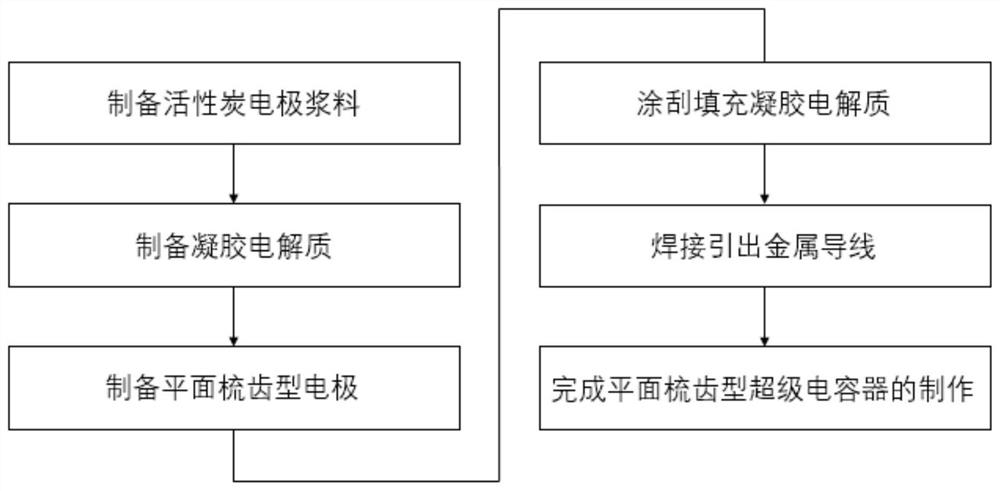

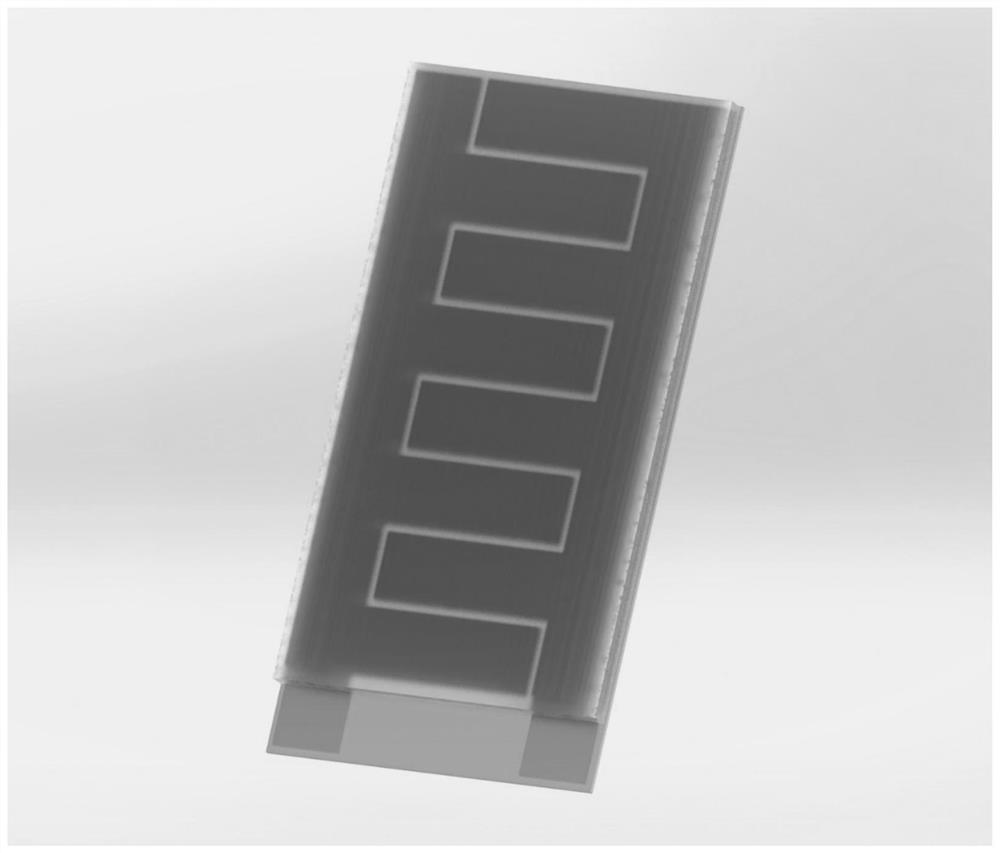

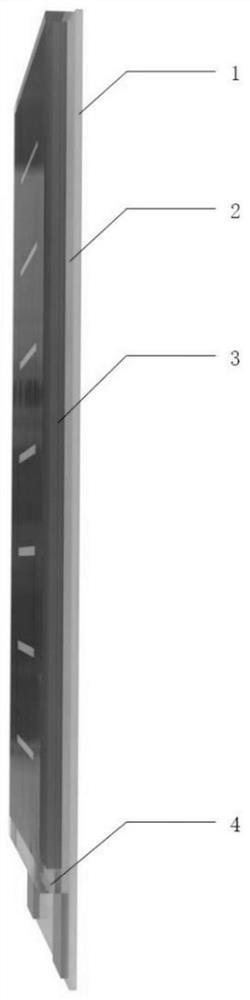

A kind of preparation method of planar comb type supercapacitor

A supercapacitor, comb-tooth type technology, applied in the field of two-dimensional planar thin comb-tooth structure supercapacitors, can solve the problems of difficulty in large-scale promotion, complex process flow, high cost, etc., and achieves compact structure, simplified production process, and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of activated carbon electrode slurry:

[0040]Grind the powder of activated carbon and carbon black with a ball mill at 300r / min for 10 hours, weigh another 2g of PVA powder and place it in a reagent bottle, pour 20mL of deionized water into it, and use a magnetic stirrer at 90°C, 1500r / min min under the condition of stirring for 2h to obtain a PVA solution. Weigh 2g of activated carbon, and take carbon black and PVA solution separately, mix activated carbon, carbon black, and PVA at a ratio of 80:10:10, stir with a magnetic stirrer for 12 hours, and evenly disperse activated carbon and carbon black to obtain activated carbon electrode slurry material.

[0041] (2) Preparation of gel electrolyte:

[0042] 1mol / L of H 2 SO 4 Mix 20mL of the solution with 2g of PVA powder, heat and stir with a magnetic stirrer for 2 hours in a water bath until the PVA powder is completely dissolved, and the solution is clear and transparent. After vacuum degassing, per...

Embodiment 2

[0049] (1) Preparation of activated carbon electrode slurry:

[0050] Grind the powder of activated carbon and carbon black with a ball mill at 300r / min for 10 hours, weigh another 2g of PVA powder and place it in a reagent bottle, pour 20mL of deionized water into it, and use a magnetic stirrer at 90°C, 1500r / min min under the condition of stirring for 2h to obtain a PVA solution. Weigh 2g of activated carbon, and take another solution of carbon black and PVA, mix activated carbon, carbon black, and PVA in a ratio of 90:5:5, stir with a magnetic stirrer for 12 hours, and evenly disperse the activated carbon and carbon black to obtain activated carbon electrode slurry material.

[0051] (2) Preparation of gel electrolyte:

[0052] 1.2mol / L of H 2 SO 4 Mix 20mL of the solution with 2g of PVA powder, heat and stir with a magnetic stirrer for 2 hours in a water bath until the PVA powder is completely dissolved, and the solution is clear and transparent. After vacuum degassing...

Embodiment 3

[0059] (1) Preparation of activated carbon electrode slurry:

[0060] Grind the powder of activated carbon and carbon black with a ball mill at 300r / min for 10 hours, weigh another 2g of PVA powder and place it in a reagent bottle, pour 20mL of deionized water into it, and use a magnetic stirrer at 90°C, 1500r / min min under the condition of stirring for 2h to obtain a PVA solution. Weigh 2g of activated carbon, take carbon black and PVA solution separately, mix activated carbon, carbon black, and PVA at a ratio of 70:15:15, stir with a magnetic stirrer for 12 hours, and evenly disperse activated carbon and carbon black to obtain activated carbon electrode slurry material.

[0061] (2) Preparation of gel electrolyte:

[0062] 0.8mol / L of H 2 SO 4 Mix 20mL of the solution with 2g of PVA powder, heat and stir with a magnetic stirrer for 2 hours in a water bath until the PVA powder is completely dissolved, and the solution is clear and transparent. After vacuum degassing, perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com