Ferroelectric thin-membrane phase shifter and preparation thereof

A technology of ferroelectric thin film and manufacturing method, which is applied in the direction of circuits, electrical components, waveguide devices, etc., and can solve the problems of weak modulation electric field, weak modulation ability of ferroelectric capacitance, and inability to fully utilize the modulation ability of barium strontium titanate thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

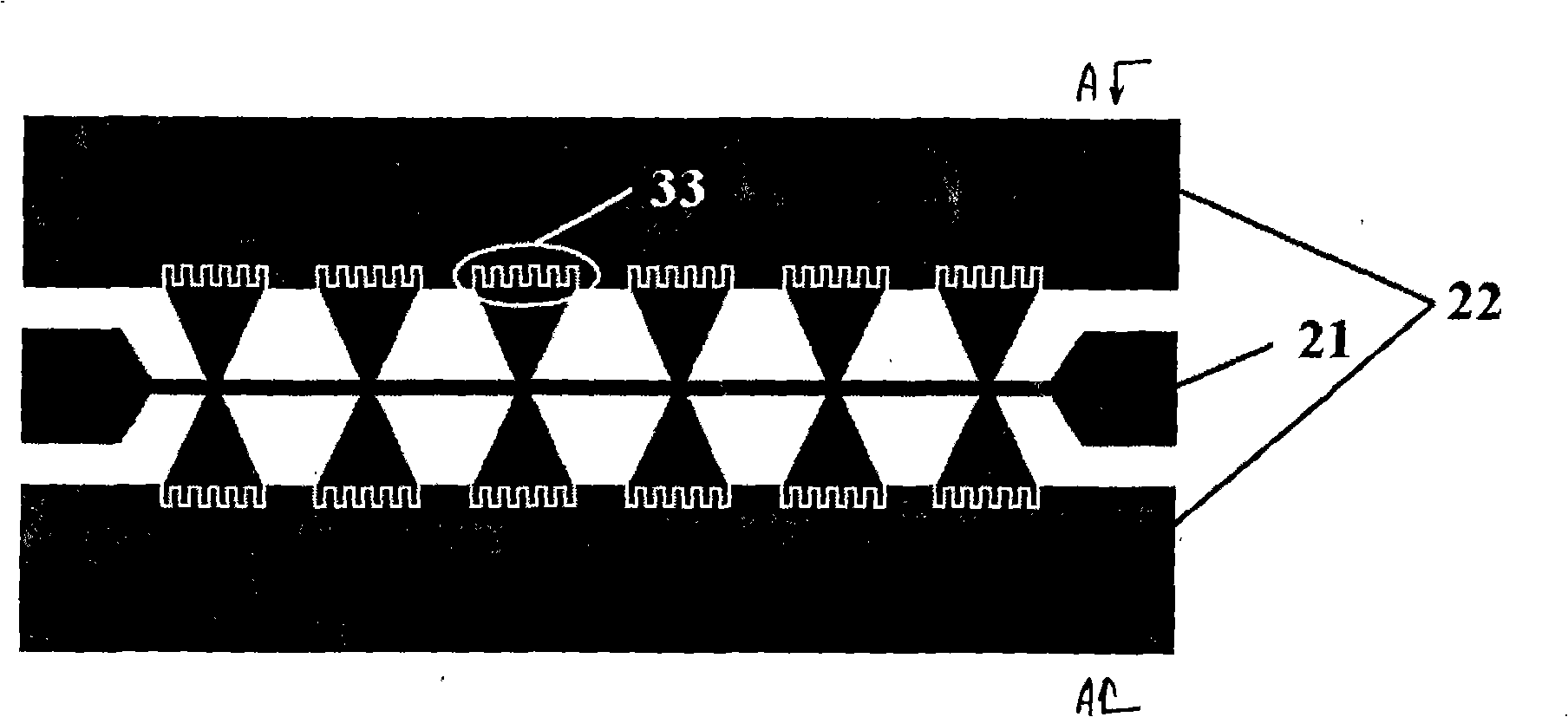

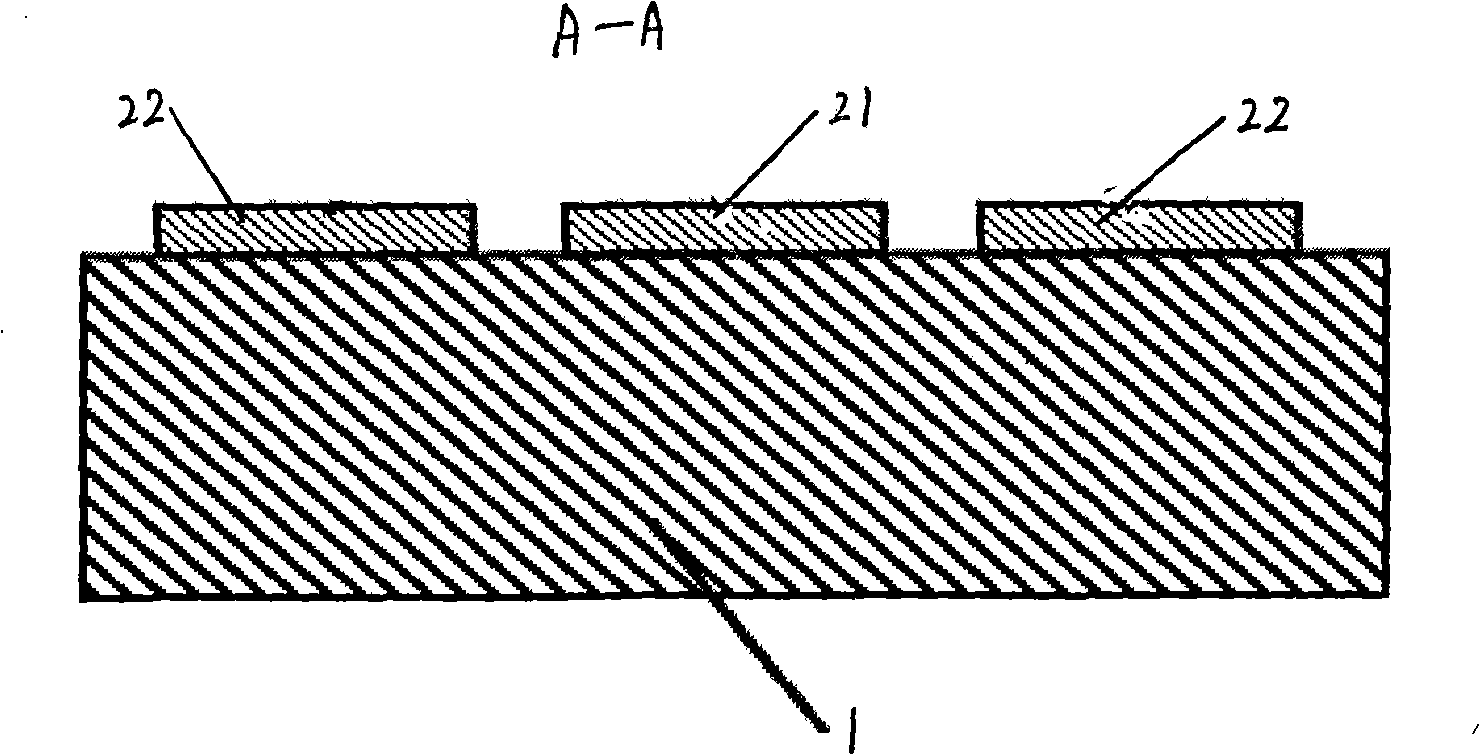

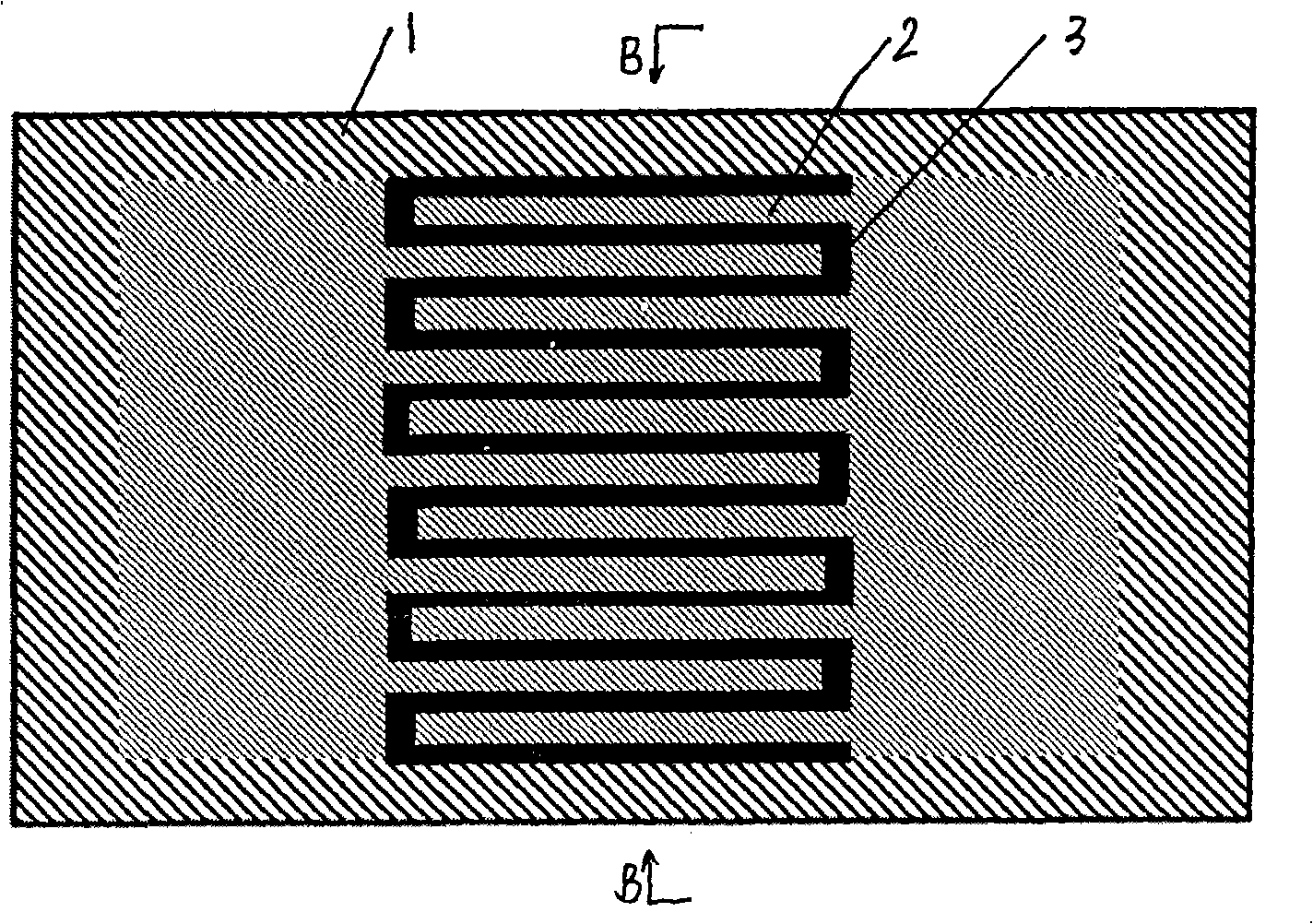

[0025] refer to figure 1 , 2 , 3, 4, the manufacturing process of the phase shifter with the new interdigitated capacitor structure periodically loaded by the coplanar line is as follows: (1) deposit the conductive thin film material 2 on the substrate substrate 1; (2) after the photolithography mask, Argon ion etching or wet etching to form a coplanar line structure (transmission line 21 and ground plane 22) and a periodically loaded interdigitated capacitance structure 33; (3) depositing a micron-scale ferroelectric film in the interdigitated capacitance region 3. Form a phase shifter with a new interdigitated capacitor structure periodically loaded by coplanar lines, and the loading capacitor is a new interdigitated capacitor. That is, a new type of interdigitated capacitor is periodically loaded on the coplanar lines. Compared with the manufacturing process of the phase shifter with parallel plate structure capacitor periodically loaded coplanar line, the manufacturing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Interdigital spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com