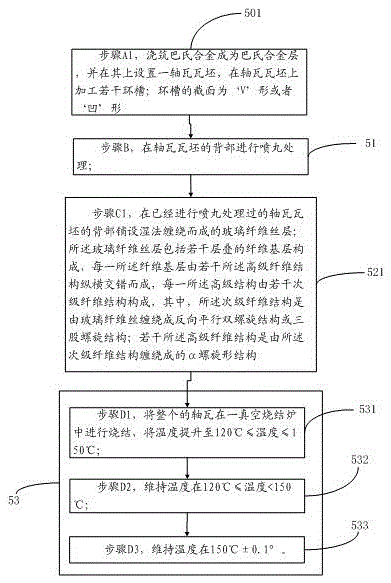

Plain bearing bush insulation structure, bearing bush and manufacturing technology of bearing bush

InactiveCN105485170AImprove insulation performanceGuaranteed uptimeShaftsBearing componentsGlass fiberManufacturing technology

The invention discloses a plain bearing bush insulation structure, a bearing bush and a manufacturing technology of the bearing bush. According to the technical scheme of the bearing bush and the manufacturing technology of the bearing bush, the bearing bush insulation structure with a babbitt metal layer poured is included; a V-shaped groove is further included; or, a fiber glass filament layer of 1 mm to 2 mm is arranged.; or, a teflon layer is arranged on the outer surface of the fiber glass filament layer; or, a primary fiber structure is composed of a plurality of secondary fiber structures, and a plurality of stacked filter base layers are included. The defects that a traditional insulation bearing is isolated from a bearing bush through teflon film pasting to cut off a shaft current path, consequently, an insulation film is quite prone to being damaged in the mounting and maintaining process, the repair technology adopted after damage is quite complex, a dedicated tool is needed, and consequently, maintaining difficulty, equipment scraping and the like are caused are overcome. The plain bearing bush insulation structure, the bearing bush and the manufacturing technology of the bearing bush are suitable for insulation plain bearing bushes adopted in various projects, and especially suitable for insulation of plain bearing bushes of matched large rotary machines in the industries such as mines, electric power, coal mines, metallurgy, traffic, chemical engineering, water conservancy, machine tools and chips.

Owner:HUNAN CHONGDE IND TECH

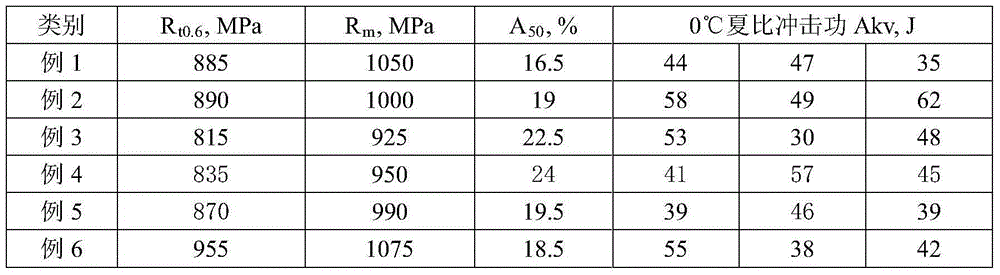

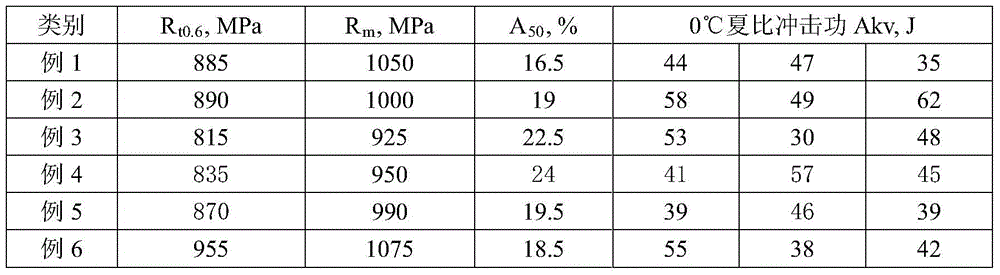

P110 externally-thickened oil well tube and manufacturing method thereof

ActiveCN104419868AAvoid risk of failureAvoids problems prone to strength softening zonesPunchingHeating time

The invention discloses a P110 externally-thickened oil well tube and a manufacturing method thereof. The P110 externally-thickened oil well tube is prepared from 0.22%-0.32% of C, 0.15%-0.45% of Si, 1.00%-1.50% of Mn, not greater than 0.03% of P, not greater than 0.03% of S, and the balance of Fe and inevitable impurities. The manufacturing method of the P110 externally-thickened oil well tube comprises the following steps of performing converter smelting, performing external refining, performing billet continuous casting, performing round billet rolling, heating round billets in a ring-shaped furnace, performing tube penetrating in a fungoid type punching machine, rolling the tube in a continuous tube rolling machine, heading and externally thickening the tube end, and performing electric-induction quenching-and-tempering heat treatment. According to the P110 externally-thickened oil well tube and the manufacturing method thereof disclosed by the invention, low-cost C-Mn steel is adopted as a round billet raw material, and noble metals are not added, so that the alloy cost is low; moreover, the steel tube heating time is short, the efficiency is high, the energy is saved and, the consumption is reduced, and the manufacturing period is shortened.

Owner:ANGANG STEEL CO LTD

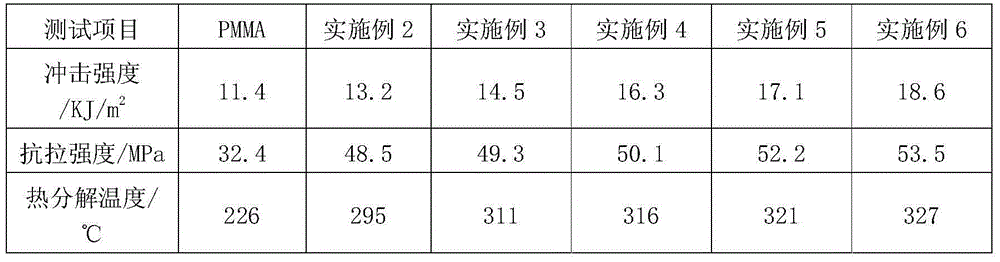

Nano-zirconia-PMMA (polymethyl methacrylate) composite material and preparation method thereof

InactiveCN104558448AThe preparation process is compactEasy to controlMethyl methacrylateIn situ polymerization

The invention discloses a nano-zirconia-PMMA (polymethyl methacrylate) composite material. The nano-zirconia-PMMA composite material is characterized by being prepared from MMA (methl methacrylate) monomers and modified nano-zirconia through in-situ polymerization, wherein modified nano-zirconia adopts coupling agent surface modified nano-zirconia; a grafting ratio of PMMA on the surface of modified nano-zirconia is not lower than 19%; and the composite material comprises the raw materials in parts by mass as follows: 3-15 parts of modified nano-zirconia and 28-54 parts of MMA monomers. The invention further provides a preparation method of the composite material. According to the composite material prepared with the in-situ polymerization method, force, strength and heat resistance are remarkably improved, and the composite material can be used in the fields of plastics, rubber, adhesives and the like.

Owner:广州高馨能生物科技有限公司

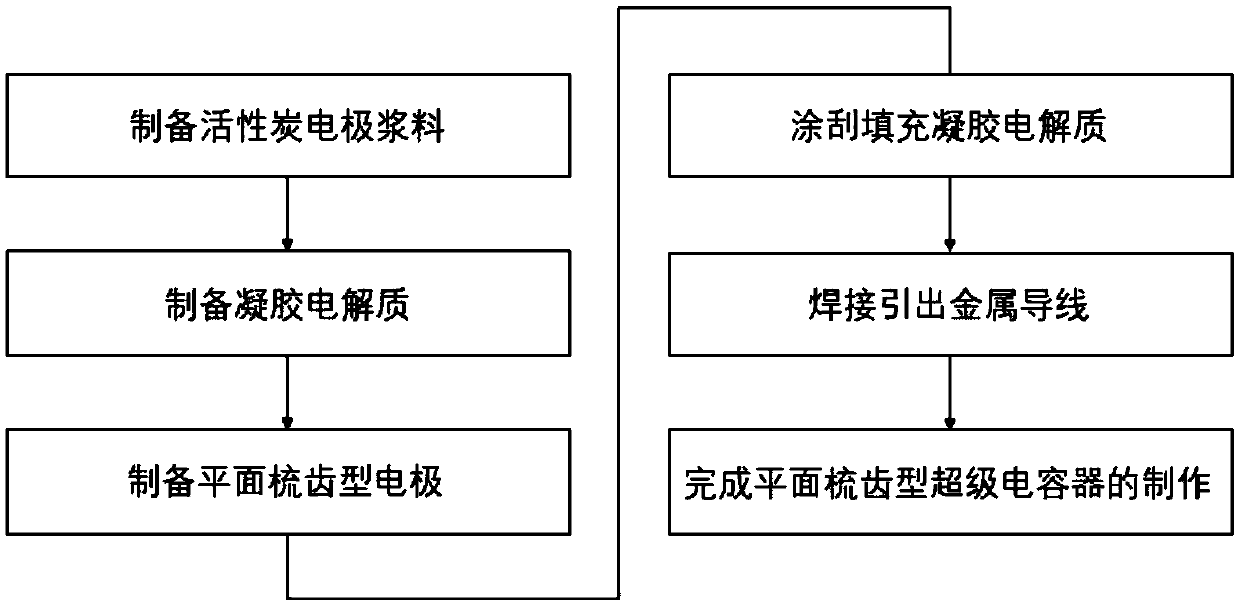

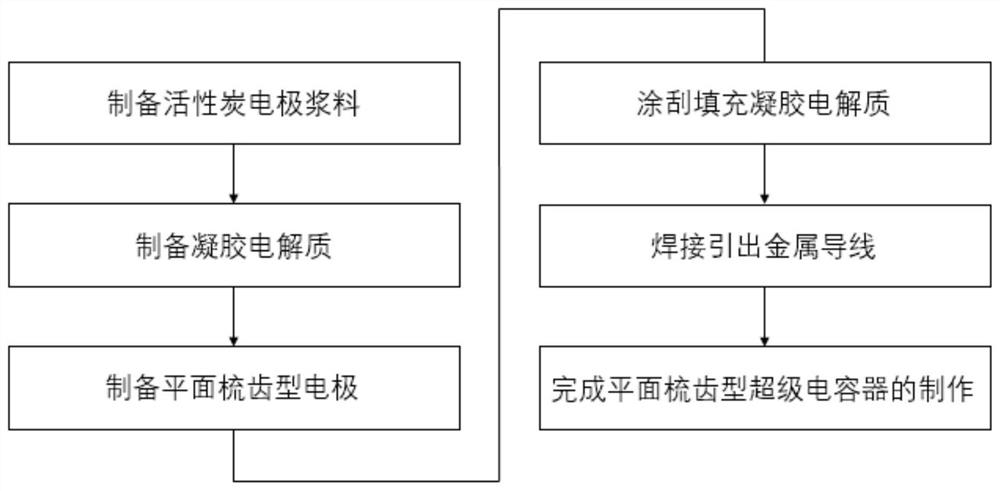

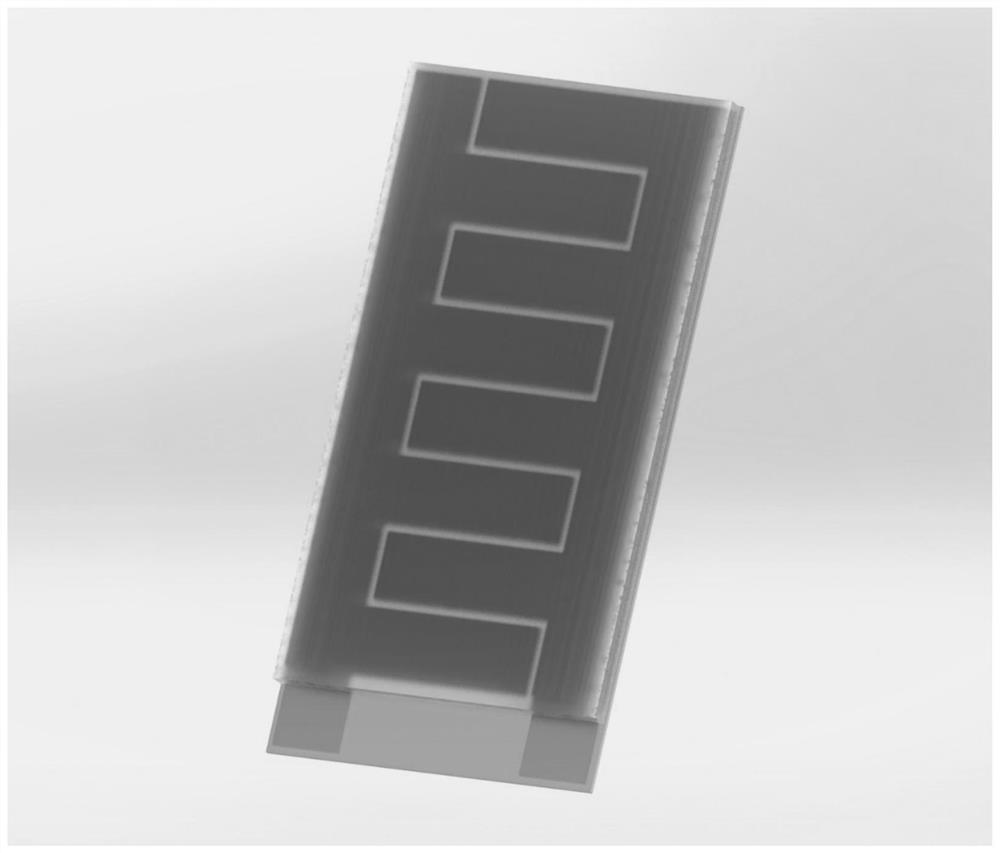

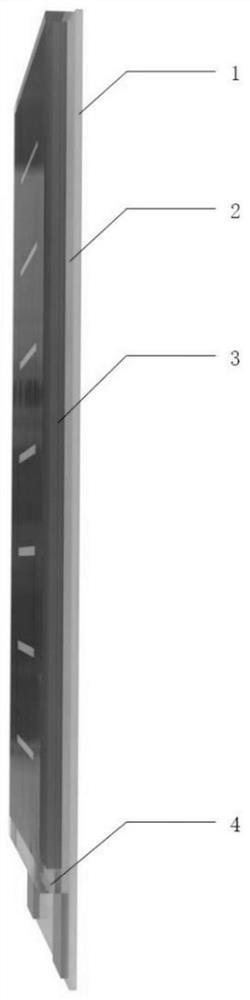

Manufacturing method of planar comb teeth type super capacitor

The invention provides a manufacturing method of a planar comb teeth type super capacitor, and belongs to the technical field of energy storage equipment. The manufacturing method of a planar comb teeth type super capacitor coats a comb teeth type metal copper layer printed on a flexible PCB with mixed slurry of active carbon, conductive agent and binder through screen printing, thus effectively solving the problem that when the active electrode materials are attached to the comb teeth type current collector with small pitch comb of in the pitch, the contact between the two electrode materialsis liable to cause a short circuit, and can precisely control the thickness of the active materials by changing the thickness of the metal mesh used in the screen printing process, thus greatly simplifying the manufacturing process of the planar comb teeth type super capacitor, and significantly improving the consistency of the specification parameters of the mass-produced planar comb teeth typesuper capacitors. The manufacturing method of a planar comb teeth type super capacitor has the advantages of simple manufacturing process, strong operability, low cost, high safety, stable performanceand high product yield, solves the problem that the existing method has a complex process, poor reliability, high cost and the like, and is suitable for industrial applications and market promotion,especially for the field of micro-energy and flexible electronics.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation process of bamboo floor

ActiveCN104085031BGuarantee processing qualityHigh strengthWood veneer joiningWood charring/burningMaterials preparationCarbonization

The invention discloses a bamboo floor preparation process. The bamboo floor preparation process includes the following steps of firstly, material preparation, secondly, rough milling, thirdly, cooking and carbonization, fourthly, drying, fifthly, manual selection, sixthly, finish milling, seventhly, splicing and pressing, eighthly, planing, tenthly, end-face tenoning, eleventhly, polishing and twelfthly, paint spraying. In the material preparation step, purchased raw bamboo is truncated and sliced into bamboo slices of the same specification and the same size; in the rough milling step, bamboo joints are planished, and part of bamboo outer skin and tabasheer of the bamboo slices are milled and removed; in the cooking and carbonization step, sugar and fat in the bamboo slices are removed; in the drying step, the bamboo slices are dried with the moisture content smaller than 7%; in the manual selection step, the bamboo slices meeting the splicing condition are selected; in the finish milling step, the bamboo outer skin and the tabasheer of the dried bamboo slices are completely milled and removed; in the splicing and pressing step, the bamboo slices are glued in a hot-press mode through a hot press, and then a bamboo blank is formed; in the planing step, the bamboo blank is planed, so that the surface of the bamboo blank is smooth; in the polishing step, a crude bamboo floor is polished through a polishing machine; in the paint spraying step, paint is sprayed to rabbets of the crude bamboo floor, then three times of priming paint coating, photocuring and priming paint polishing are sequentially and respectively conducted on the surface of the crude bamboo floor, and a finished bamboo floor is acquired. The bamboo floor prepared through the process has enough strength and rigidity, and is not prone to getting mildew and further capable of effectively resisting moths.

Owner:贵州新锦竹木制品有限公司

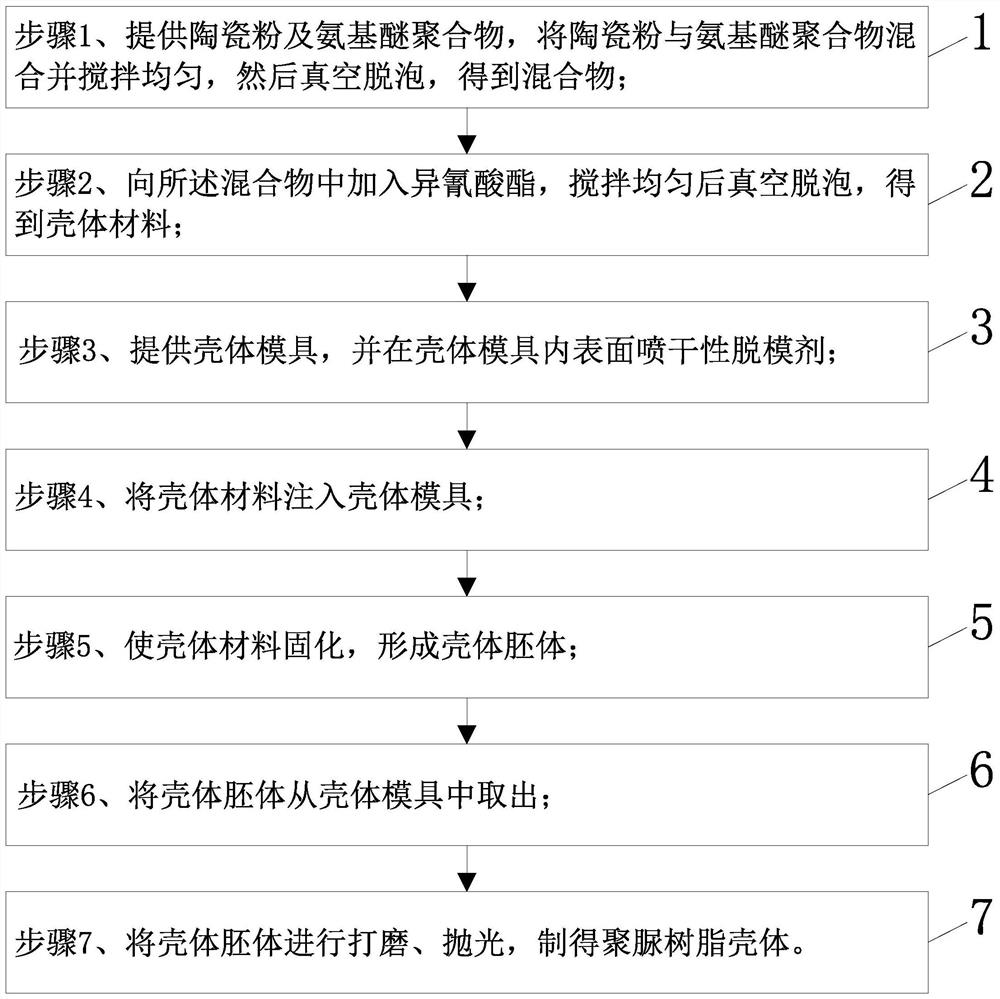

Polyurea resin shell and manufacturing method thereof

The invention provides a polyurea resin shell and a manufacturing method thereof. Materials of the polyurea resin shell comprise ceramic powder, isocyanate and an amino ether polymer, so that the polyurea resin shell can be used as a protective shell of a product, particularly can be used as a rear shell of a mobile phone, has enough strength and hardness, can protect the mobile phone, avoid damage to internal components and prolongs the service life of the mobile phone, and is low in price and good in use hand feeling. According to the manufacturing method of the polyurea resin shell, the ceramic powder, the isocyanate and the amino ether polymer are adopted as raw materials to manufacture a shell material, then the shell material is cured, ground and polished to obtain the polyurea resin shell, and after grinding and polishing, the polyurea resin shell can be smooth in surface and good in using hand feeling and cannot scratch a product. The manufacturing process is simple, and the cost is low. The shell material obtained in the manufacturing process is good in consistency, so that the prepared polyurea resin shell is compact in structure and excellent in performance.

Owner:深圳市宏通新材料有限公司

Method for preparing high-purity white carbon black from silicon-containing raw material

The invention discloses a method for preparing high-purity white carbon black from a silicon-containing raw material. The method specifically comprises the following steps: sufficiently stirring and uniformly mixing the silicon-containing raw material and sodium hydroxide to obtain a mixed raw material; carrying out oxidization roasting on the mixed raw material; then carrying out high-pressure leaching and filtering to obtain filtrate; diluting the filtrate with pure water to obtain high-purity sodium silicate; adding a chemical agent into the high-purity sodium silicate; and carrying out deposition, filtering and drying to, and calcining to obtain the high-purity white carbon black. The method disclosed by the invention comprises two processes of preparing the high-purity sodium silicateand preparing the white carbon black; sulfuric acid is not used in a whole process, so that the method is more environmentally friendly; the method has the advantages of novel route, great raw material selectivity and compact preparation technology; and the white carbon black prepared by the method has the advantages of extremely high purity, extremely stable quality and controllable impurity variety and content.

Owner:LONGZHOU WANHE TRADING CO LTD

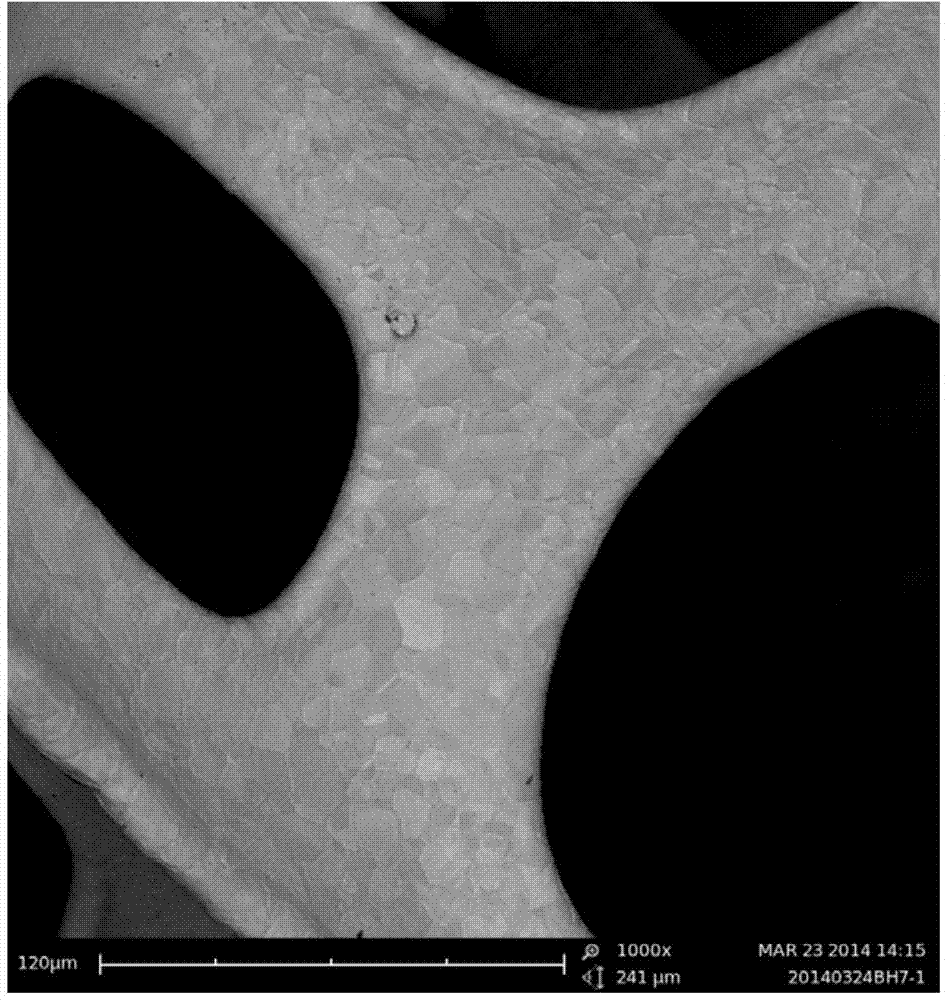

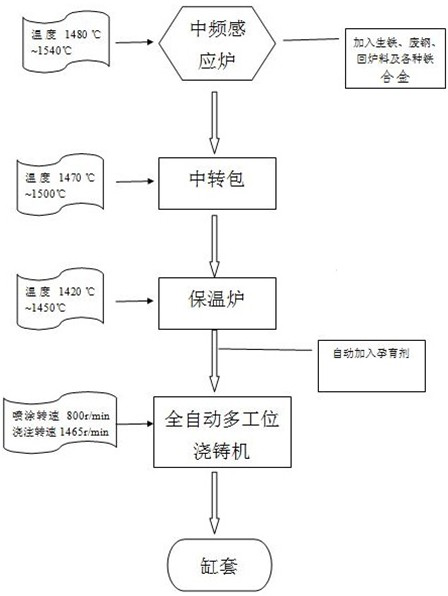

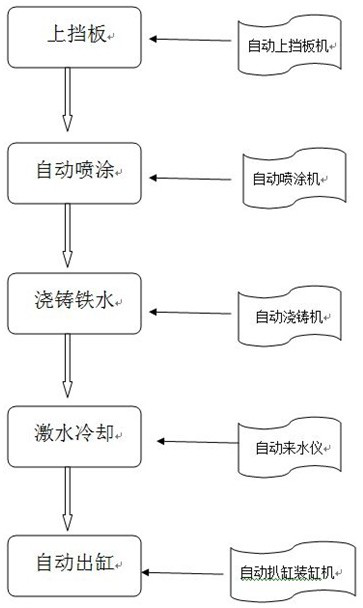

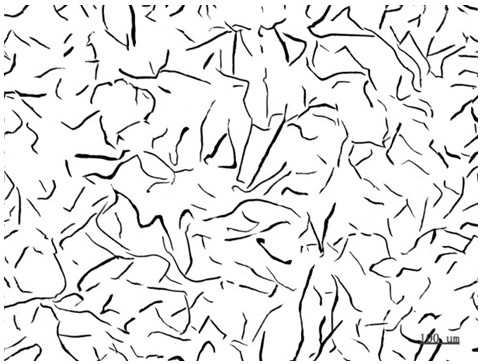

A kind of vanadium-titanium alloy gray cast iron cylinder liner and preparation method thereof

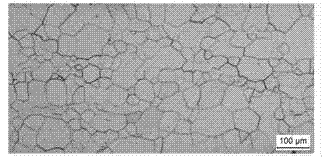

ActiveCN111455264BEvenly distributedHigh degree of automationProcess efficiency improvementTitaniumGraphite

The present invention provides an alloy gray cast iron cylinder liner, the alloy gray cast iron cylinder liner contains vanadium and titanium elements; the metallographic structure of the alloy gray cast iron cylinder liner includes graphite and vanadium-titanium phases; The matrix structure of the alloy gray cast iron includes pearlite; the amount of the pearlite is greater than 98%; and the proportion of the fine plate pearlite in the pearlite is greater than or equal to 98%. The alloy gray cast iron cylinder liner provided by the invention has a high proportion of fine pearlite, uniform vanadium-titanium phase structure distribution and a large number. The matrix structure of the vanadium-titanium alloy gray cast iron cylinder liner has a large proportion of pearlite, especially thin flake pearlite. The proportion of the body can reach 100%, and the distribution of the vanadium-titanium phase structure is more uniform, the quantity is large, the impurity content is low, it has the characteristics of high strength and good wear resistance, and at the same time, the process automation is high, the process is compact and more stable, and the product quality is stable. , which greatly reduces labor costs and production costs, and is more suitable for industrial promotion and use.

Owner:ZYNP GRP

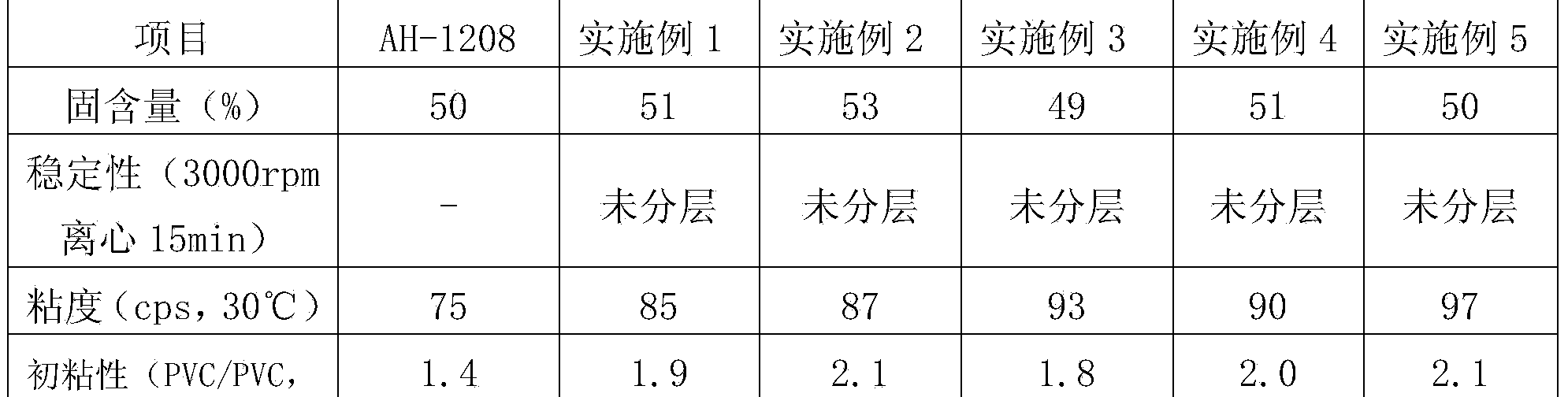

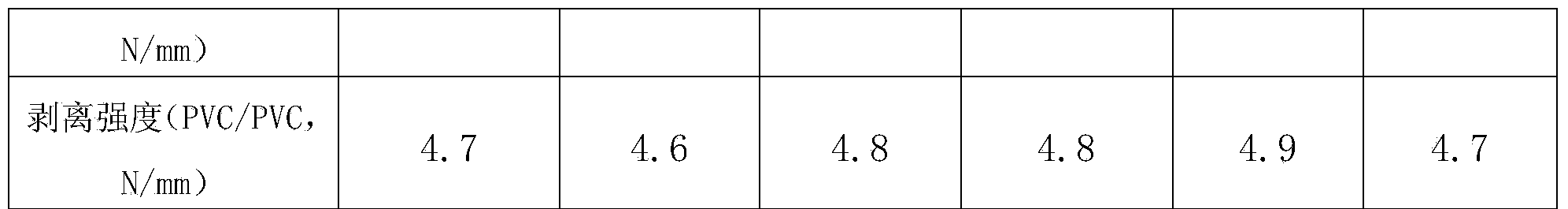

High-initial-adhesion waterborne polyurethane adhesive and preparation method thereof

InactiveCN103421462BMeet initial tack requirementsGreat operating flexibilityPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses high-initial-adhesion waterborne polyurethane adhesive and a preparation method thereof. The preparation method includes: adding 78-82 parts of polyester polyol and 0.8-1.3 parts of 1, 4-butanediol into a reactor, evacuating, cooling, adding 0.002-0.06 part of catalyst, 10-12 parts of isophorone diisocyanate and 2.5-2.9 parts of hexamethylene diisocyanate, heating up, adding butanone after 0.5-0.8h of reaction, allowing for continuous reaction, adding 1.2-2 parts of isophorone diisocyanate and 0.3-0.5 part of hexamethylene diisocyanate to allow for reaction for 0.4-0.6h, cooling, adding solvent acetone, adding hydrophilic chain extender, and allowing for reaction to discharge a product, high-initial-adhesion waterborne polyurethane adhesive which is larger than or equal to 1.9N / mm in initial adhesion. The high-initial-adhesion waterborne polyurethane adhesive has the advantages that initial adhesion and solid content of the waterborne polyurethane adhesive are increased, comprehensive performances are excellent, and the adhesive is suitable for adhering shoe materials, leathers and PVC boards.

Owner:SOUTH CHINA UNIV OF TECH

A kind of preparation method of planar comb type supercapacitor

ActiveCN109659164BThe production process is simpleLow costHybrid/EDL manufactureFlexible electronicsMaterials science

The invention provides a manufacturing method of a planar comb teeth type super capacitor, and belongs to the technical field of energy storage equipment. The manufacturing method of a planar comb teeth type super capacitor coats a comb teeth type metal copper layer printed on a flexible PCB with mixed slurry of active carbon, conductive agent and binder through screen printing, thus effectively solving the problem that when the active electrode materials are attached to the comb teeth type current collector with small pitch comb of in the pitch, the contact between the two electrode materialsis liable to cause a short circuit, and can precisely control the thickness of the active materials by changing the thickness of the metal mesh used in the screen printing process, thus greatly simplifying the manufacturing process of the planar comb teeth type super capacitor, and significantly improving the consistency of the specification parameters of the mass-produced planar comb teeth typesuper capacitors. The manufacturing method of a planar comb teeth type super capacitor has the advantages of simple manufacturing process, strong operability, low cost, high safety, stable performanceand high product yield, solves the problem that the existing method has a complex process, poor reliability, high cost and the like, and is suitable for industrial applications and market promotion,especially for the field of micro-energy and flexible electronics.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

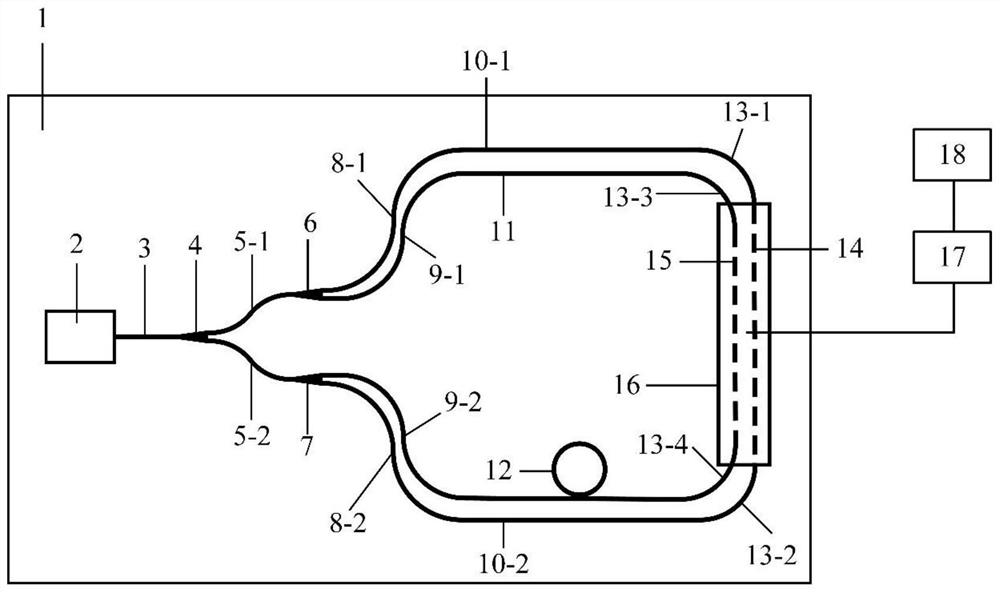

Integrated Optical Autocorrelator Based on Transverse Double Frequency Effect of Two-dimensional Materials

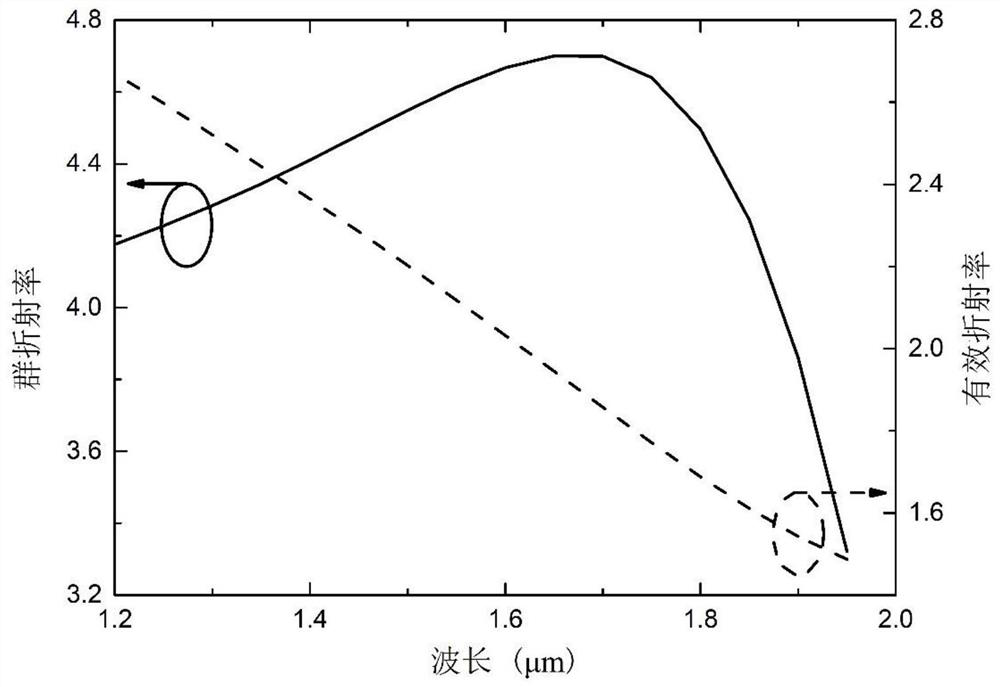

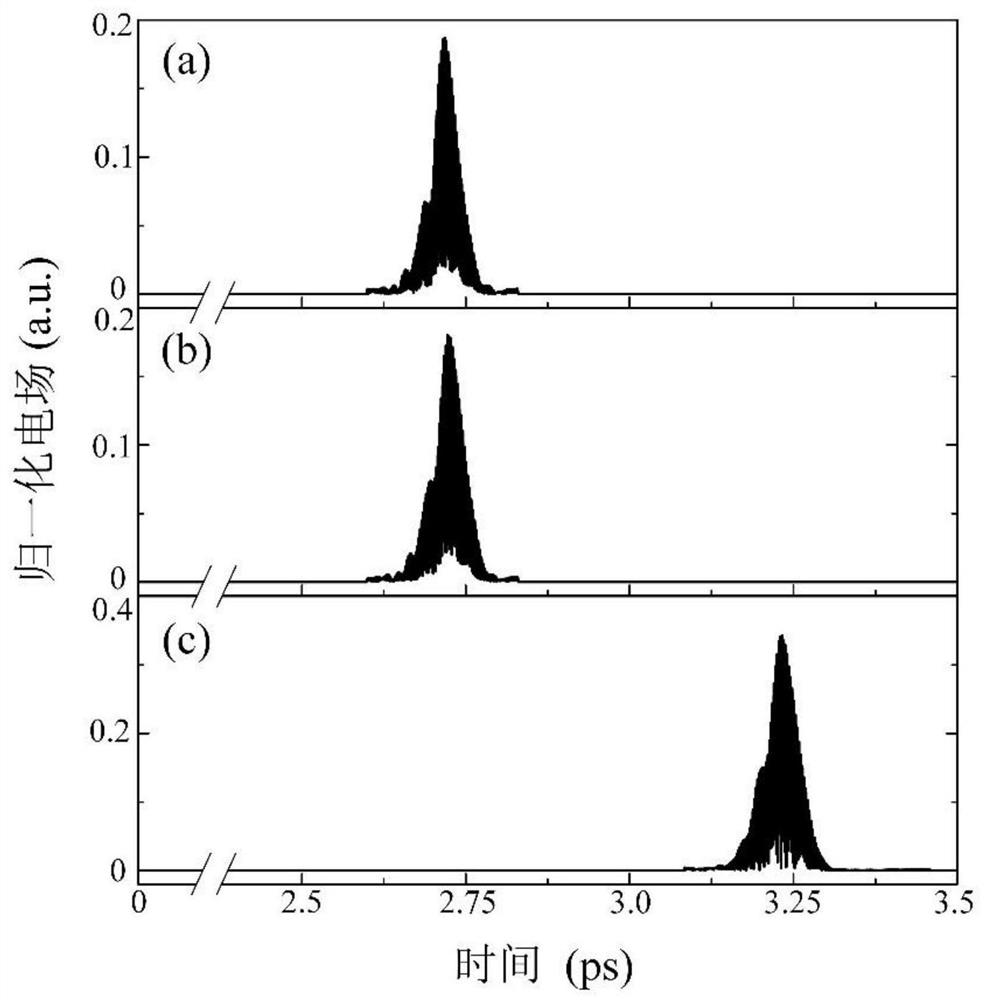

ActiveCN111637980BHighly integratedImprove time resolutionCoupling light guidesOptical waveguide light guideBeam splitterGrating

The invention discloses an integrated optical autocorrelator based on the transverse doubling frequency effect of two-dimensional materials, comprising a substrate, an on-chip coupling system integrated on the substrate, a two-dimensional material film, a convex lens and an imaging camera; the on-chip coupling system includes a grating Coupler, three 1×2 beam splitters with a beam splitting ratio of 50:50, the first S-shaped waveguide, the second S-shaped waveguide, the third S-shaped waveguide, the fourth S-shaped waveguide, and the first arc-shaped waveguide , the second arc-shaped waveguide, the third arc-shaped waveguide, the fourth arc-shaped waveguide, the first straight waveguide and the second straight waveguide; the two-dimensional material film is a single-layer film with second-order nonlinear effect, and the two-dimensional The material film completely covers the first straight waveguide and the second straight waveguide, and the frequency-doubled light excited by the two-dimensional material film enters the imaging camera through the convex lens for imaging. The invention has high time resolution and greatly improves the integration degree of the on-chip coupling system, and can save the delay device commonly used in the prior art, and has low cost and wide application range.

Owner:ZHEJIANG UNIV

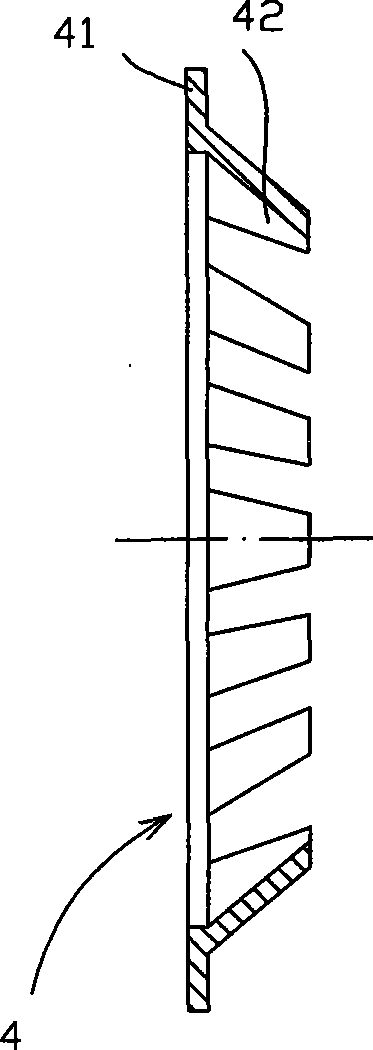

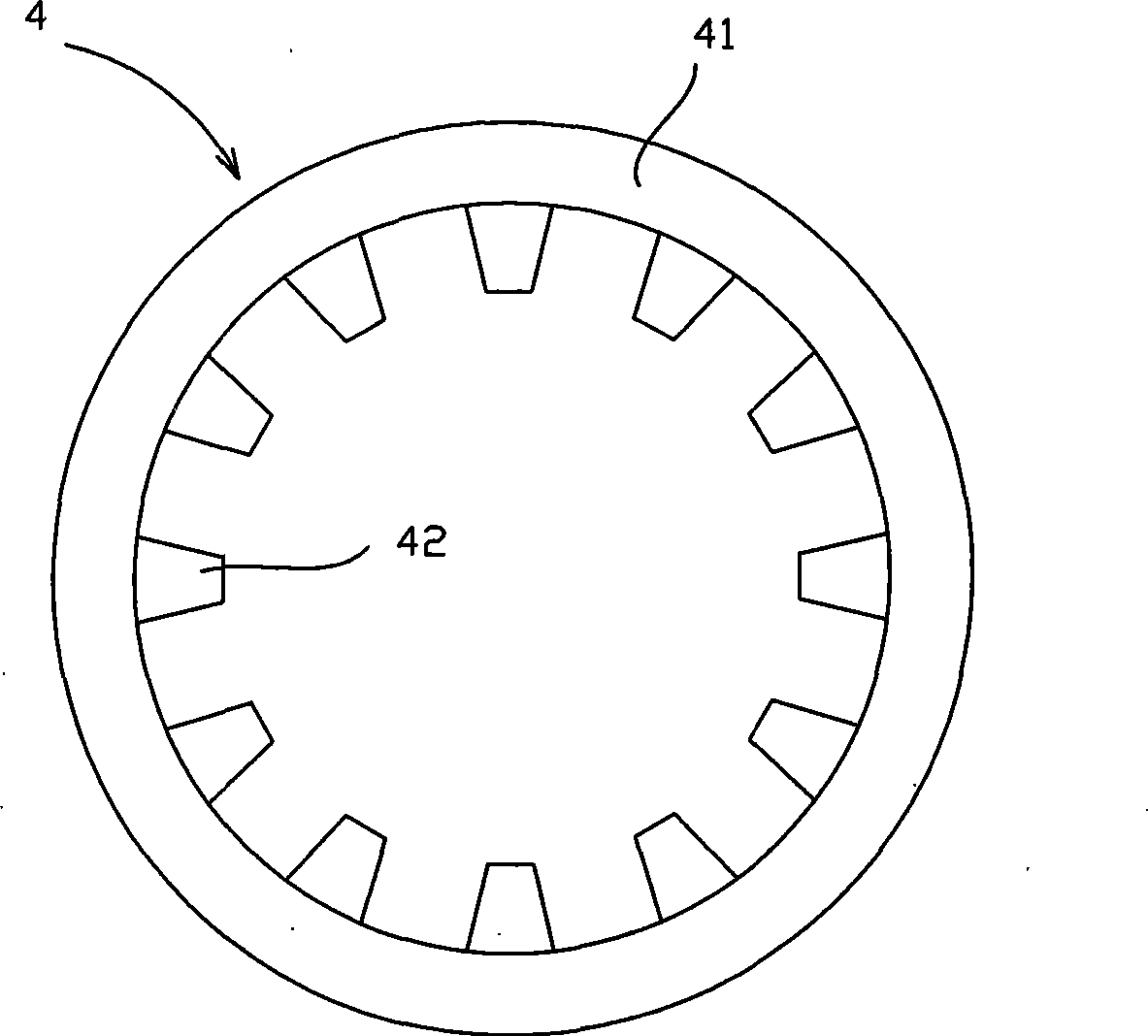

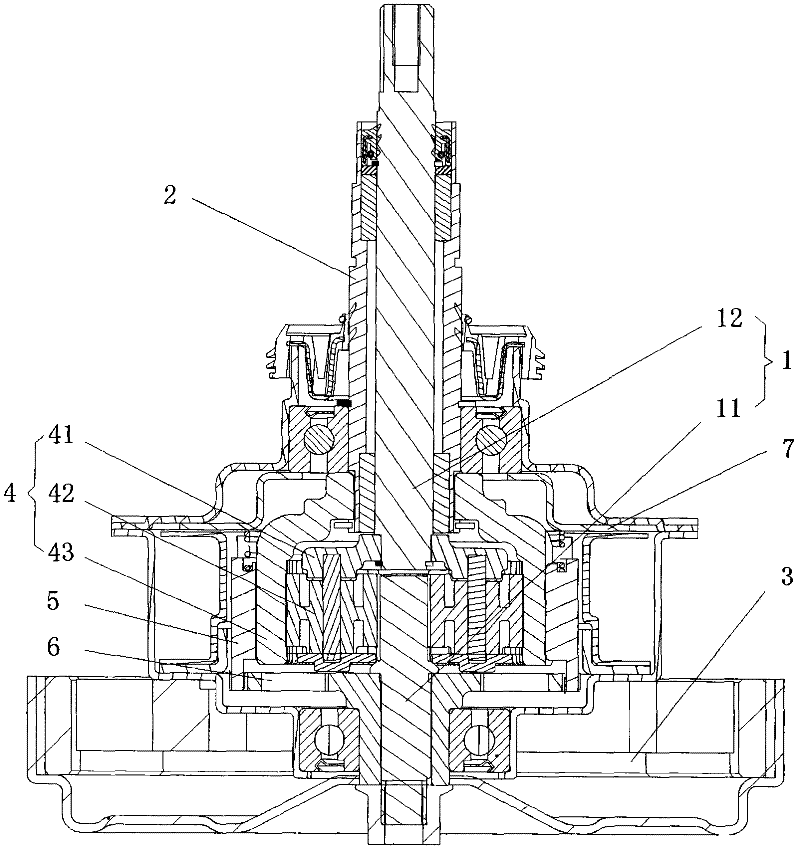

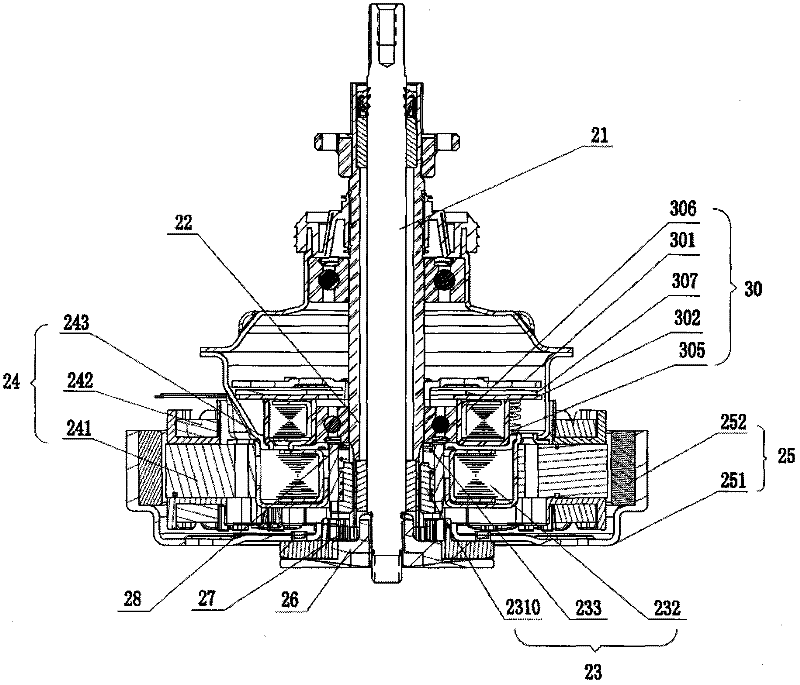

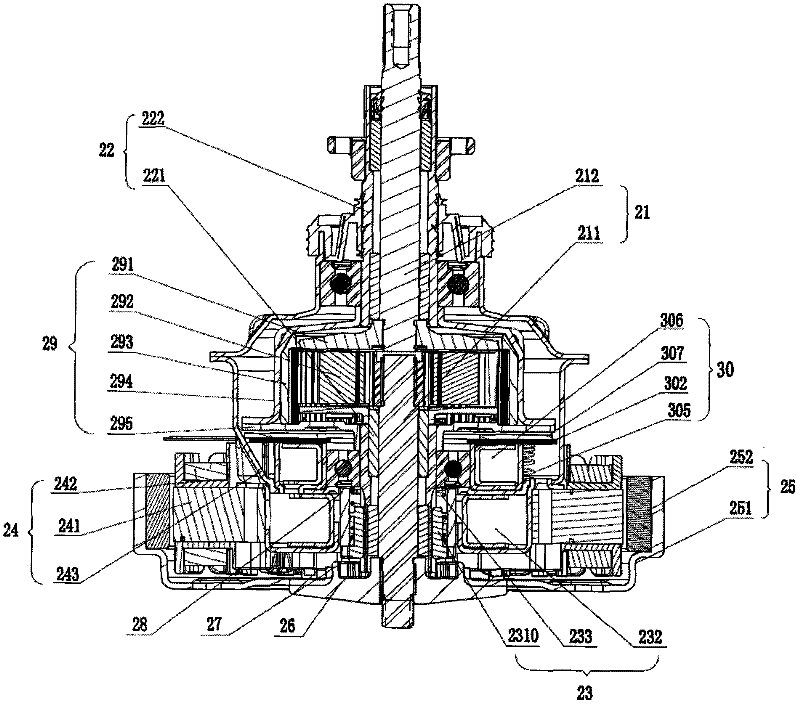

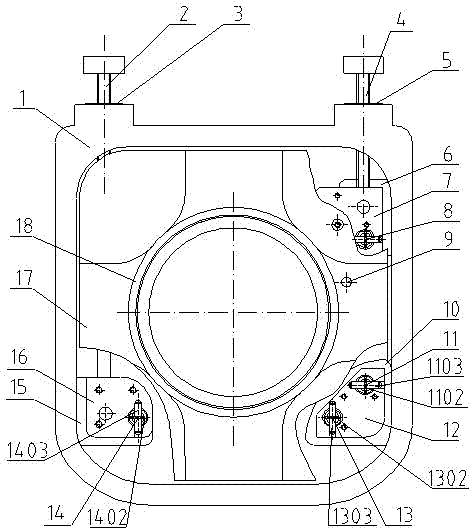

Transmission device of washing machine

InactiveCN102206914BReduce volumeReduce weightOther washing machinesTextiles and paperLaundry washing machineClutch control

The invention relates to a part of a washing machine, in particular to a transmission device of the washing machine. The transmission device comprises a drive shaft, a drive shaft sleeve, a clutch, a stator component, a rotor component and a brake mechanism, wherein the drive shaft is rotatably arranged in the drive shaft sleeve; the clutch controls the rotation of the drive shaft and the drive shaft sleeve; the stator component is positioned in the rotor component; the rotor component is fixedly connected with one end of the drive shaft through a coupler; the clutch comprises a sliding pieceand an electromagnetic coil positioned outside the sliding piece; the sliding piece can be meshed with the external teeth of the drive shaft sleeve in a vertical sliding mode; a meshing part which can be meshed with the sliding piece is arranged at the joint of the rotor component and the drive shaft; the stator component is provided with a meshing part which can be meshed with the sliding piece;the brake mechanism comprises a brake plate, a brake disc and a brake disc retainer; and the brake plate is fixedly connected with the drive shaft sleeve. The transmission device has a simple and compact structure, small volume and low manufacturing cost, and is flexibly controlled.

Owner:CHANGZHOU MASTER MACHINERY

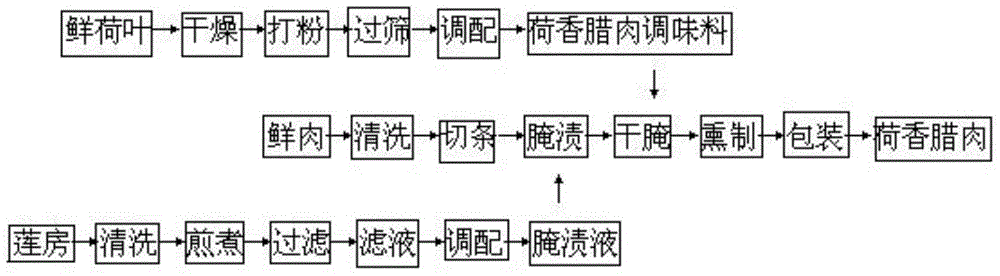

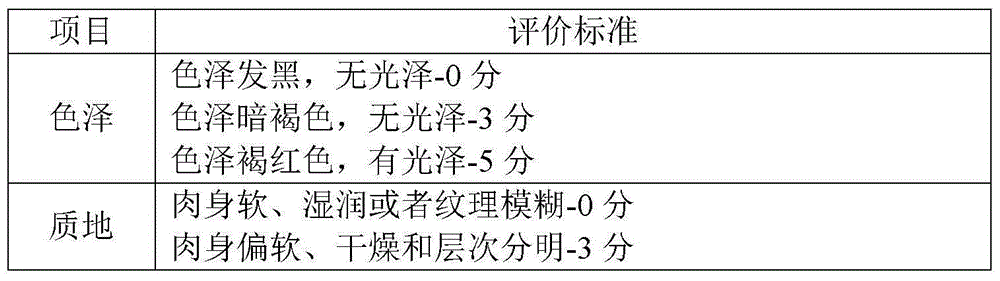

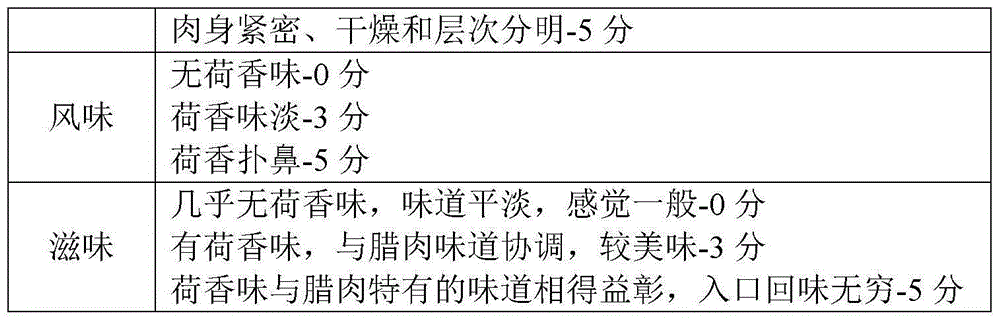

Preparation method of lotus-flavored bacon

ActiveCN103637153BSimple preparation processThe preparation process is compactFood preparationSugarDorycnium herbaceum

The invention relates to the technical field of processing of meat products, and in particular relates to a preparation method for lotus-flavor preserved meat. A lotus-flavor preserved meat seasoning is used for the method, and comprises the following components in parts by weight: 50 to 70 parts of lotus leaf powder, 4 to 6 parts of salt, 1 to 3 parts of white granulated sugar, 2 to 4 parts of pepper powder, 6 to 12 parts of red chilli powder, 1 to 3 parts of star aniseed powder, 1 to 3 parts of ground cinnamon and 10 to 20 parts of cooking wine. The preparation method comprises the steps of preparation of a lotus seed pot curing solution, curing of fresh meat, dry-curing, smoking and the like. The preparation method for the lotus-flavor preserved meat is easy to operate and convenient to implement; lotus seed pot, lotus leaves and lotus petioles are fully utilized as raw auxiliaries; the prepared lotus-flavor preserved meat has bright color and luster, close texture, dry meat body, distinct layers and tangy lotus flavor, tastes fat but not greasy and thin but not stiff, can leave a rich aftertaste, and is nutrient-rich.

Owner:重庆百农网投资有限公司

Pipe connector

Owner:佛山市立联吉管业科技有限公司

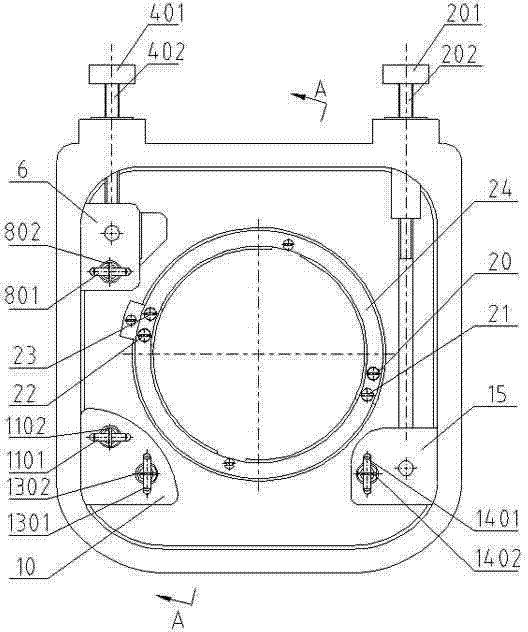

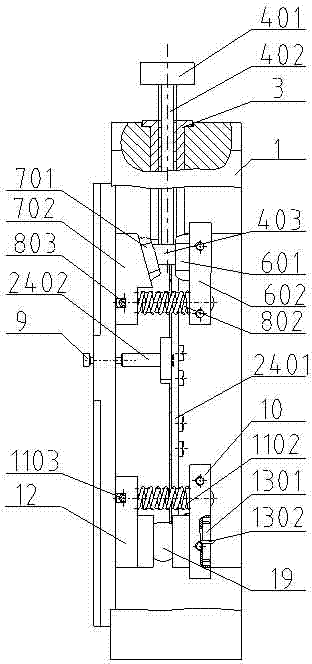

Two-degree-of-freedom fine moving and tuning adjusting rack

InactiveCN102854599BEasy to installEasy to install and adjustMountingsControl theoryMechanical engineering

A two-degree-of-freedom fine-tuning adjustment frame includes a housing, a lens, a movable block, and a lens clamping assembly. The two sides of the lens are symmetrically provided with a first adjustment rod and a second adjustment rod perpendicular to the axis of the housing. The third adjustment assembly and the fourth adjustment assembly are fixed on the front and rear sides of the lower end of the first adjustment rod, and the fourth adjustment assembly is provided with a fourth reset assembly connected with the third adjustment assembly; the upper part of the second adjustment rod and the second adjustment rod The first adjustment assembly and the second adjustment assembly are fixed on the front and rear sides, the second adjustment assembly is provided with the first reset assembly connected with the first adjustment assembly, and the second adjustment rod is fixed with the second adjustment rod on the front and rear sides of the lower end of the second adjustment rod. A positioning block and a second positioning block, the second positioning block is respectively provided with a second reset assembly and a third reset assembly connected to the first positioning block; the structure is simple, the cost is low, the reset accuracy is high, and it can be reset in a small The two-dimensional rotation adjustment of the mechanism can be realized in the same direction in the space.

Owner:CHINA UNIV OF MINING & TECH

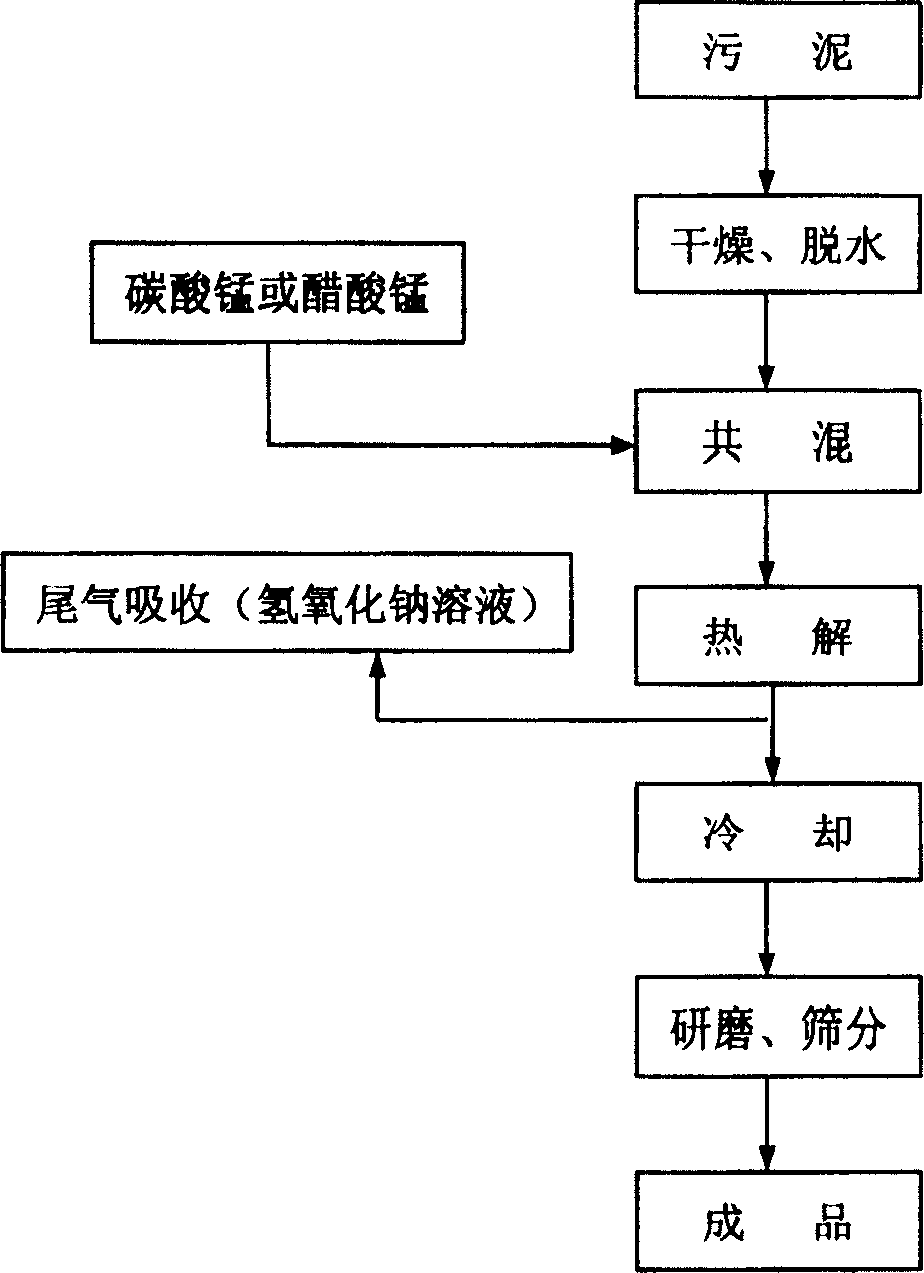

Method for preparing mud adsorbent used for desulfurization of flue-gas

InactiveCN100348309CImprove desulfurization effectGuaranteed desulfurization effectOther chemical processesSludge treatment by pyrolysisSorbentFlue gas

Owner:NANJING UNIV OF SCI & TECH

A p110 externally thickened oil well pipe and its manufacturing method

ActiveCN104419868BAvoid risk of failureAvoids problems prone to strength softening zonesPunchingHeating time

Owner:ANGANG STEEL CO LTD

White graphene fluorescent fiber and preparation method thereof

PendingCN113802206AThe preparation process is compactExcellent fluorescence performanceElectro-spinningMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a white graphene fluorescent fiber and a preparation method thereof. The preparation method comprises the steps that step 1, resin powder is taken and added into a solution; step 2, white graphene powder is added into the resin powder, a first additive is added, and stirring is carried out; step 3, a dispersing agent is added for being continuously stirred; step 4, a second additive is added into fluorescent powder, heating and stirring are carried out; step 5, the fluorescent powder mixture obtained in the step 4 is added into the mixture obtained in the step 3, and stirring is carried out while the temperature is kept to obtain a spinning solution; step 6, heat preservation and standing are carried out on a spinning stock solution, and vacuumizing is carried out to remove bubbles to obtain a spinning solution; step 7, the spinning solution is sucked into an injector for spinning; and step 8, process parameters are set, and uniform and continuous fluorescent fibers are prepared. The invention further provides the white graphene fluorescent fiber prepared by the method. The fluorescent fiber is better in fluorescent effect, more stable and long in service life, and further has the advantages of being excellent in mechanical property, not prone to being broken and the like.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Ferroelectric thin-membrane phase shifter and preparation thereof

InactiveCN101335371BSimple preparation processImprove Modulation CapabilitiesWaveguide type devicesCapacitanceManufacturing technology

Owner:HENAN UNIV OF SCI & TECH

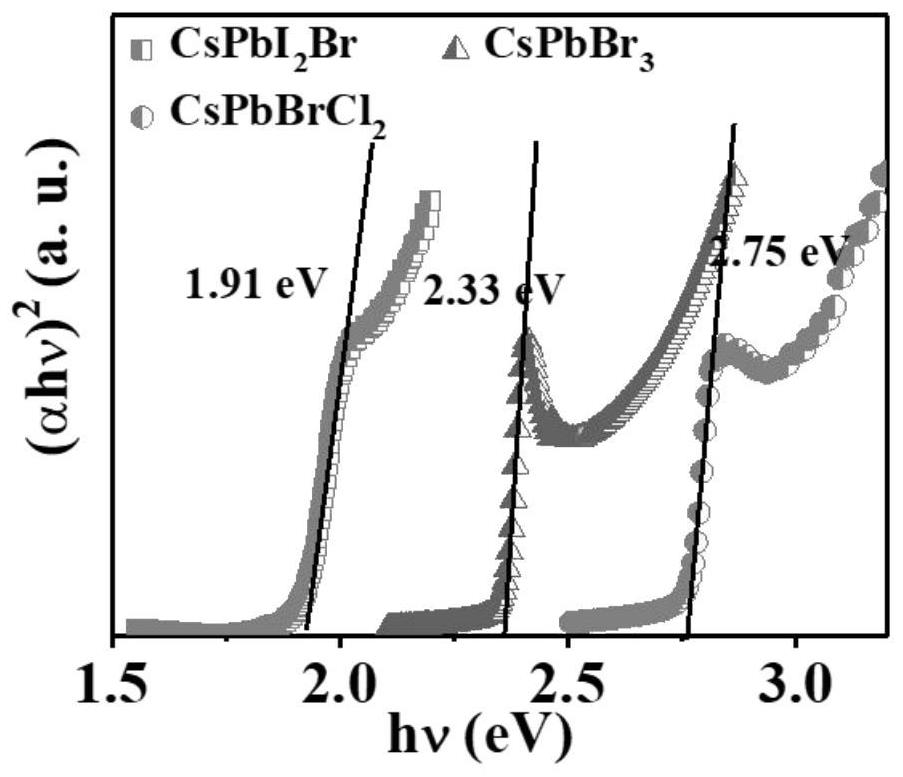

Diode type photoelectric sensor and preparation method thereof

PendingCN114050219AImprove photoelectric performanceGood lookingSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneOrganic semiconductor

The invention provides a diode type photoelectric sensor, which comprises a substrate, a perovskite film layer, an organic semiconductor layer and electrodes, wherein the perovskite film layer is arranged on a part of the upper surface of the substrate, the perovskite film layer is prepared by adopting a chemical vapor deposition method, the material of the perovskite film layer comprises lead halide and cesium halide, a molar ratio of the lead halide to the cesium halide is 1: 1, a part of the organic semiconductor layer is arranged on the upper surface of the substrate, the rest part of the organic semiconductor layer is arranged on the upper surface of the perovskite film layer, and the electrodes comprise a positive electrode and a negative electrode, so that the problems that in the prior art, a diode type photoelectric sensor is complex in preparation process, prone to electric leakage and large in dark current, only light intensity detection can be achieved, and light color information cannot be obtained are solved. The invention also provides a preparation method of the diode type photoelectric sensor.

Owner:FUDAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com