Blade tip gap measuring system and method based on AC discharging

A technology of blade tip clearance and AC discharge, applied in the field of blade clearance measurement, can solve the problems of friction between blade tip and inner wall of casing, affecting engine safety, and damage to parts and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

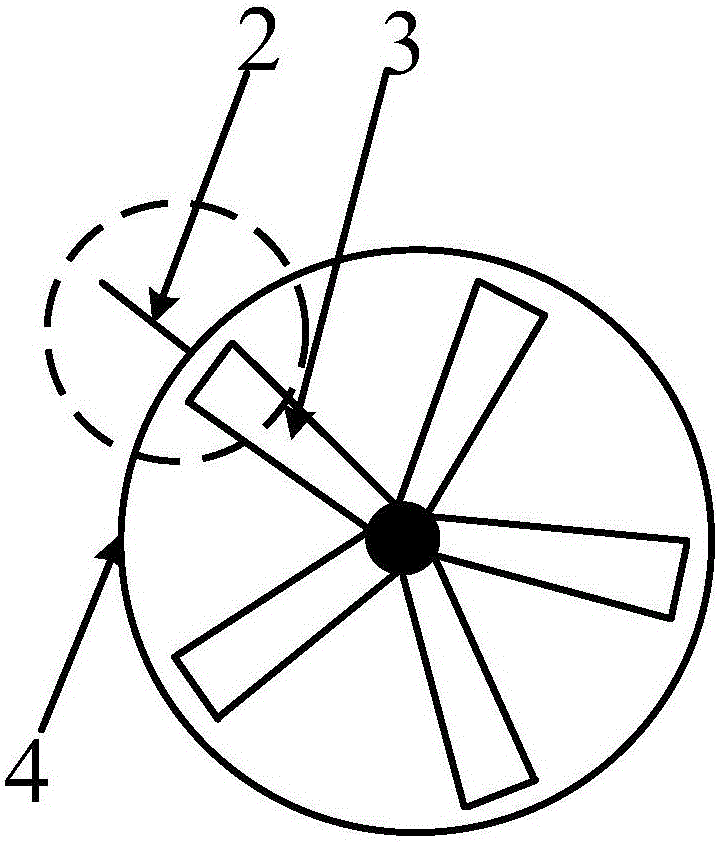

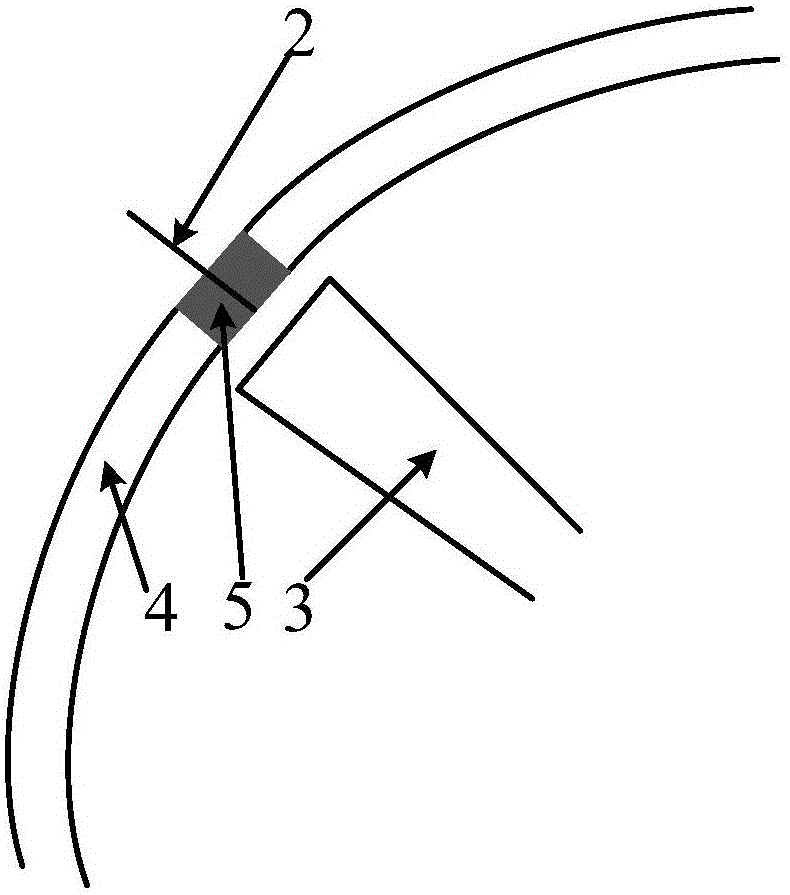

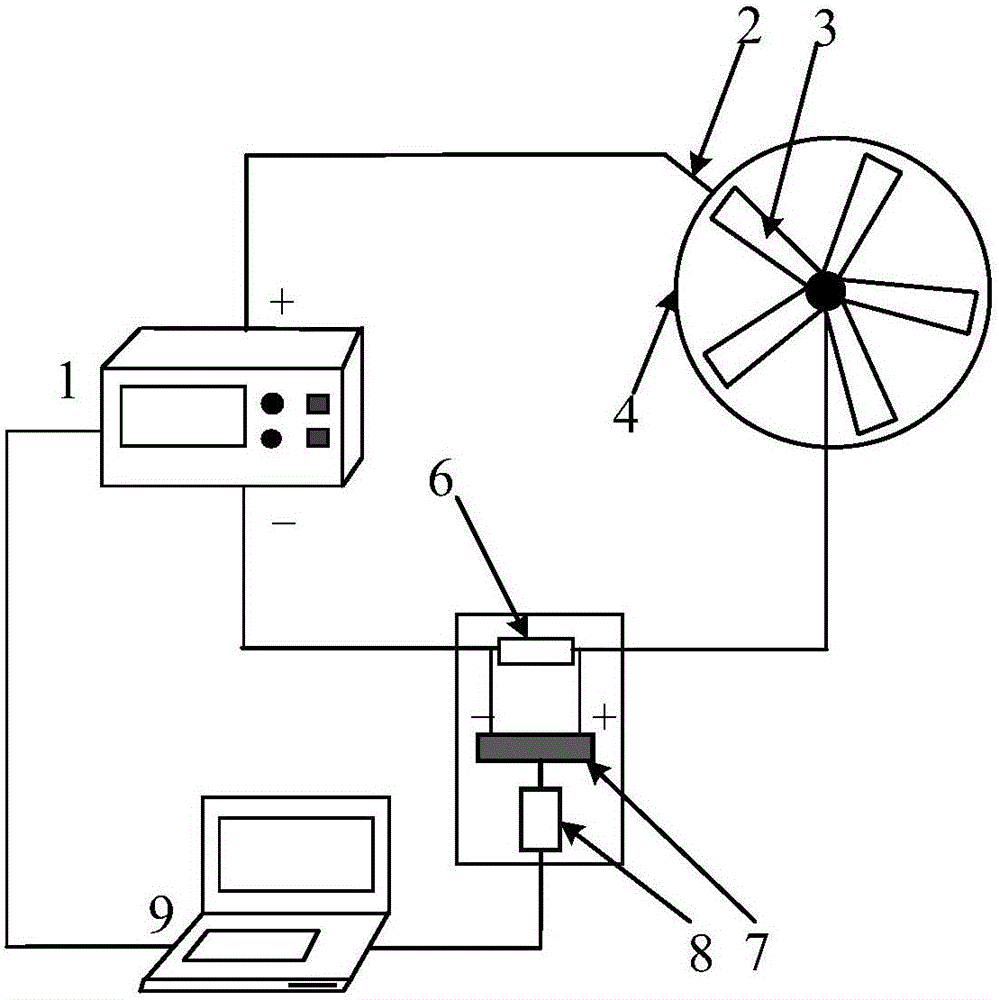

[0027] Such as image 3 As shown, the present invention provides a blade tip clearance measurement system based on AC discharge, including an AC numerical control adjustable excitation 1, a discharge probe 2, a detection resistor 6, a voltage sensor 7, an analog-to-digital converter 8 and a data processing module 9, Wherein, discharge probe 2 is inserted into casing 4 by the outside of casing 4, cooperates figure 1 with figure 2 As shown, and make one end of the discharge probe 2 flush with the inner wall of the casing 4, while the other end is exposed outside the casing 4, and the insulating layer 5 is wrapped in the part where the discharge probe 2 is inserted into the casing 4, and the The discharge probe 2 is completely isolated from the casing 4; the high-voltage end of the AC numerical control adjustable excitation 1 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com