Foundation slab post-cast strip waterproof steel plate combined structure and bracing method thereof

A water-stop steel plate and combined structure technology, which is applied in the direction of basic structure engineering, underwater structures, water conservancy projects, etc., can solve the problems of insignificant anti-leakage effect, insignificant effect, damage, etc., and achieve the goal of overcoming concrete external Leakage, water-stop effect is remarkable, to avoid the effect of easy deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

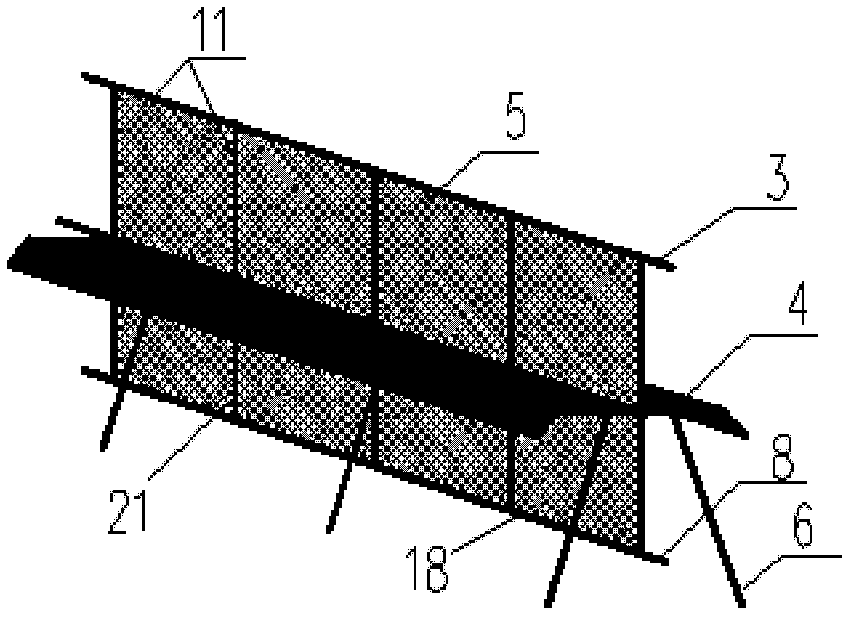

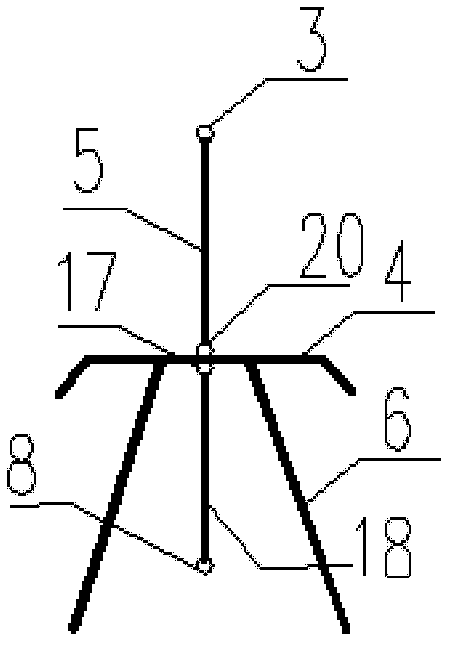

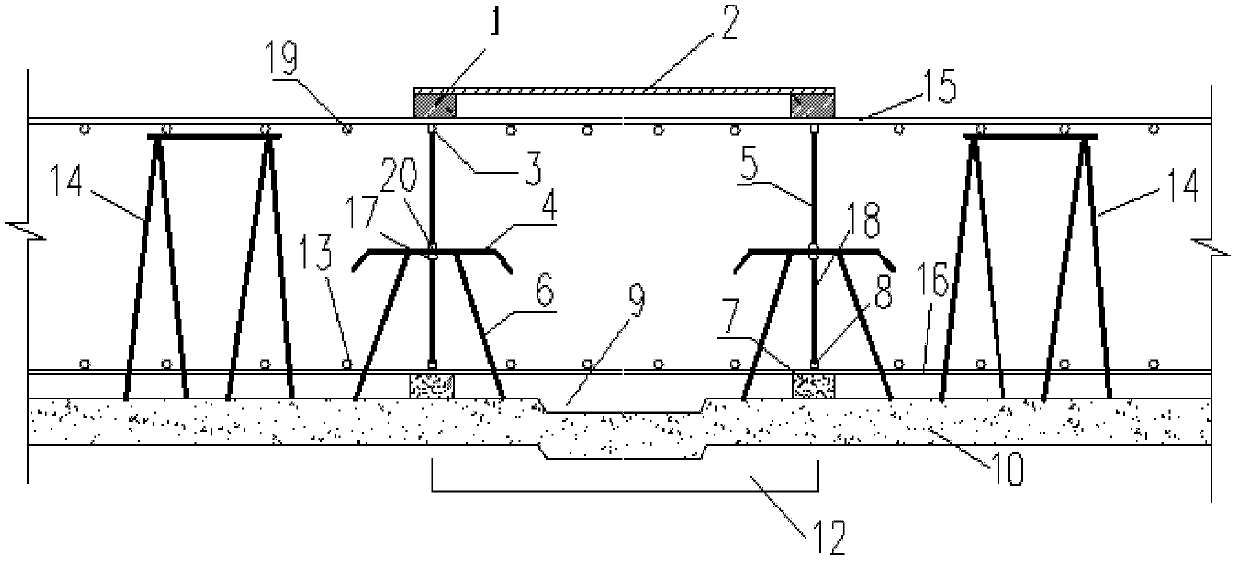

[0052] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0053] refer to figure 1 , figure 2 , the combined structure of the base plate post-casting water-stop steel plate of the present invention includes a water-stop steel plate 4, and the upper and lower parts of the water-stop steel plate 4 are respectively provided with an upper steel mesh sheet 5 and a lower steel mesh sheet 18 located in the longitudinal center thereof; The upper steel mesh sheet 5 and the lower steel mesh sheet 18 are respectively supported by several upright upper supporting bars 11 and lower supporting bars 21; 3 and the second main reinforcement 20 that is connected to its lower end are fixed; several described lower supporting reinforcements 21 are respectively fixed by the third main reinforcement 17 that is connected to its upper end and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com