Nano-zirconia-PMMA (polymethyl methacrylate) composite material and preparation method thereof

A technology of nano-zirconia and composite materials, which is applied in the field of high-temperature-resistant nano-zirconia-PMMA composite materials and its preparation, and can solve the problems of insufficient strength, toughness, high-temperature resistance of composite materials, poor product quality stability, and many steps in the preparation method, etc. problems, to achieve the effect of enhancing comprehensive physical and chemical properties, compact preparation process, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

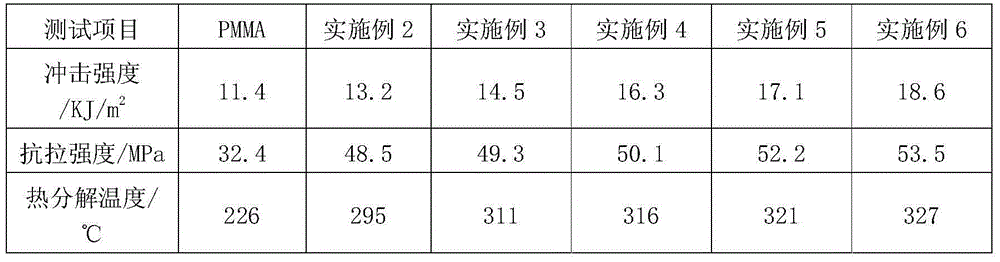

Examples

Embodiment 1

[0041] The nano-zirconia-PMMA composite material provided by the embodiment of the present invention is prepared by in-situ polymerization of MMA and modified nano-zirconia; the modified nano-zirconia is a coupling agent surface-modified nano-zirconia, which The raw material components include: 3-15 parts of modified nano zirconia, 28-54 parts of MMA, and the grafting rate of PMMA on the surface of the modified nano zirconia is not less than 19%.

[0042] Wherein, the preparation steps of the modified nano-zirconia are as follows:

[0043] 1) Add 5-14 parts of nano zirconia particles, 180-450 parts of absolute ethanol, and 2-4 parts of silane coupling agent into the reactor, stir evenly, and magnetically stir at 40-60°C for 12 hours.

[0044] 2) After the reaction is completed, filter, wash with absolute ethanol, and dry to obtain a silane coupling agent-modified nano-zirconia product powder.

[0045] The nano-zirconia-PMMA composite material is used as a raw material to prep...

Embodiment 2

[0061] Nano zirconia-PMMA composite material provided by the present invention and preparation method thereof are basically the same as in Example 1, the difference being:

[0062] The raw material components include: 3 parts of modified nano zirconia, 28 parts of MMA; the grafting rate of PMMA on the surface of the modified nano zirconia is 20%.

[0063] The nano zirconia-PMMA composite material and its preparation method comprise the steps of:

[0064] (1), surface modification of nano-zirconia

[0065] a. Add 5 parts of nano-zirconia particles, 180 parts of absolute ethanol, and 2 parts of silane coupling agent into the reactor, specifically using KH550, stir evenly, and magnetically stir at 40°C for 12 hours;

[0066] b. After the reaction is finished, filter, wash with absolute ethanol, and dry to obtain a silane coupling agent modified nano-zirconia product powder;

[0067] (2), MMA grafted on the surface of nano-zirconia

[0068] c. Add 3 parts of modified nano-zirco...

Embodiment 3

[0074] Nano zirconium oxide-PMMA composite material provided by the present invention and preparation method thereof are basically all substantially the same as in Embodiment 1 and 2, and its difference is:

[0075] The raw material components include: 6 parts of modified nano zirconia and 34 parts of MMA; the grafting rate of PMMA on the surface of the modified nano zirconia is 27.1%.

[0076] (1), surface modification of nano-zirconia

[0077] a. Add 7 parts of nano-sized zirconia particles, 220 parts of absolute ethanol, and 3 parts of silane coupling agent KH560 into the reactor, stir evenly, and magnetically stir at 46°C for 12 hours;

[0078] b. After the reaction is finished, filter, wash with absolute ethanol, and dry to obtain a silane coupling agent modified nano-zirconia product powder;

[0079] (2), MMA grafted on the surface of nano-zirconia

[0080] c. Add 6 parts of modified nano-zirconia, 34 parts of MMA monomer, and 14 parts of acetone into the reactor, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com