Method for preparing mud adsorbent used for desulfurization of flue-gas

A sludge adsorption and adsorbent technology, which is applied in the direction of separation method, pyrolysis treatment of sludge, chemical instruments and methods, etc., can solve the problems of long preparation period, complicated process, and increased preparation cost, and achieve the reduction of preparation cost and the preparation The effect of simple process and saving reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

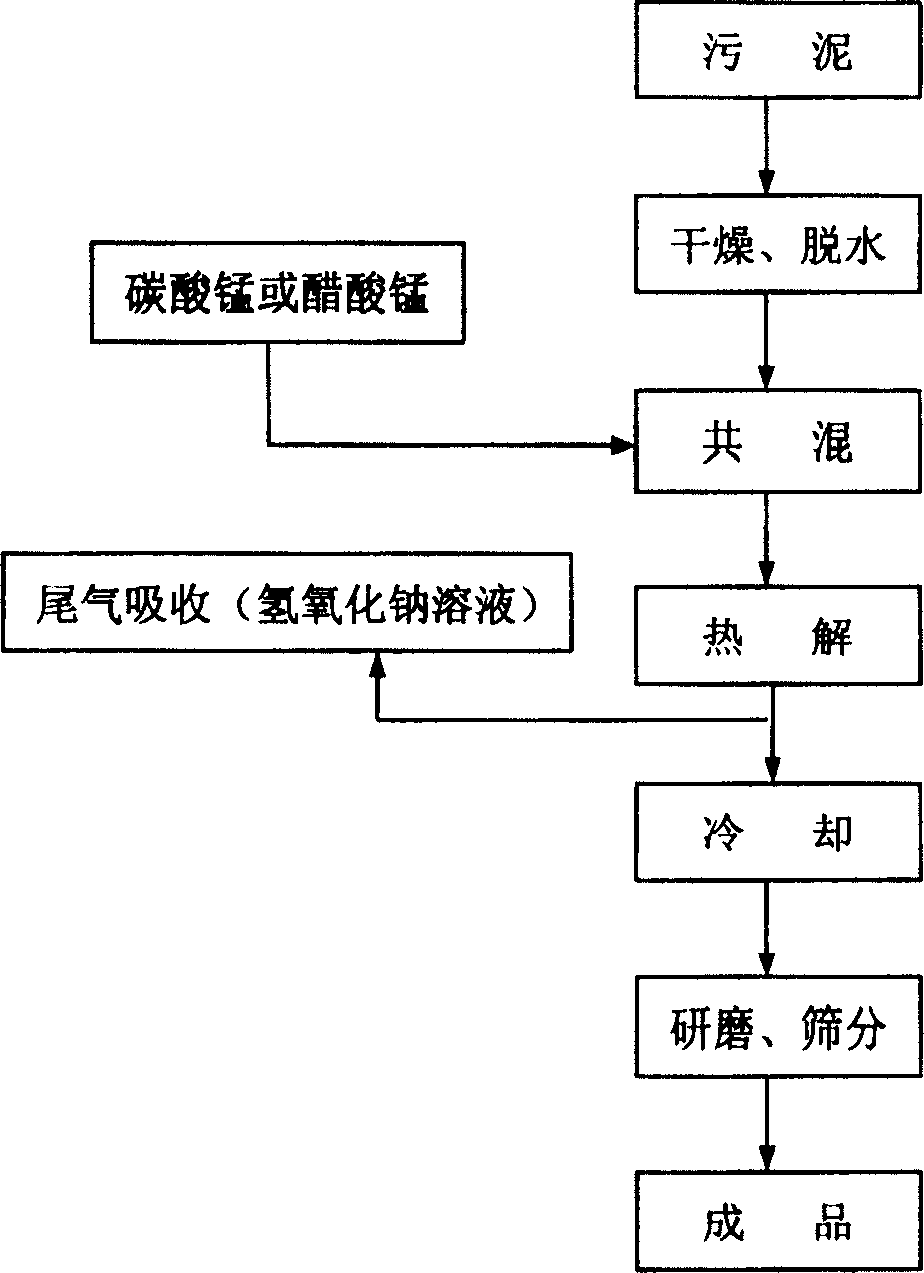

[0016] According to a specific implementation of the process shown in the accompanying drawings:

[0017] Step 1: Put about 3000g of sludge with high moisture content into a desktop drying oven with a working capacity of 250×250×250mm, a rated power of 0.88kW, a rated temperature of 250°C, and an error of ±1°C, and dry it at 103°C After 24 hours, about 30 g of dry sludge with a moisture content of less than 10% was obtained.

[0018] The second step: take 30g of the dry sludge obtained in the first step, and add 4.5g of manganese carbonate according to the loading capacity of 20%. The manganese carbonate is a chemically pure reagent with a content of 44-48%. Add 10 mL of deionized water and manually stir with a glass rod to mix the dry sludge and salt evenly, put it in a drying oven, and dry at 103 °C for 3 h.

[0019] Step 3: Fill the blended dry product obtained in the second step into a φ30×800mm stainless steel heating tube from the opened flange end. When adding, be care...

Embodiment 2

[0023] According to another kind of specific implementation of flow process shown in accompanying drawing: its concrete steps are identical with embodiment 1, and difference is:

[0024] Step 2: Add 6.8g of manganese carbonate according to the loading capacity of 30%, add 10mL of deionized water and stir manually with a glass rod to mix the dry sludge and salt evenly, put it in a drying oven, and dry at 103°C for 3h. Sludge adsorbents with different adsorption properties are prepared through subsequent steps.

Embodiment 3

[0026] According to the third specific implementation of the process flow shown in the accompanying drawings: its specific steps are the same as in Example 1, except that:

[0027]Step 2: Add 6.7 g of manganese acetate according to the loading capacity of 20%. The manganese acetate is an analytical reagent with a content of ≥99.0%. Add 10 mL of deionized water and manually stir with a glass rod to mix the dry sludge and salt evenly, put it in a drying oven, and dry at 103 °C for 3 h. Sludge adsorbents with different adsorption properties are prepared through subsequent steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com