Polyurea resin shell and manufacturing method thereof

A technology of polyurea resin and its manufacturing method, which is applied in the field of polyurea resin casing and its manufacture, and can solve the problems of low surface hardness and strength, power failure, and affecting the service life of mobile phones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

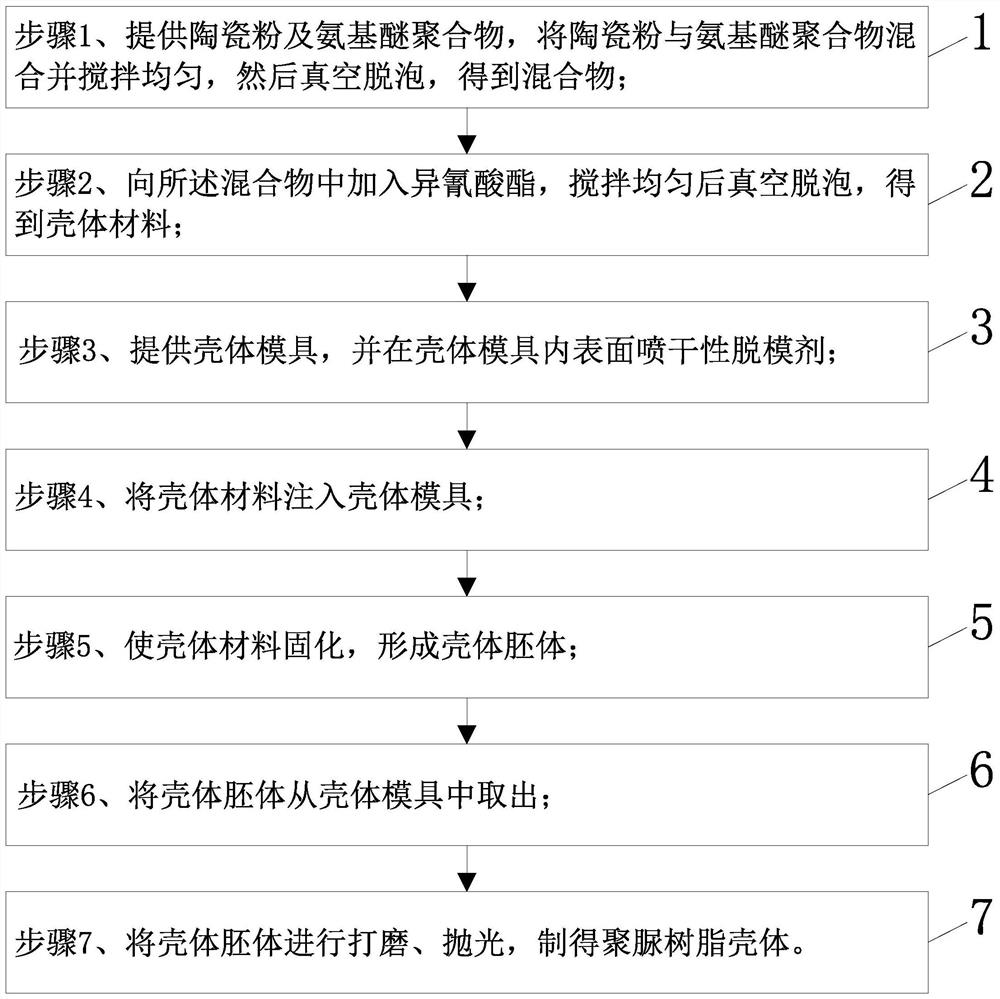

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0028] The invention provides a polyurea resin shell, which can be used as the back shell of a mobile phone in particular. The material of the polyurea resin shell includes ceramic powder, isocyanate, and aminoether polymer.

[0029] Specifically, the particle size of the ceramic powder is equal to or smaller than 100 nanometers. The Engler viscosity of the isocyanate at normal temperature is 200-300, and the Rockwell hardness (HRB) is greater than 80. The amino ether polymer adopts bis(2-dimethylaminoethyl) ether.

[0030] Specifically, in the polyurea resin shell, the amount of ceramic powder is 10-20 parts by weight, the amount of isocyanate is 40-45 parts by weight, and the amount of aminoether polymer is 40-45 parts by weight.

[0031] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com