A p110 externally thickened oil well pipe and its manufacturing method

A manufacturing method and oil well pipe technology, applied in P110 steel grade extra thick oil well pipe and its manufacturing field, can solve the problems of increased alloy cost, low product profit margin, increased energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

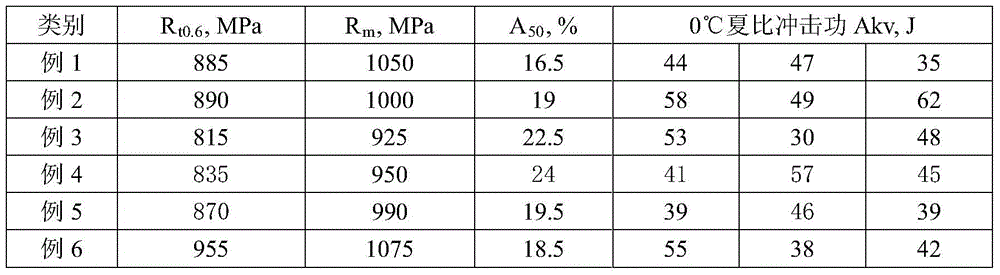

[0022] The present invention will be further described in conjunction with the following, and the embodiment is only a description of the best implementation mode of the present invention, and does not limit the scope of the present invention in any way.

[0023] Table 1 shows the chemical composition of the steel in the example, and its technological process is converter smelting—outside furnace refining—square billet continuous casting—round billet rolling—ring furnace heating—fungal piercing machine pipe piercing—continuous pipe rolling mill pipe rolling—fixed Diameter forming—on-line pier thickening and external thickening—on-line induction quenching and tempering heat treatment. The specific process system of the embodiment is shown in Table 2, and Table 3 shows the mechanical properties of the steel of the embodiment.

[0024] The chemical composition (wt%) of the embodiment of table 1

[0025] category C Si mn P S Fe example 1 0.26 0.30 1.36 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com