Wafer cleaning device

A technology for cleaning devices and wafers, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems affecting wafer quality, liquid splashing, liquid penetration, etc., to improve user convenience, improve cleanliness, The effect of preventing conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

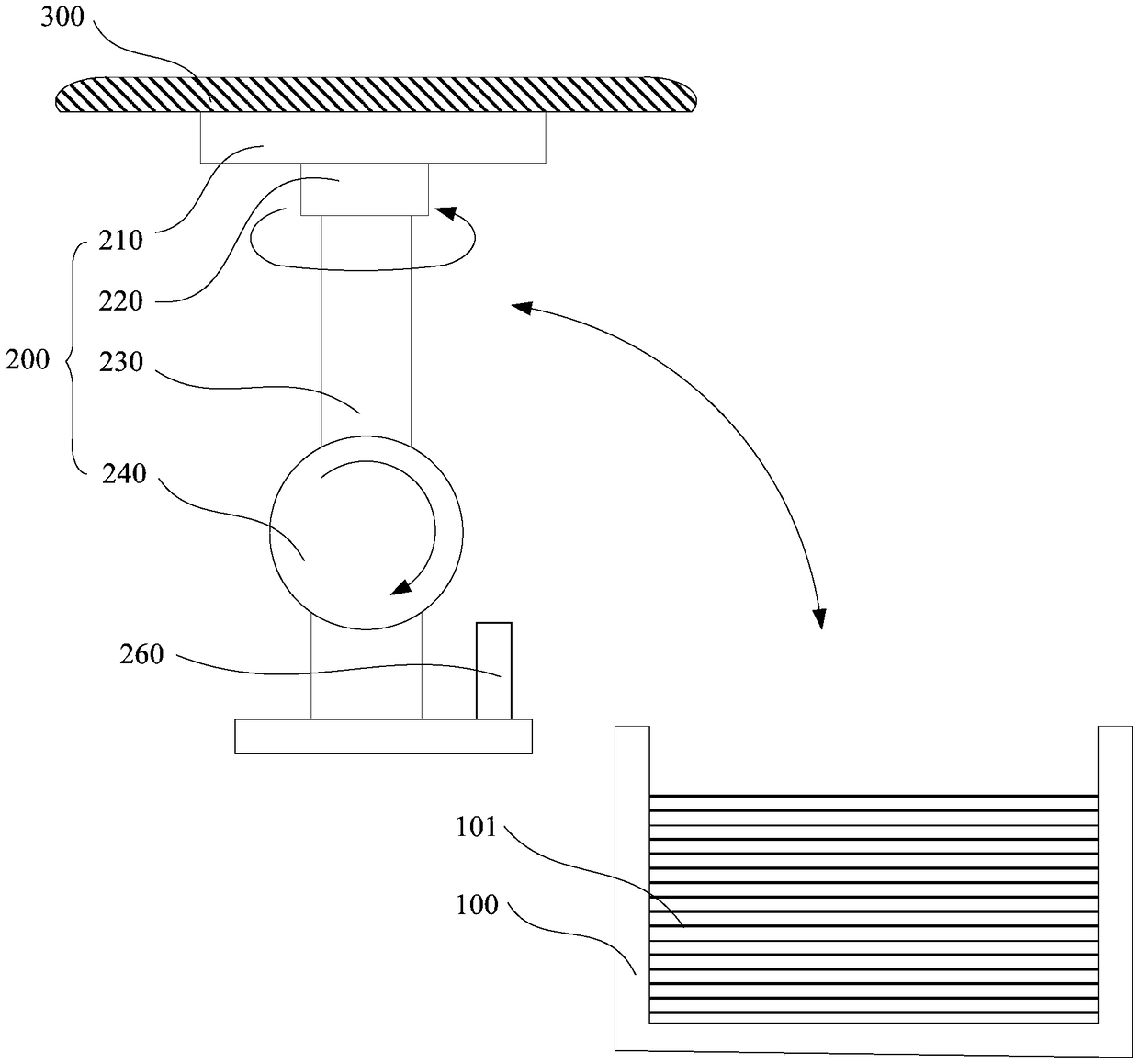

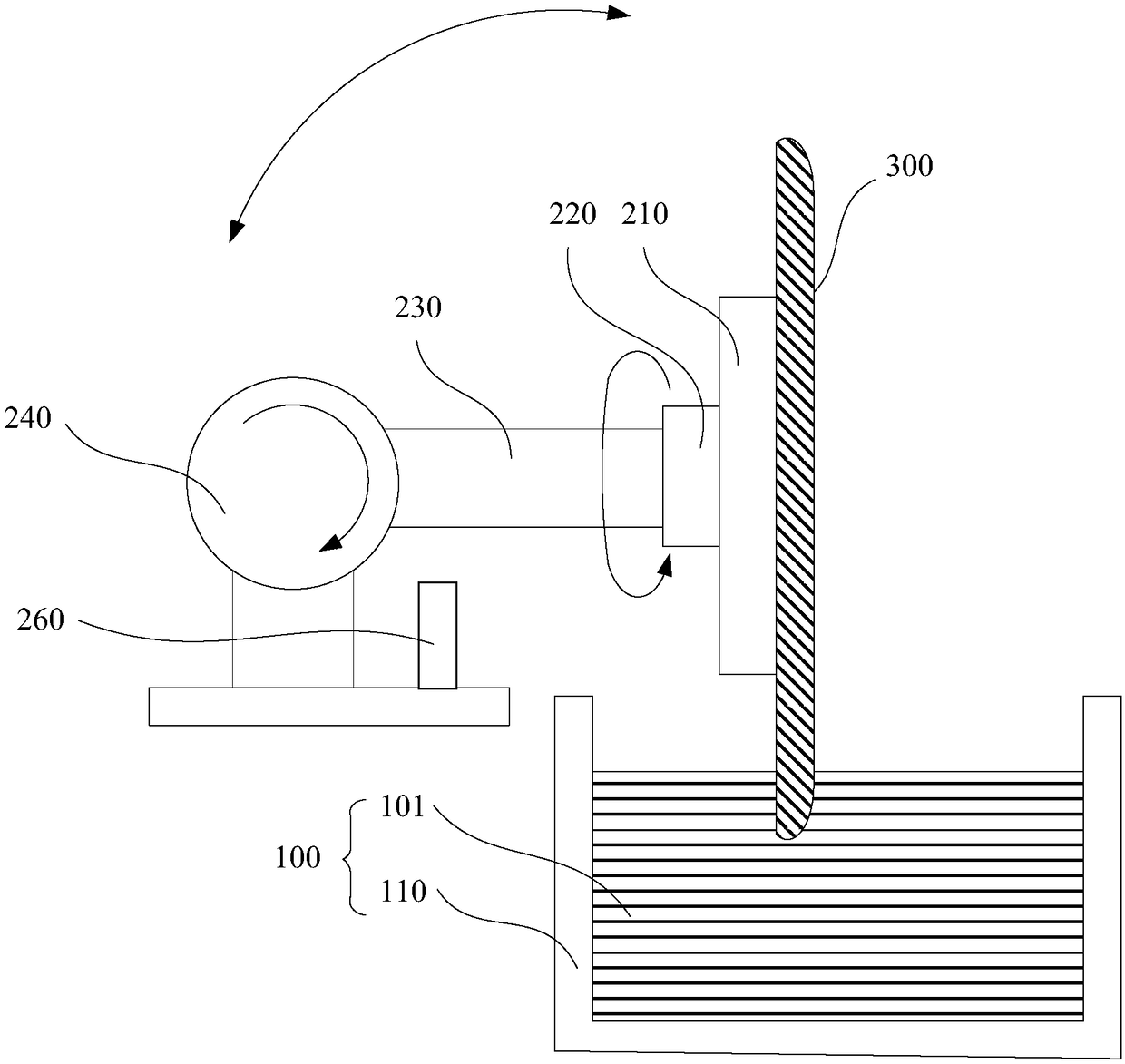

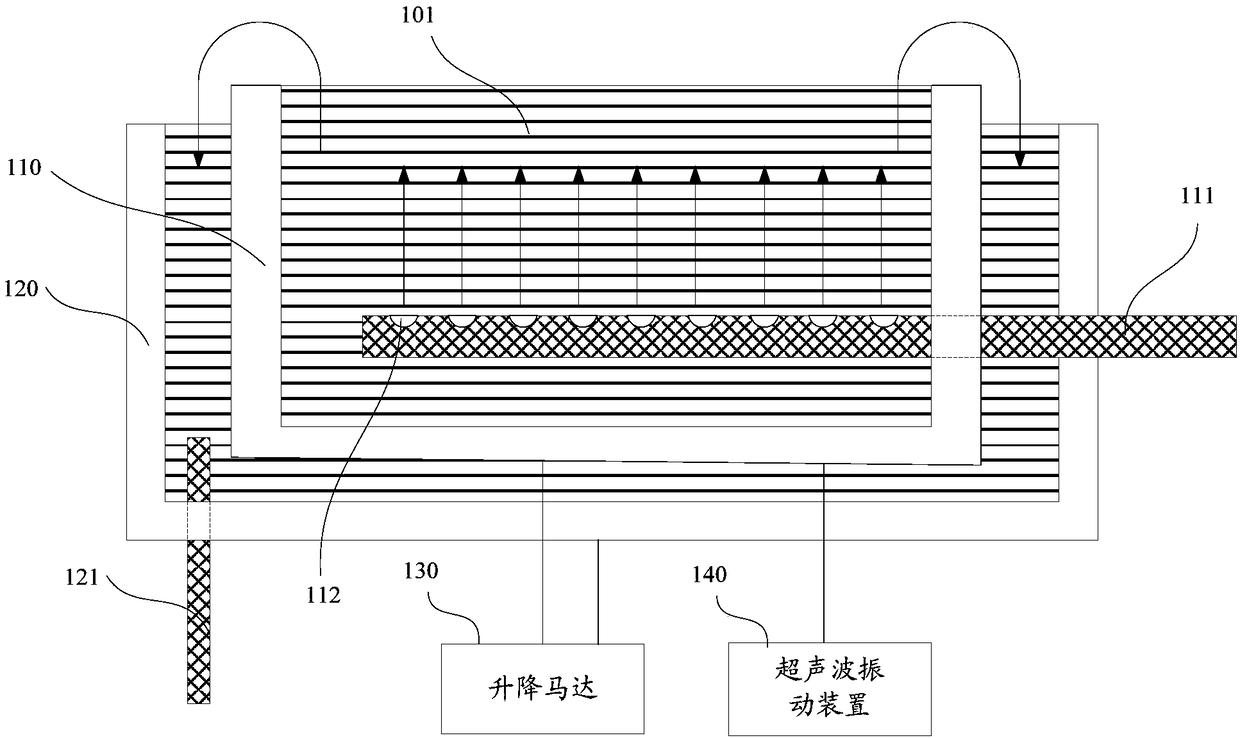

[0027] In the prior art, in the front bonding process of the carrier wafer and the semiconductor substrate, it is required to be tightly bonded and the bonding surface is free of solid particles and air bulges, so it is necessary to improve the front, back and edge of the wafer. cleanliness. However, in the prior art, the particle cleaning effect at the edge of the wafer is poor.

[0028] More specifically, the main factors affecting the cleanliness of the wafer are the film layer at the edge of the wafer and particle defects such as particles, chips, and peeling, followed by particle defects on the surface of the wafer. The granular particles on the front and back of the wafer can be effectively controlled by the existing wafer surface treatment technology. However, the etching of the film layer at the edge of the wafer and the defect treatment cannot achieve accurate etching and effective cleaning in the existing hardware design.

[0029] The inventor of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com