Method and device for three-point bending mechanical property test of small-sized sheet sample

A technology of three-point bending and testing method, which is applied in the direction of applying stable bending force to test the strength of materials, etc. It can solve the problems of impracticability, large samples, and inability to realize high-speed crack cracking research of small-scale samples, so as to avoid interference with acquisition signals , to prevent the effect of conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

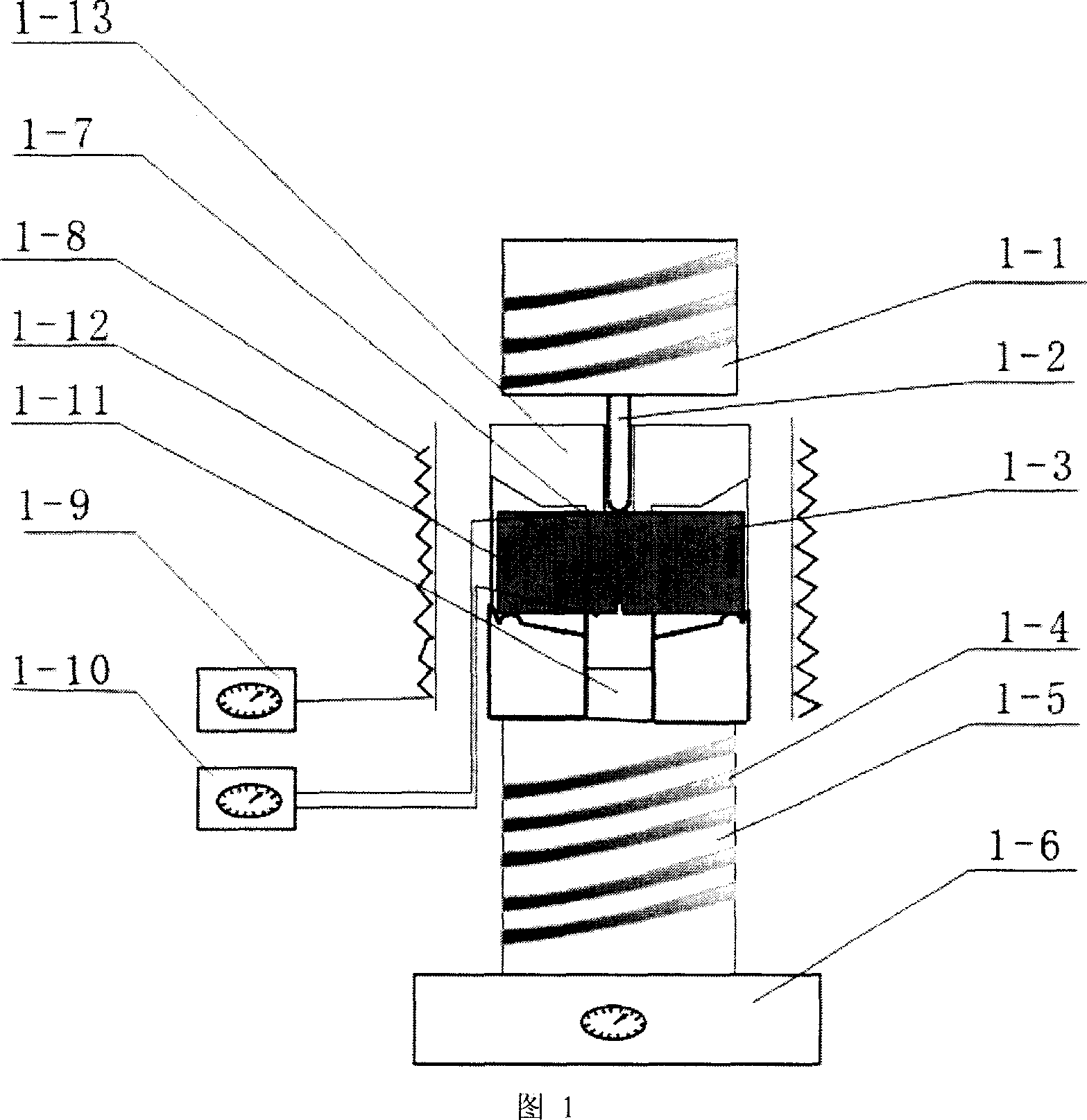

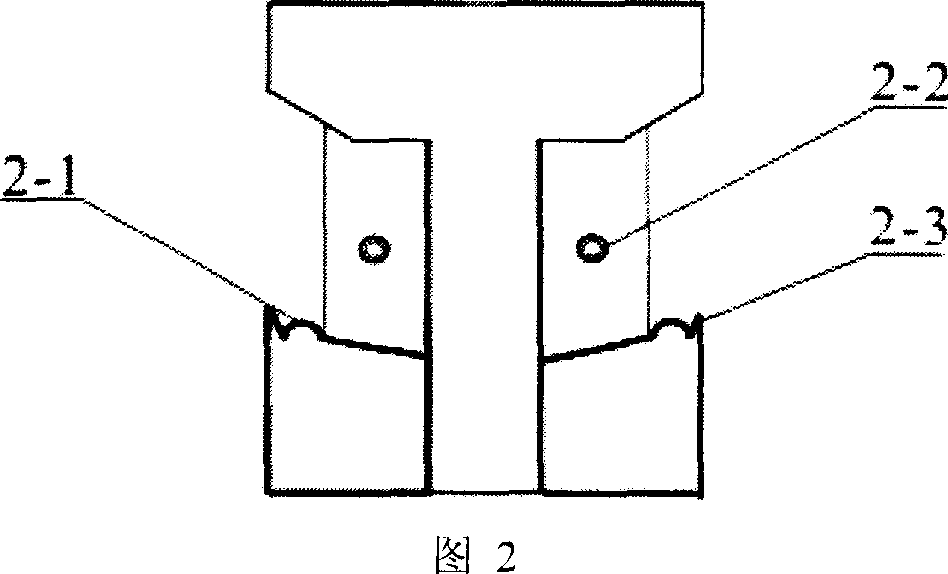

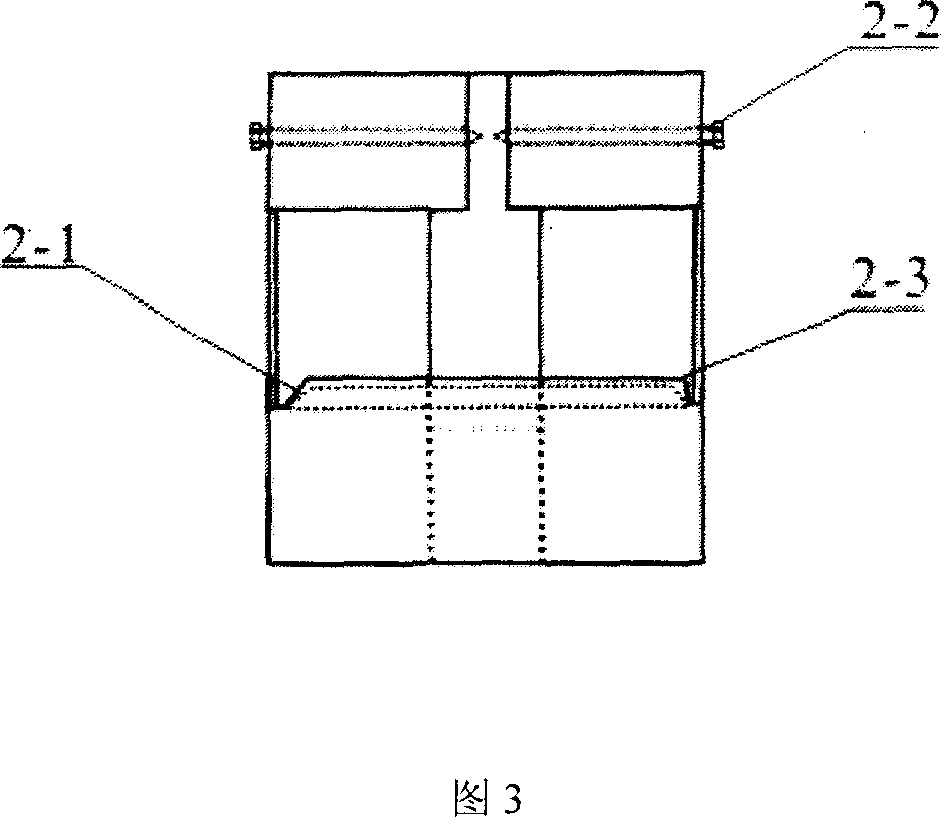

[0030] As shown in Figures 1 to 3, the device for testing the three-point bending mechanical properties of small-scale flake samples according to the present invention is composed of a sample stage, a sample stage support system, a cooling system, a heating system, a loading system, and a testing system. The sample stage is a three-point bending sample stage. The three-point bending sample stage is made of high-temperature alloy. There are narrow slots for placing sheet samples 1-3, two sample support points 2-1 and sample support point 2-1. The outer sample limit point 2-3, the surface of the sample table 1-13 corresponding to the vertically placed sheet sample 1-3 is equipped with a limit bolt 2-2, and the limit bolt 2-2 adjusts the sheet sample 1-3 vertical position. The sample stage support system includes a sample stage support point 1-5 and a sample stage suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com