Turnable sealing ring assembly in puncture outfit

A technology of rotating seals and trocars, applied in the direction of puncture needles, trocars, etc., can solve problems such as inability to seal surgical instruments, deformation of the circular channel orifice of the spherical sealing ring, gas leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

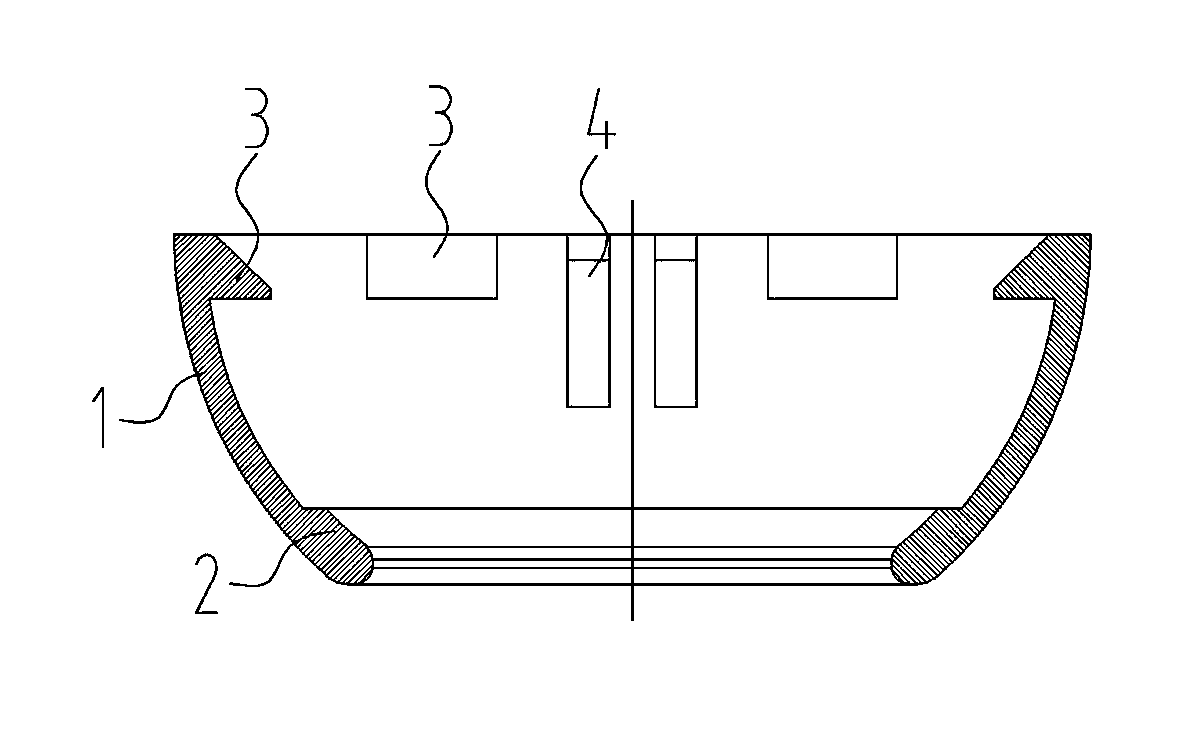

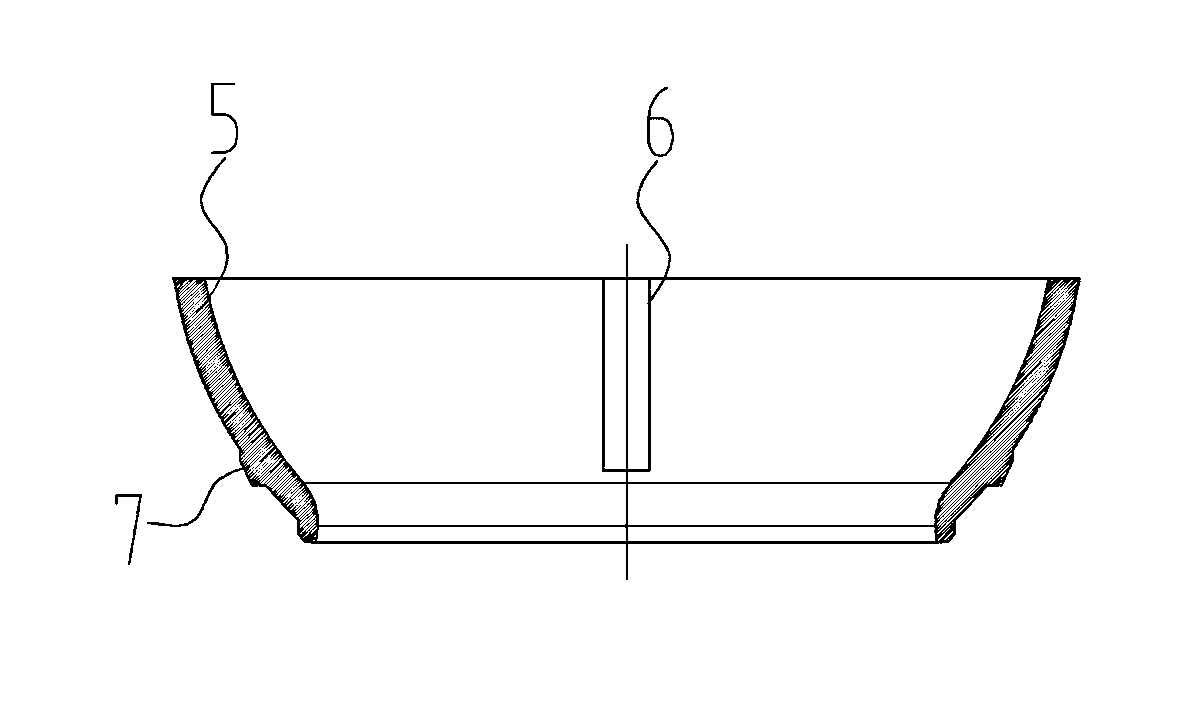

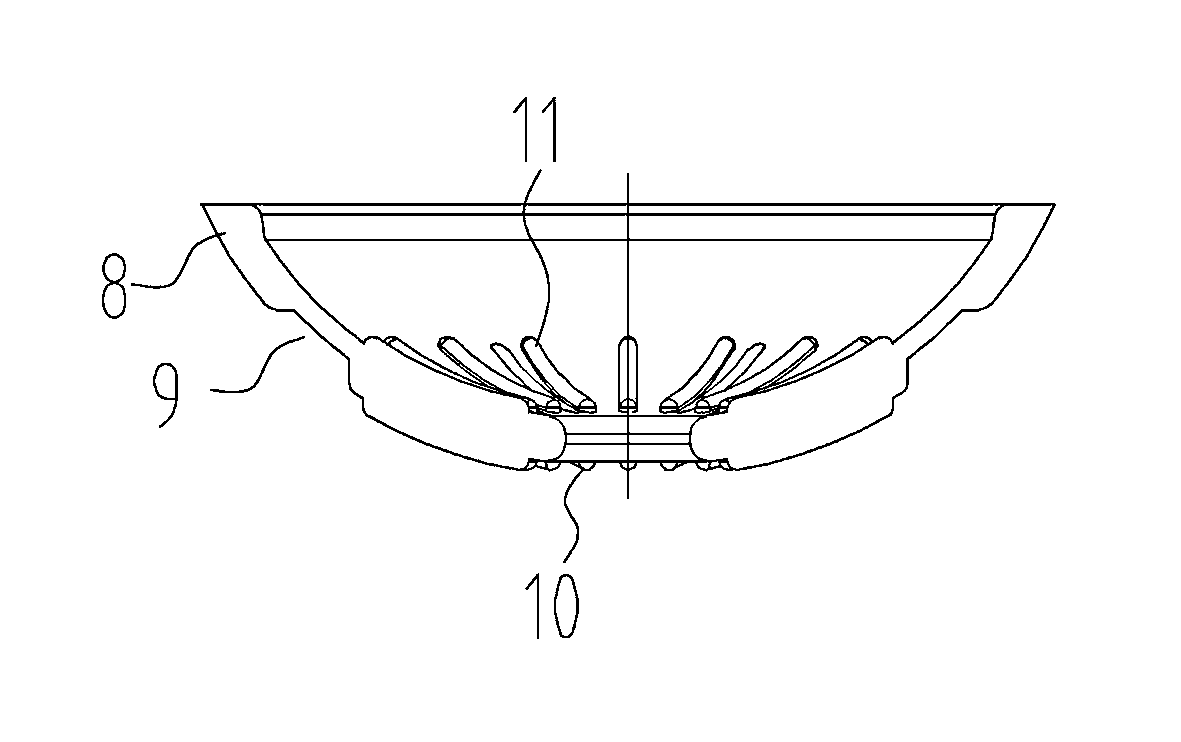

[0023] Such as image 3 with Figure 4 As shown, the rotatable sealing ring assembly in the puncture device of the present invention includes a spherical sealing ring 8, and the inner and outer surfaces of the spherical sealing ring 8 are uneven non-continuous smooth surfaces. Preferably, the middle part of the outer surface of the spherical sealing ring 8 has a ring shape Groove 9, the lower part of the outer surface of the spherical sealing ring 8 is provided with sixteen outer convex ribs 10 uniformly distributed around the axis, and the lower part of the inner surface of the spherical sealing ring 8 is provided with sixteen inner ribs uniformly distributed around the axis Rib 11 also includes a pair of fastened spherical bowl-shaped inner clamping shells 5 and spherical bowl-shaped outer clamping shells 1, such as figure 1 As shown, the inner side below the upper edge of the spherical bowl-shaped outer clamping shell 1 has six wedge-shaped bosses 3 uniformly distributed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com