Two-degree-of-freedom fine moving and tuning adjusting rack

A technology for adjusting the frame and degrees of freedom, applied in installation, optics, instruments, etc., can solve the problems of difficult adjustment accuracy, high manufacturing cost, low positioning accuracy, etc., and achieve the effect of compact structure, low cost, and convenient and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

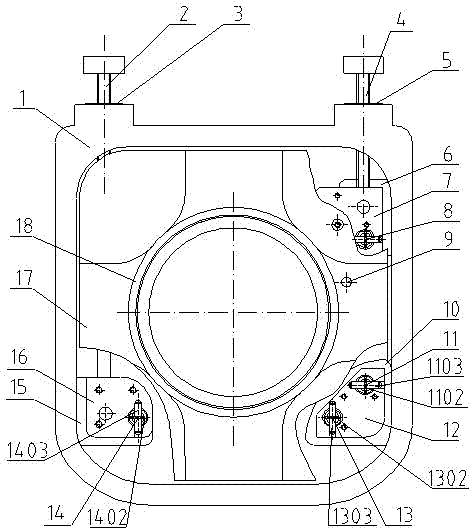

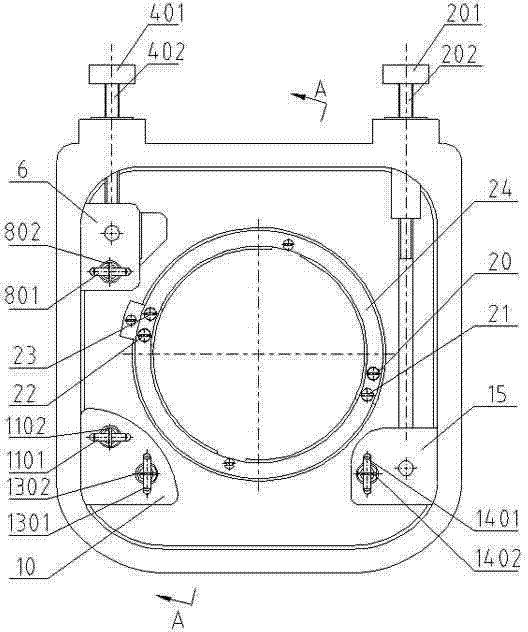

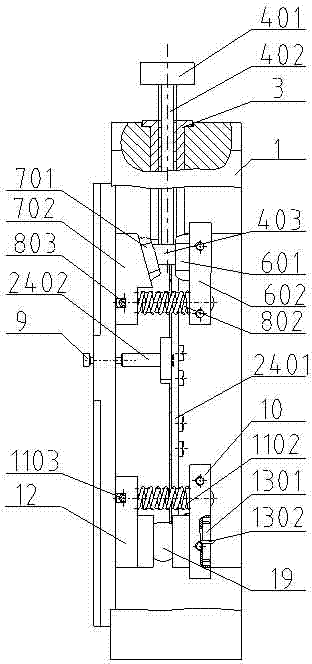

[0031] Such as figure 1 , 2 As shown, the two-degree-of-freedom fine-tuning adjustment frame of the present invention is mainly composed of a housing 1, an adjustment rod, a lens 18, an adjustment block assembly, a positioning block and a reset assembly. The lens 18 is set in the casing 1, the outer edge of the front part of the lens 18 is provided with a movable block 17, the movable block 17 is provided with 9 screw holes, and the front end of the lens 18 is provided with a lens clamping assembly 24. The lens The clamping assembly 24 includes a lens clamping ring 2401, a clamping connector 2402, a hook fixing screw 2403, and a hook 2404. The lens clamping ring 2401 is positioned in the groove of the movable block 17, and is pre-tightened by adjusting the clamping ring. The collar pre-tightening screws in the first assembly 20, the second collar pre-tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com