Transmission device of washing machine

A transmission device, washing machine technology, applied in washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of lack of integrity, high preparation cost, inconvenient use, etc., and achieve simple and compact, long service life, compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

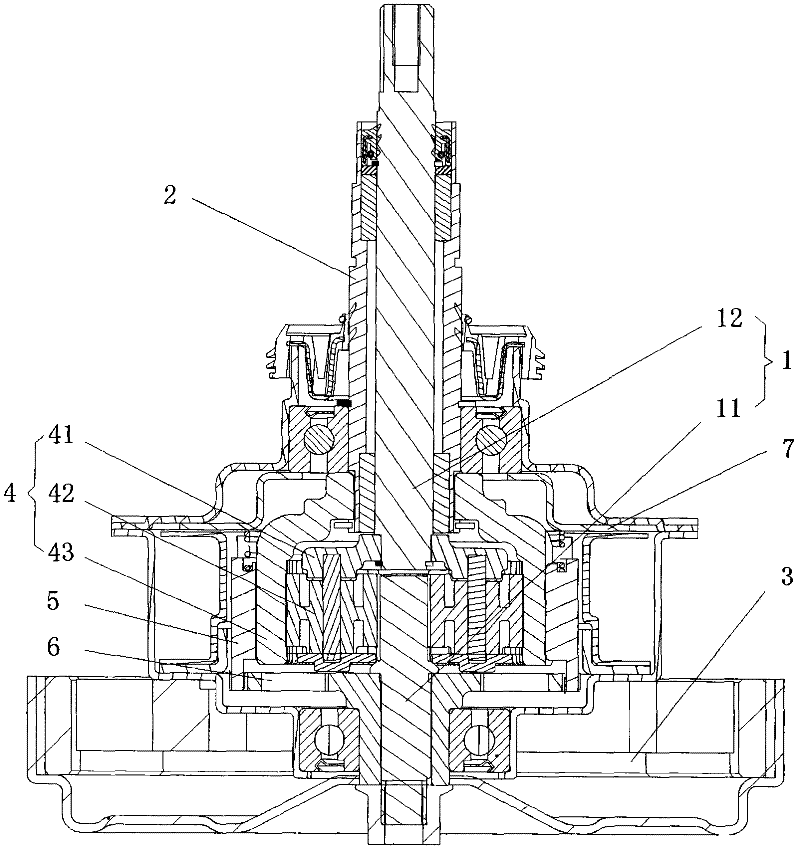

[0058] Embodiment 1, as figure 2 , Figure 4 , Figure 5 , Figure 8 with Figure 9 As shown, a washing machine transmission device includes a drive shaft 21, a drive sleeve 22, a clutch 23, a stator assembly 24, a rotor assembly 25, and a brake mechanism 30, wherein the drive shaft 21 is rotatably arranged in the drive sleeve 22, and the clutch 23 controls The rotation of the drive shaft 21 and the drive sleeve 22, wherein: the stator assembly 24 is located in the rotor assembly 25; the clutch 23 includes a clutch ring gear 2310 and an electromagnetic coil 232 located outside the clutch ring gear 2310, and the clutch ring gear 2310 includes a The magnetically conductive part 2312 and the non-magnetically permeable part 2311 located inside, the magnetically permeable part 2312 and the non-magnetically permeable part 2311 are fixedly connected as one, and the non-magnetically permeable part 2311 is engaged with the external teeth of the drive bushing 22 to slide up and down...

Embodiment 2

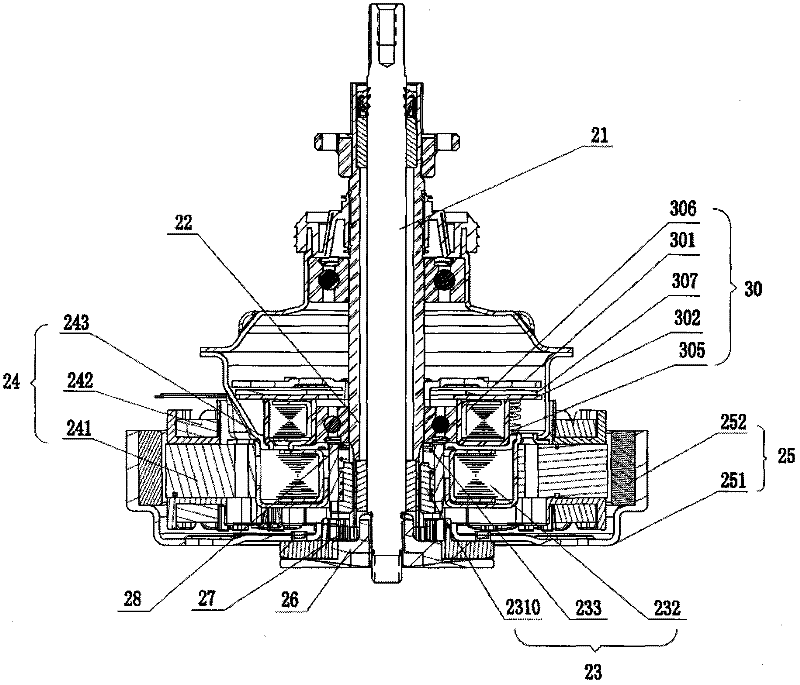

[0059] Embodiment 2, as image 3 , Figure 4 , Figure 5 , Figure 8 with Figure 9As shown, a washing machine transmission device includes a drive shaft 21, a drive sleeve 22, a clutch 23, a stator assembly 24, a rotor assembly 25, and a brake mechanism 30, wherein the drive shaft 21 is rotatably arranged in the drive sleeve 22, and the clutch 23 controls The rotation of the drive shaft 21 and the drive shaft sleeve 22, wherein: the drive shaft 21 includes a power shaft 211 and an output shaft 212 coaxially arranged in the up and down direction, the power shaft 211 is used to receive the rotational force of the rotor assembly 25, and the output shaft 212 It is used to connect the pulsator and output the rotational force accordingly; the drive bushing 22 includes an input bushing 221 and an output bushing 222 coaxially arranged in the up and down direction; the stator assembly 24 is located in the rotor assembly 25; the clutch 23 includes a clutch The ring gear 2310 and th...

Embodiment 3

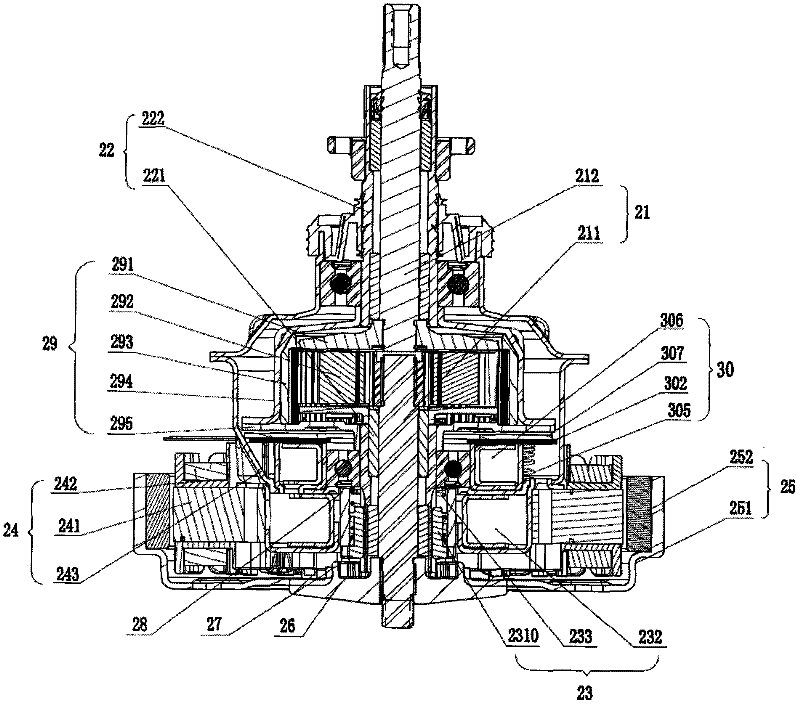

[0060] Embodiment 3, as Image 6 with Figure 7 As shown, a transmission device for a washing machine, wherein the coupling 26 is made of non-magnetic material; the clutch ring gear 2310 includes an outer magnetic member 2312 and an inner non-magnetic member 2311 , the magnetically conductive part 2312 and the non-magnetically conductive part 2311 are fixedly connected as one, the non-magnetically conductive part 2311 and the external teeth of the input shaft sleeve 221 can slide up and down, and the upper and lower ends of the magnetically conductive part 2312 are evenly distributed with slotted teeth; the shaft coupling The gear 26 is provided with an engaging part 27 that can be engaged with the groove teeth distributed at the lower end of the magnetic conducting part 2312, and the engaging part 27 and the shaft coupling 26 are of an integrated structure; The meshing part 28 of groove tooth meshing, all the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com