Piezoelectric fan

a technology of piezoelectric elements and fans, applied in the direction of machines/engines, positive displacement liquid engines, machine/engine details, etc., can solve the problems of disturbance of drive signals for driving piezoelectric elements, inability to obtain desired vibration, and possible electrical conduction. , to achieve the effect of reliably obtaining desired vibration and preventing electrical conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

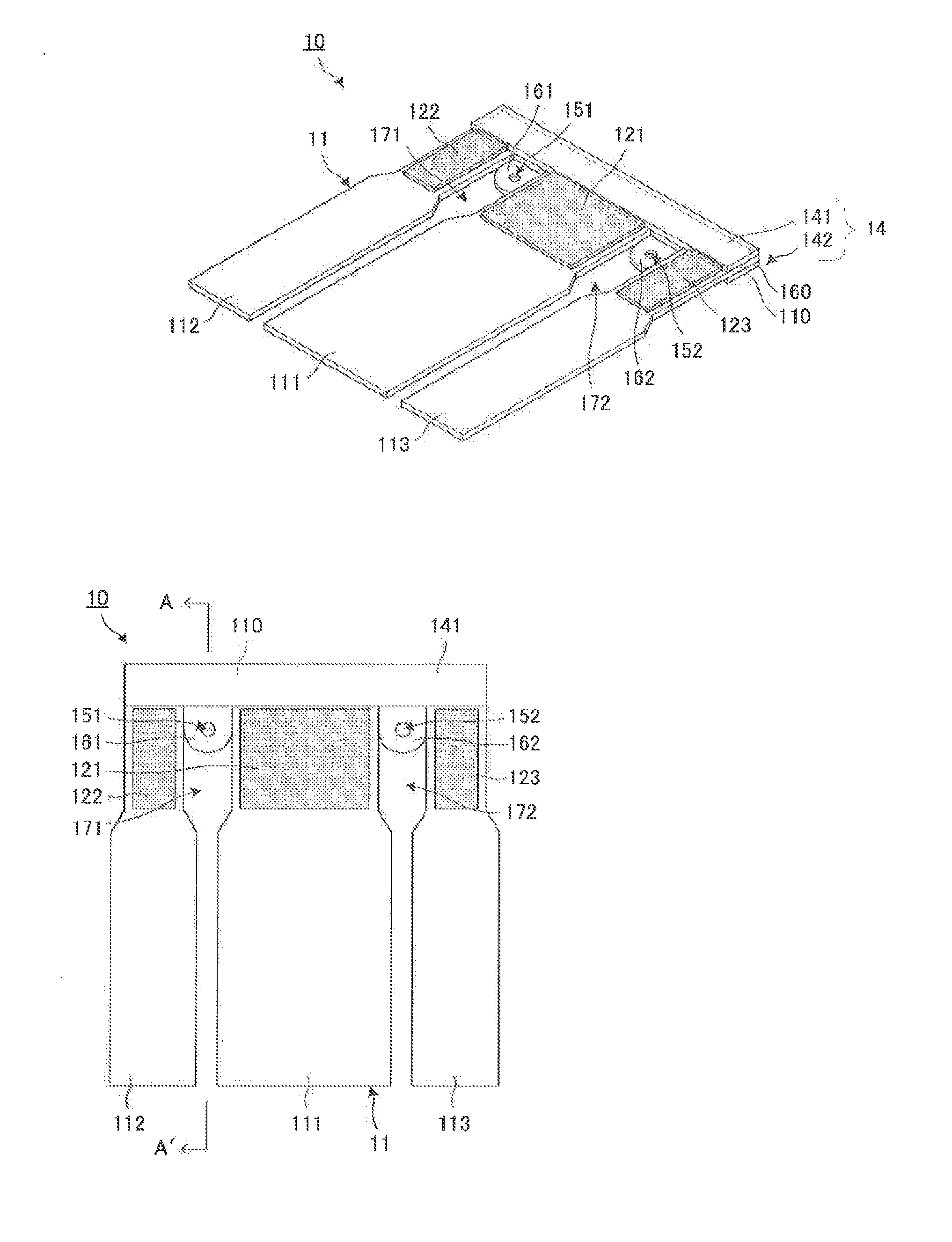

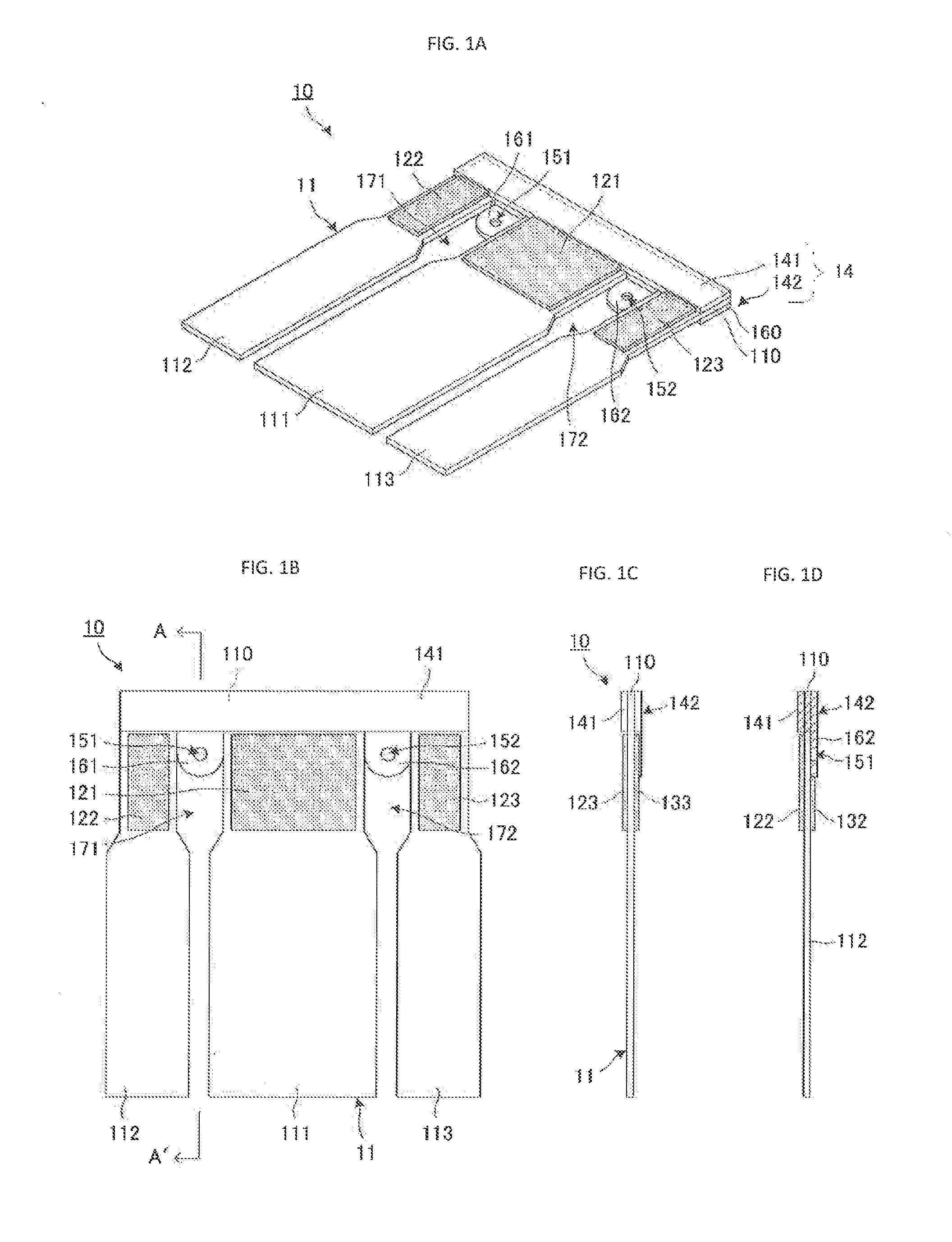

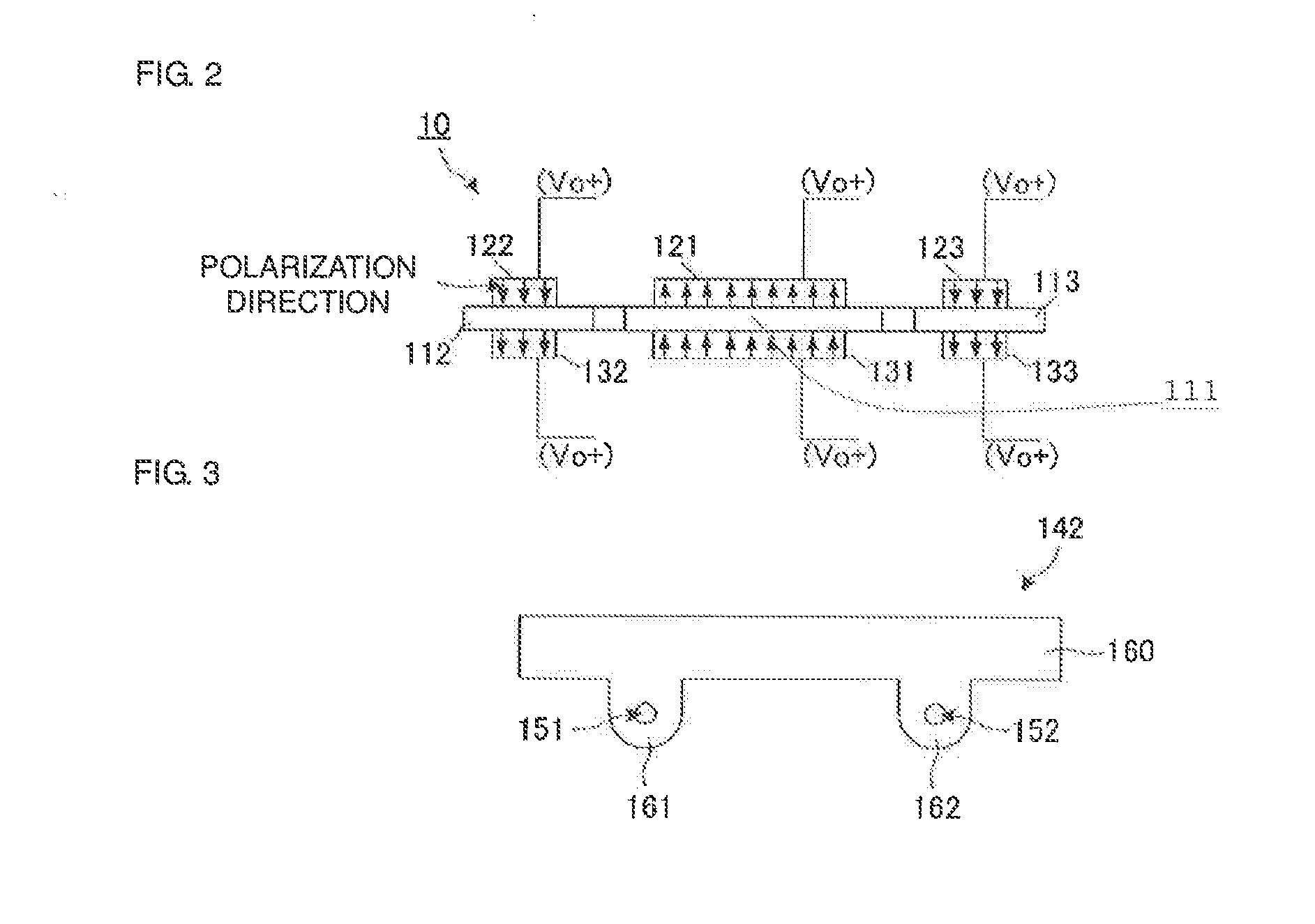

[0033]A piezoelectric fan according to a first preferred embodiment of the present invention will be described with reference to the drawings. FIG. 1A is an external perspective view of a piezoelectric fan 10 according to the first preferred embodiment of the present invention. FIG. 1B is a plan view of the piezoelectric fan 10 according to the first preferred embodiment of the present invention. FIG. 1C is a lateral view of the piezoelectric fan 10 according to the first preferred embodiment of the present invention. FIG. 1D is a cross-sectional view taken along line A-A′ of the piezoelectric fan 10 according to the first preferred embodiment of the present invention. FIG. 2 illustrates a driving concept of the piezoelectric fan 10 according to the first preferred embodiment of the present invention. FIG. 3 is a plan view of a holding member 142 according to the first preferred embodiment of the present invention.

[0034]The piezoelectric fan 10 includes a vibrating plate 11, piezoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com