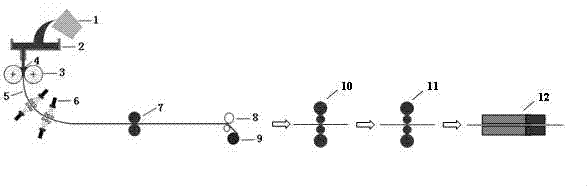

Method for manufacturing non-oriented silicon steel plate based on twin-roll thin strip continuous casting technology

A technology of twin-roll thin strip continuous casting and manufacturing method, applied in the field of metallurgy, can solve the problems of transverse cracks on the surface of the cast strip, difficulty in direct cold rolling, affecting the rolling process, etc., so as to improve the magnetic induction intensity, save the hot rolling process, The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

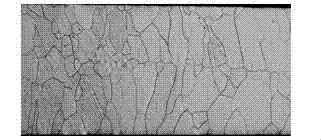

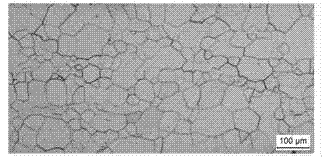

[0028] Smelted by intermediate frequency vacuum induction furnace, the composition is: C 0.0037wt%, Si 3.23wt%, Mn 0.22wt%, P 0.006wt%, S0.0028wt%, N 0.0033wt%, Al 0.71wt%, the balance is Fe and impurities Control the temperature of the molten steel at 1650°C and pour it into the tundish. The molten steel flows through the tundish into the cavity formed by two crystallization rollers rotating at a line speed of 40m / min and side sealing plates to form a molten pool. The molten steel and crystallization Condensation occurs when the roll contacts, and a cast strip with a thickness of 2.0mm and a width of 250mm is exported from the crystallization roll. The cast strip is coiled after being trimmed online, and then the cast strip is cooled to 400°C in the air for warm rolling. The deformation of warm rolling is 10%. After pickling, the cast coils after warm rolling are cold-rolled to obtain a cold-rolled sheet with a thickness of 0.50 mm. After layering, a non-oriented silicon st...

Embodiment 2

[0031] Smelted by intermediate frequency vacuum induction furnace, the composition is: C 0.002wt%, Si 3.5wt%, Mn 0.3wt%, P 0.009wt%, S0.0048wt%, N 0.0029wt%, Al 0.2wt%, the balance is Fe and impurities Control the temperature of the molten steel at 1610°C and pour it into the tundish. The molten steel flows through the tundish into the cavity formed by two crystallization rollers rotating at a line speed of 60m / min and side sealing plates to form a molten pool. The molten steel and crystallization Condensation occurs when the roll contacts, and the cast strip with a thickness of 1.0mm and a width of 100mm is exported from the crystallization roll. The cast strip is coiled after being trimmed online, and then the cast strip is cooled to 600°C in the air and then warm rolled. The deformation of warm rolling is 30%. After pickling, the cast coils after warm rolling are cold-rolled to obtain a cold-rolled sheet with a thickness of 0.50 mm. After layering, a non-oriented silicon ...

Embodiment 3

[0033] Smelted by intermediate frequency vacuum induction furnace, the composition is: C 0.01wt%, Si 2.9wt%, Mn 0.1wt%, P 0.018wt%, S0.0035wt%, N 0.0044wt%, Al 1.0wt%, the balance is Fe and impurities Control the temperature of the molten steel at 1720°C and pour it into the tundish. The molten steel flows through the tundish into the cavity formed by two crystallization rollers rotating at a linear speed of 20m / min and side sealing plates to form a molten pool. The molten steel and crystallization Condensation occurs in contact with the rollers, and a cast strip with a thickness of 5.0mm and a width of 2000mm is exported from the crystallization roller. The rolling deformation is 5%. After pickling, cold-roll the warm-rolled cast coil to obtain a 0.50mm thick cold-rolled sheet, and then anneal the cold-rolled sheet at 1150°C for 0.5min. After layering, a non-oriented silicon steel plate product is obtained. The horizontal and vertical average magnetic induction intensity B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com