Nano-range nickel gamma-hydroxy oxide and preparing process thereof

A nickel oxyhydroxide, nano-scale technology, applied in the direction of nickel oxide/nickel hydroxide, nickel carbonyl, electrical components, etc., can solve the problems of low initial discharge specific capacity, small particle size, small bulk density, etc., to achieve easy large-scale Large-scale industrial production, easy structure and performance, and the effect of preventing agglomeration and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh an appropriate amount of nickel chloride (NiCl 2 ·6H 2 O) Dissolved in tap water to prepare 100ml aqueous solution. The concentration of the aqueous solution was 0.1M. Add cobalt chloride with a weight percent content of 1% therein, and mix uniformly to prepare a reaction liquid.

[0030] Weigh 1% potassium hydroxide by weight and dissolve it in water to prepare 250ml of alkaline aqueous solution, then add 250ml of 10% by weight potassium persulfate solution to prepare 500ml of oxidant aqueous solution.

[0031] Weigh an appropriate amount of surfactant sodium dodecylsulfonate and dissolve it in water to prepare 10ml of an aqueous solution. The weight percent content of the surfactant is 0.1%.

[0032] Put 500ml of aqueous oxidant solution in an ultrasonic reactor for ultrasonic vibration dispersion, add 10ml of sodium dodecylsulfonate aqueous solution and heat to 45°C, and add 100ml of the reaction solution prepared above dropwise. After the reaction solutio...

Embodiment 2

[0036] Weigh an appropriate amount of nickel sulfate (NiSO 4 ·7H 2 O) dissolved in distilled water to prepare 100ml aqueous solution. The concentration of the aqueous solution is 10M. Add cobalt sulfate with a weight percent content of 1% and cadmium chloride with a weight percent content of 4% therein, and mix uniformly to prepare a reaction liquid.

[0037] Take by weight 10% sodium hydroxide and dissolve in water to prepare 250ml of alkaline aqueous solution, then add 250ml of 15% by weight sodium hypobromite aqueous solution to prepare 500ml of oxidizing agent aqueous solution.

[0038] Weigh an appropriate amount of surfactant quaternary ammonium salt and dissolve in water to prepare 10ml of aqueous solution. The weight percent content of surfactant is 0.5%.

[0039] Put 500ml of aqueous oxidant solution in an ultrasonic reactor for ultrasonic vibration dispersion, add 10ml of quaternary ammonium salt solution and heat to 65°C, and add 100ml of the reaction solution p...

Embodiment 3

[0043] Weigh an appropriate amount of nickel nitrate (NiNO 3 ·6H 2 O) be dissolved in deionized water and be mixed with 100ml aqueous solution. The concentration of the aqueous solution is 5M. Add cobalt chloride with a weight percent content of 1% and zinc chloride with a weight percent content of 2% therein, and mix uniformly to prepare a reaction liquid.

[0044] Weigh 4% potassium hydroxide by weight and dissolve it in water to prepare 250ml of alkaline aqueous solution, then add 250ml of 12% by weight sodium hypochlorite aqueous solution to prepare 500ml of oxidant solution.

[0045] Weigh an appropriate amount of surfactant TX-100 (OP) and dissolve it in water to prepare 10ml of an aqueous solution. The weight percent content of the surfactant is 0.3%.

[0046] Put 500ml of aqueous oxidant solution in an ultrasonic reactor for ultrasonic vibration dispersion, add 10ml of TX-100 aqueous solution and heat to 55°C, and add 100ml of the reaction solution prepared above d...

PUM

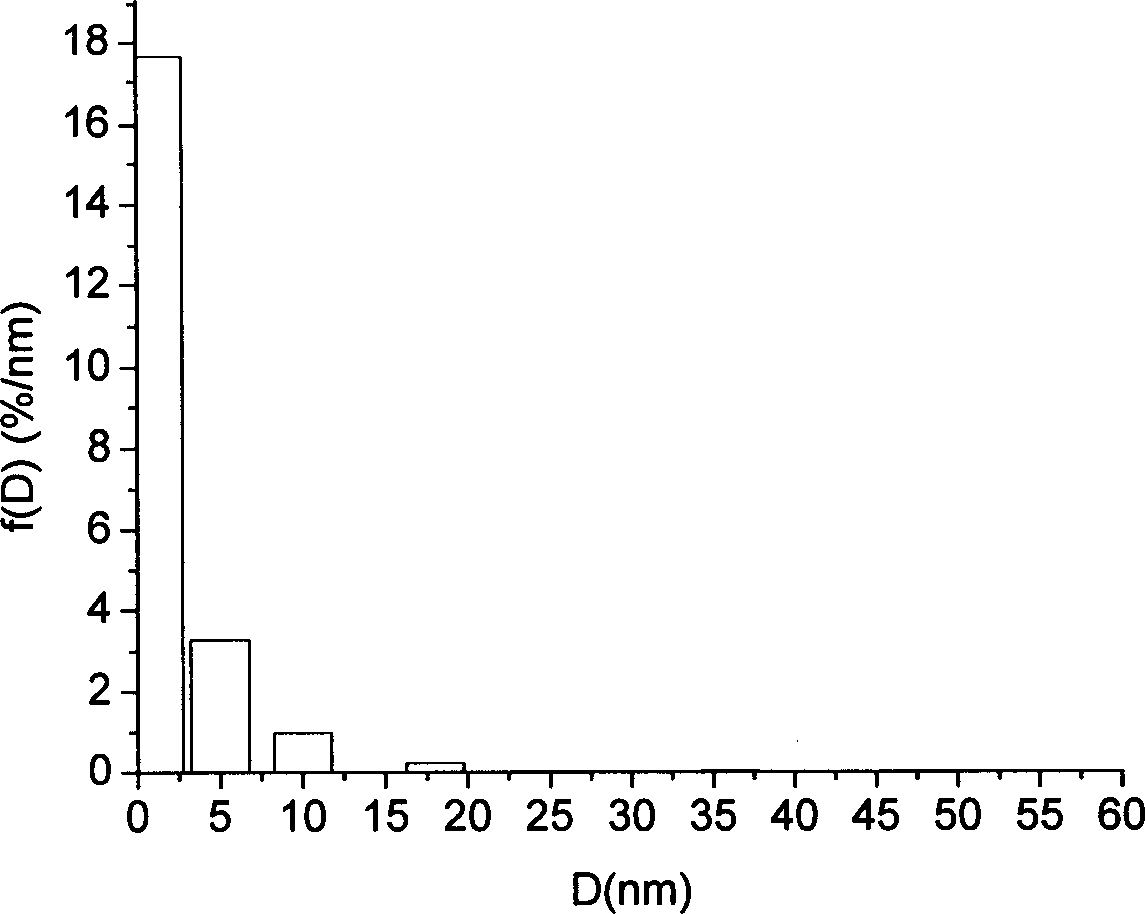

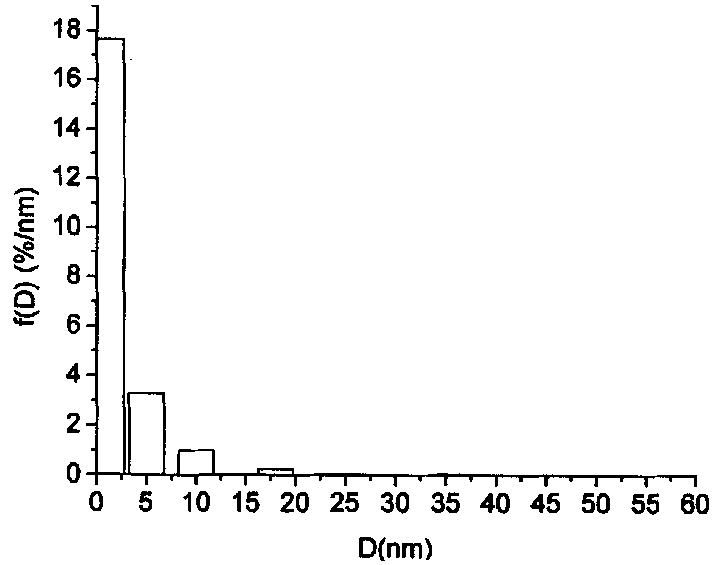

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com