Terminal unit and method of manufacturing the same

a terminal unit and terminal technology, applied in the field of terminal units, can solve problems such as unfavorable electrical conductivity, and achieve the effect of preventing the variation of electric conductivity in the terminal uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

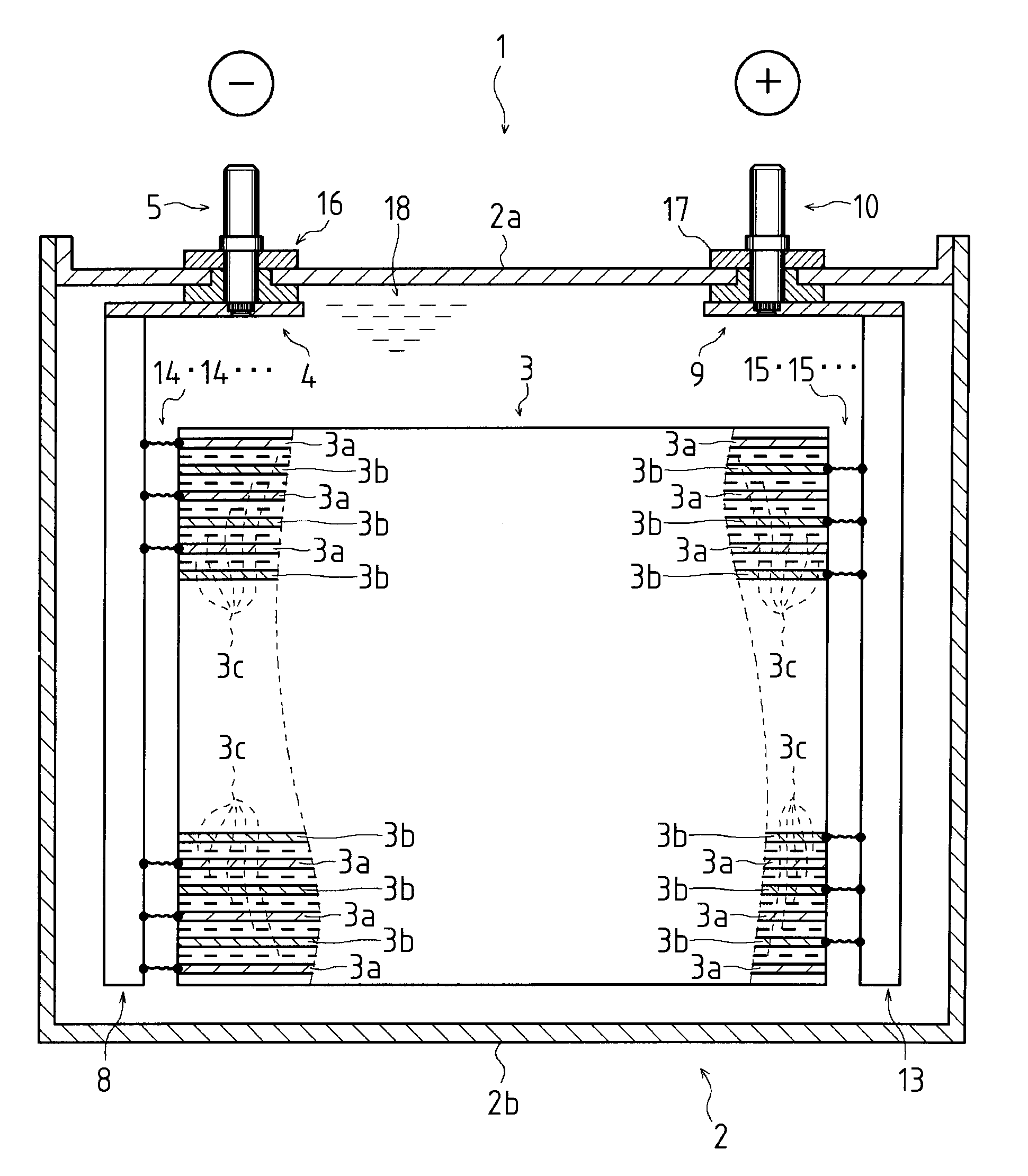

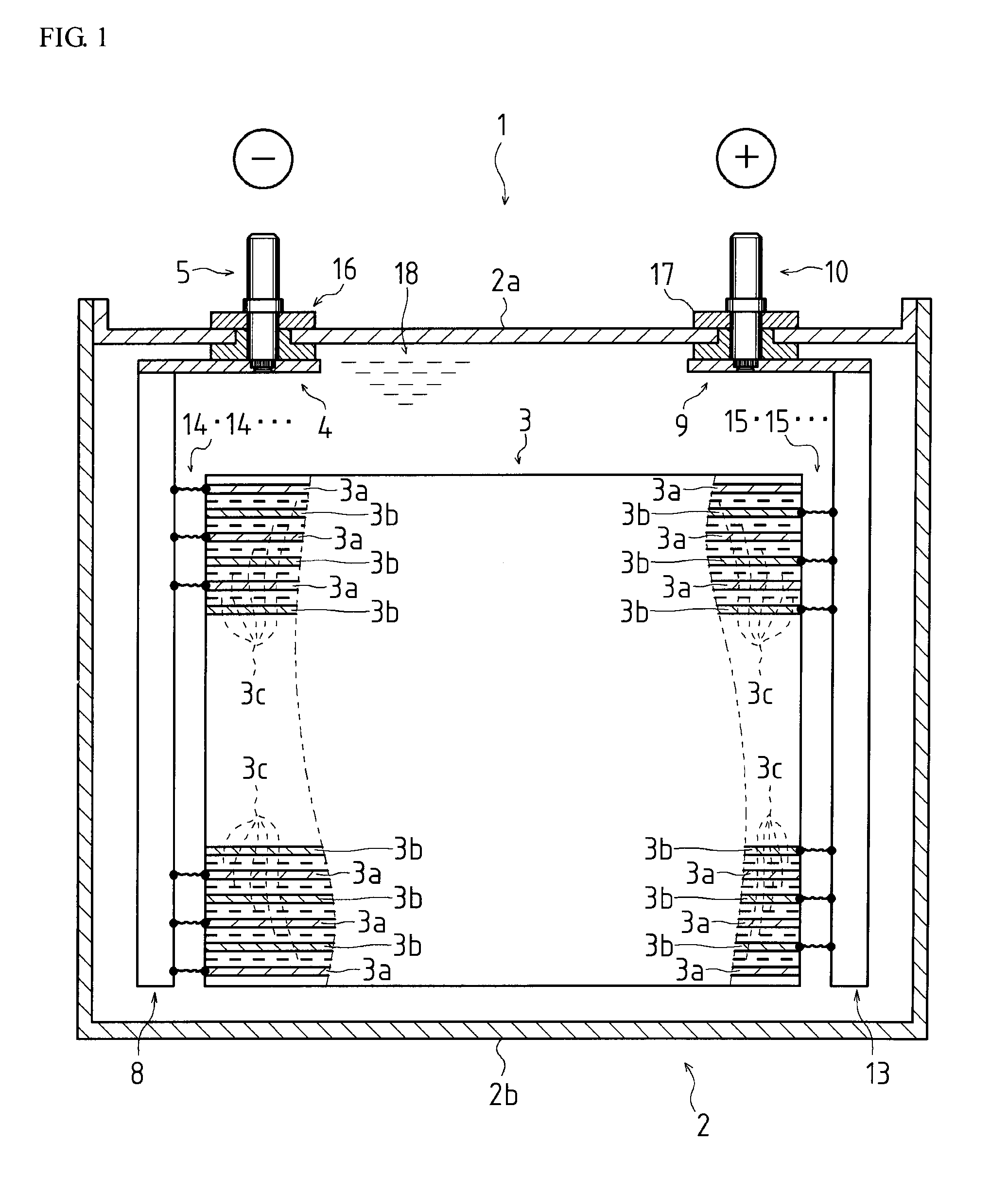

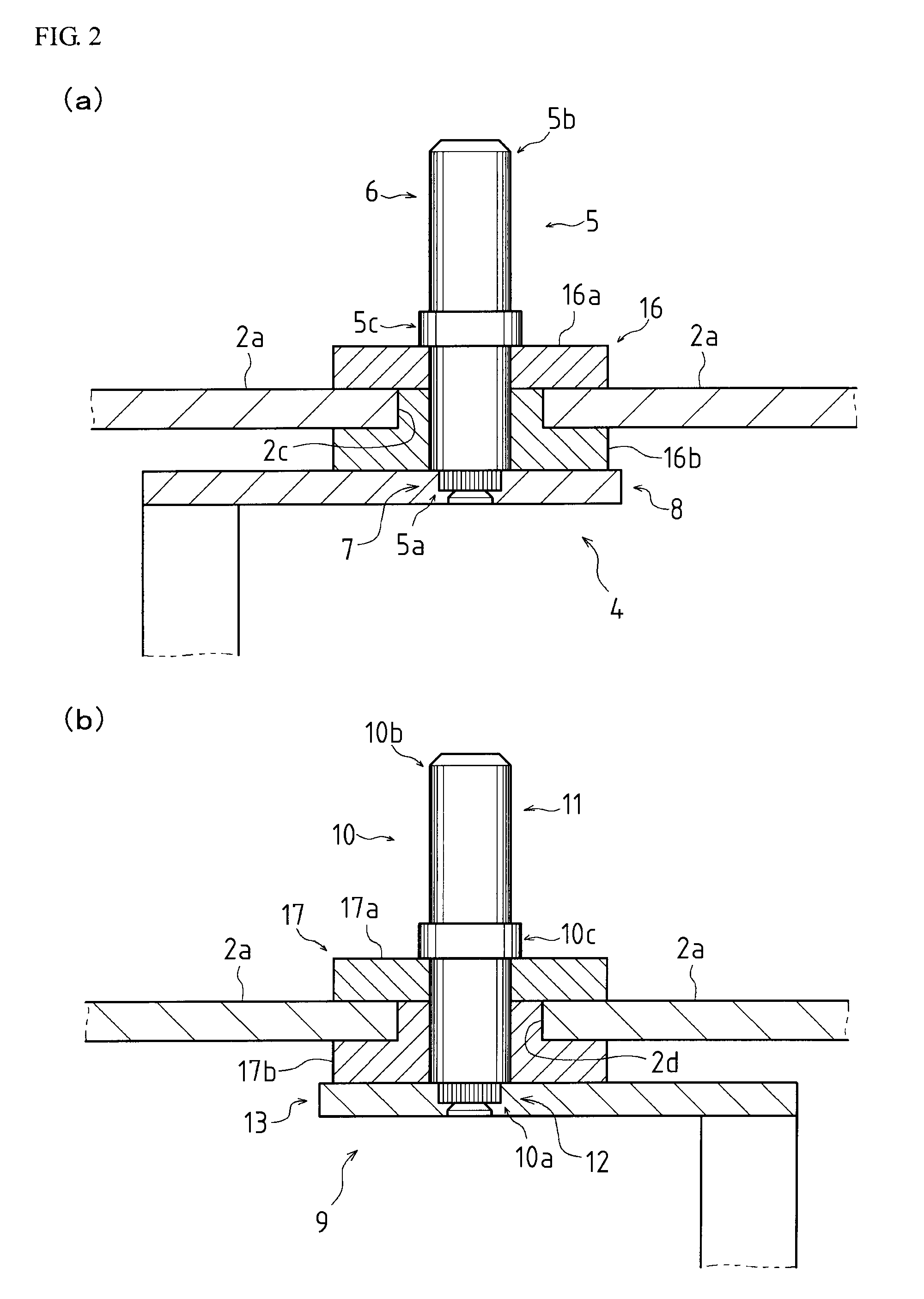

[0032]Referring FIG. 1, the whole structure of a battery 1 will be described, which includes terminal units 4, 9, each of which is one embodiment of a terminal unit according to the present invention.

[0033]It should be noted that the battery 1 including the terminal units 4, 9 is described in this description, though the terminal unit according to the present invention may be broadly applied, not limited to the battery.

[0034]As shown in FIG. 1, the battery 1 is a box-shaped lithium-ion battery, containing a case 2, an electrode body 3, and the terminal units 4, 9.

[0035]The case 2 is composed of a lid part 2a and a case part 2b, and is filled with an electrolyte solution 18 that behave as an electrically conductive medium.

[0036]The electrode body 3 is, for example, composed of a negative electrode sheet 3a such as a copper sheet coated with a carbon substance, a positive electrode sheet 3b such as a aluminum sheet coated with a lithium-ion compound and a separator sheet 3c, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters D1 | aaaaa | aaaaa |

| heights H1 | aaaaa | aaaaa |

| diameters D2 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com