High-initial-adhesion waterborne polyurethane adhesive and preparation method thereof

A water-based polyurethane, high initial viscosity technology, applied in the field of adhesives, can solve the problems of complicated preparation process, low production efficiency, difficult marketization, etc., and achieves the advantages of compact preparation process, high success rate, shortened drying time and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

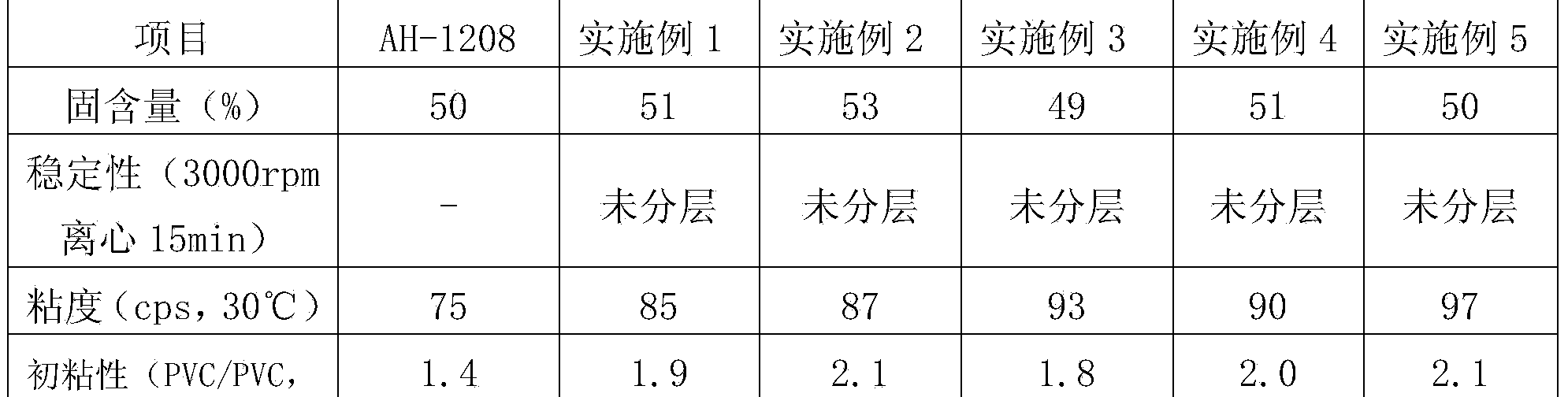

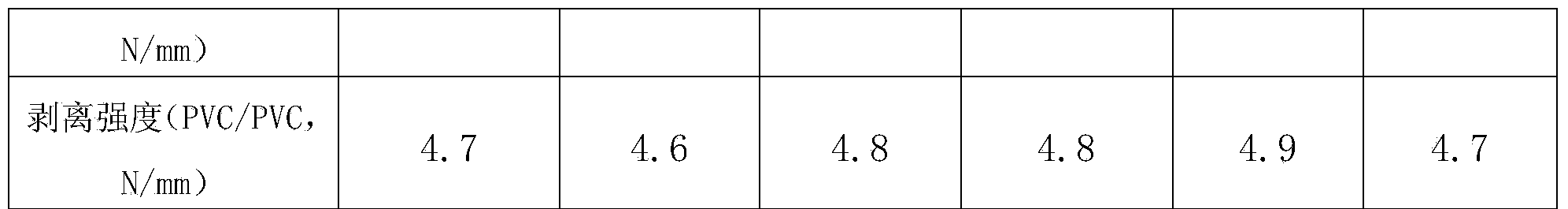

Examples

Embodiment 1

[0022] In parts by weight, add 78 parts of poly-1,4-butanediol adipate (number average molecular weight 2000), 1.3 parts of 1,4-butanediol to the reactor equipped with a stirrer and condensation reflux device , at 110°C, vacuumize to remove water for 1 hour, lower the temperature to 70°C, and control the speed to 140rpm, add 0.02 parts of dibutylsilyl lauric acid, 10.55 parts of isophorone diisocyanate, 2.66 parts of hexaethylene oxide into the reactor Methyl diisocyanate, heat up to 80°C, start the reaction, after 0.5 hours of reaction, add 25 parts of butanone, continue the reaction for 2.2 hours, add 1.86 parts of isophorone diisocyanate, 0.47 parts of hexamethylene diisocyanate, and react for 0.4 h. Cool down to 55°C, add 85 parts of acetone, adjust the rotation speed to 500 rpm, add 2.5 parts of a 50% aqueous solution of sodium ethylenediaminoethanesulfonate, and react for 0.5 hours. Discharge, under the high-speed shear mixer, add 98 parts of deionized water, set the ro...

Embodiment 2

[0024] In parts by weight, add 80 parts of poly-1,4-butanediol adipate (number average molecular weight 2200), 1.1 parts of 1,4-butanediol to the reactor equipped with a stirrer and condensation reflux device , at 120°C, vacuumize to remove water for 1 hour, lower the temperature to 74°C, and control the speed to 145rpm, add 0.04 parts of dibutylsilyl lauric acid, 11.18 parts of isophorone diisocyanate, 2.66 parts of hexaethylene oxide into the reactor Methyl diisocyanate, heat up to 85°C, start the reaction, after 0.5 hours of reaction, add 30 parts of butanone, continue the reaction for 2.5 hours, add 1.24 parts of isophorone diisocyanate, 0.47 parts of hexamethylene diisocyanate, and react for 0.6 h. Cool down to 59°C, add 95 parts of acetone, adjust the rotation speed to 520rpm, add 2.6 parts of an aqueous solution with a mass fraction of sodium ethylenediaminoethanesulfonate of 49%, and react for 0.5h. For discharging, under the high-speed shear mixer, add 99 parts of de...

Embodiment 3

[0026]In parts by weight, add 82 parts of poly-1,4-butanediol adipate (number average molecular weight 1800), 1.0 parts of 1,4-butanediol to the reactor equipped with a stirrer and condensation reflux device , at 110°C, vacuumize to remove water for 1.2h, cool down to 70°C, and control the speed to 150rpm, add 0.02 parts of stannous octoate, 10.55 parts of isophorone diisocyanate, 2.82 parts of hexamethylene Base diisocyanate, heat up to 85°C, start to react, after 0.8h of reaction, add 30 parts of butanone, continue to react for 2.5h, add 1.86 parts of isophorone diisocyanate, 0.31 parts of hexamethylene diisocyanate, react for 0.6h . Cool down to 57°C, add 100 parts of acetone, adjust the rotation speed to 515 rpm, add 2.7 parts of a 50% aqueous solution of sodium ethylenediaminoethanesulfonate, and react for 0.6 hours. For discharging, under the high-speed shear mixer, add 100 parts of deionized water, set the rotation speed at 5500 rpm, emulsify for 15 minutes, add 0.3 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com