Pipe connector

A technology for pipe joints and connecting pipes, which is applied in the field of pipe joints, can solve the problems of high manufacturing cost, complex structure, and difficult promotion, and achieve the effect of low cost, compact structure, and quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

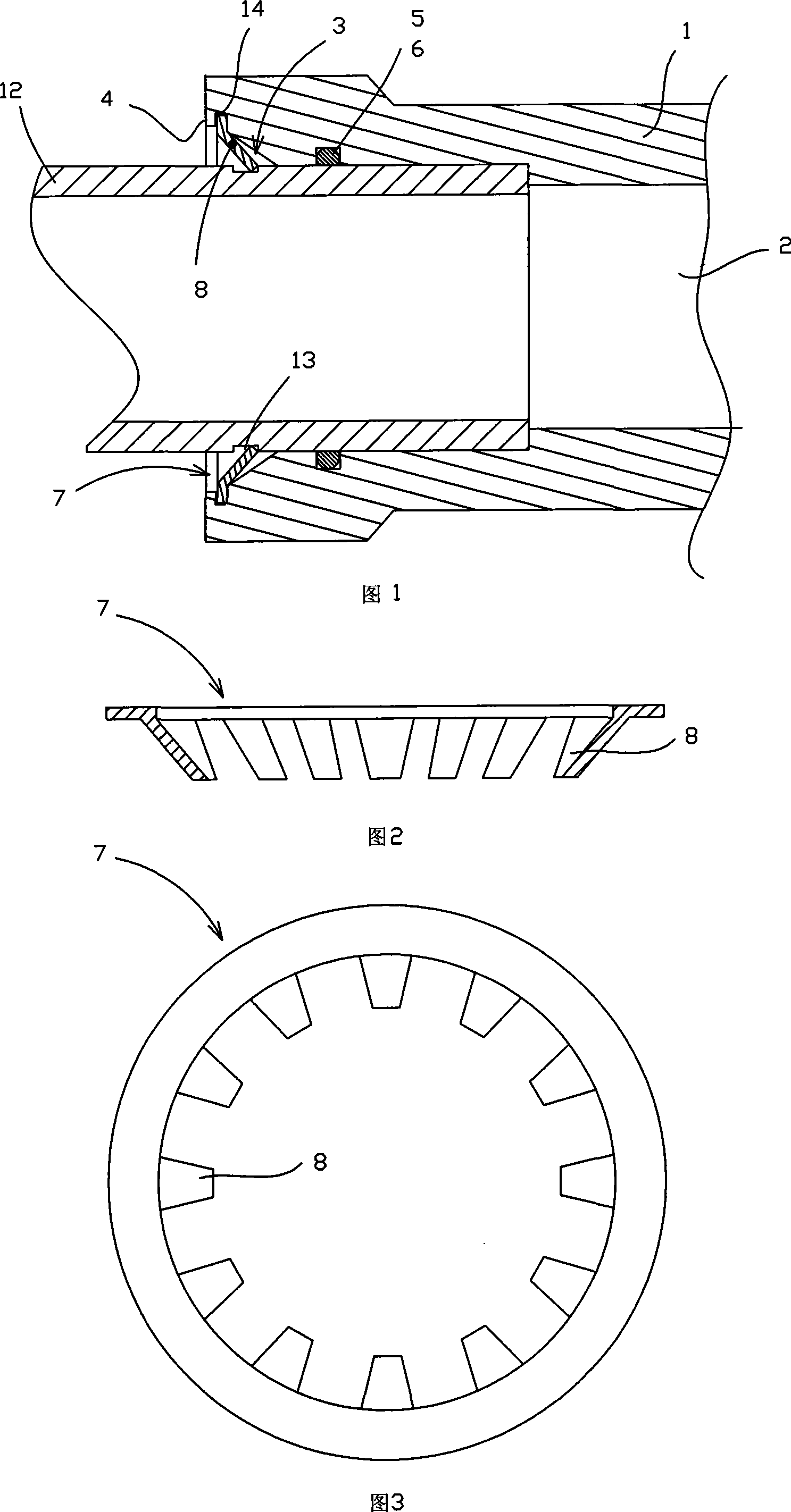

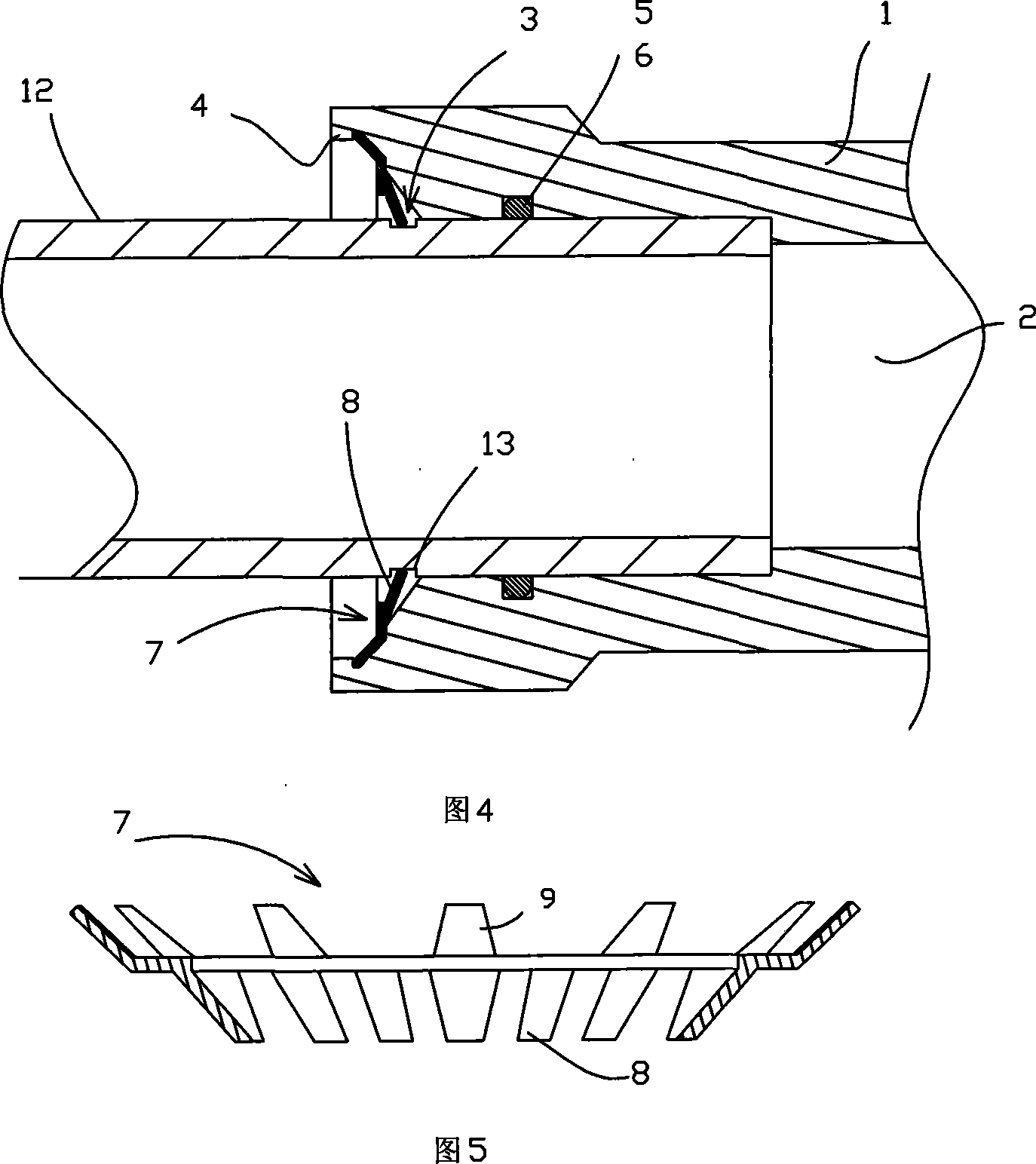

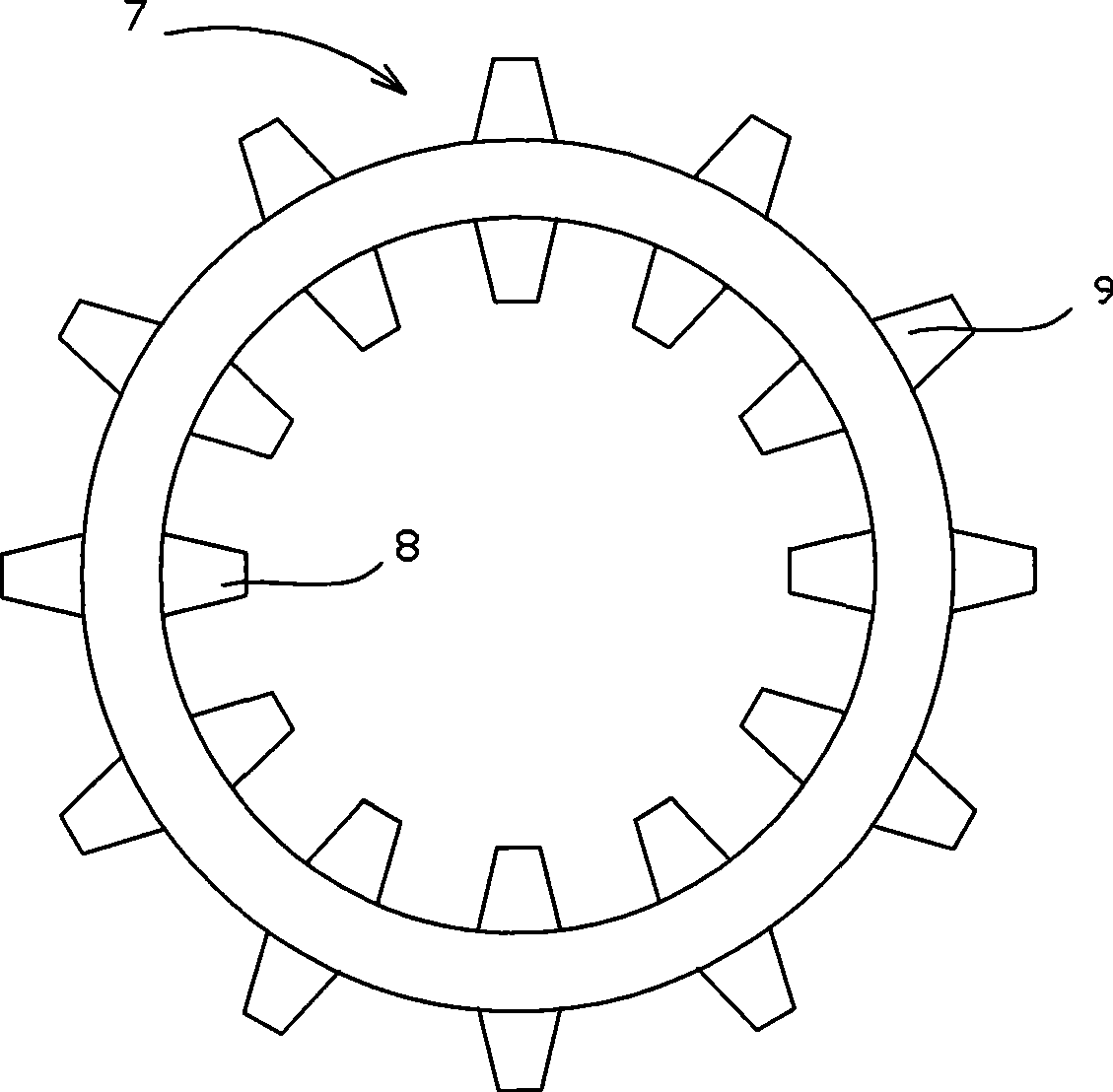

[0044] Figure 19 yes Figure 18 top view diagram.

[0045] In the figure: 1-joint body, 2-through hole, 3-flare mouth, 4-protruding ring or bump, 5-apron groove, 6-sealing rubber ring, 7-elastic locking gear ring, 8-inner Folding teeth, 9-fixed teeth, 10-gap of the elastic locking gear ring, 11-ring hole, 12-connected pipe, 13-outer clamping pipe groove of the connected pipe, 14-positioning groove.

[0046] like Figure 1 to Figure 3 The shown pipe joint embodiment 1 includes a joint body 1 with a through hole 2. There is a positioning step in the middle of the through hole 2 for the positioning of the connected pipe 12. On the inner wall of the through hole 2, there is a rubber ring groove 5 equipped with a seal. The rubber ring 6 is used to ensure the sealing between the connected pipe and the pipe joint; the two ports of the through hole 2 are the bell mouth 3, and the outer end of the bell mouth is connected with a counterbore, and the bell mouth 3 is equipped with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com