Patents

Literature

68results about How to "Ensure filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

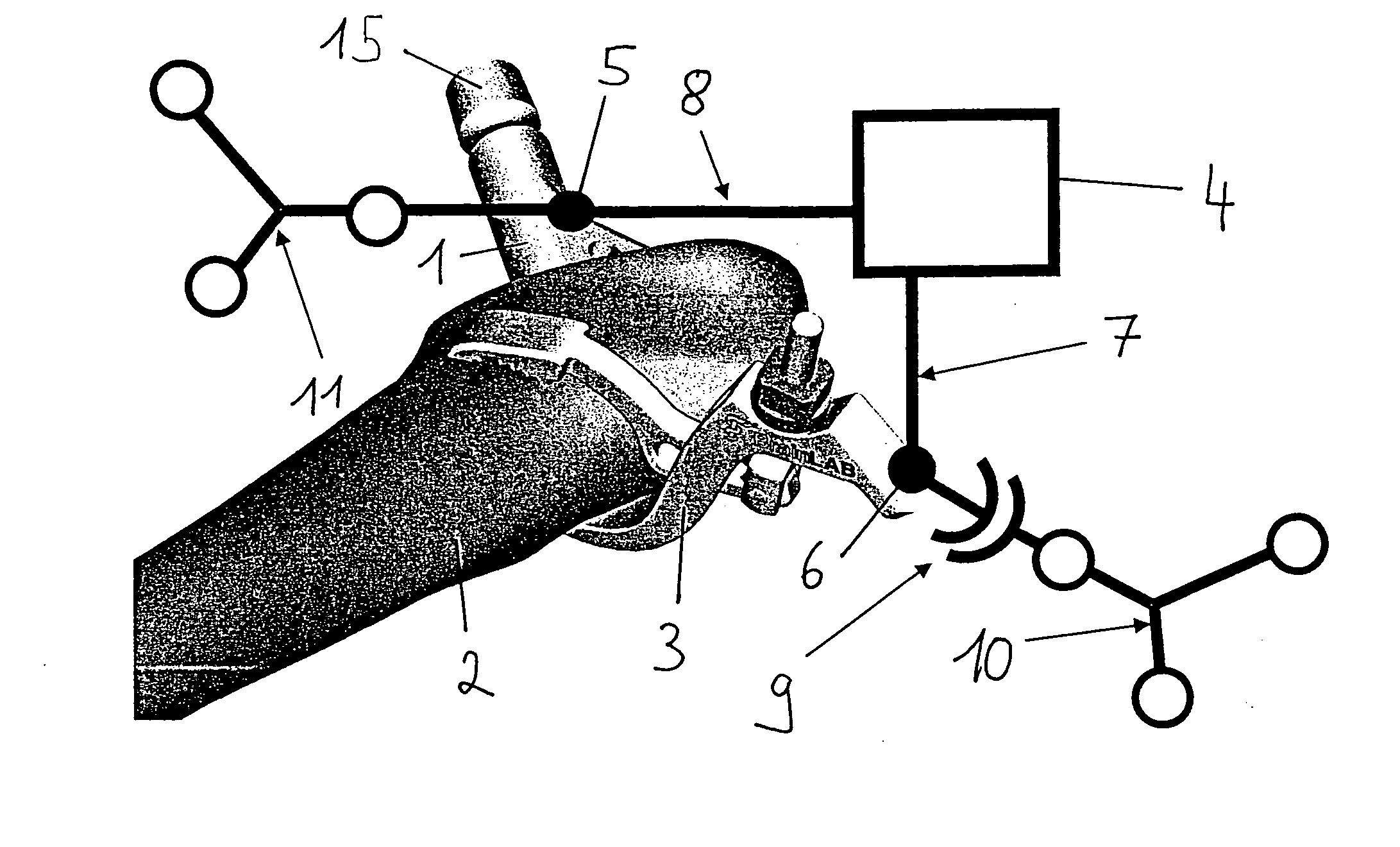

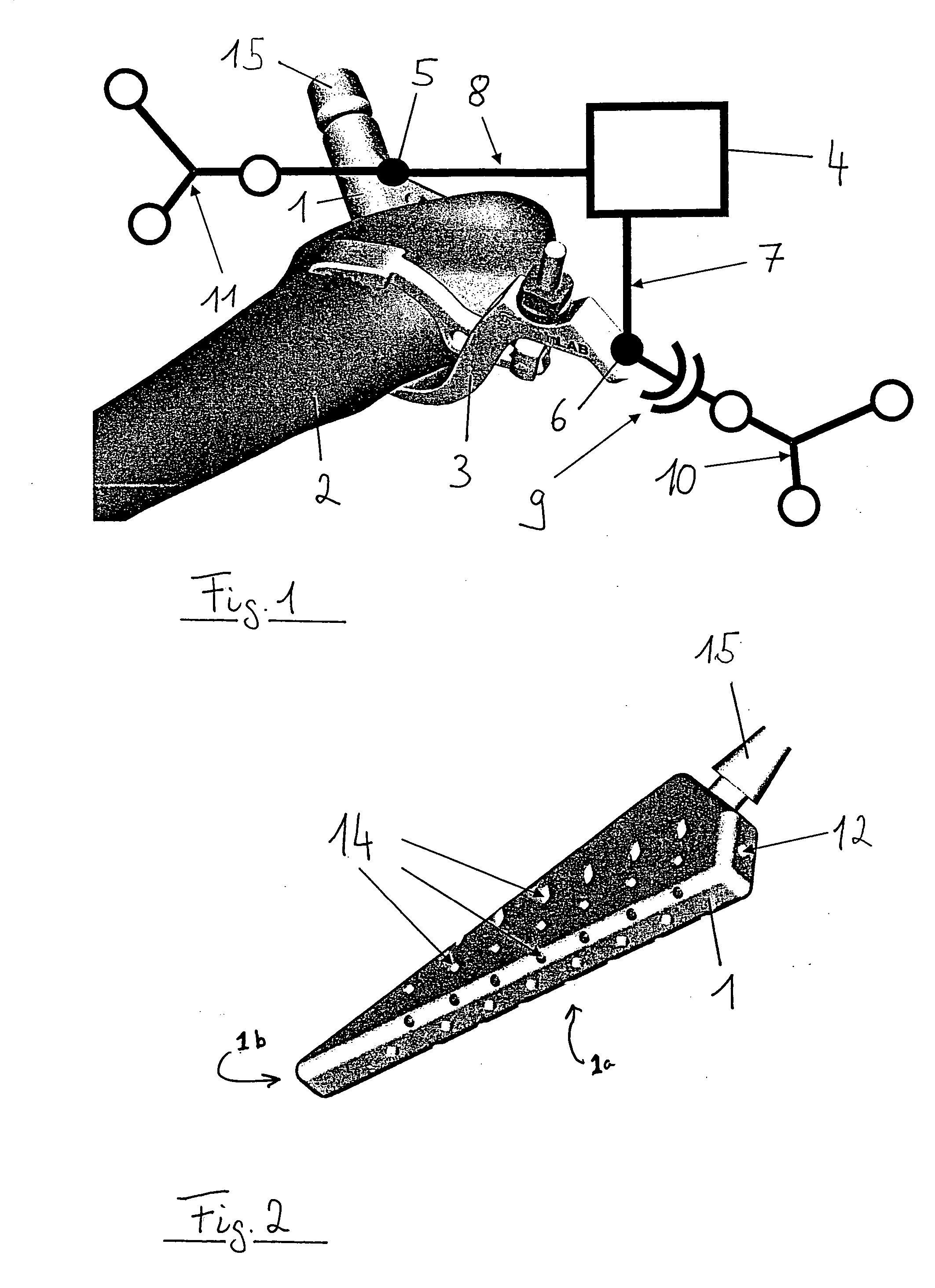

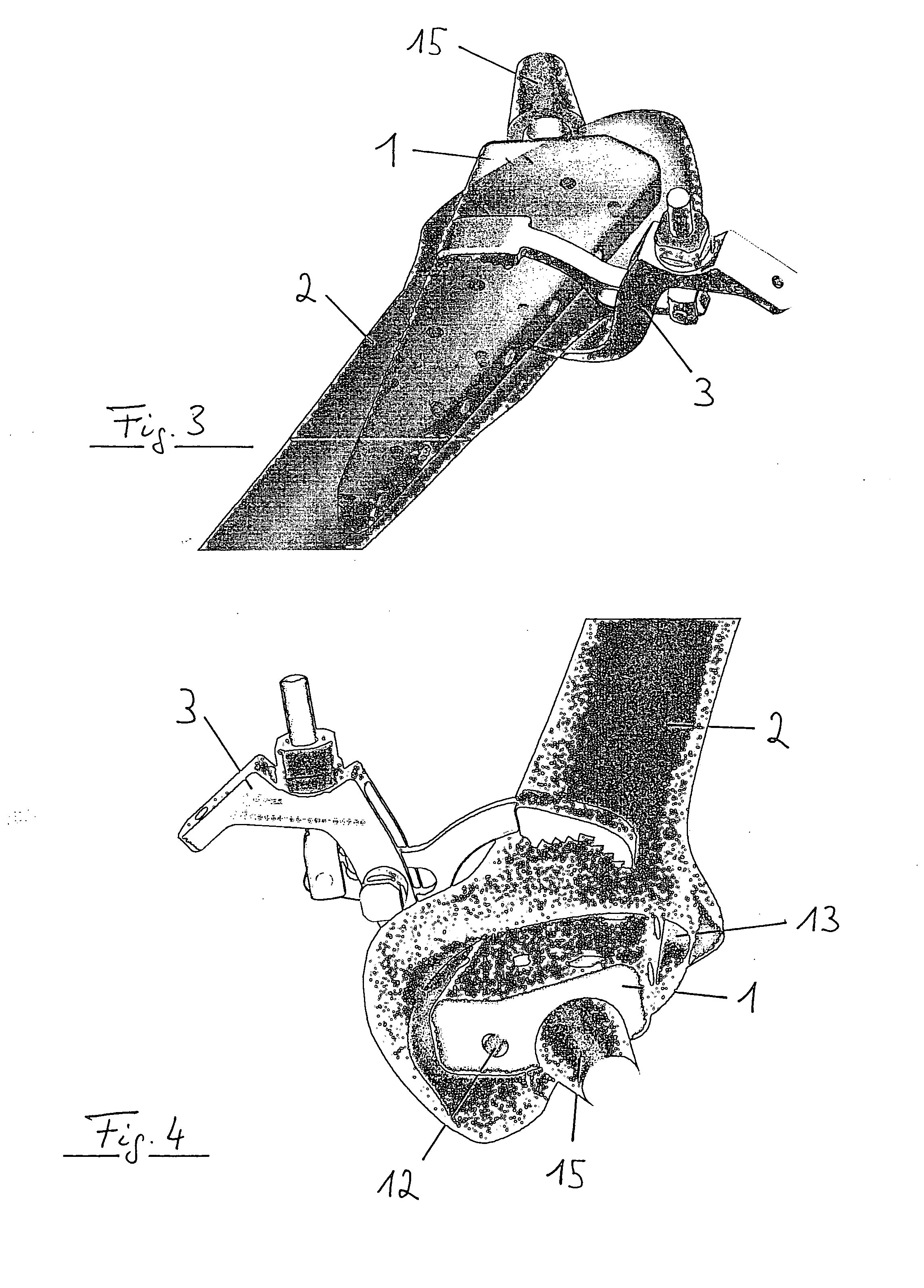

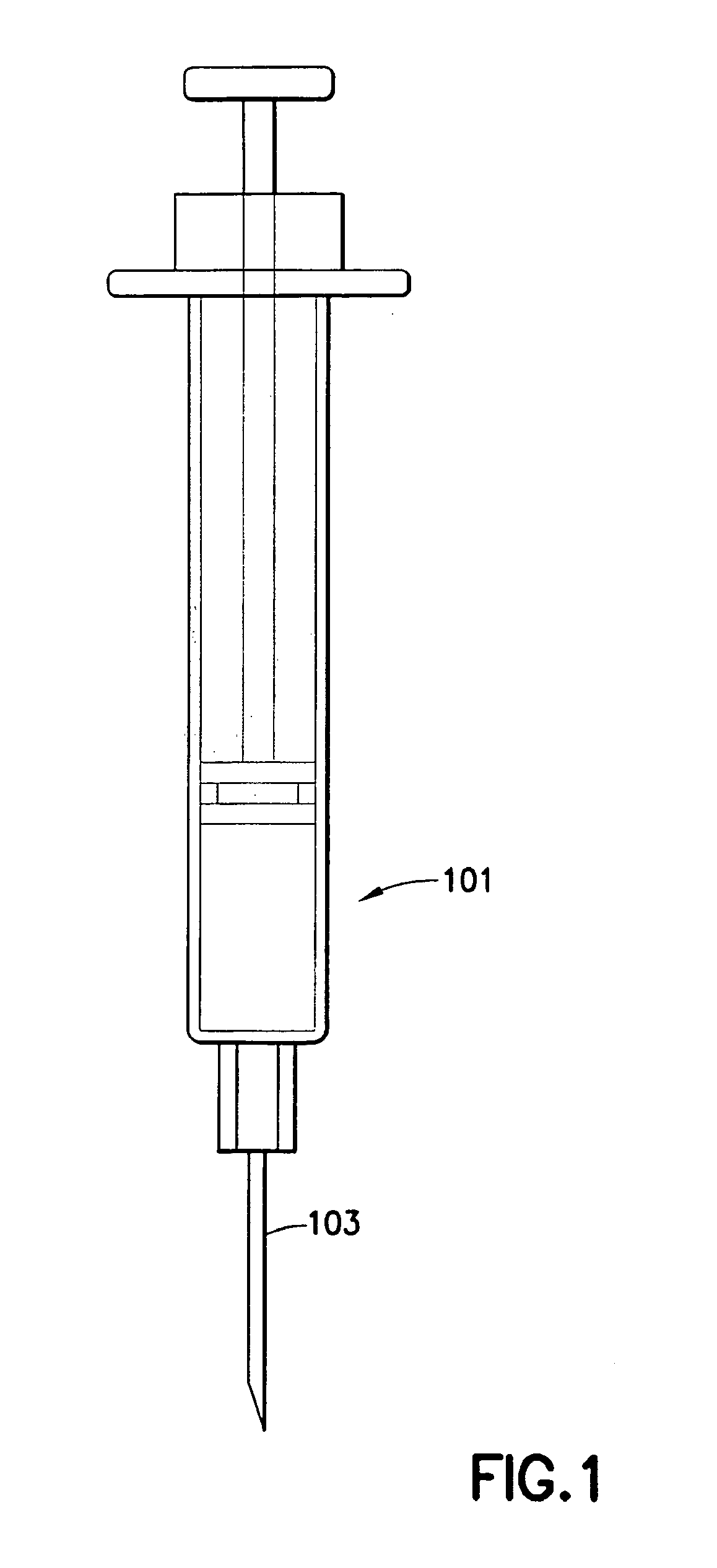

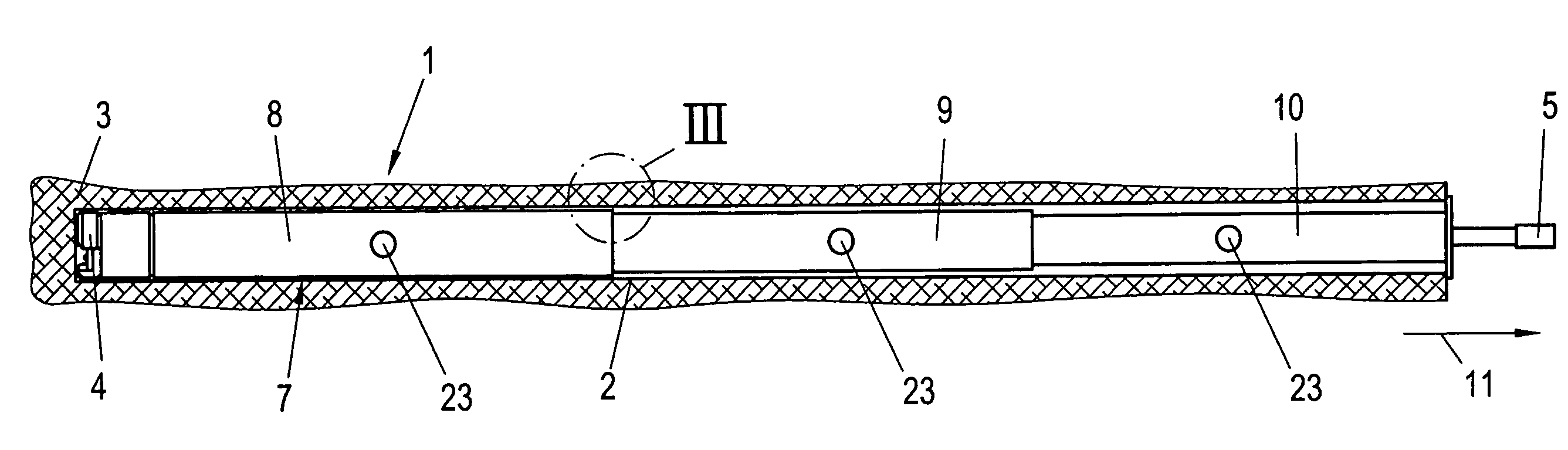

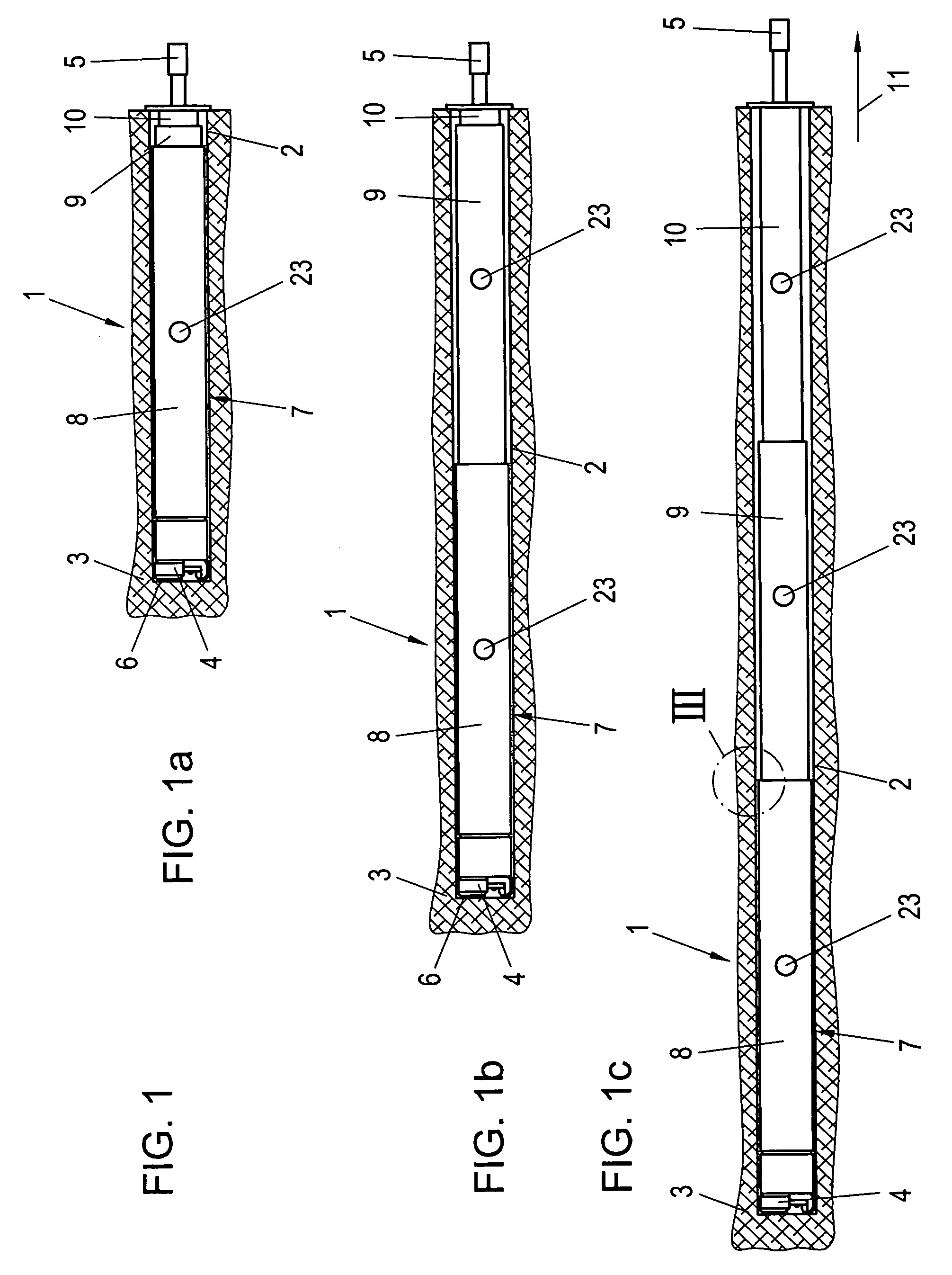

Positioning system with cannulated implant

InactiveUS20060015119A1Minimizes and eliminates large forcePrecise positioningDiagnosticsJoint implantsBiomedical engineeringImplant placement

A positioning system for placing an implant into a cavity of a bone, comprising a cannulated implant that is substantially smaller in the implanting area than the cavity and a positioning device that can hold the implant in a settable position in the cavity.

Owner:SMITH & NEPHEW INC +2

Coating for one or more display areas on a glass or glass-ceramic plate, process for producing said coating, and uses thereof

ActiveUS20100219176A1High surface resistancePrevent electrical conductivityDoors for stoves/rangesDomestic stoves or rangesSol-gelMedicine

The transparent coating for one or more display areas of a glass or glass-ceramic plate is made by a process using a sol-gel paint containing alkyl silicates as binding agents. The transparent coating is provided on areas of the glass or glass-ceramic plate that have been left uncoated by a color-imparting opaque coating and is formed by applying the sol-gel paint to the areas left open and then thermally treating the sol-gel paint so as to cross-link reactive groups of the alkyl silicates. The coating has organic, non-hydrolyzable groups bound directly to silicon. A process for making the coating and the uses of the coated glass or glass-ceramic plate are part of the invention.

Owner:SCHOTT AG

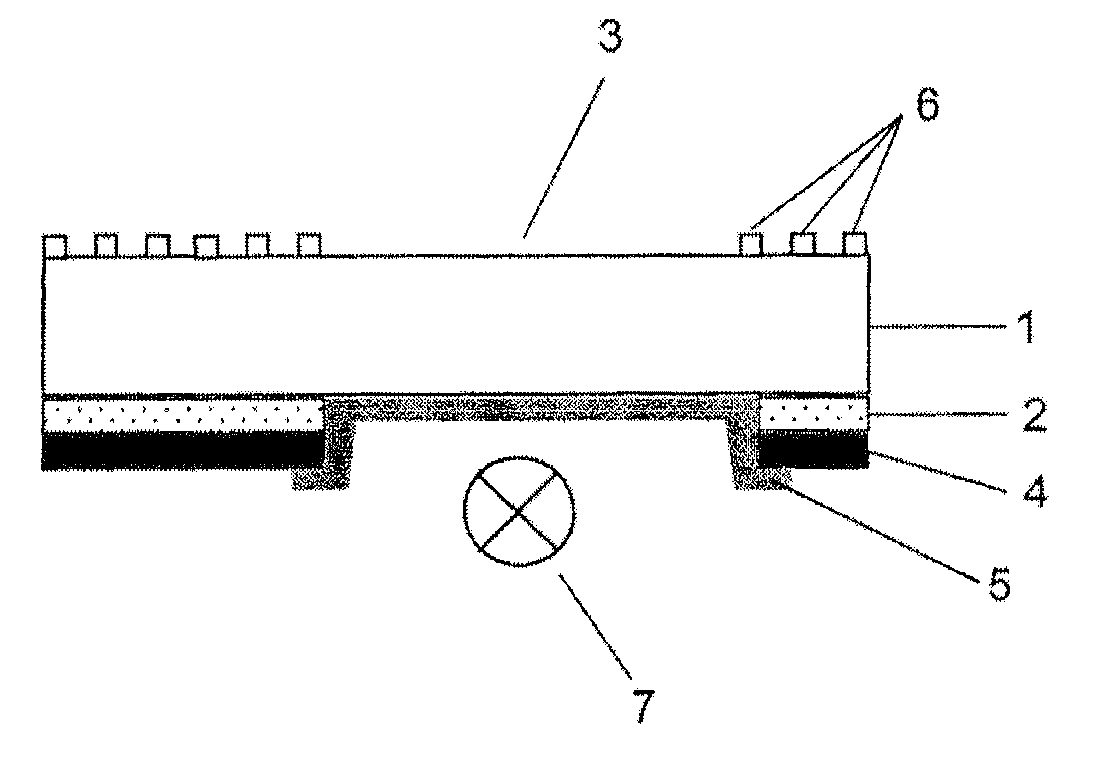

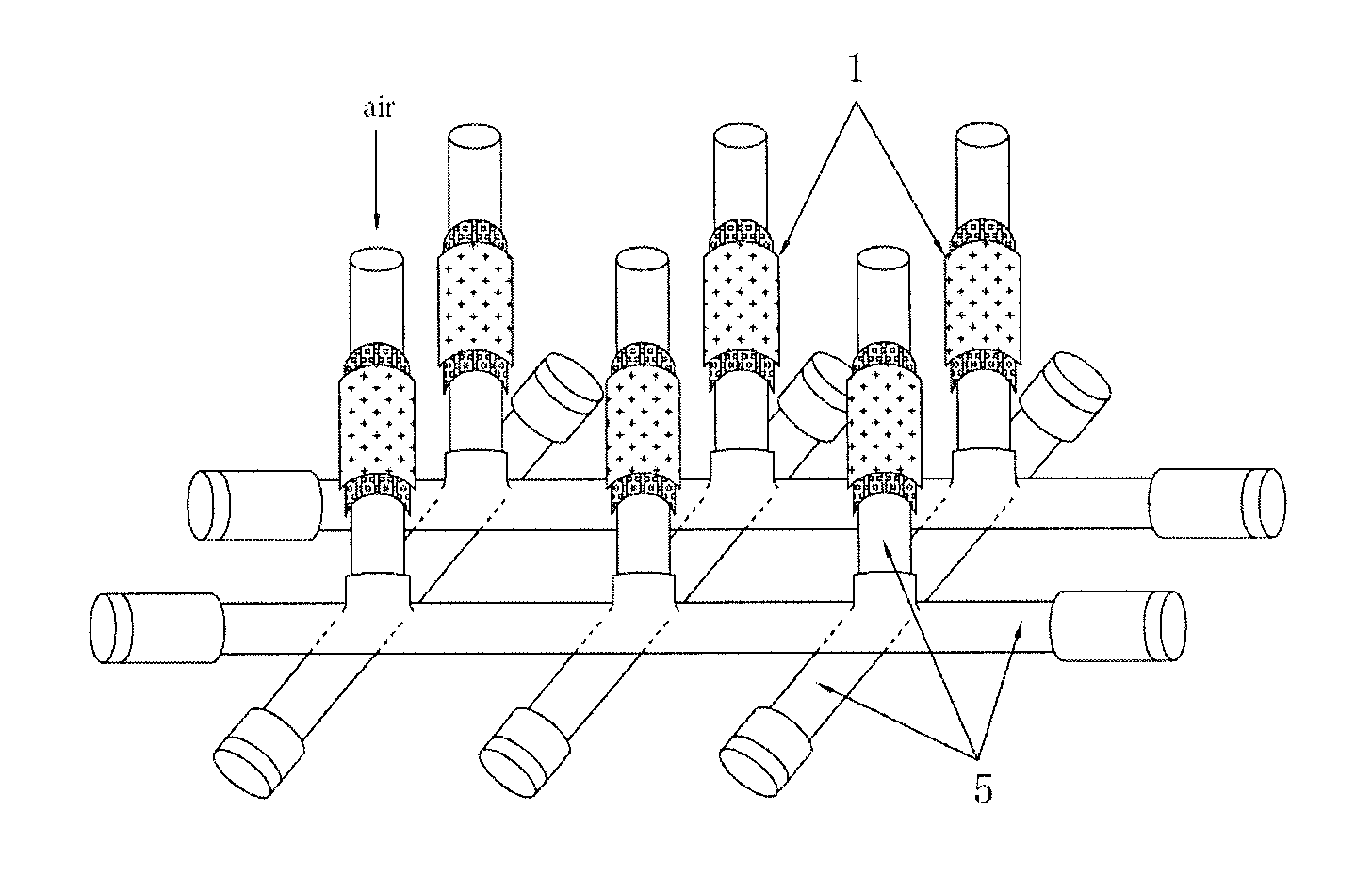

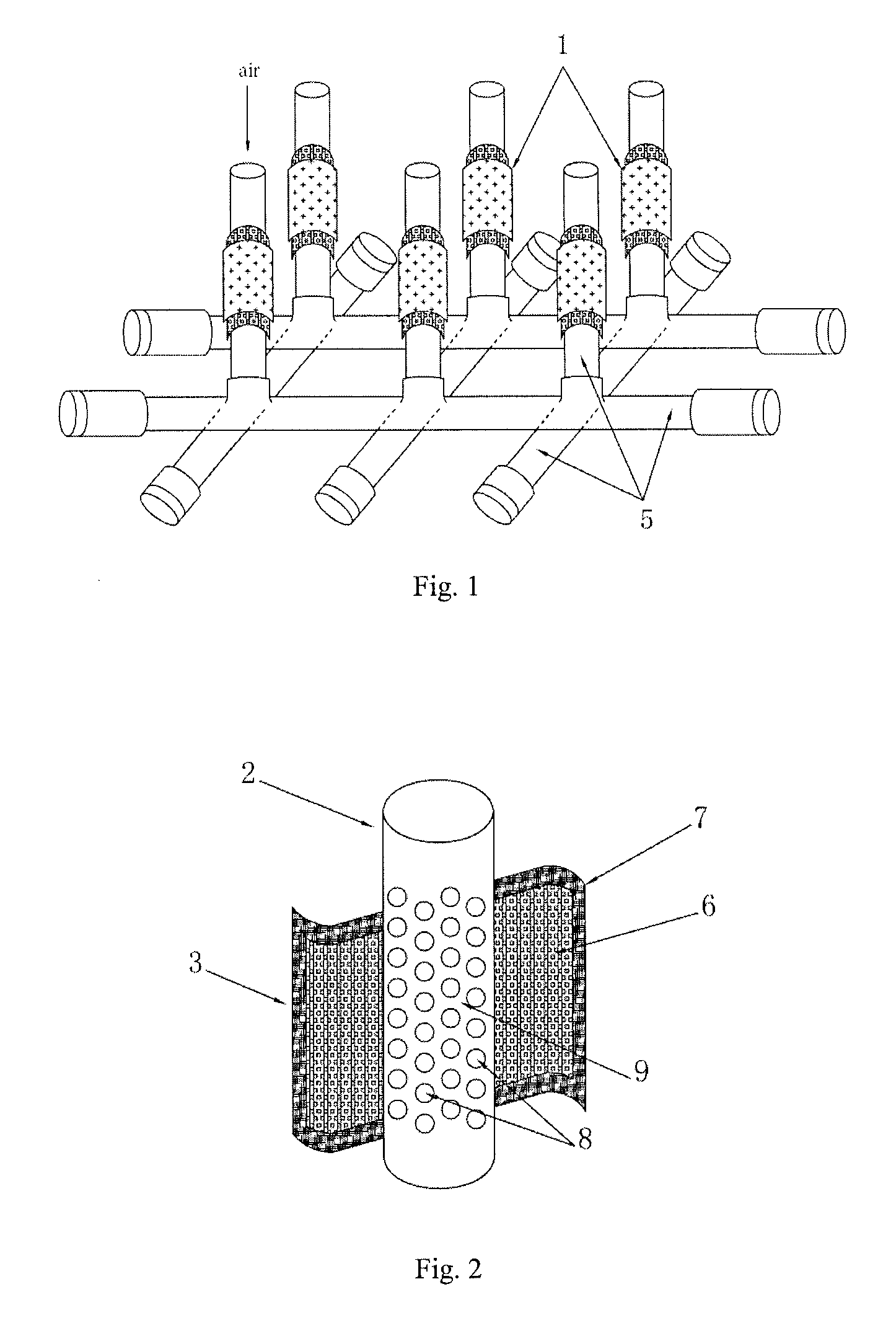

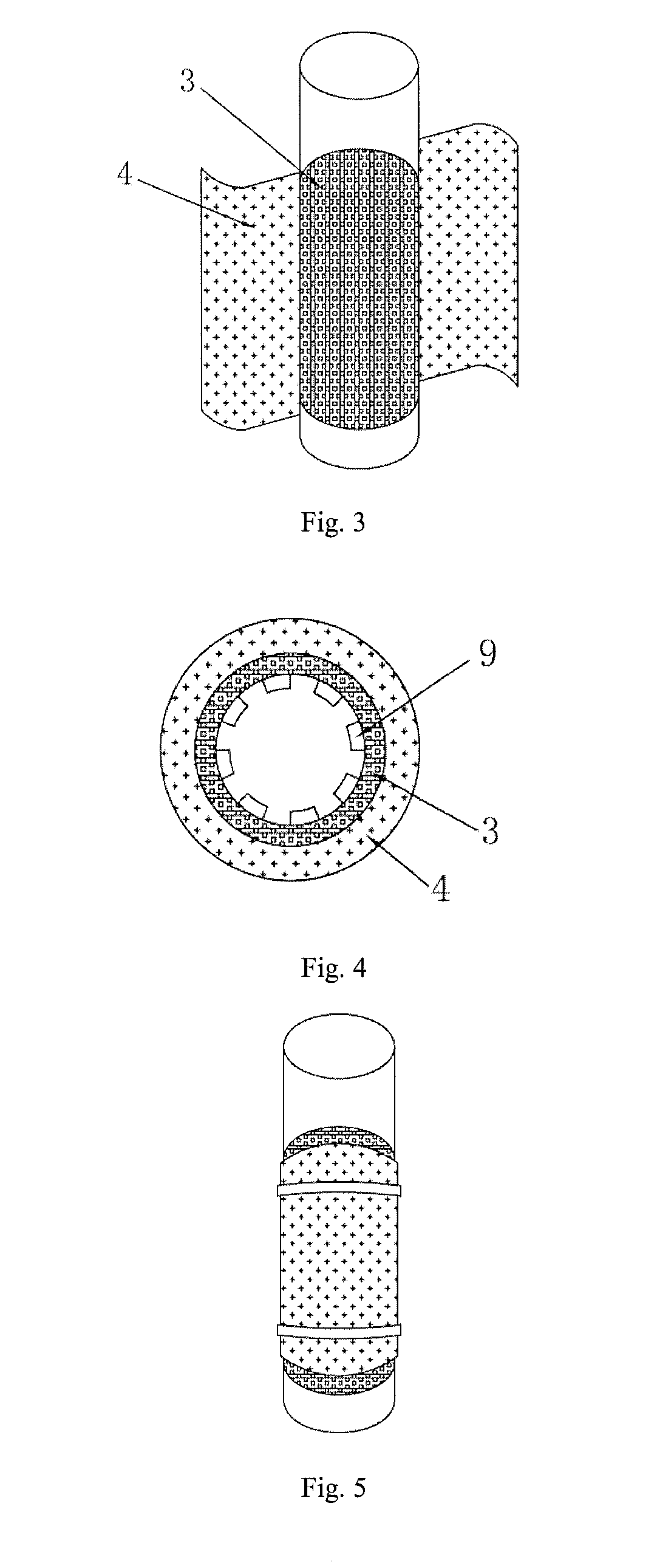

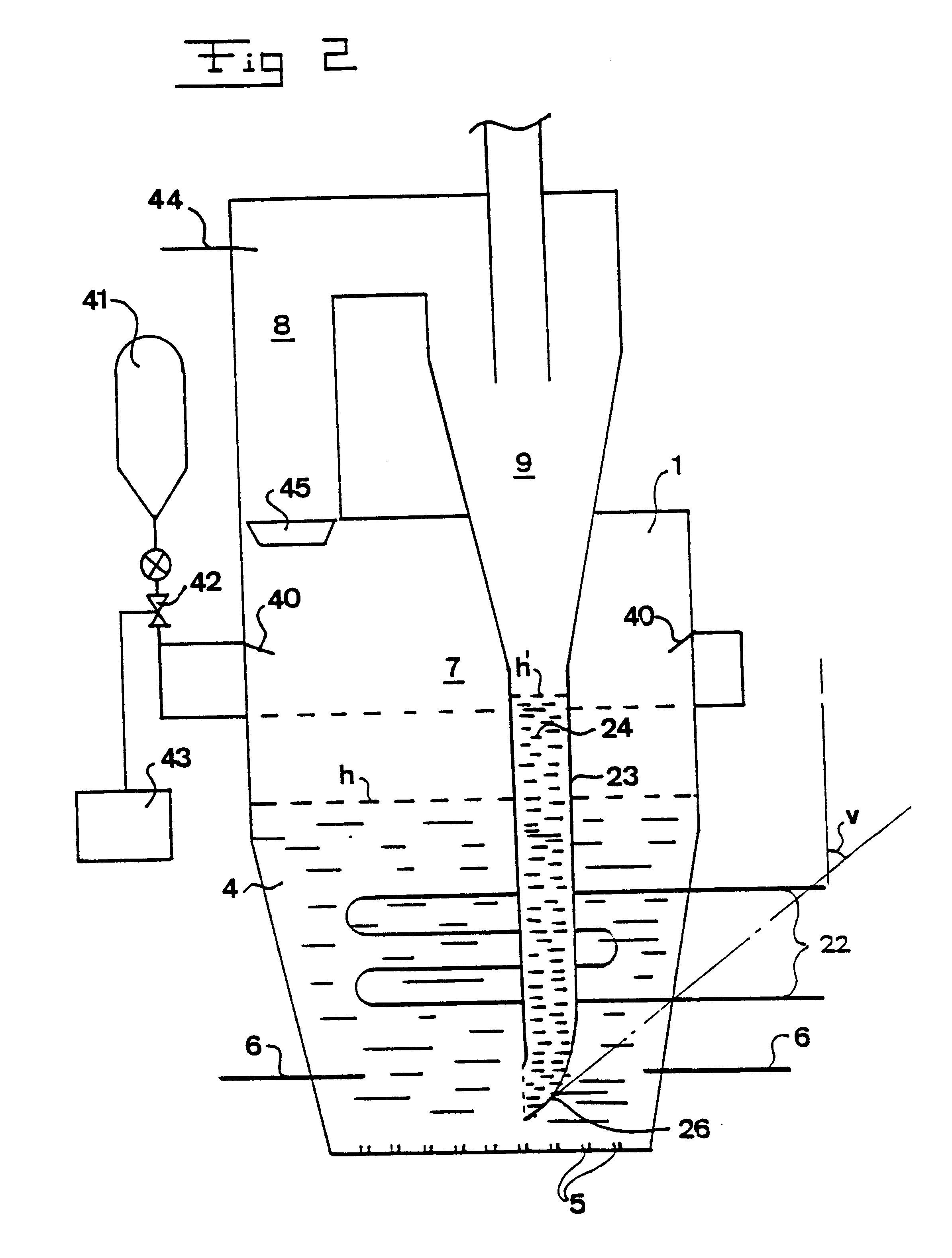

Methods and devices for in-situ treatment of sediment simultaneous with microbial electricity generation

ActiveUS20120276418A1Easy to placeGood effectTreatment by combined electrochemical biological processesFinal product manufactureEnvironmental resistanceMicrobial fuel cell

A method for in-situ treatment of sediment simultaneous with microbial electricity generation is provided, comprising steps of constructing a microbial fuel cell, placing the microbial fuel cell in the sediment, forming a cell circuit, and cultivating microorganisms to generate electrical power. The method overcomes shortcomings found in the prior art and uses organics in the sediment as fuels to in-situ treat the sediment with simultaneous electricity generation. A device for implementing the method is also provided, which can be expanded in different directions as needed and is easy to maintain during long-term operation. The device has many advantages including compact structure, easy operation, low cost, high output power density, significant reduction in sediment COD, no influence on water flow, and environment-friendly

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

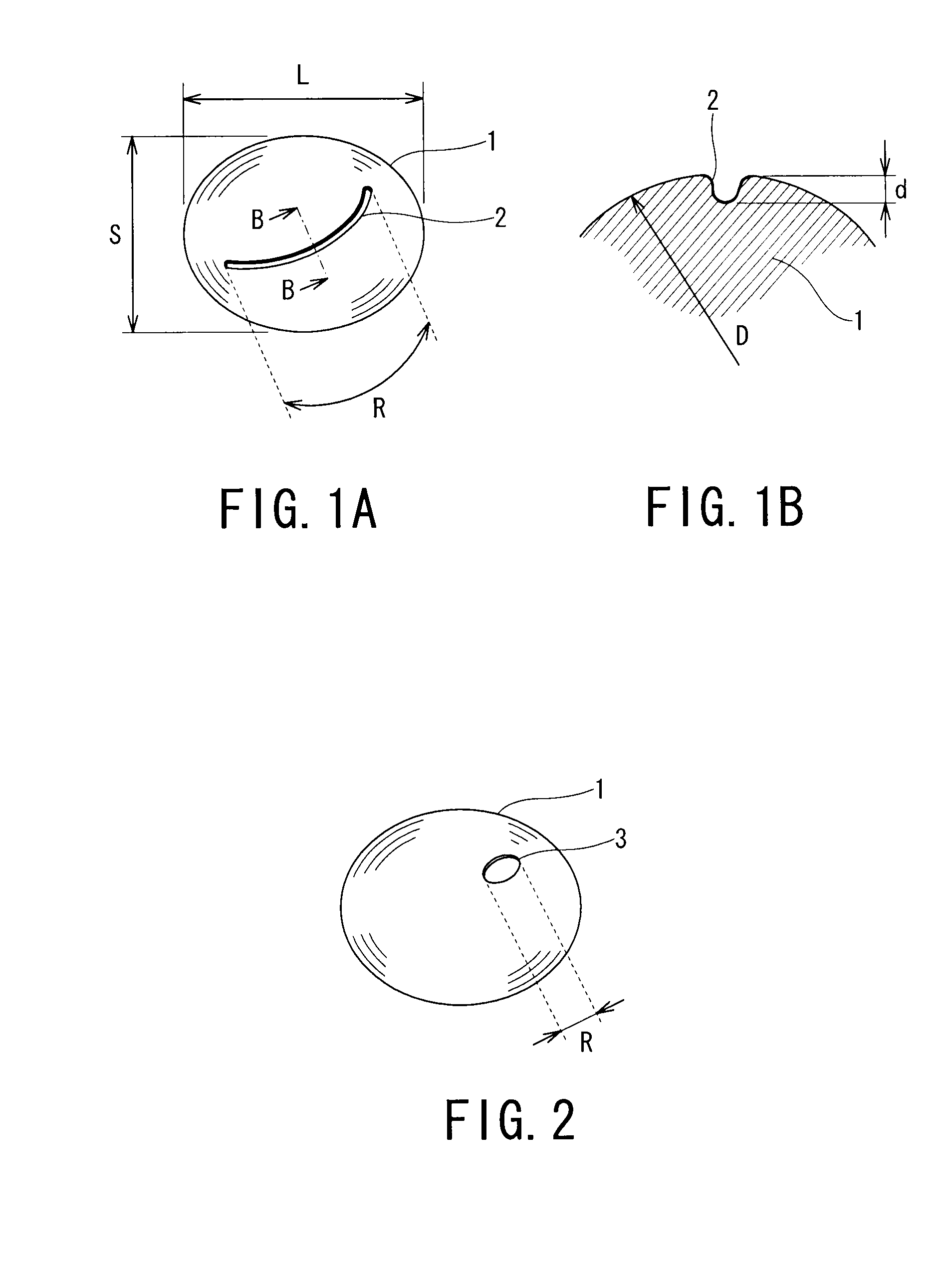

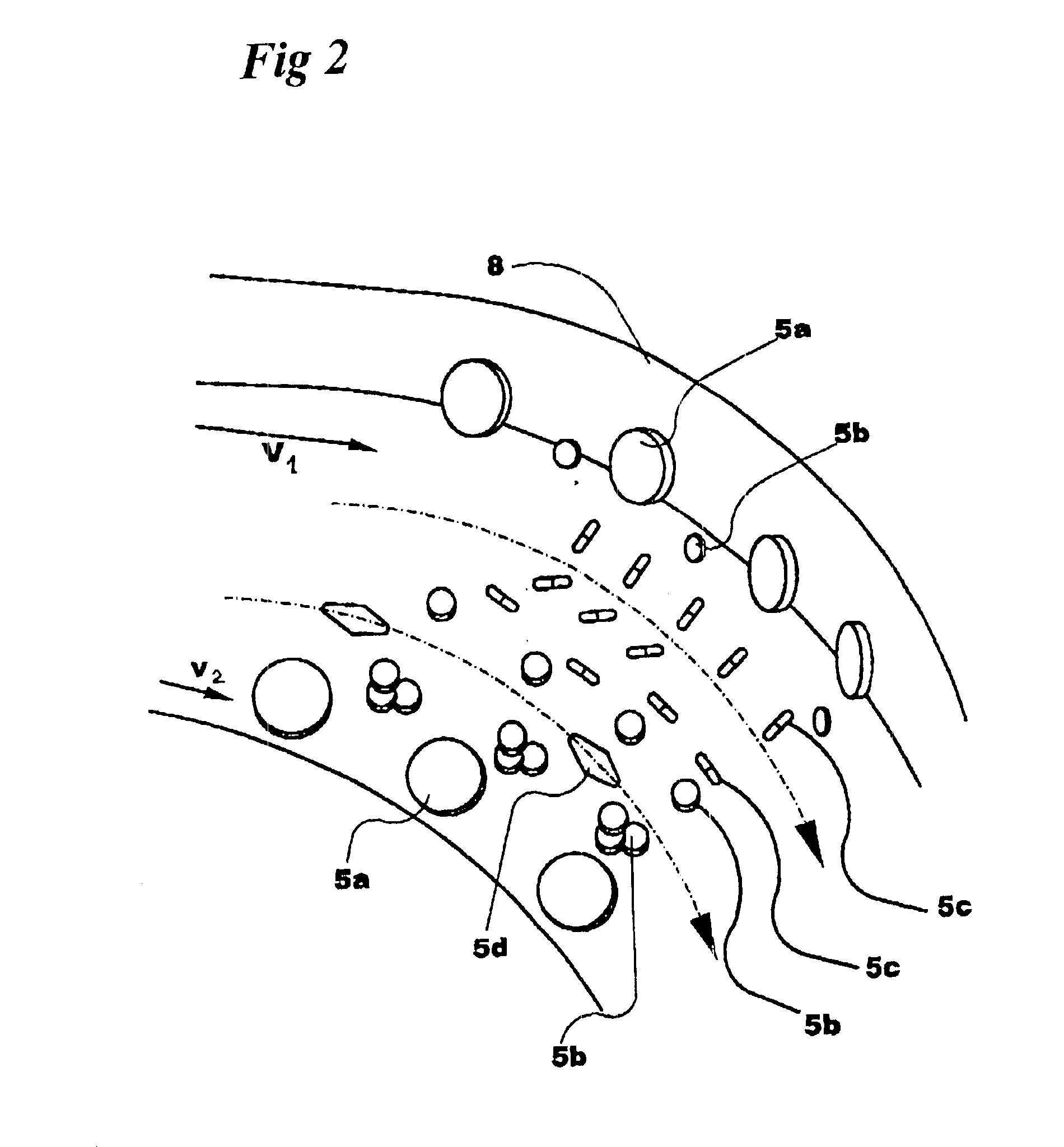

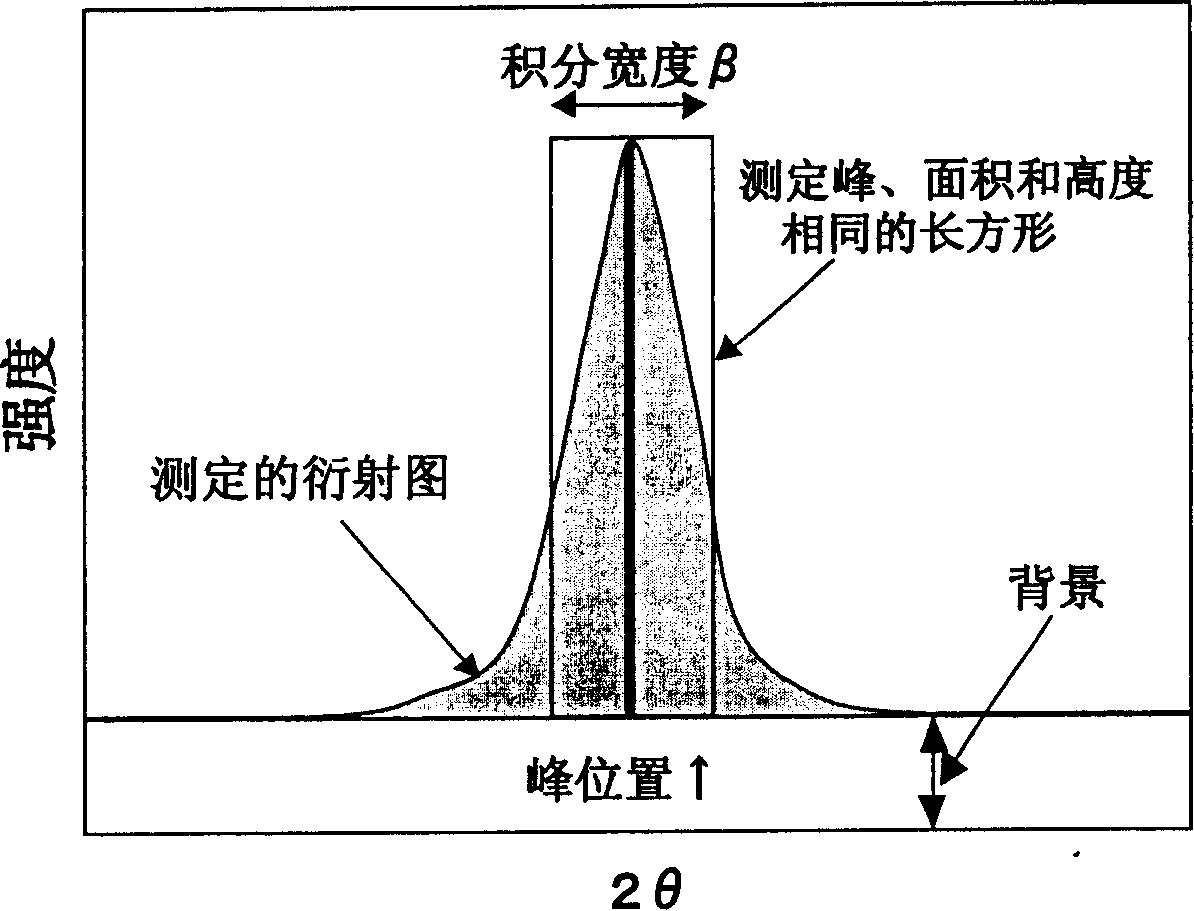

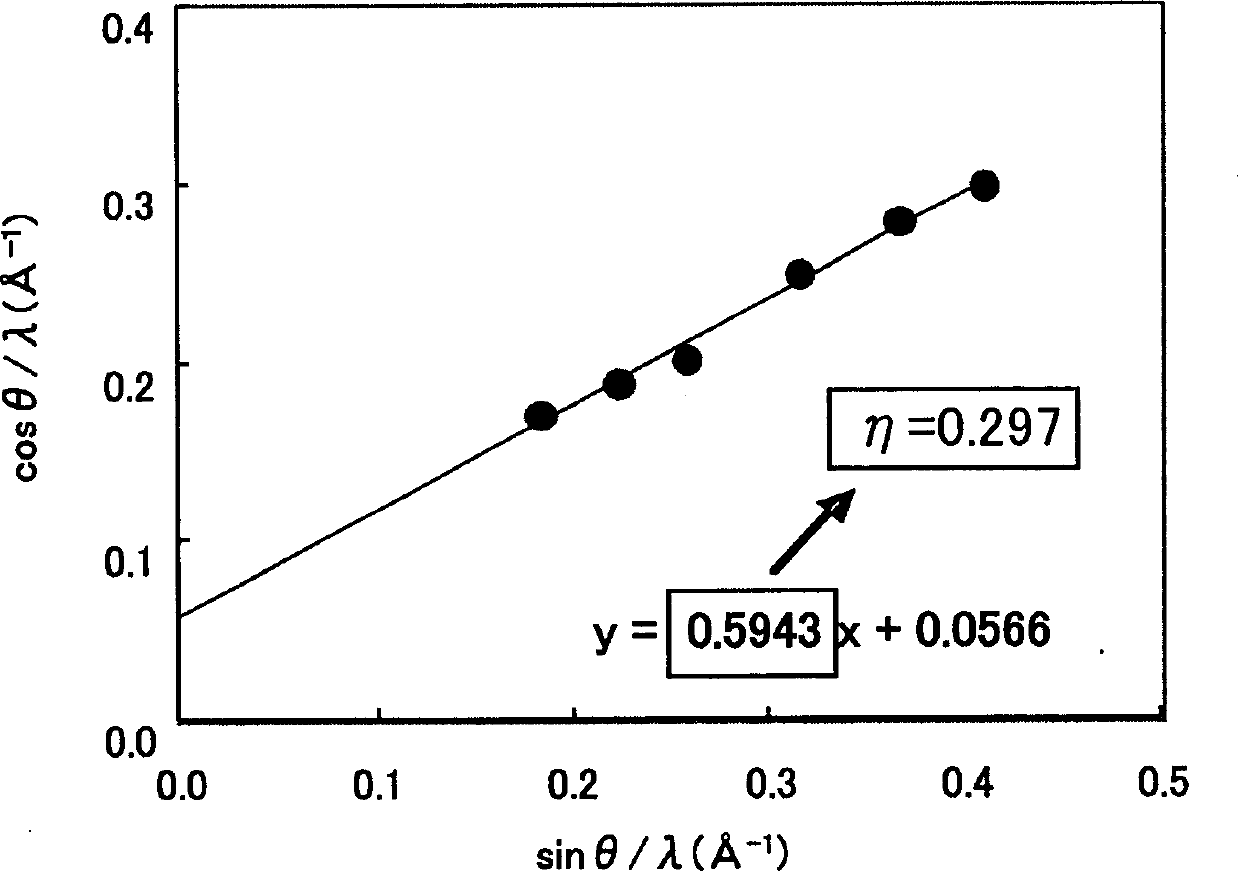

Rare-earth regenerator material particles, and group of rare-earth regenerator material particles, refrigerator and measuring apparatus using the same, and method for manufacturing the same

ActiveUS20120157320A1Avoid smallImprove featuresLayered productsHeat-exchange elementsLongest DiameterRare earth

Provided is a group of rare-earth regenerator material particles having an average particle size of 0.01 to 3 mm, wherein the proportion of particles having a ratio of a long diameter to a short diameter of 2 or less is 90% or more by number, and the proportion of particles having a depressed portion having a length of 1 / 10 to ½ of a circumferential length on a particle surface is 30% or more by number. By forming the depressed portion on the surface of the regenerator material particles, it is possible to increase permeability of an operating medium gas and a contact surface area with the operating medium gas.

Owner:KK TOSHIBA +1

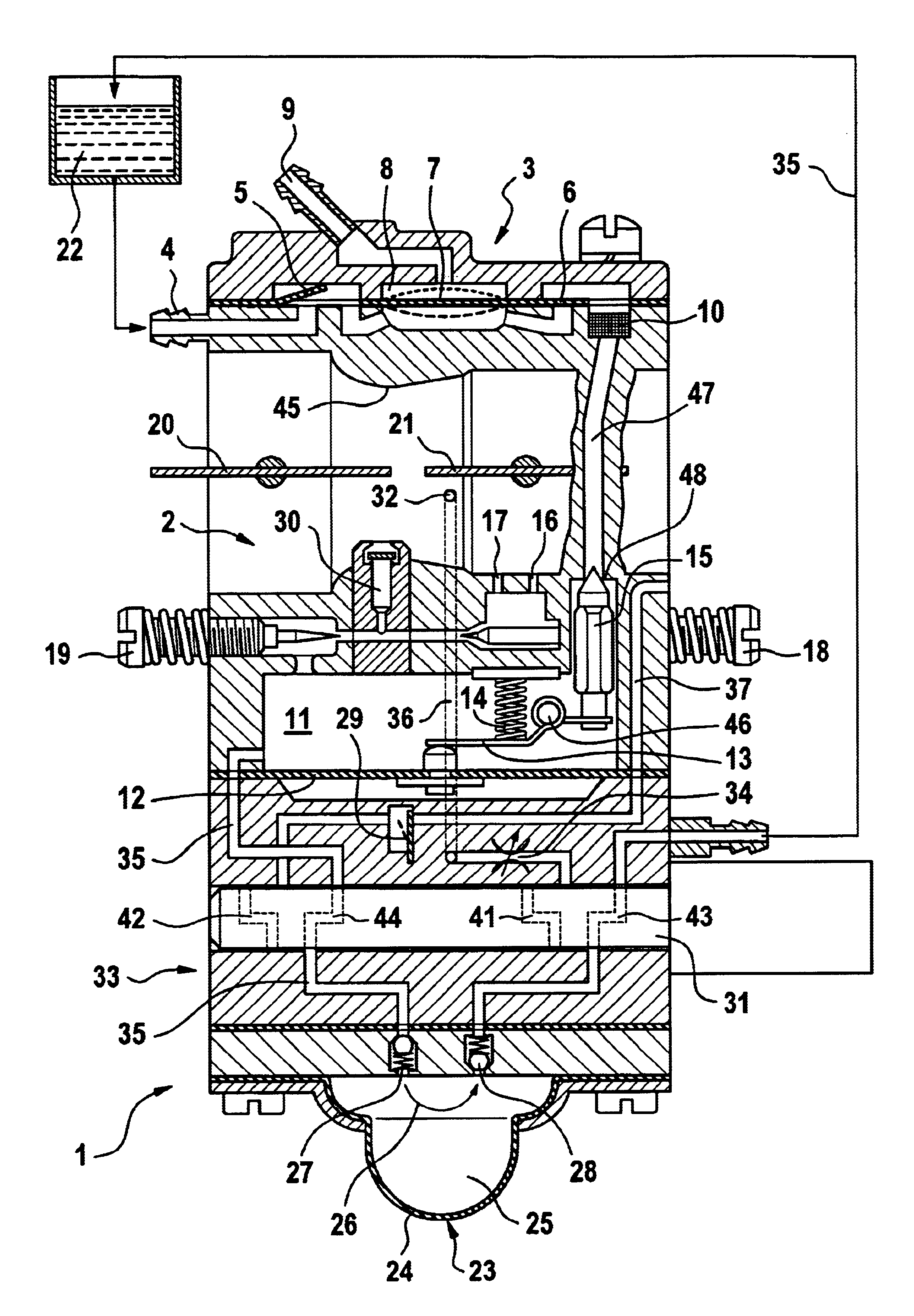

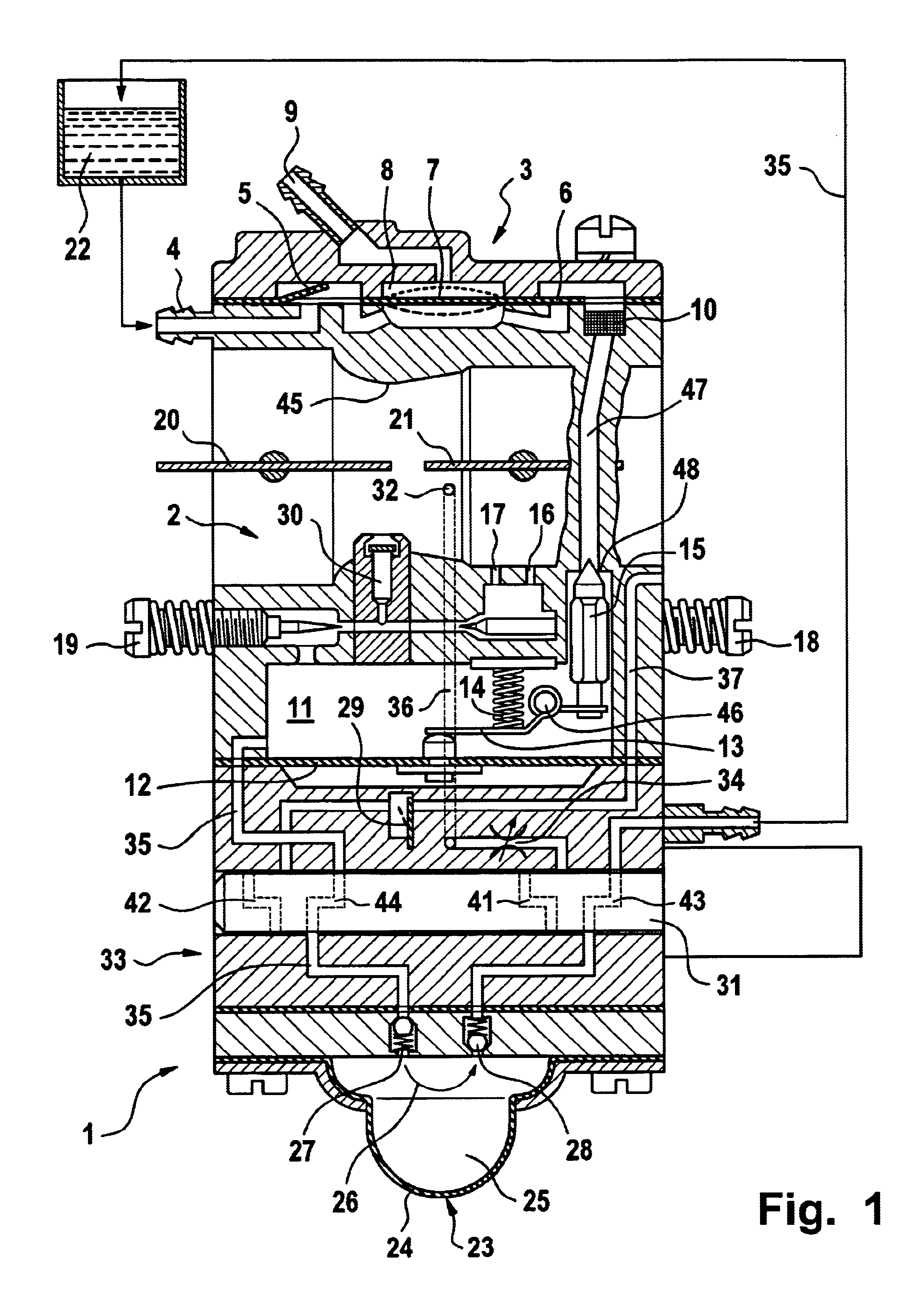

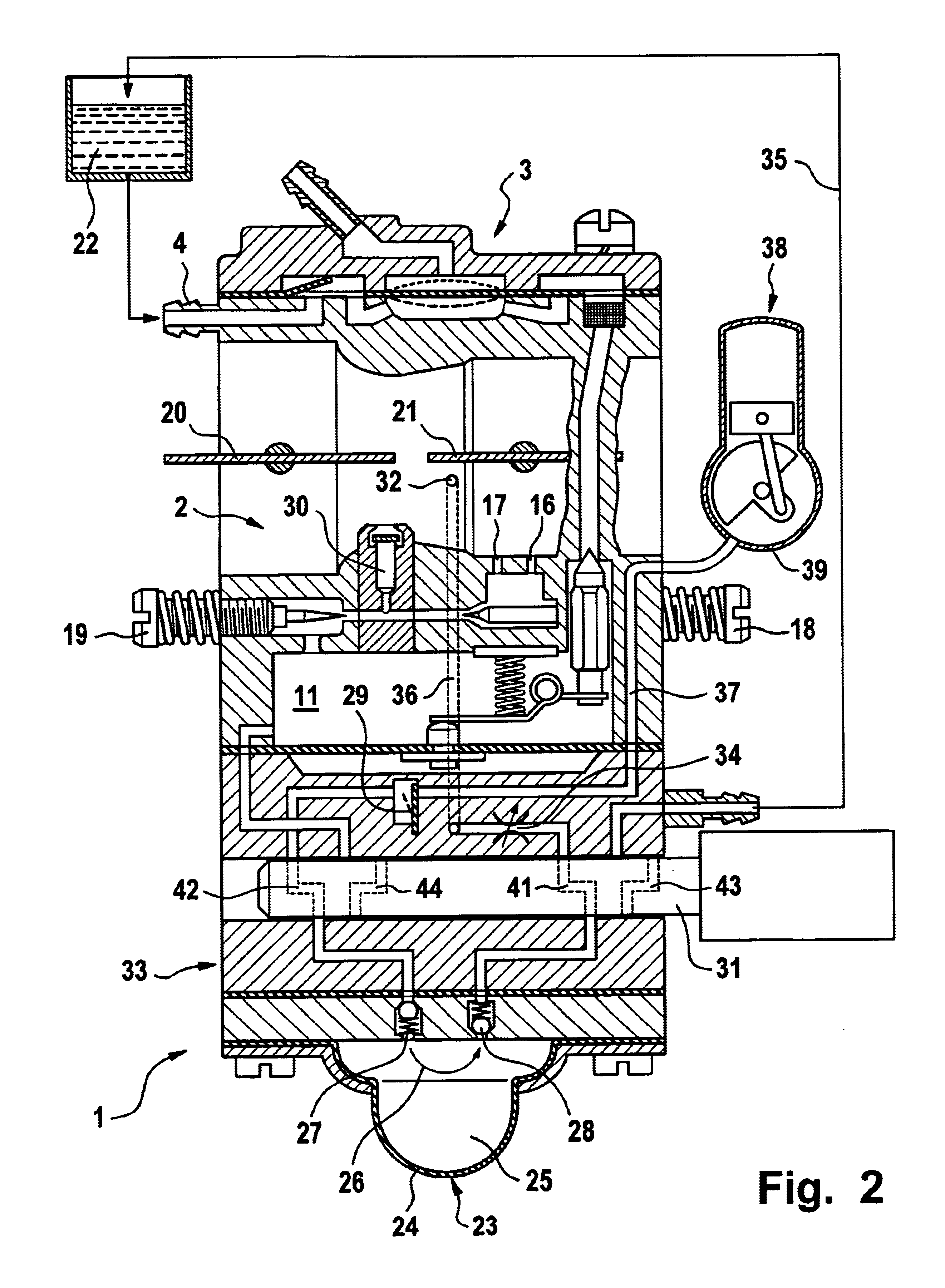

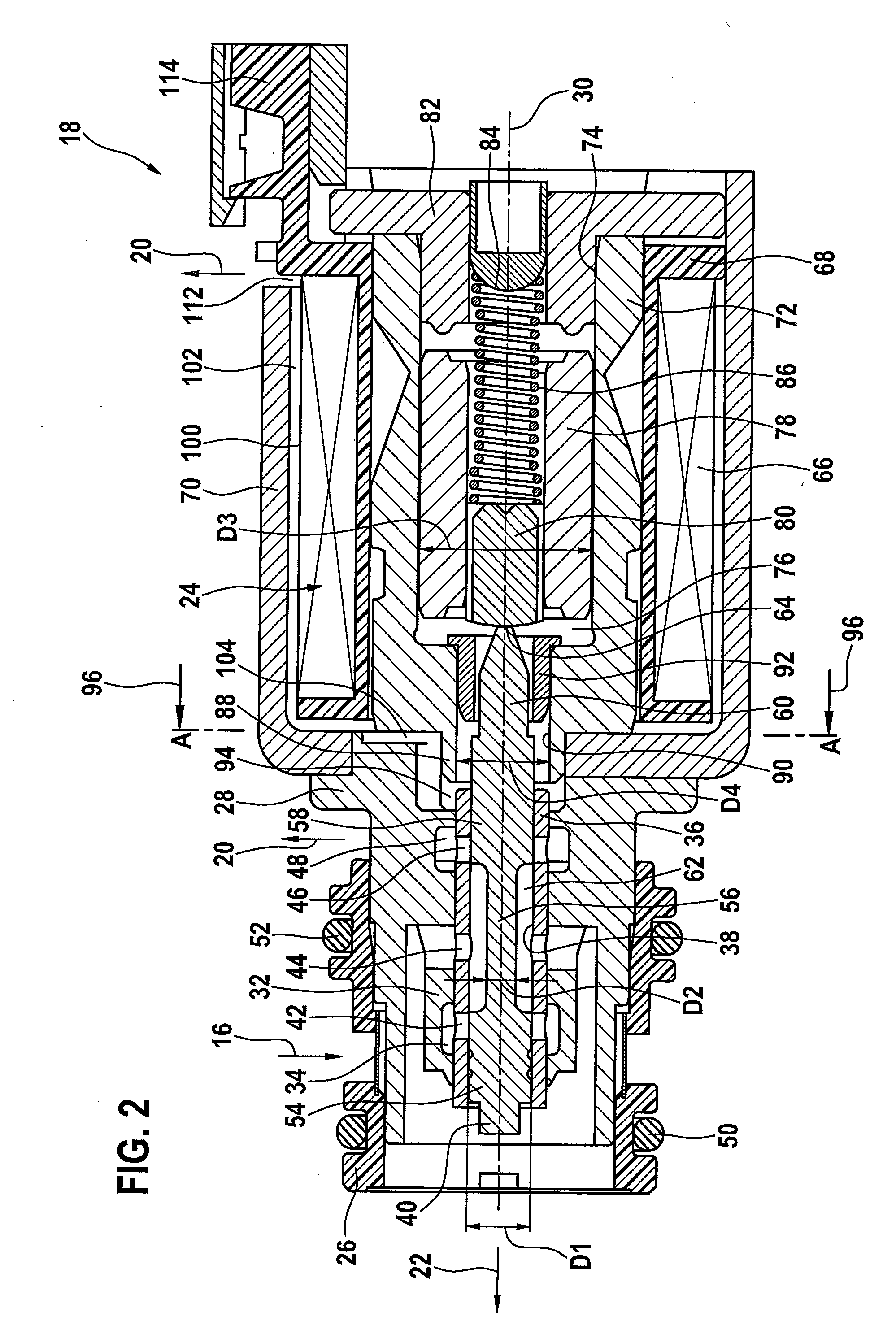

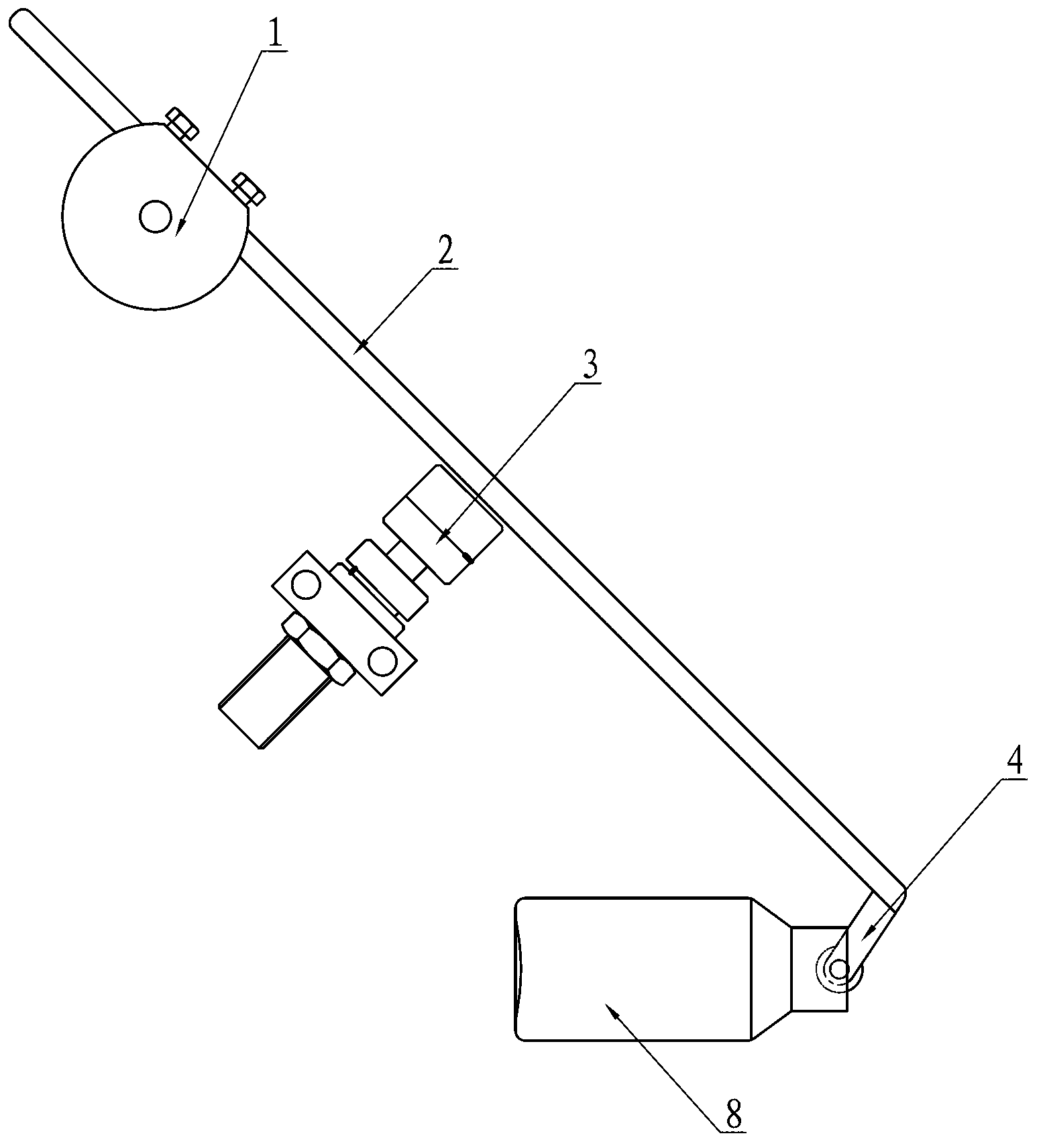

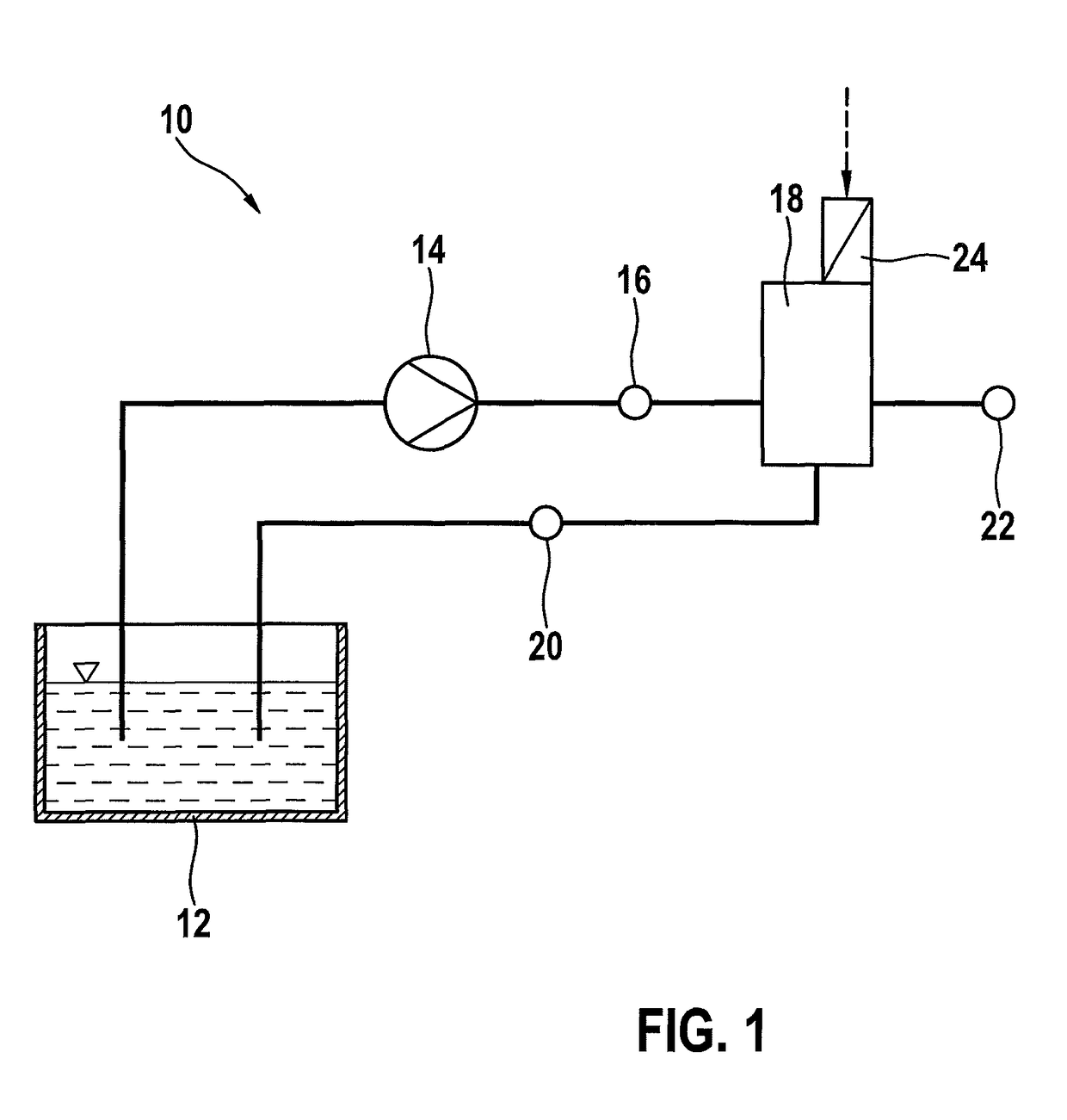

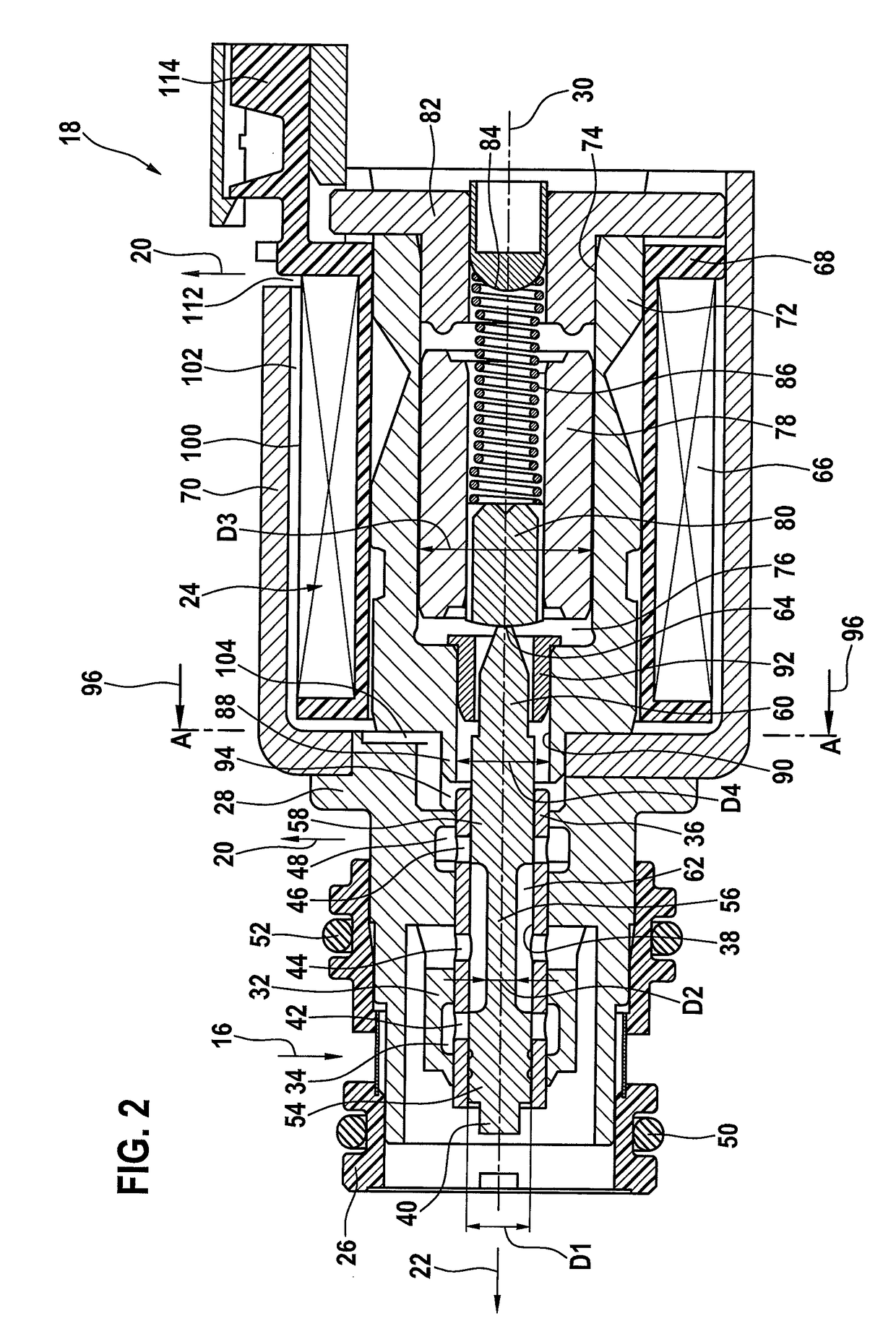

Carburetor arrangement

ActiveUS6913250B2Reliable couplingEasy to operateLighting and heating apparatusUsing liquid separation agentPump chamberFuel tank

A carburetor arrangement for an internal combustion engine in a manually guided implement, such as a power chainsaw, a cut-off machine, etc. is provided. A regulating chamber delimited by a regulating diaphragm is provided. Upon deflection of the diaphragm due to underpressure in the regulating chamber, the latter is connected with a fuel tank. Via at least one nozzle, the regulating chamber opens into an air channel that supplies fuel / air mixture to the engine. The carburetor arrangement includes a scavenging pump that is disposed in a return line from the regulating chamber to the fuel tank, and in which is formed a pump chamber. The scavenging pump serves to completely fill the regulating chamber with fuel before start-up of the engine. To prevent the fuel / air mixture from becoming too lean after start-up, especially upon opening of the choke valve, a supply line is provided from the pump chamber into the air channel and supplies additional fuel to the air channel during the run-up phase.

Owner:ANDREAS STIHL AG & CO KG

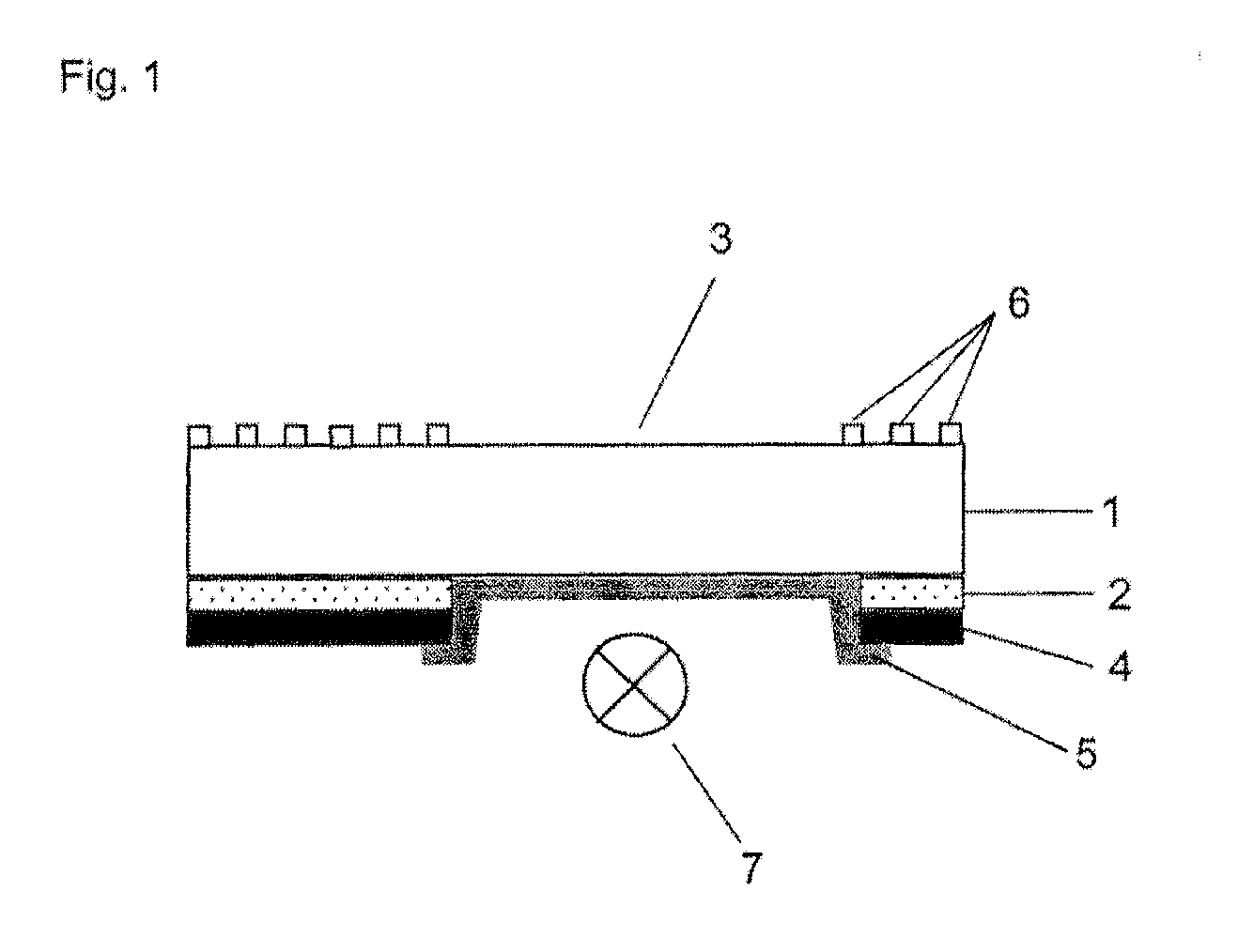

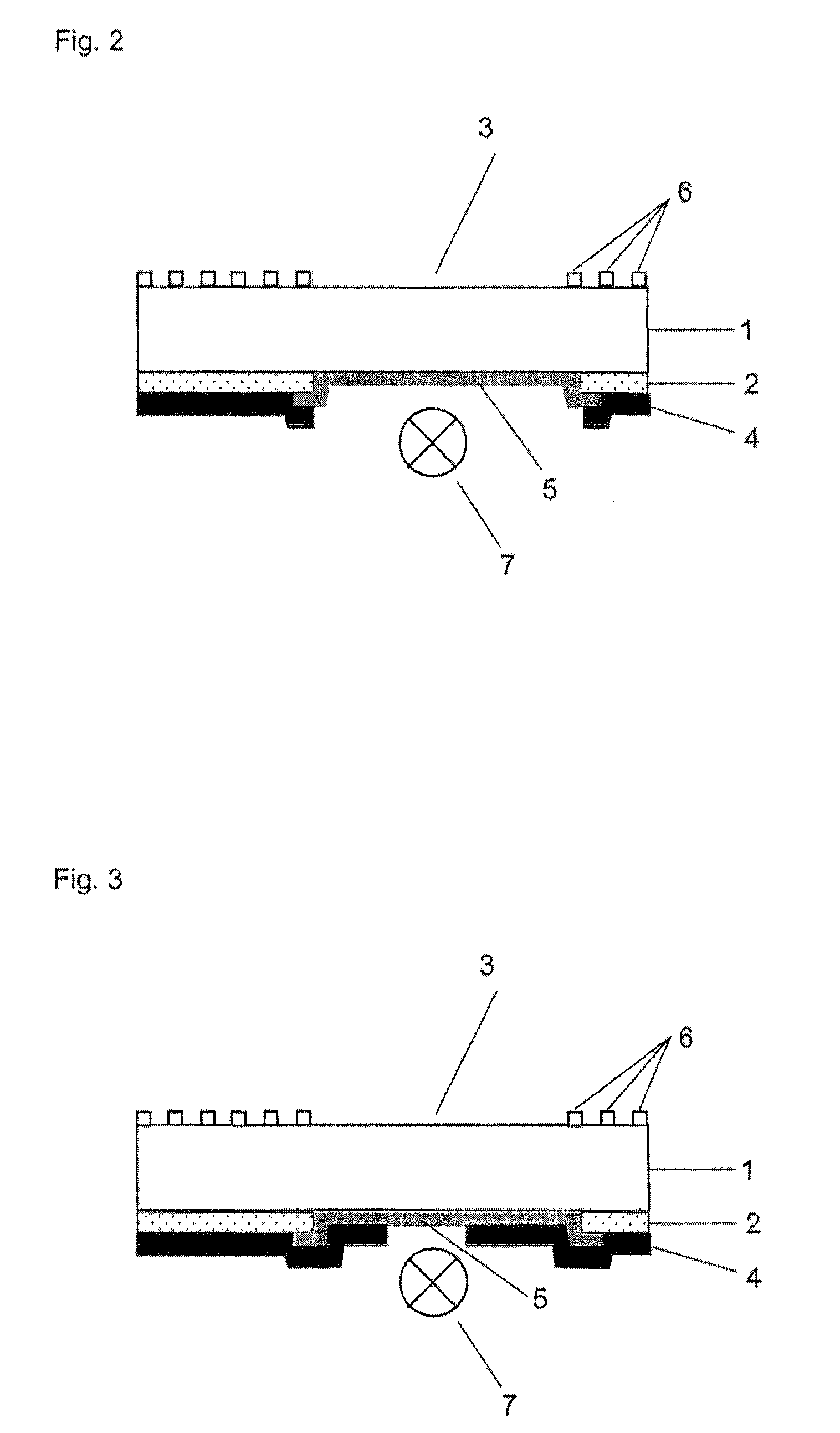

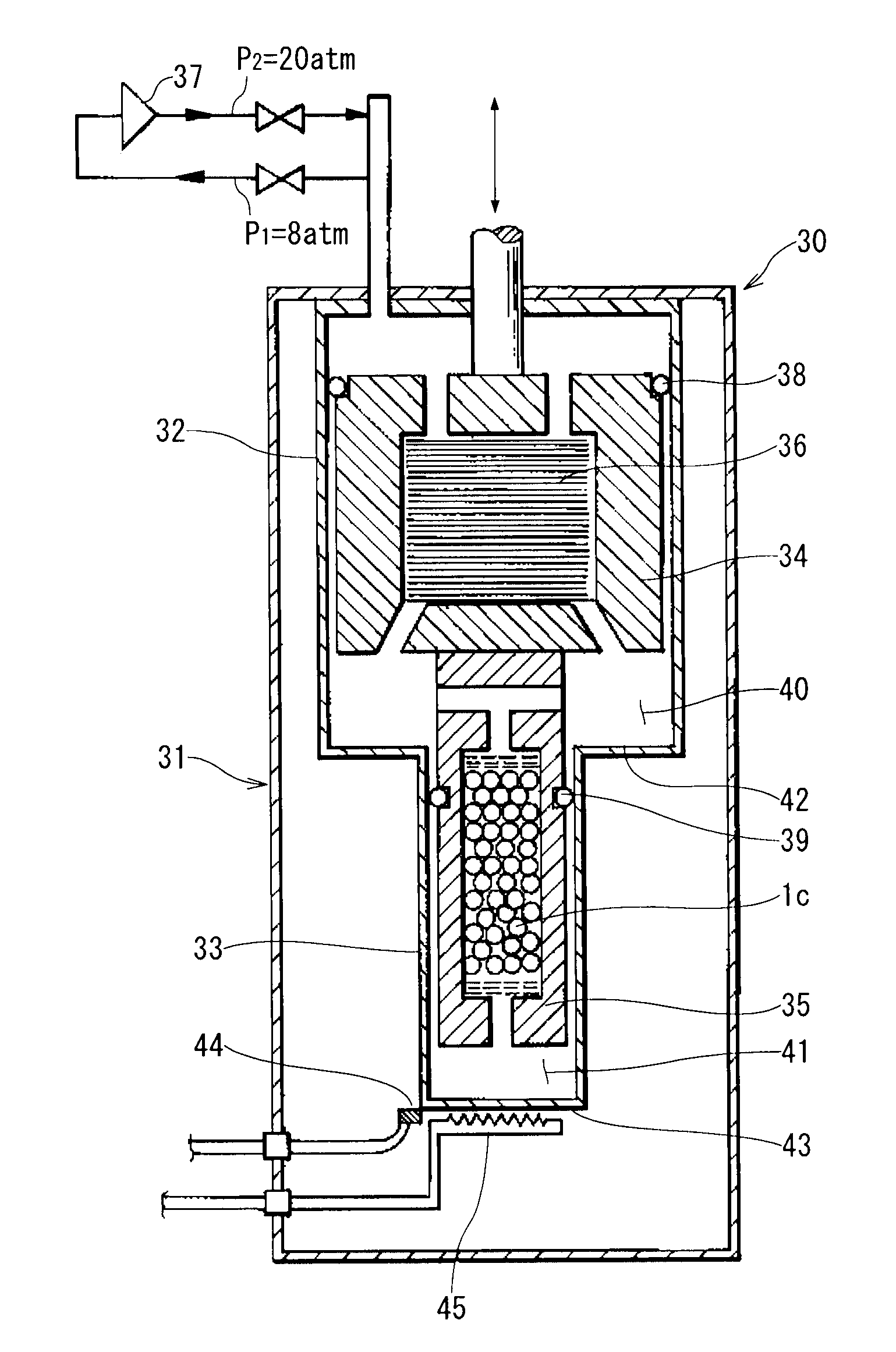

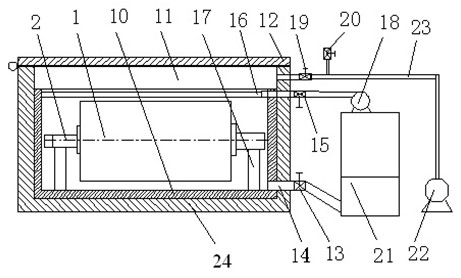

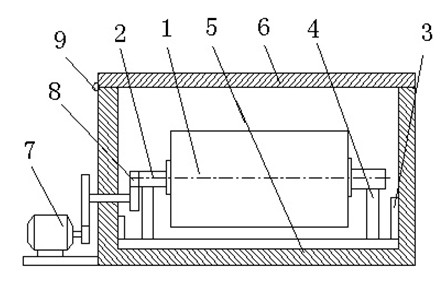

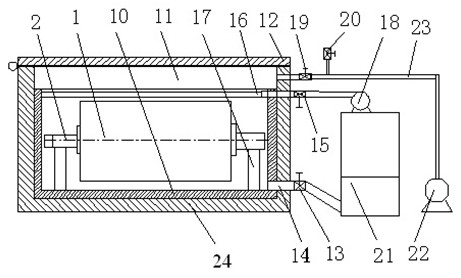

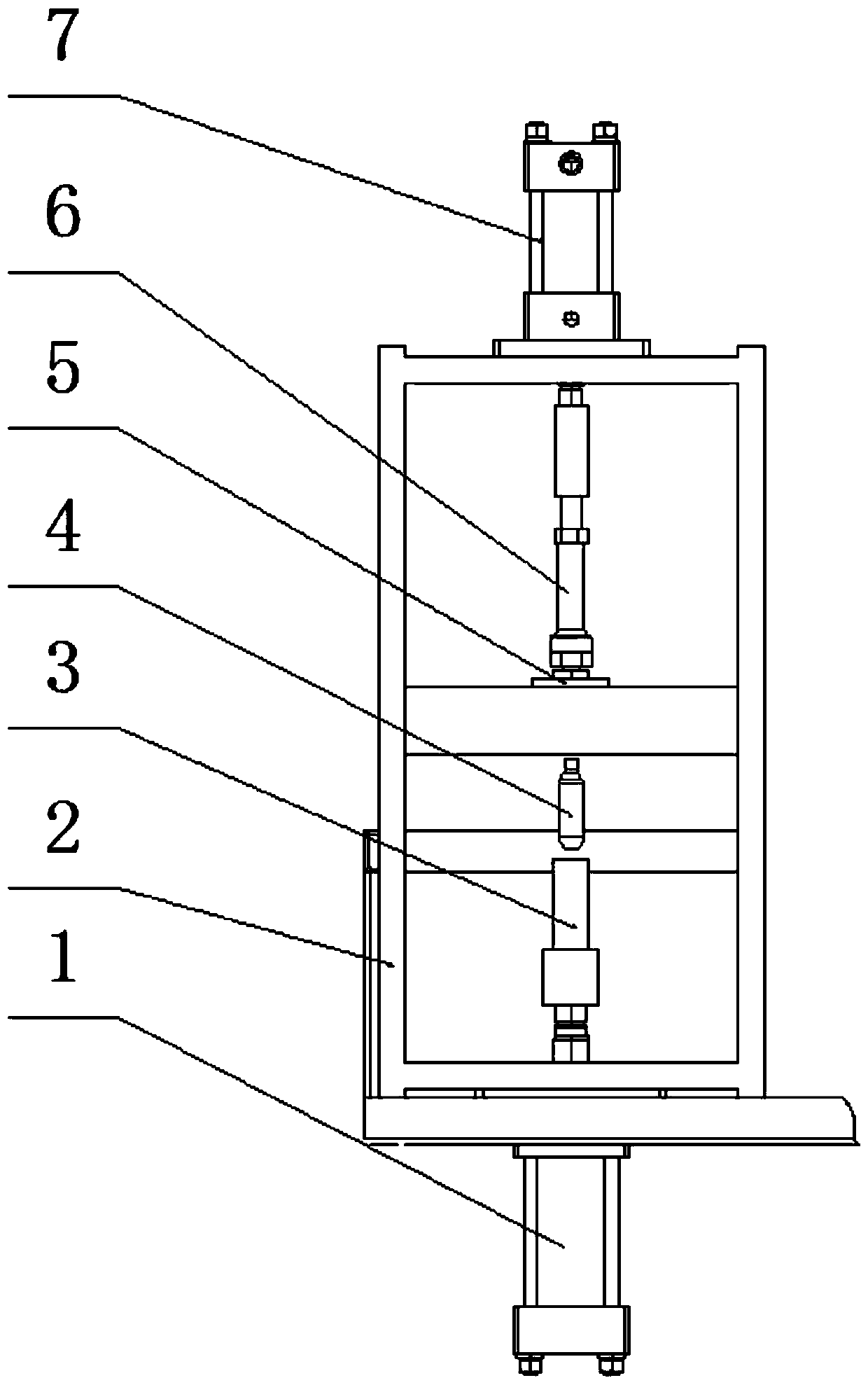

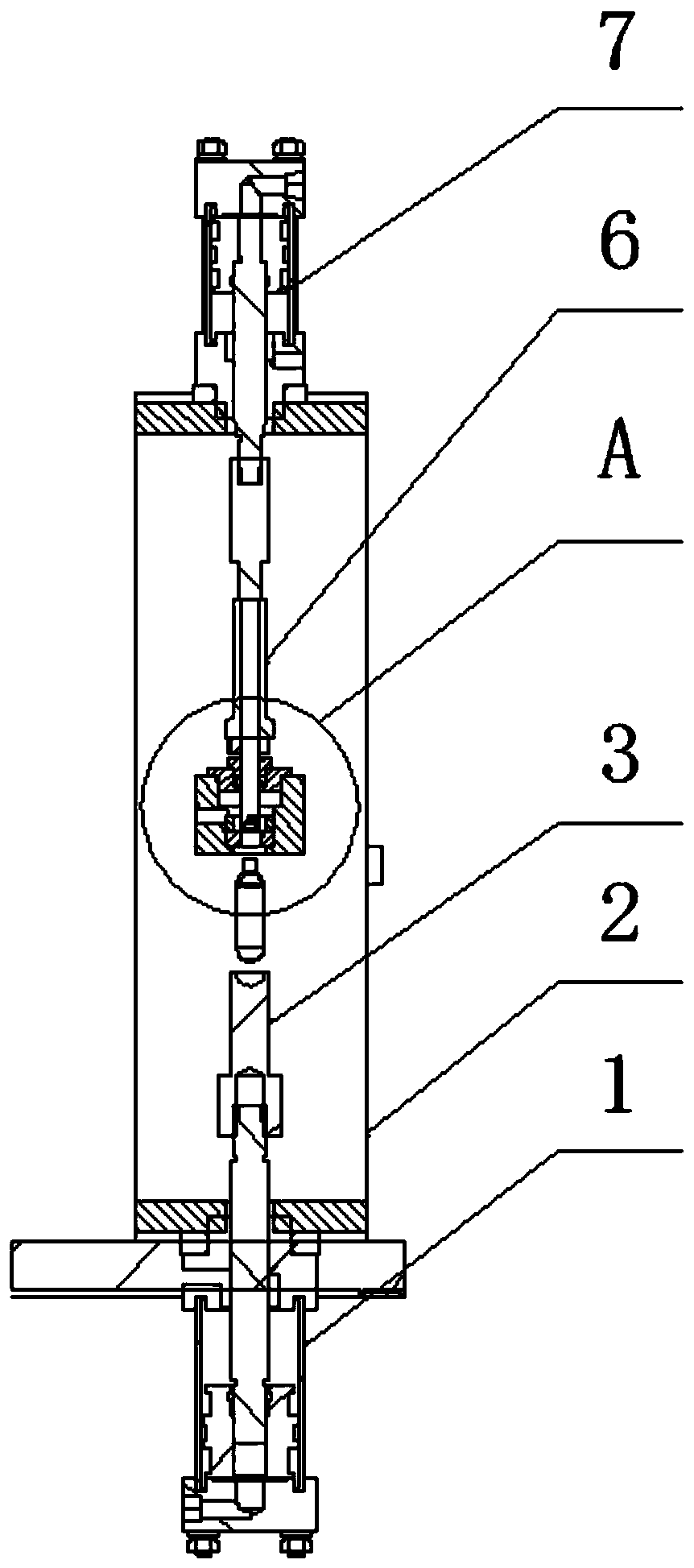

Method and device for treating stator of large wind turbine with insulating varnish and device for baking insulating varnish on stator

ActiveCN102097901AEnsuring impregnation fillabilityEnsure fillingApplying solid insulationVacuum pressureTurbine

The invention provides a method and device for treating a stator of a large wind turbine with insulating varnish and a device for baking the insulating varnish on the stator. The method is characterized by adopting the process combining integral horizontal type vacuum pressure impregnation and rotary baking to treat the stator of the large permanent magnet direct-drive wind turbine with insulating varnish, wherein the step of treating the stator with insulating varnish is as follows: sleeving the stator of the wind turbine on a false shaft, then placing the false shaft on a false shaft supporting rotating mechanism in a baking oven, driving the false shaft to rotate via the false shaft supporting rotating mechanism and furthering driving the stator to rotate to realize horizontal type rotary baking of the stator, wherein the false shaft is parallel to the ground along the direction of the stator core slot. By utilizing the process combining vacuum pressure impregnation and rotary baking, the stator of the large permanent magnet direct-drive wind turbine is treated with the insulating varnish, the functions of the process completely conform to the requirements of production insulation treatment, and the loss of the insulating varnish in the baking process is reduced, the amount of the varnish on the surfaces of the windings is ensured and the process time and energy consumptionare simultaneously reduced while ensuring the filling property of the insulating varnish on the stator windings.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

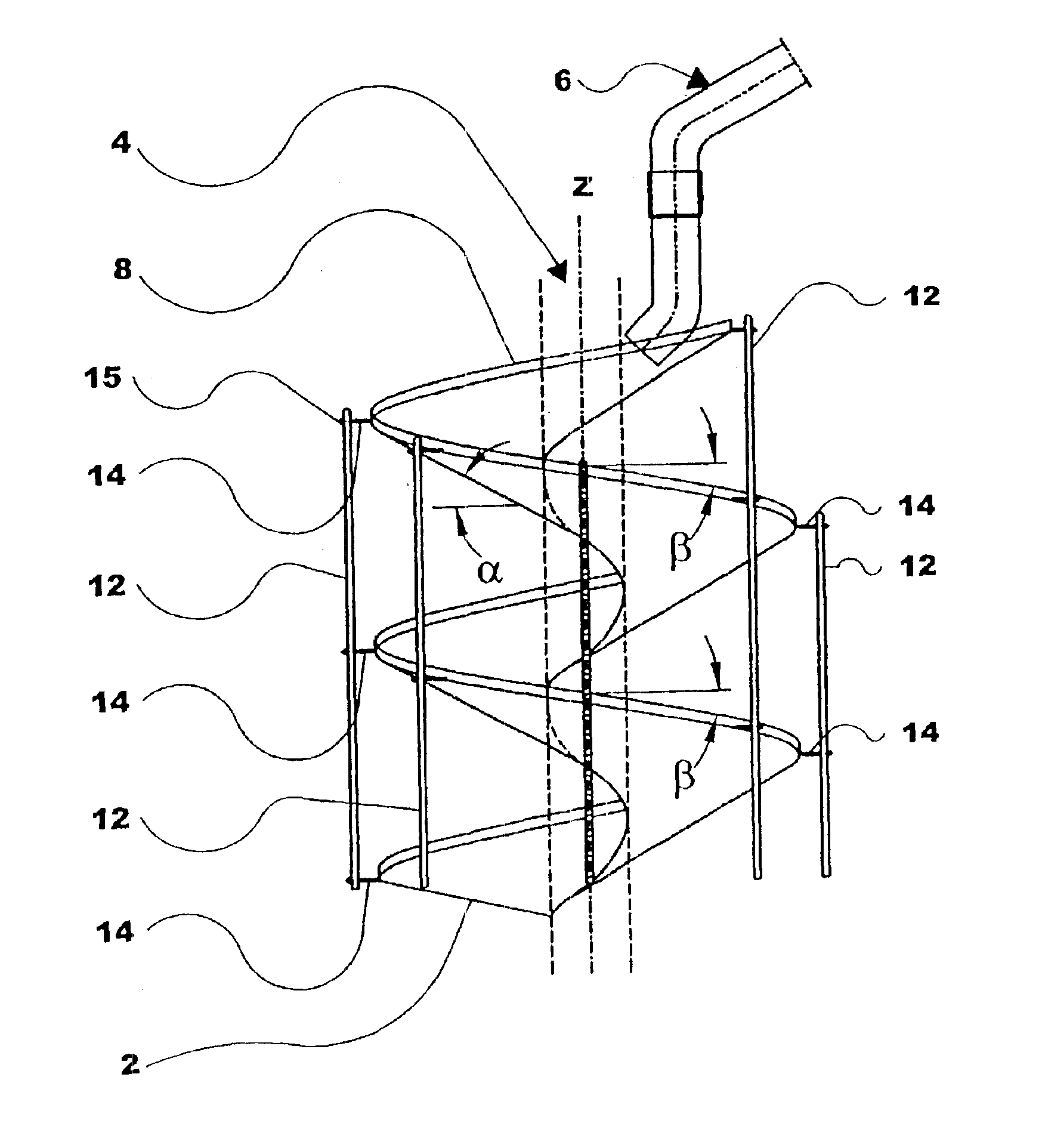

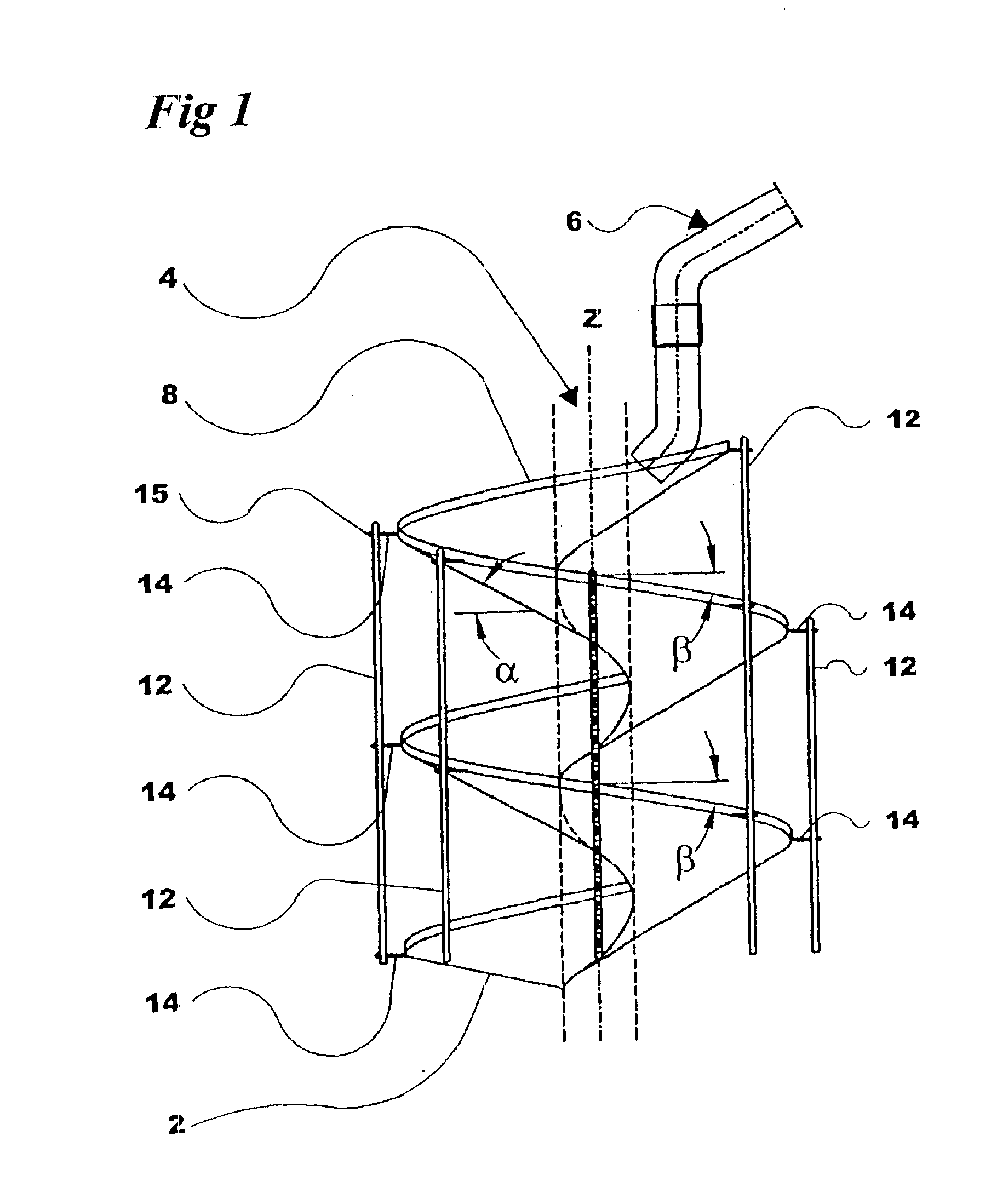

Distributing chute conveyor

InactiveUS6851911B2Break limitIncrease flow ratePharmaceutical product form changeLoading/unloadingStructural engineeringDrug product

A helical distributing chute conveyor for a receptacle for transferring loose varied fragile chemical and pharmaceutical products, particularly of the granular or pulverulent type. This chute conveyor, placed in a receptacle, comprises helical chute paths developed about a vertical axis; each chute path, whom cross section is straight, is inclined transversely towards the vertical axis, the angle of inclination of the chute path being calculated such that, whatever their size, the particles of material transported deviate towards the vertical axis when the centrifugal force which originally keeps them on the chute path cancels out or drops below a critical value.

Owner:ELVECO MSJ

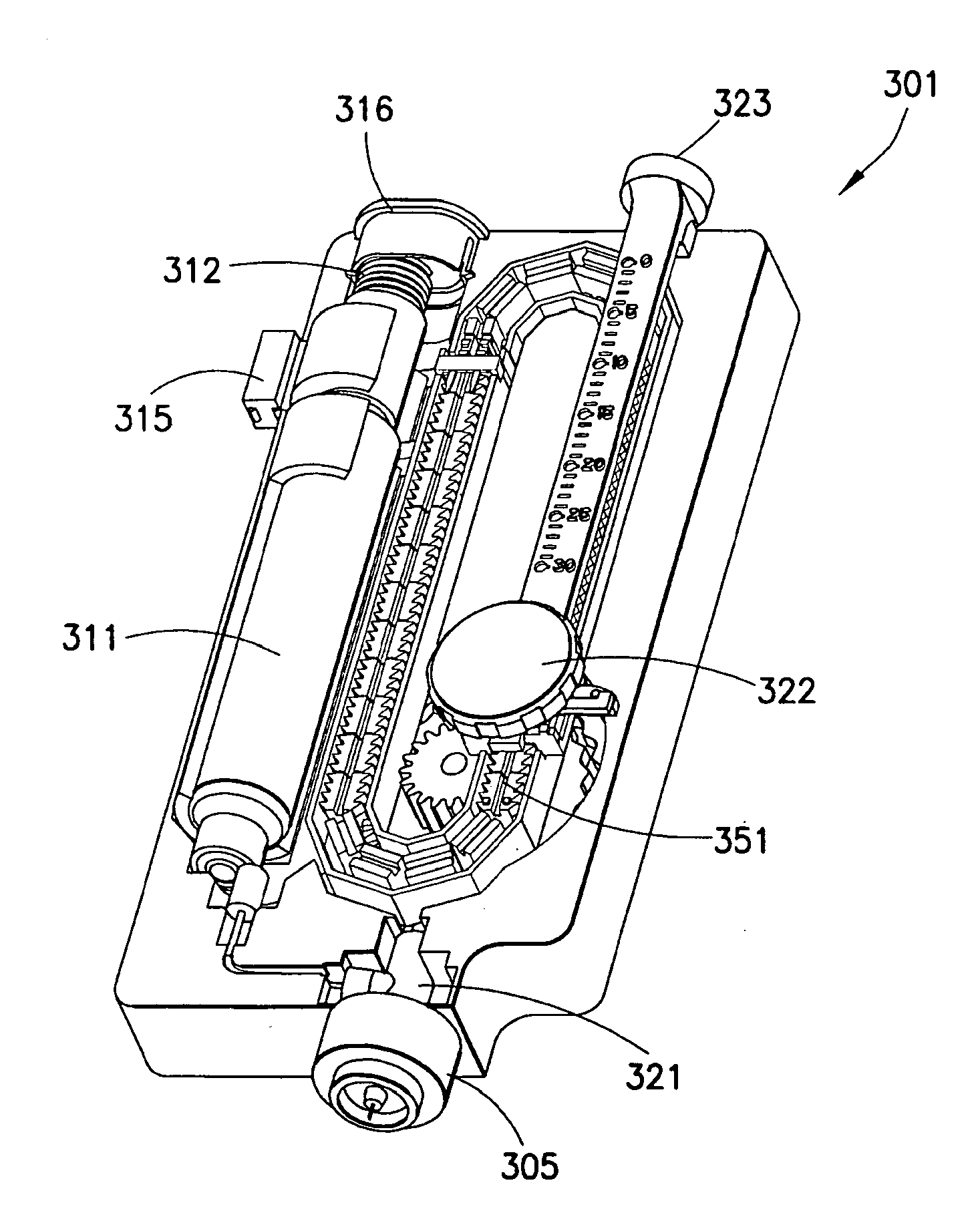

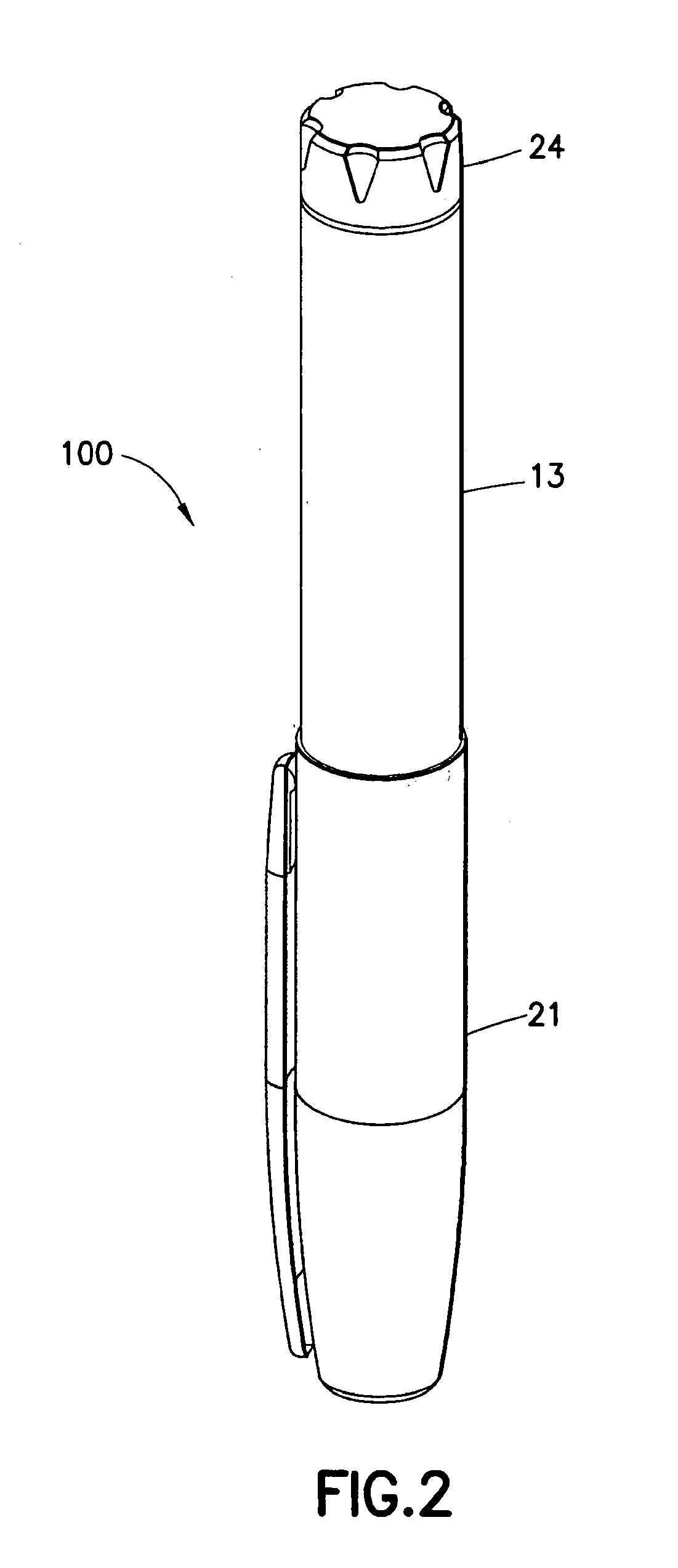

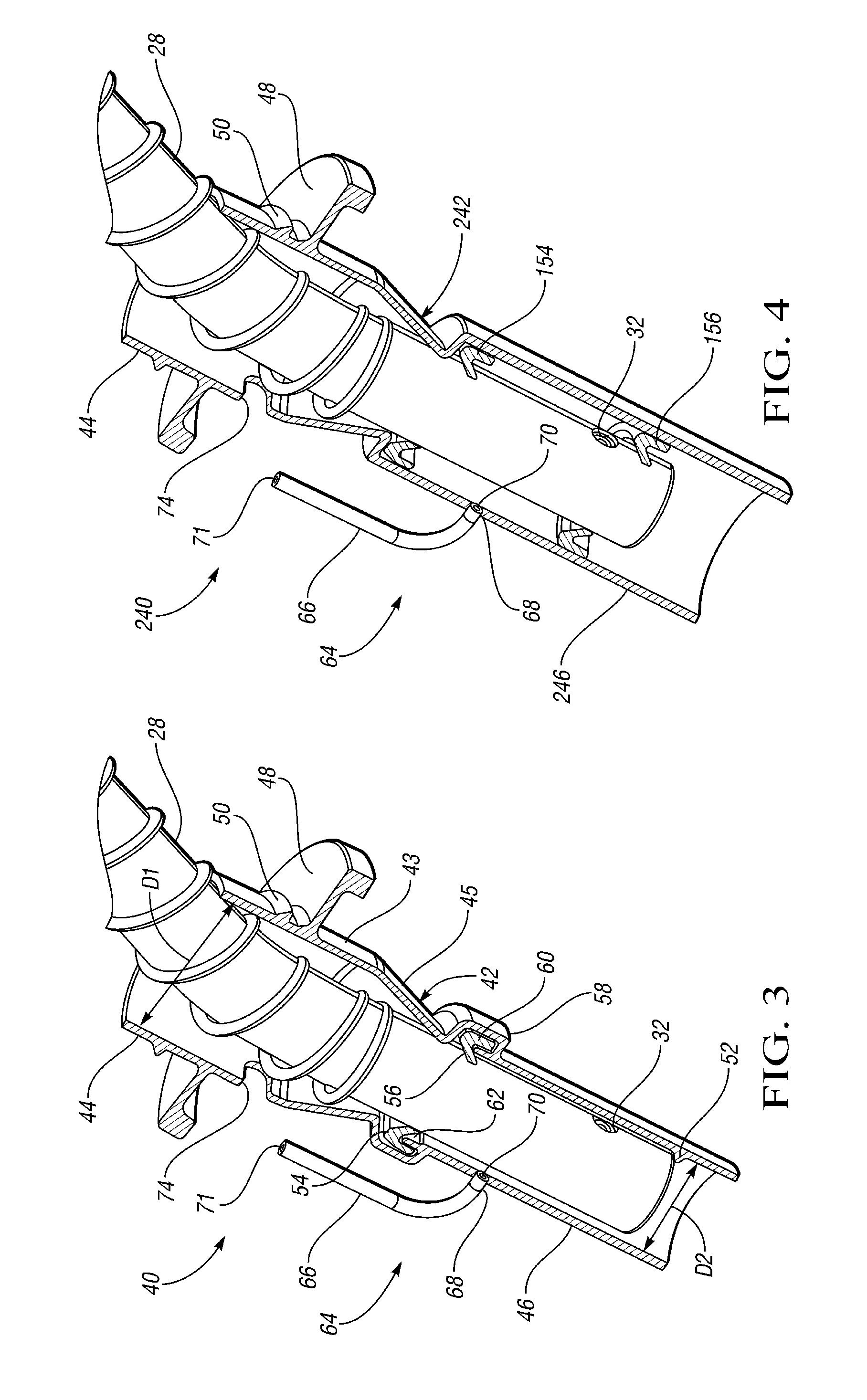

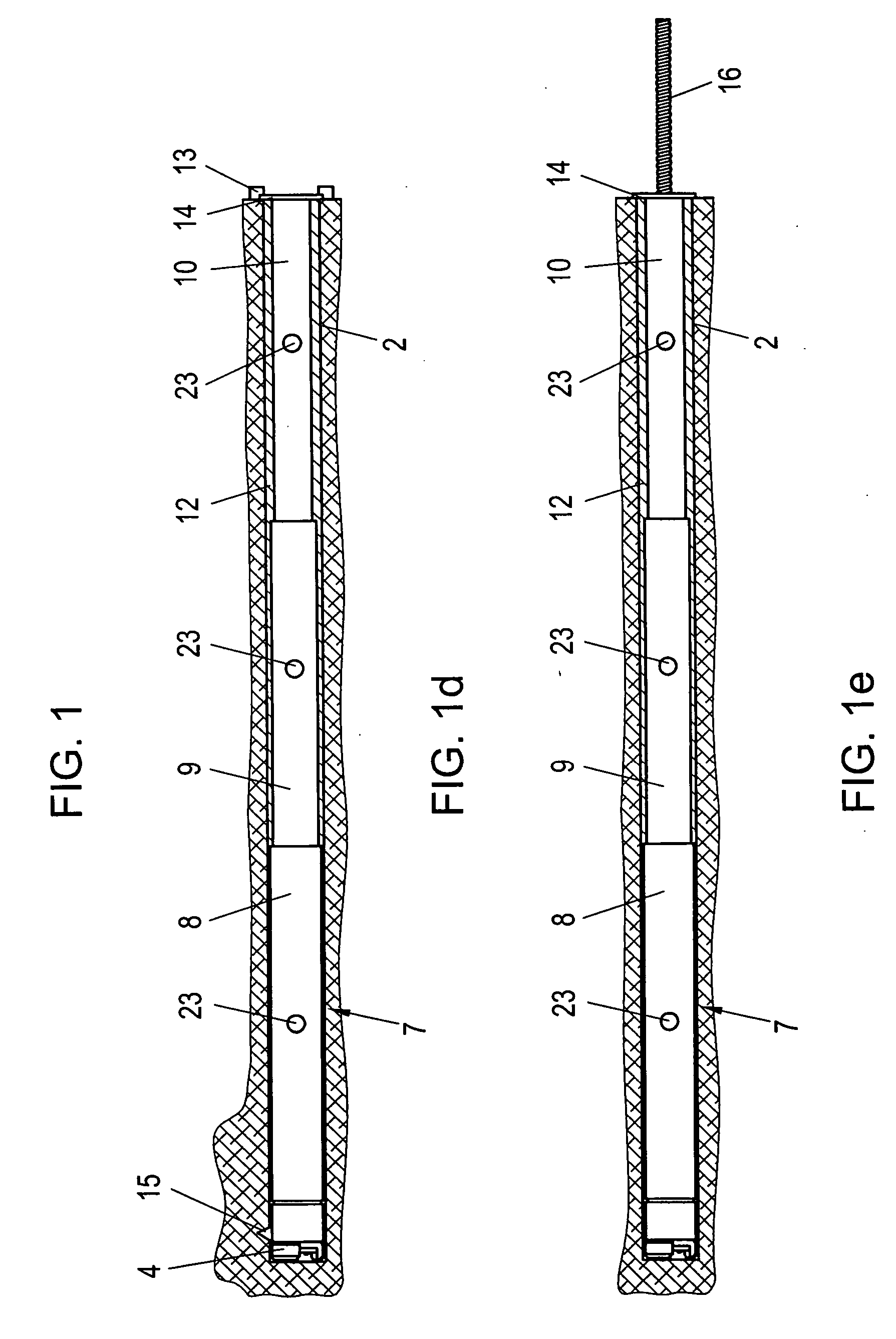

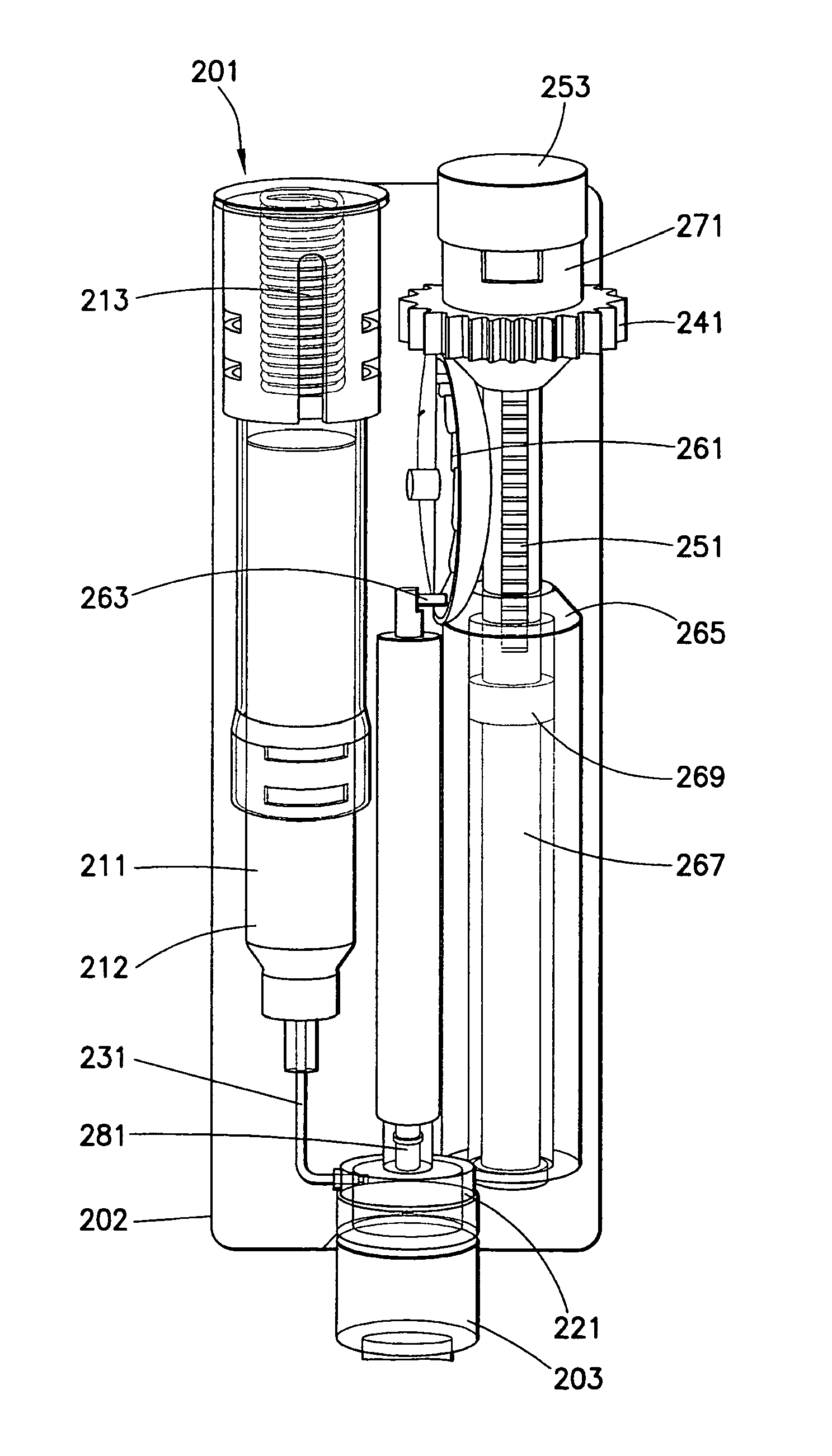

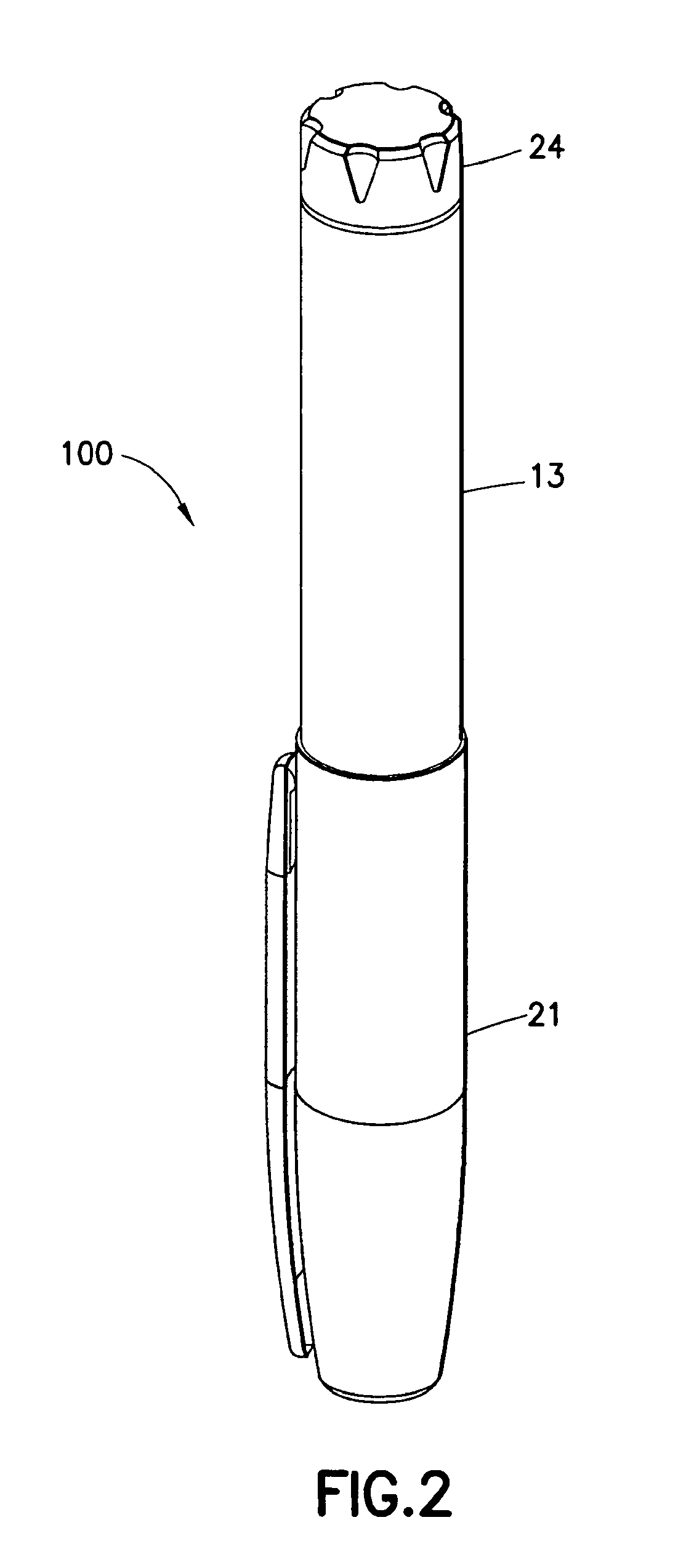

Multi-stroke delivery pumping mechanism for a drug delivery device for high pressure injections

ActiveUS20120004639A1Facilitates injecting insulin and other medicamentHigh pressureInfusion syringesMedical devicesDrug deliveryPiston

A dual-chambered drug delivery device (201) includes a cartridge (211) having a first chamber (212) for storing a medicament and a second chamber (211) in fluid communication with the first chamber (212). A dose setting member (241) is used to set a medicament dose to be injected at an injection site. A piston (281) is disposed in the second chamber (221). An upward stroke of the piston (281) draw a portion of the medicament dose into the second chamber (221) and a downward stroke of the piston (281) expels the portion of the medicament dose. A needle (205) communicates with the second chamber (221) for sequentially injecting the portions of the medicament dose into the injection site.

Owner:BECTON DICKINSON & CO

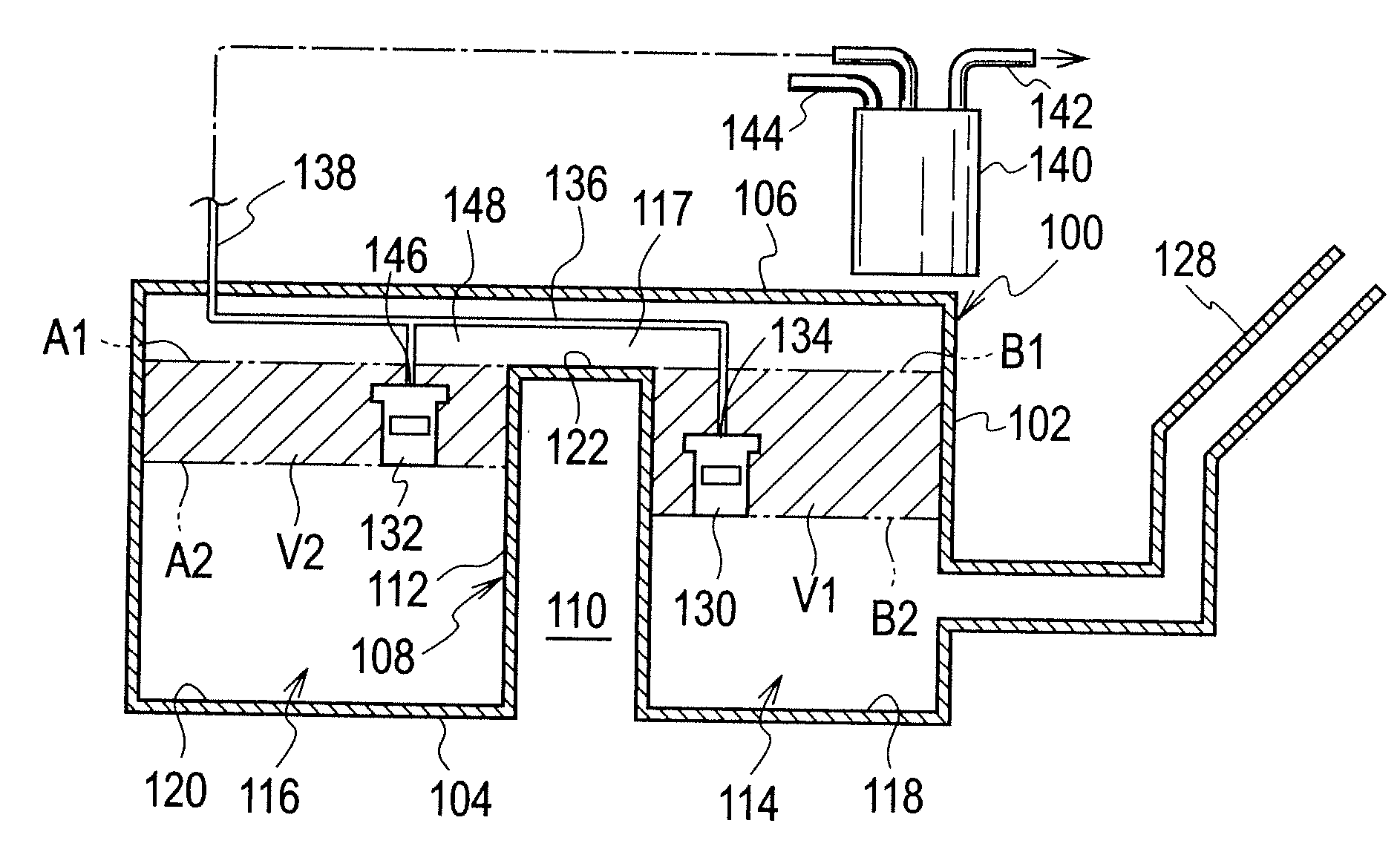

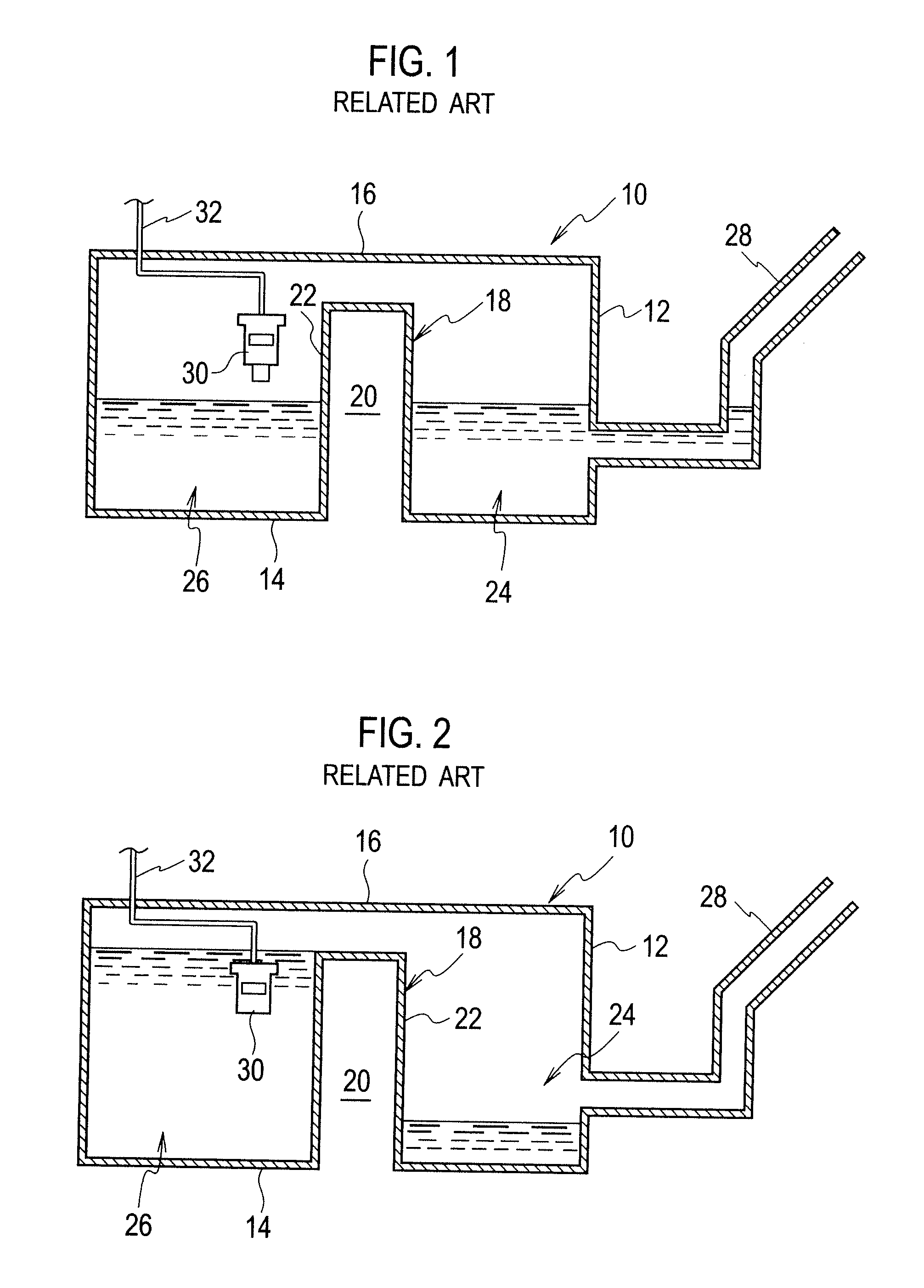

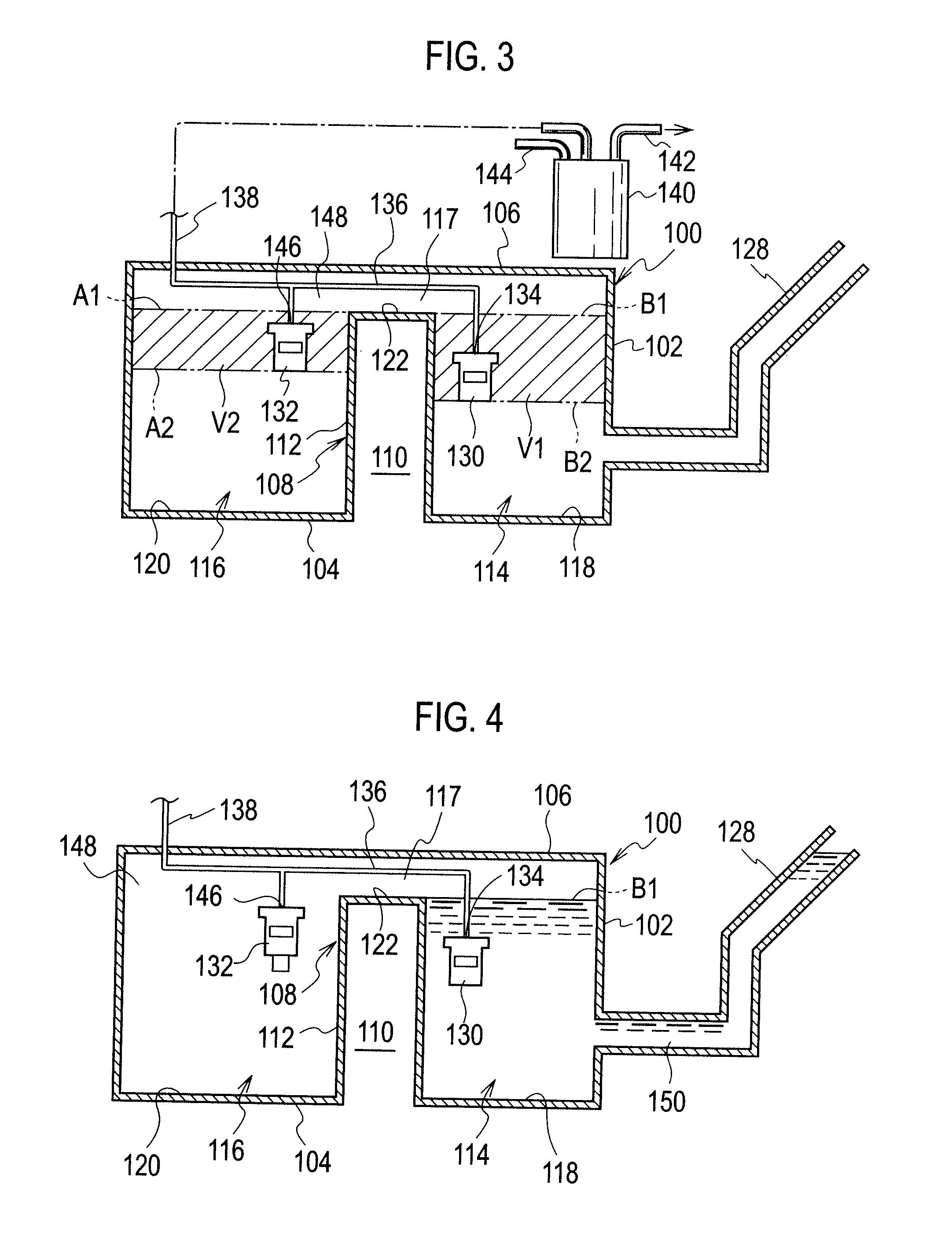

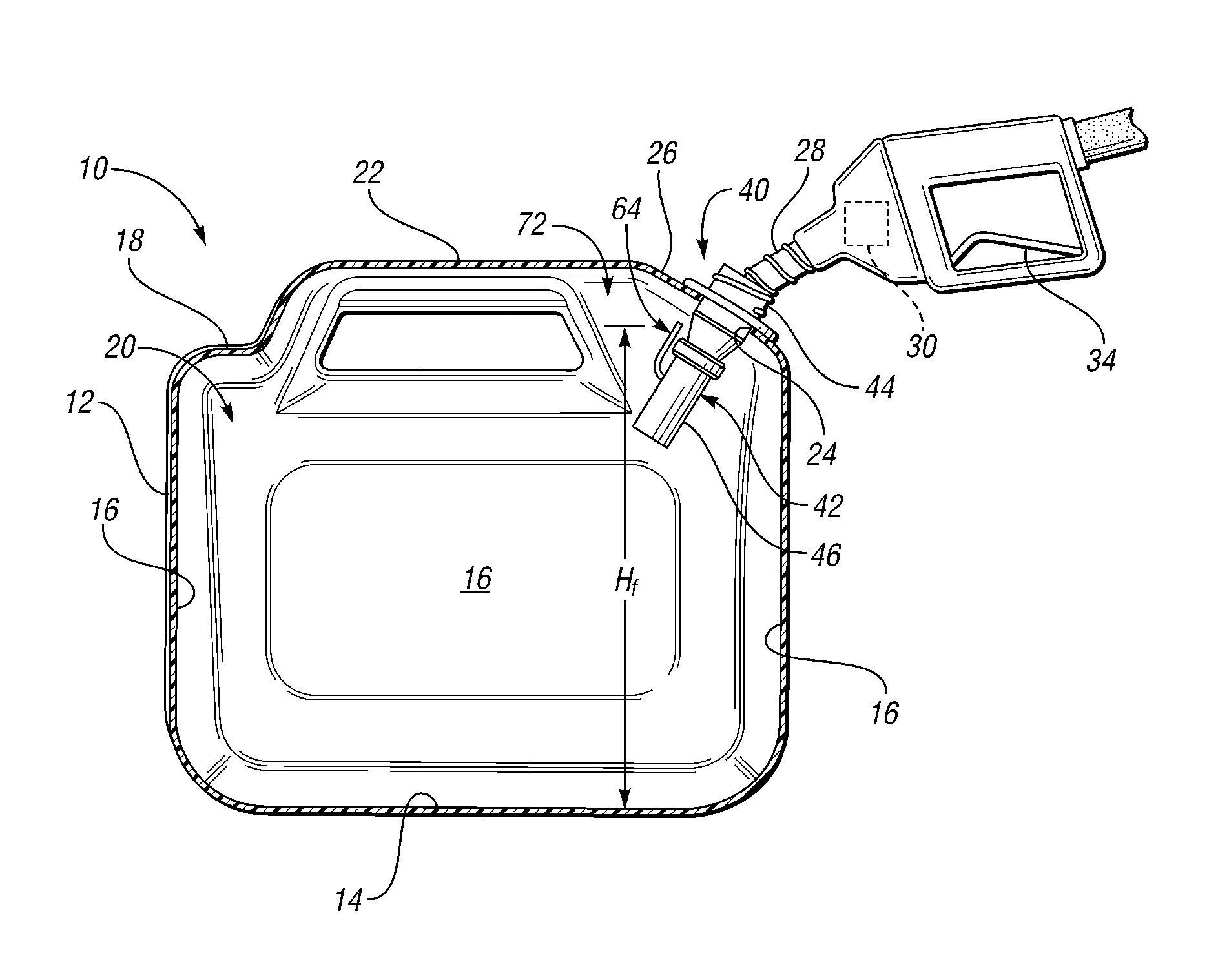

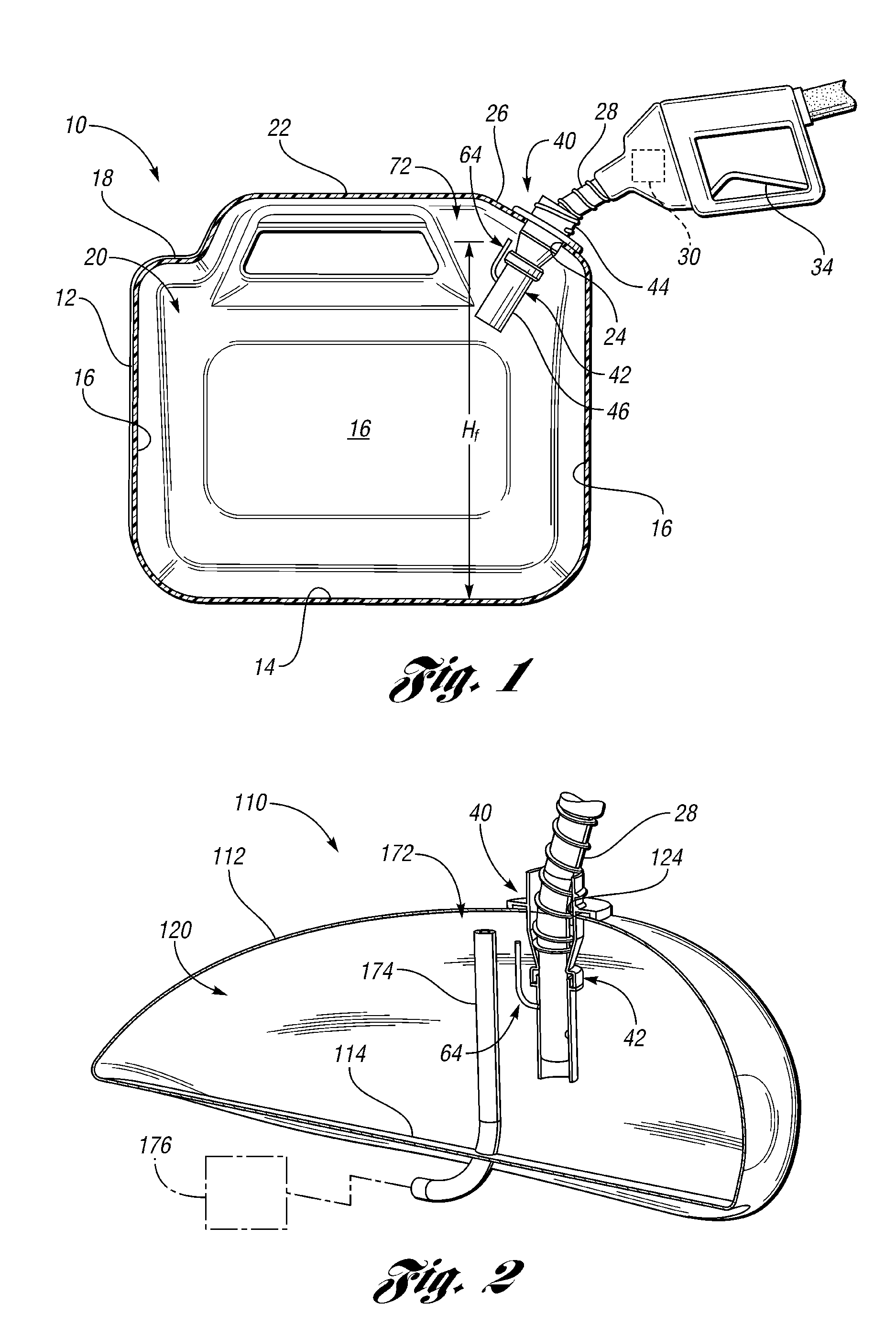

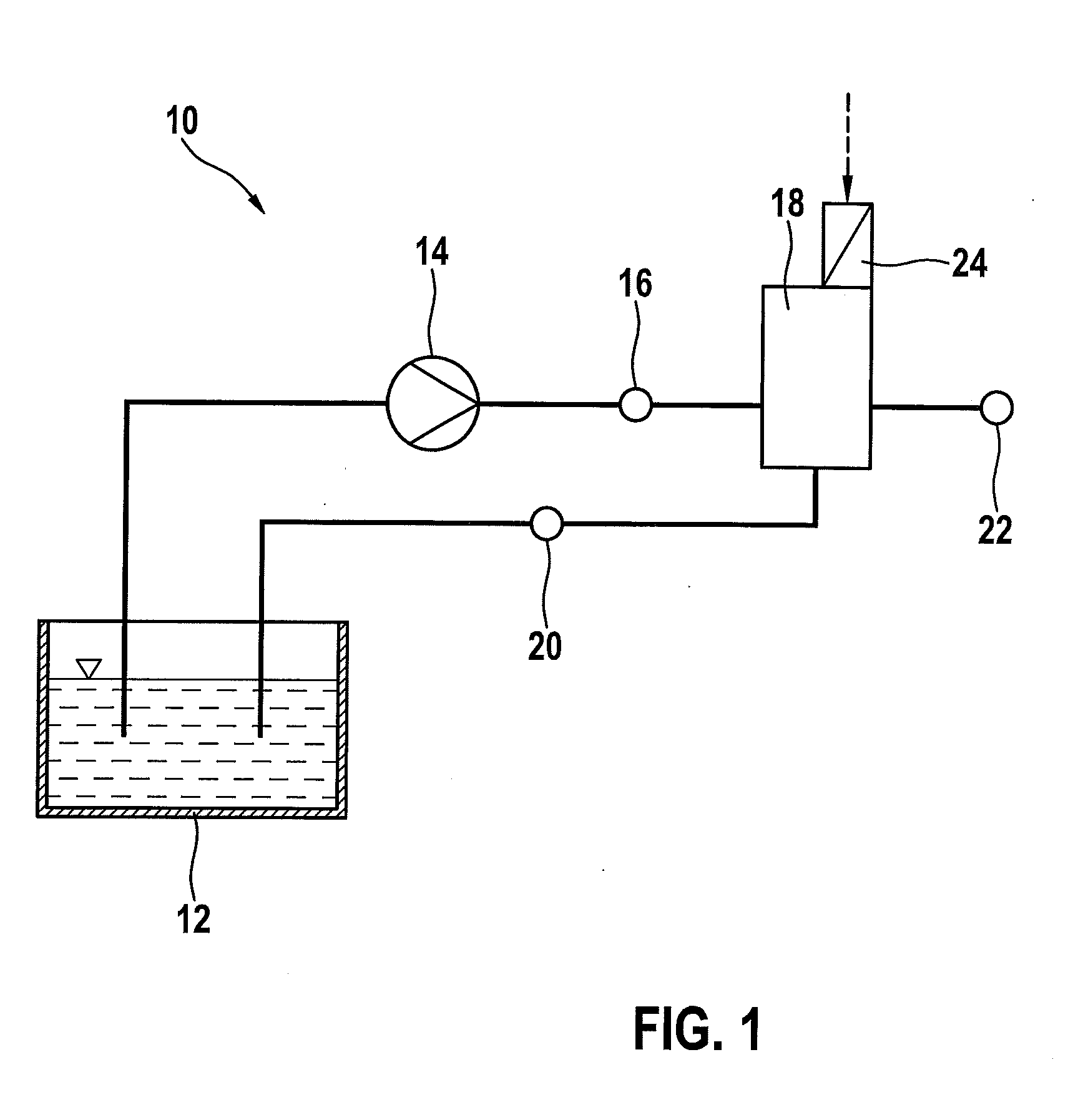

Fuel tank

ActiveUS20090085342A1Ensure fillingOverfilling is reliably avoidedUsing liquid separation agentLarge containersFuel tankSump

A fuel tank has a primary sump and secondary sump. A first vent valve and a second vent valve are disposed within the fuel tank. The first vent valve is closed when a level of fuel in the primary sump is equal to or higher than a first predetermined filling level, and the second vent valve is closed when a level of fuel in the secondary sump is equal to or higher than a second predetermined filling level in a refueling procedure.

Owner:NISSAN MOTOR CO LTD

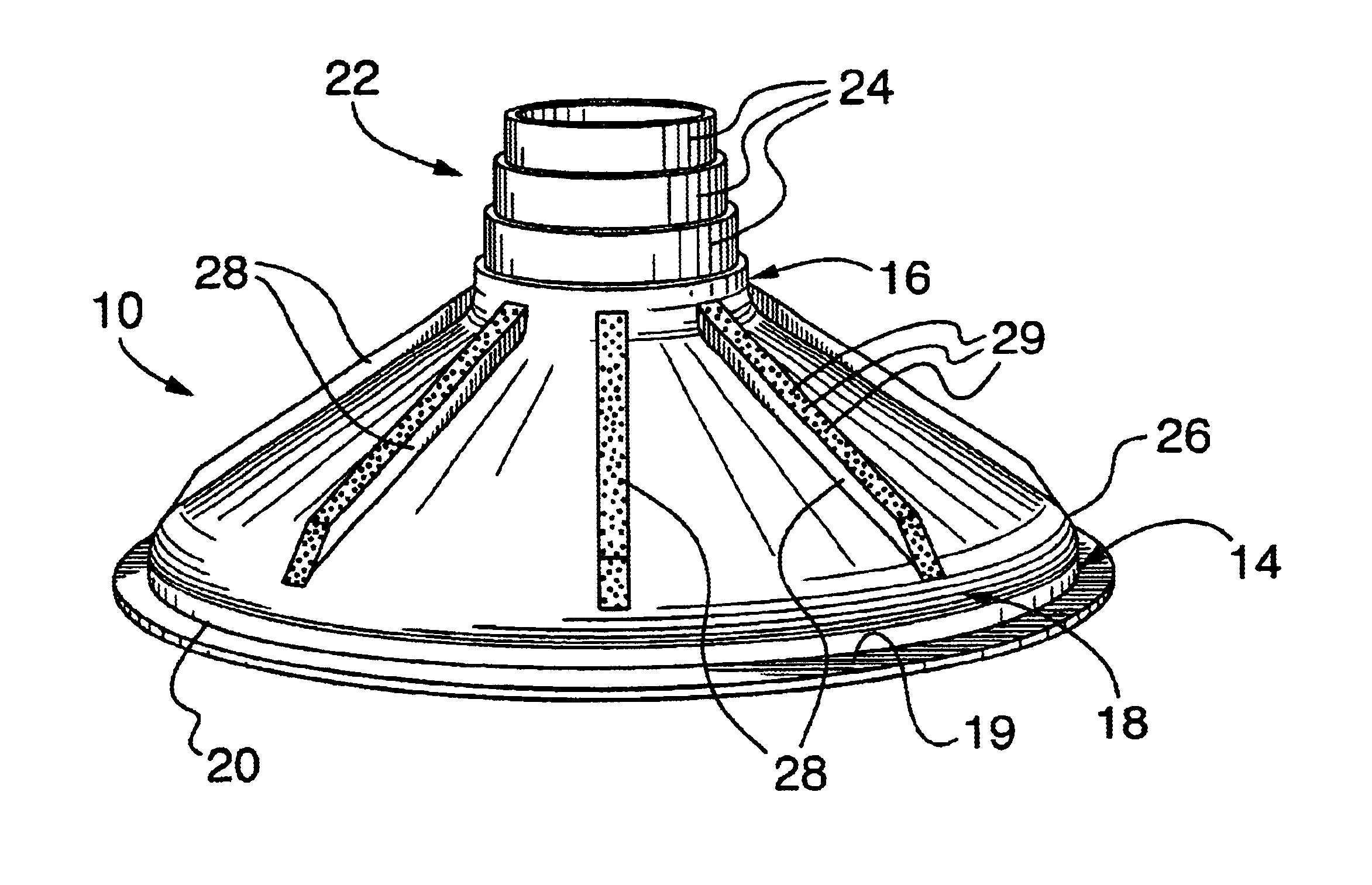

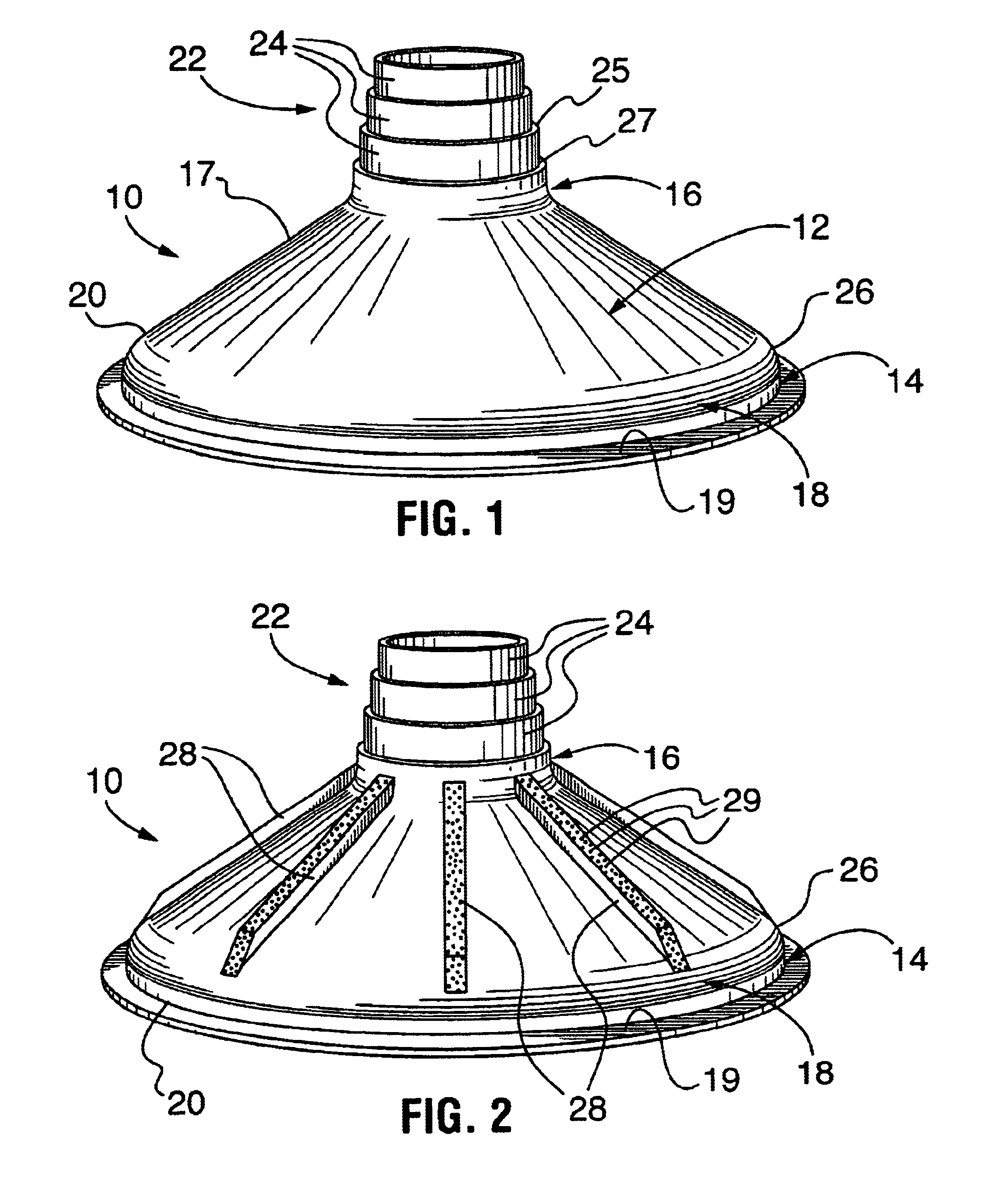

Footing form

InactiveUS6840491B2Small heightAvoid dangerStrutsForms/shuttering/falseworksThermoplasticHigh density

A prefabricated concrete form for the pouring of a footing for a structural pillar is disclosed. The form is preferably constructed from a thermoplastic such as a high density polyethylene or ABS and is molded as a single disposable unit. The form is bell-shaped and has dimensions which render it useful in industrial size applications with large footprints. The dimensioning of the form also reduces the amount of material used for the manufacture of the form, allows the form to be backfilled without cave-in and to reliably support a tubular form for the pillar without an additional bracing or supporting structure. The form is in particular a low profile form wherein the sidewall is inclined at an angle below 45° relative to the bottom edge. A top flange of the form is preferably adapted to accommodate two or more different diameters of the tubular form for the structural pillar. The sidewall may include integral ribs which open inwardly to facilitate evacuation of air as the form is filled and to lend rigidity to the sidewall. The sidewall may further include vent openings for the escape of air which is possibly temporarily entrapped during filling of the form. The advantage is an inexpensive form which does not have an excessive height despite large footprints, fills reliably and supports a tubular form for a pillar without the need for cross-pieces, even at sidewall angles below 45°.

Owner:BIGFOOT SYST

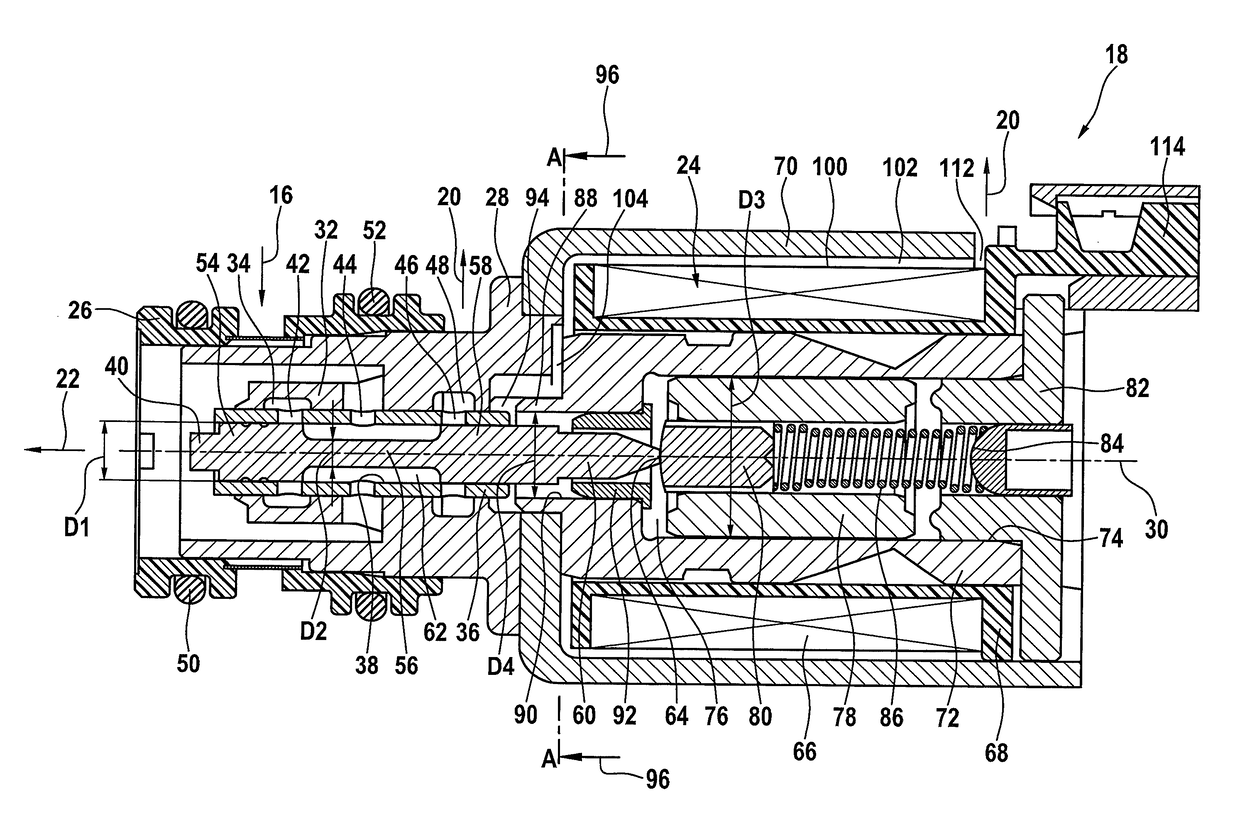

Metering valve with a hydraulic transmission element

InactiveUS7669783B2Improve functionalityEnsure fillingOperating means/releasing devices for valvesMovable spraying apparatusPiezoelectric actuatorsEngineering

The invention relates to an injection valve which has a piezo actuator that is functionally connected to a nozzle needle by a hydraulic transmission device. The hydraulic transmission device is connected to a pressure reservoir by a sealing gap so that the pressure differences between the pressure reservoir and a hydraulic chamber of the hydraulic transmission device are compensated in the long term.

Owner:CONTINENTAL AUTOMOTIVE GMBH

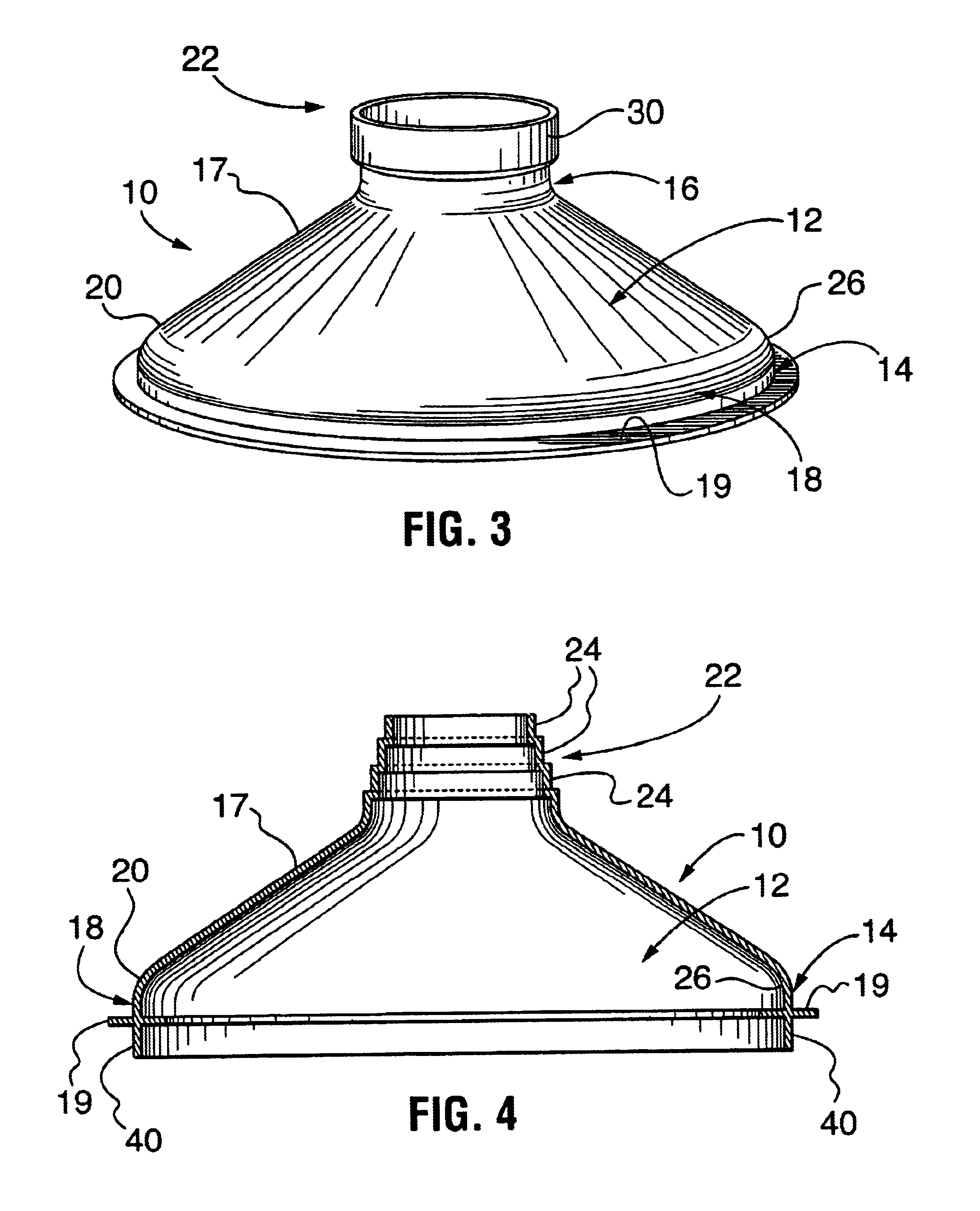

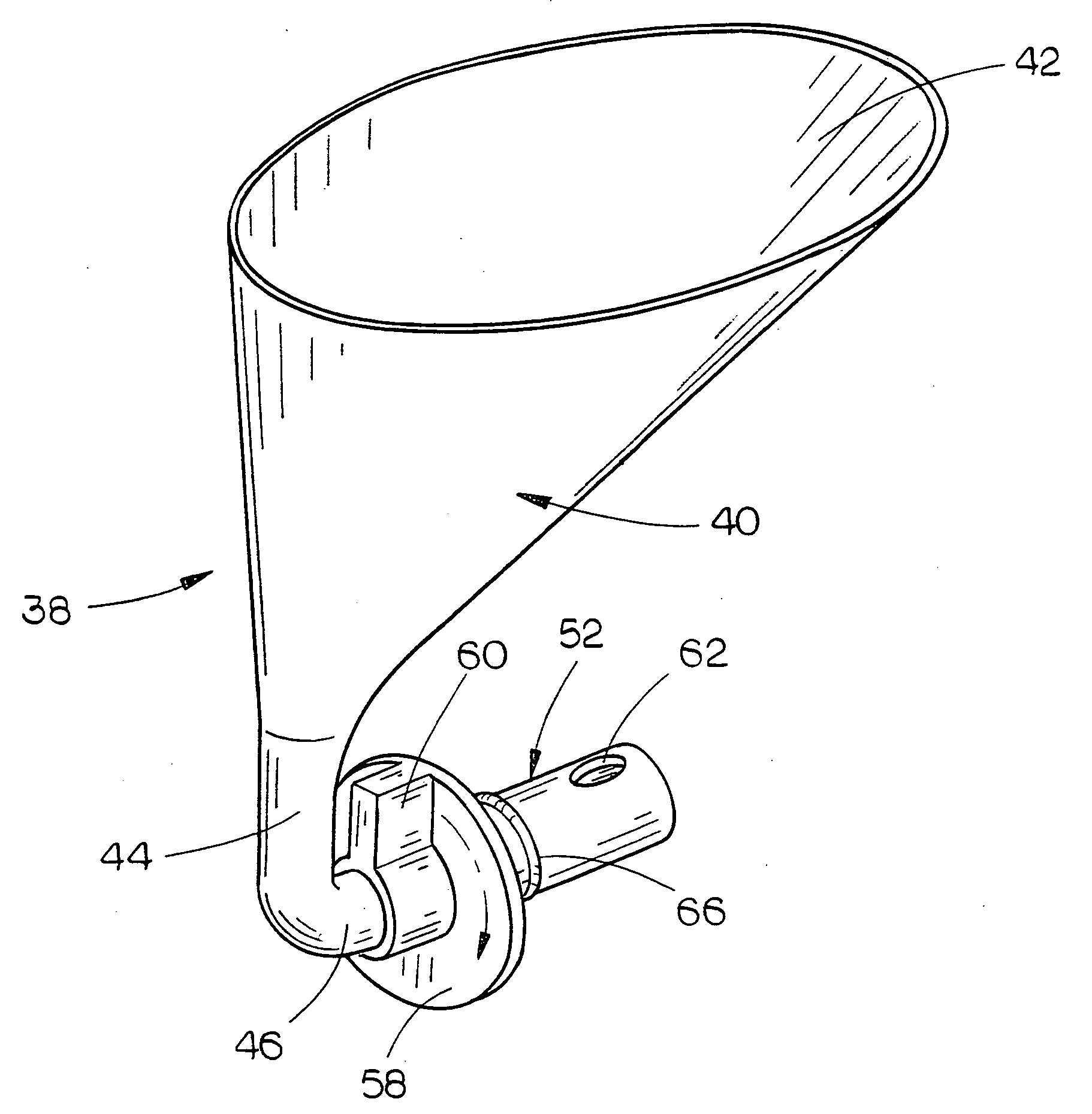

Overfill prevention control for fluid storage container

ActiveUS8056589B2Prevent overflowEnsure fillingLarge containersPackaging automatic controlEngineeringPrevention control

An overfill prevention device is provided for preventing overflow of a fluid storage tank. The overfill prevention device includes a filler cup designed to fit within the fill opening of the tank body and attach thereto. A seal that is adapted for receiving and sealing to a fill nozzle is placed between upper and lower regions of the filler cup. A breather piece, which defines a vapor path with first and second openings, is integrated with the filler cup. The first opening of the breather piece is fluidly coupled to the lower cup region, whereas the second opening is positioned above the first opening, located at or below the full level of the storage tank.

Owner:EATON INTELLIGENT POWER LTD

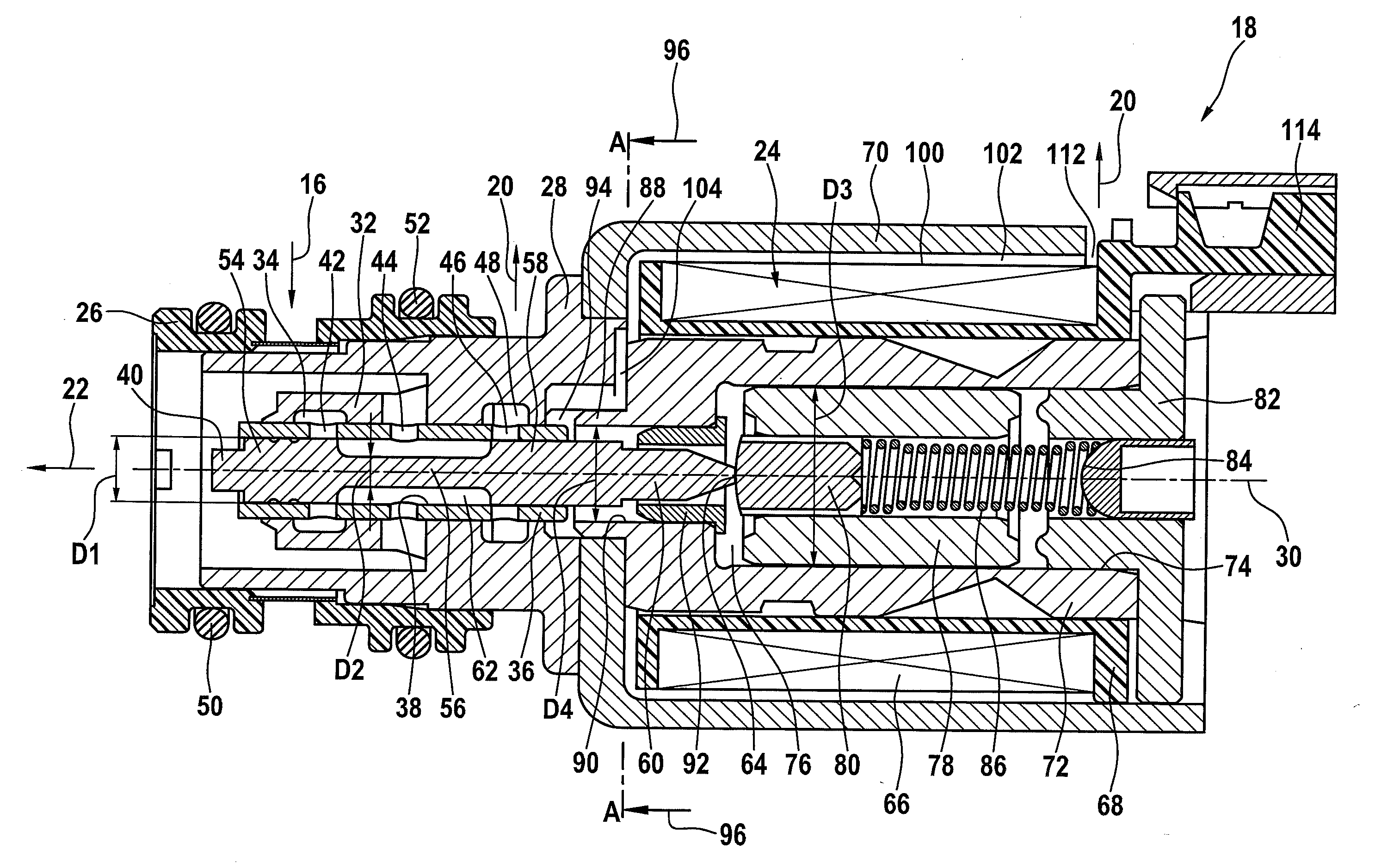

Pressure control valve including a compensating chamber

ActiveUS20150176700A1Simple to manufactureSimple and cost-effectiveOperating means/releasing devices for valvesGearing controlPistonMagnet

A pressure control valve, in particular for an automatic transmission in a motor vehicle, including a housing and including a control piston situated in the housing, the control piston being actuatable by an armature situated in a magnet chamber of a pole tube, the magnet chamber being hydraulically connected to a compensating chamber provided in the housing, which is delimited, in particular by a lateral surface of a solenoid coil and the housing.

Owner:ROBERT BOSCH GMBH

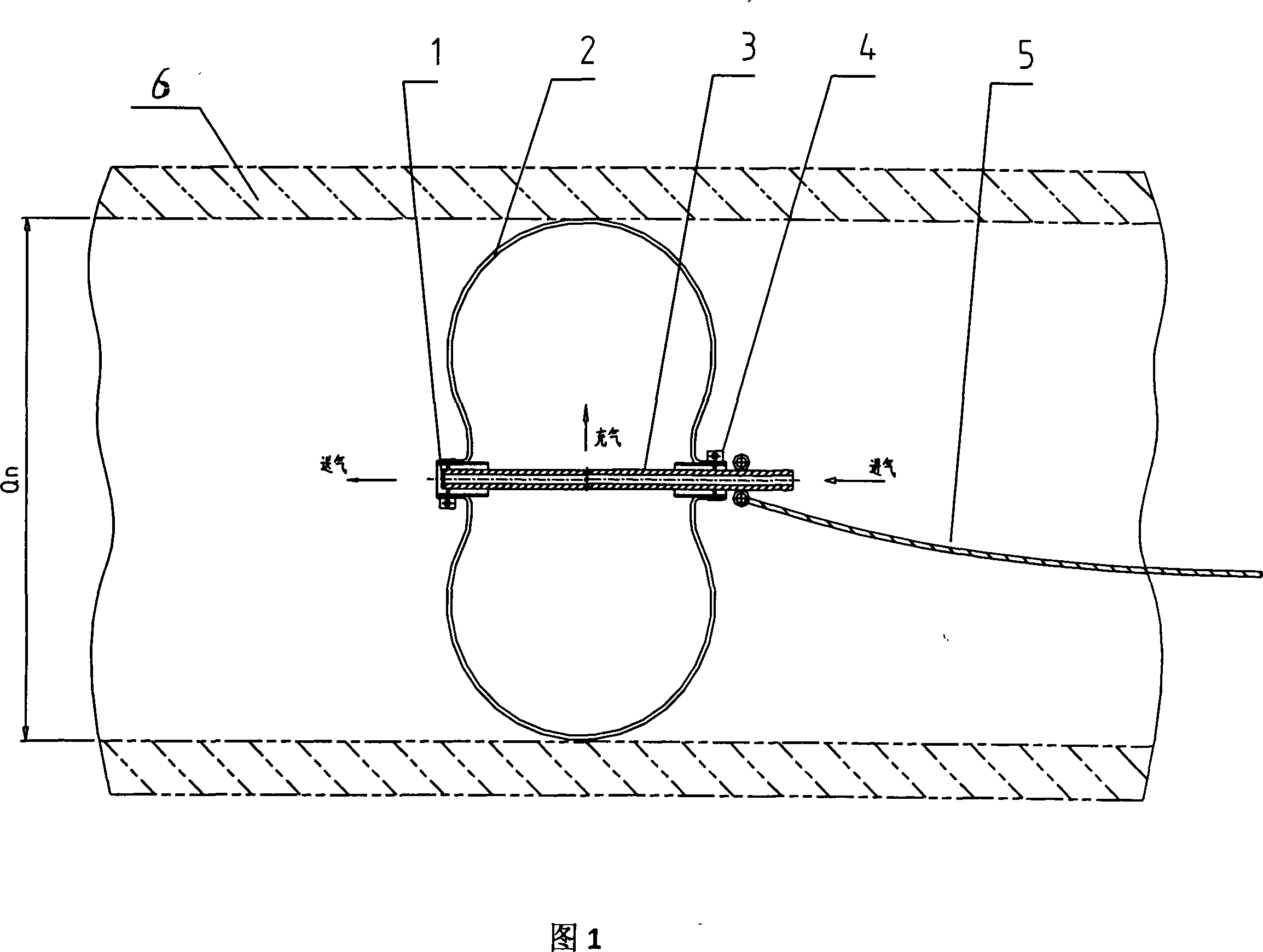

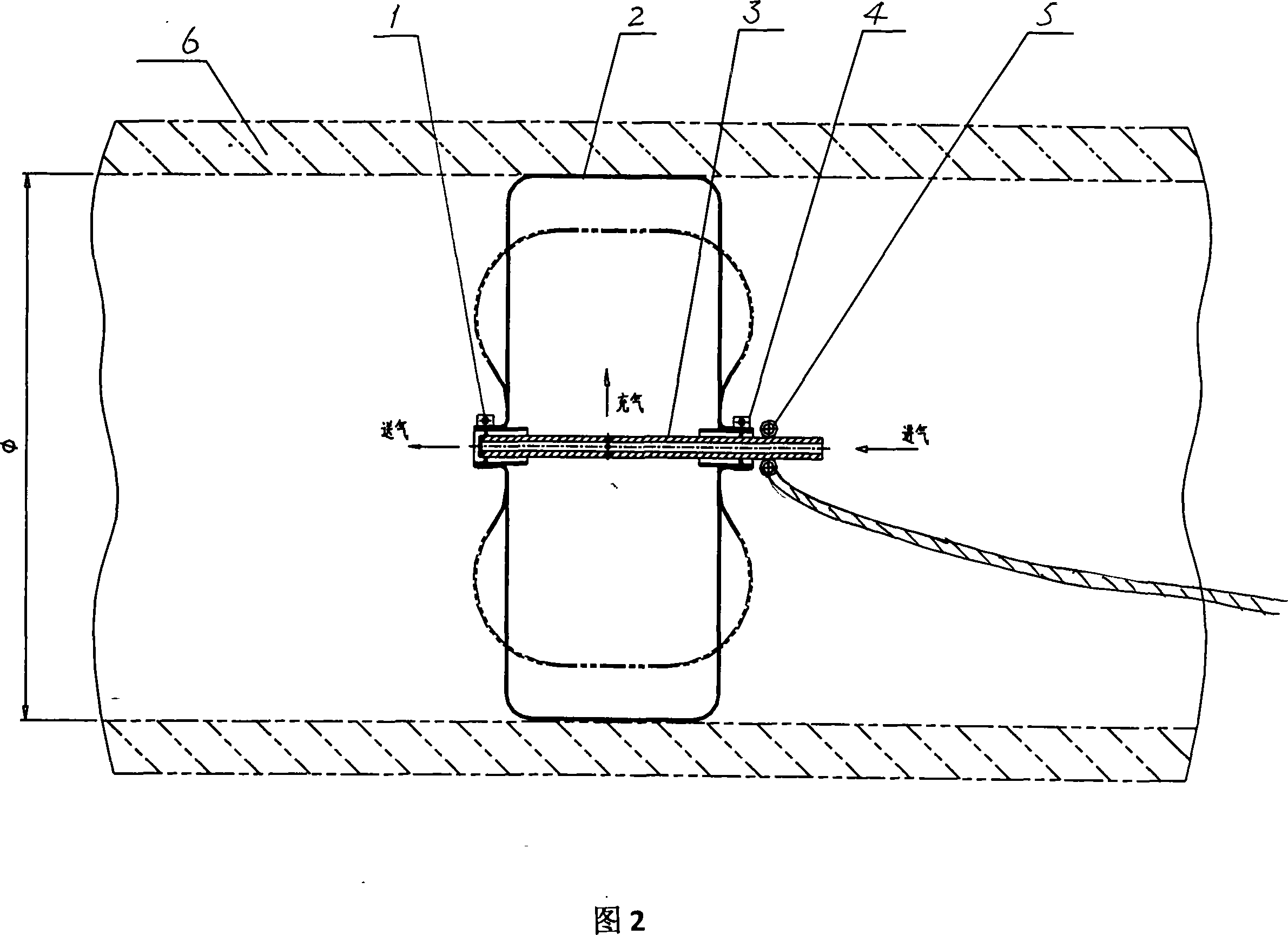

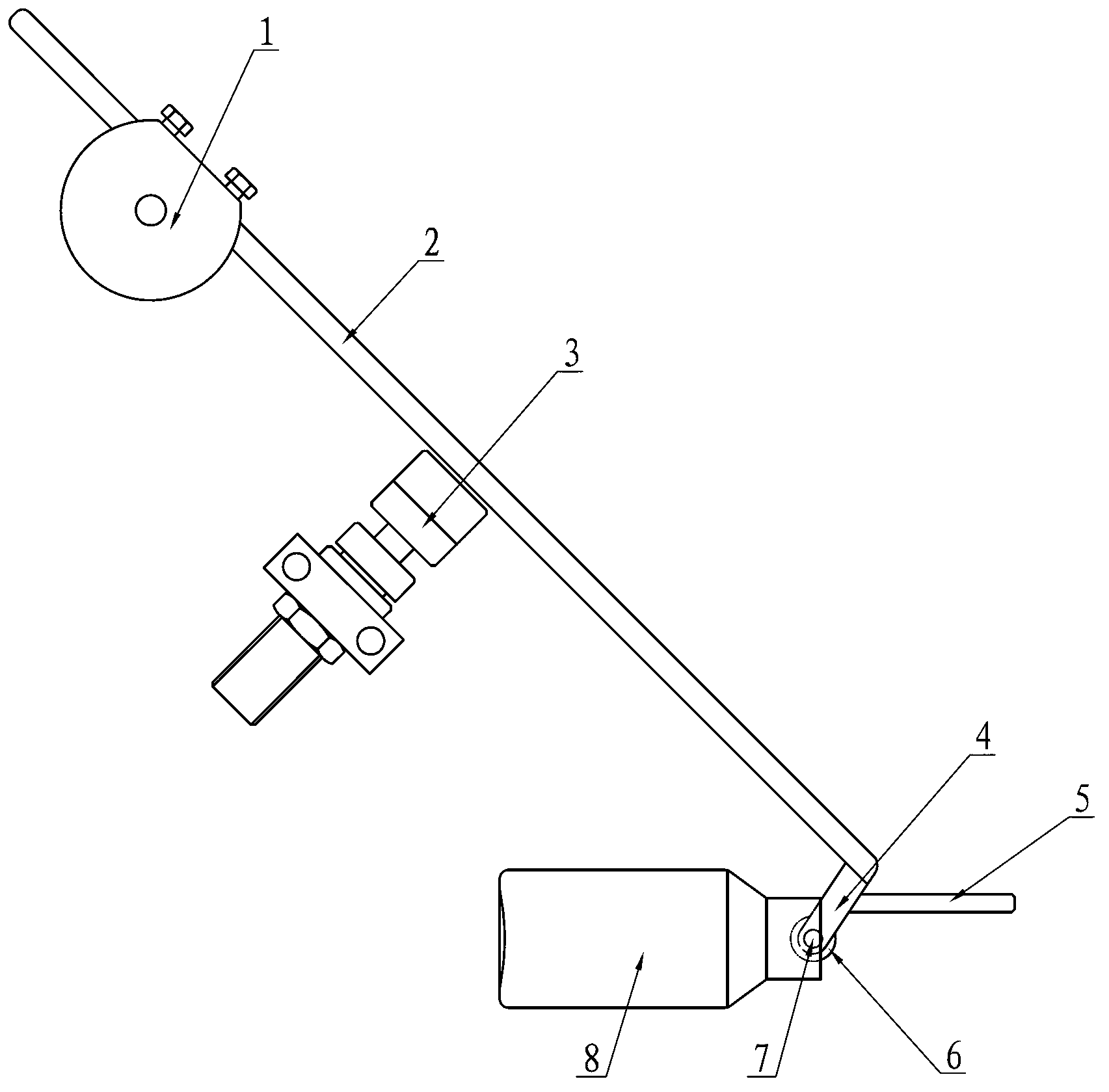

Inner sealing device

InactiveCN101224521AEnsure fillingEnsure expansion plugWelding/cutting auxillary devicesAuxillary welding devicesWorking environmentEngineering

The invention relates to an internal sealing device. The invention is characterized in that the invention consists of an air-feeding adjusting valve, an inflation device, an argon pipe, a withdrawing pulling ring and a traction rope; the argon pipe with a stomata passes through the inflation device; one end of the argon pipe is provided with the air-feeding adjusting valve and the other end thereof is provided with the withdrawing pulling ring; the traction rope is connected with the withdrawing ring. The invention has the advantages of novel and light structure, being suitable for severe welding working environment, being especially suitable for the sealing protection of abnormal section internal chamber, and convenient application.

Owner:SHANGHAI BOILER WORKS

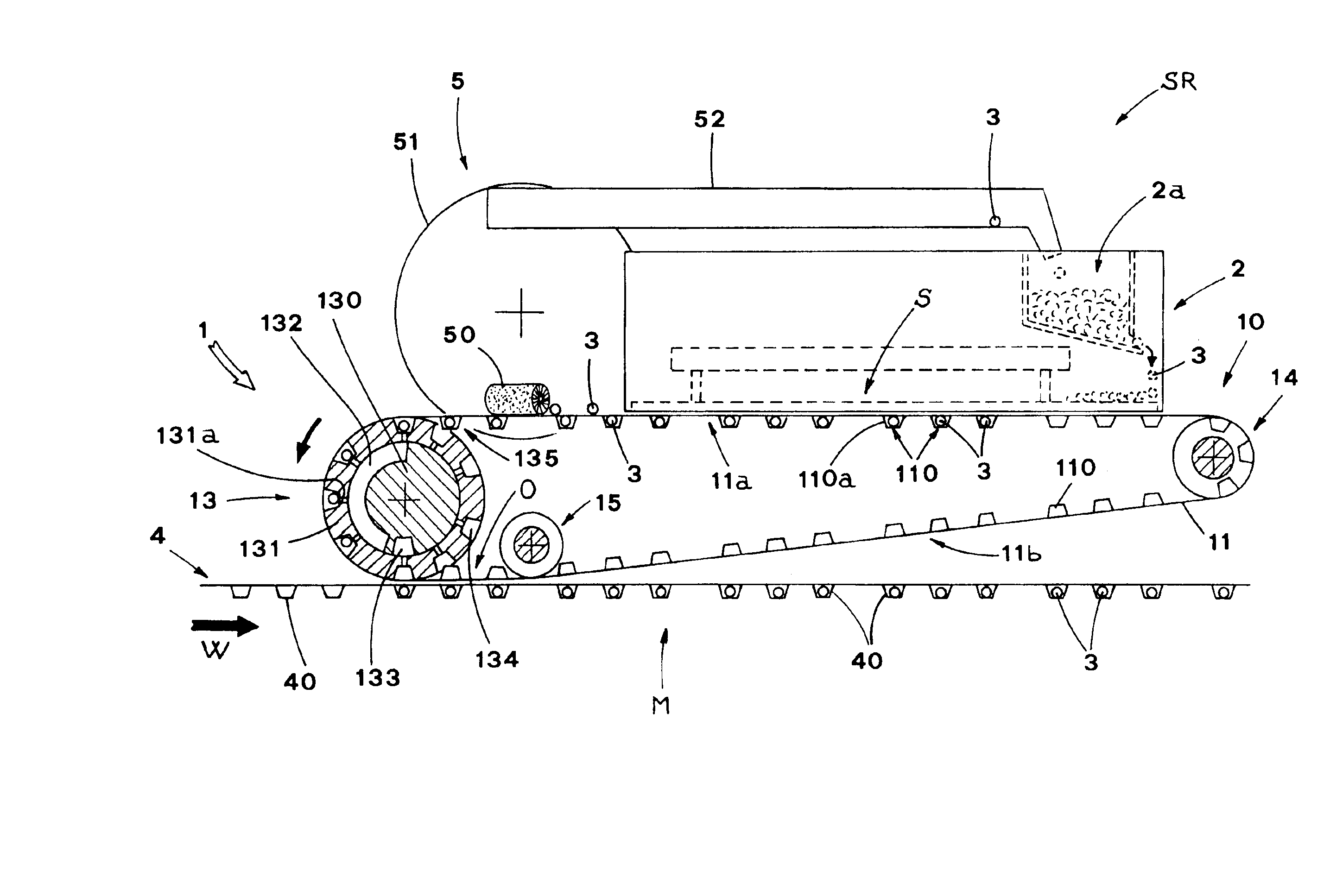

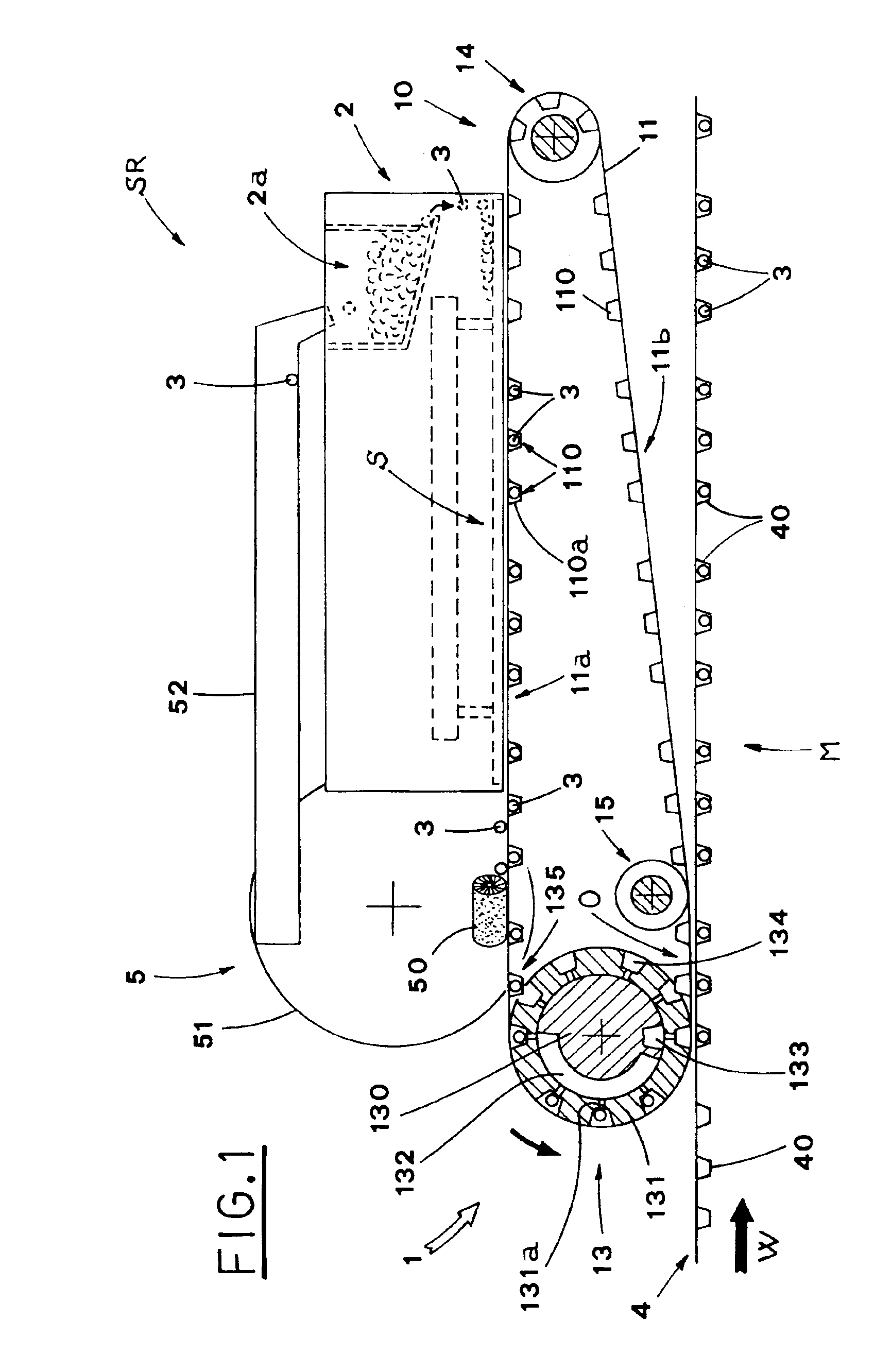

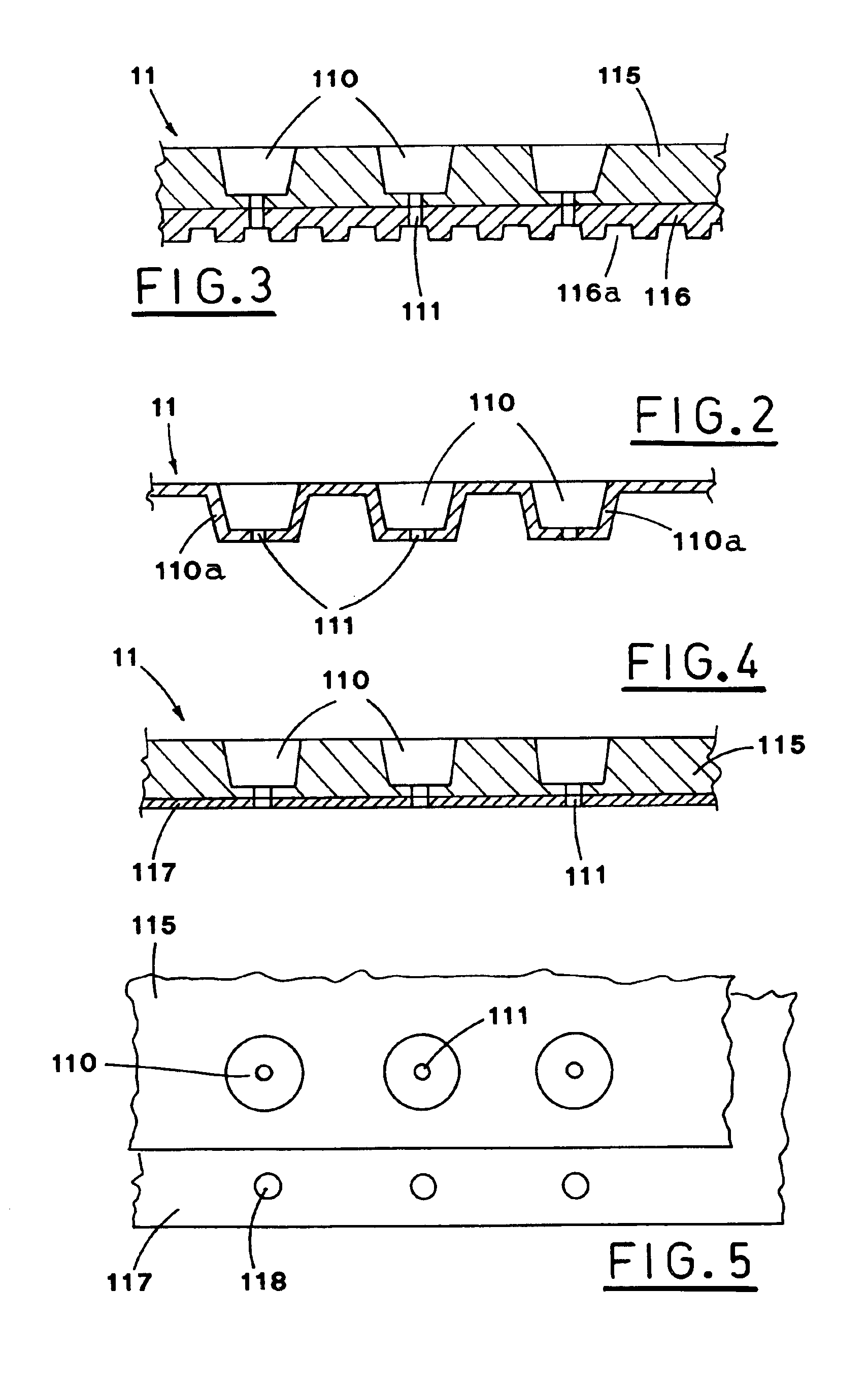

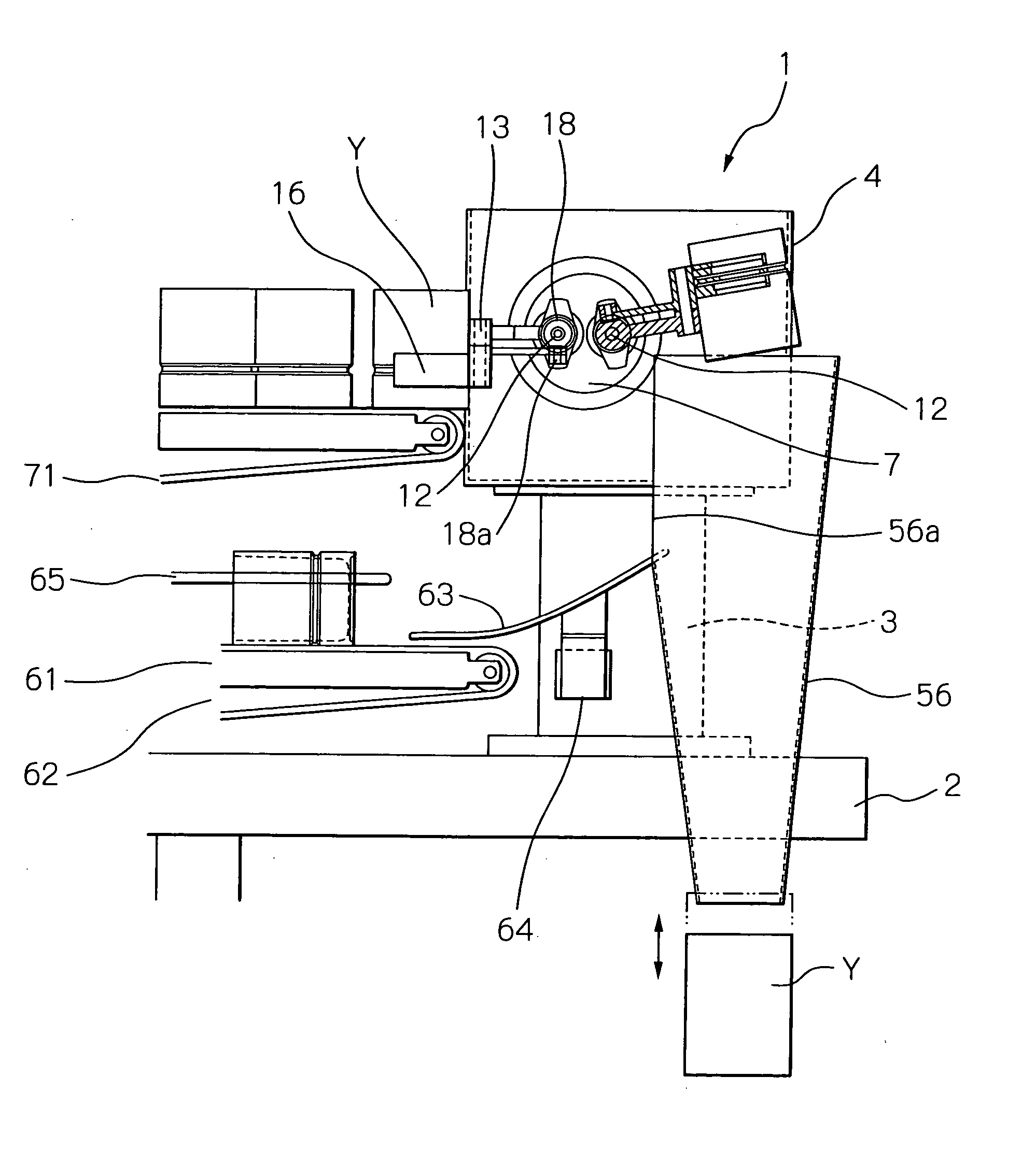

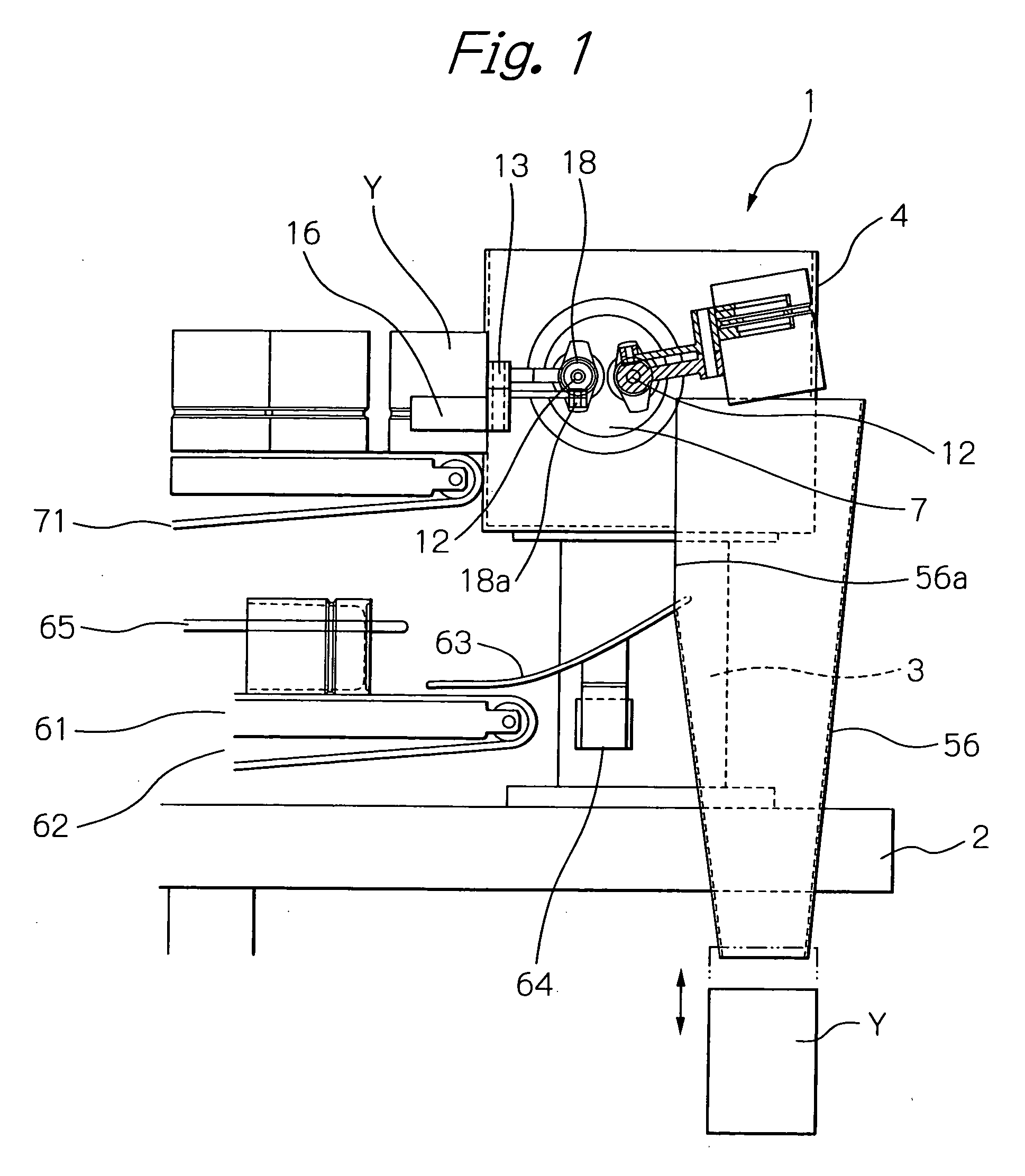

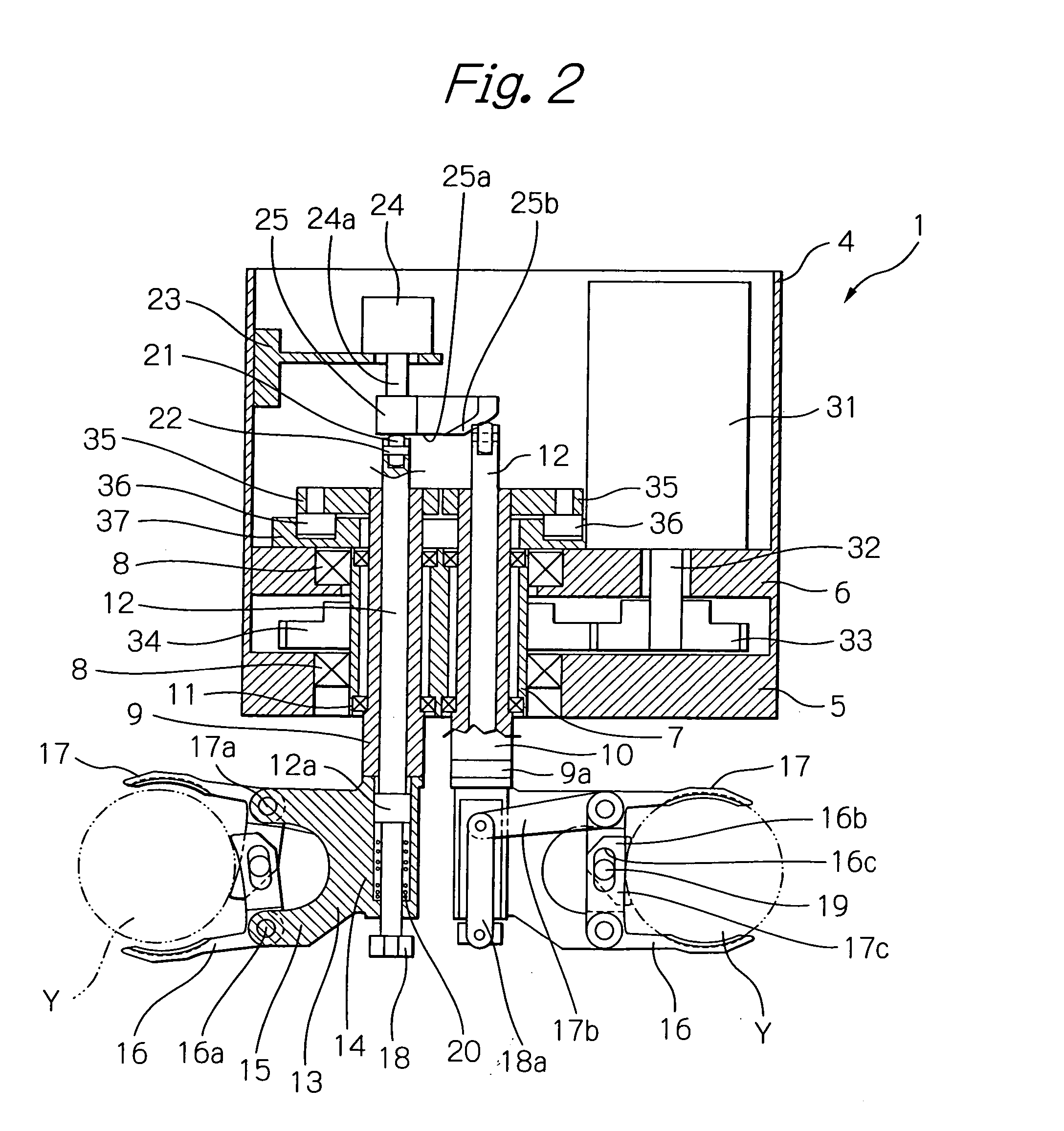

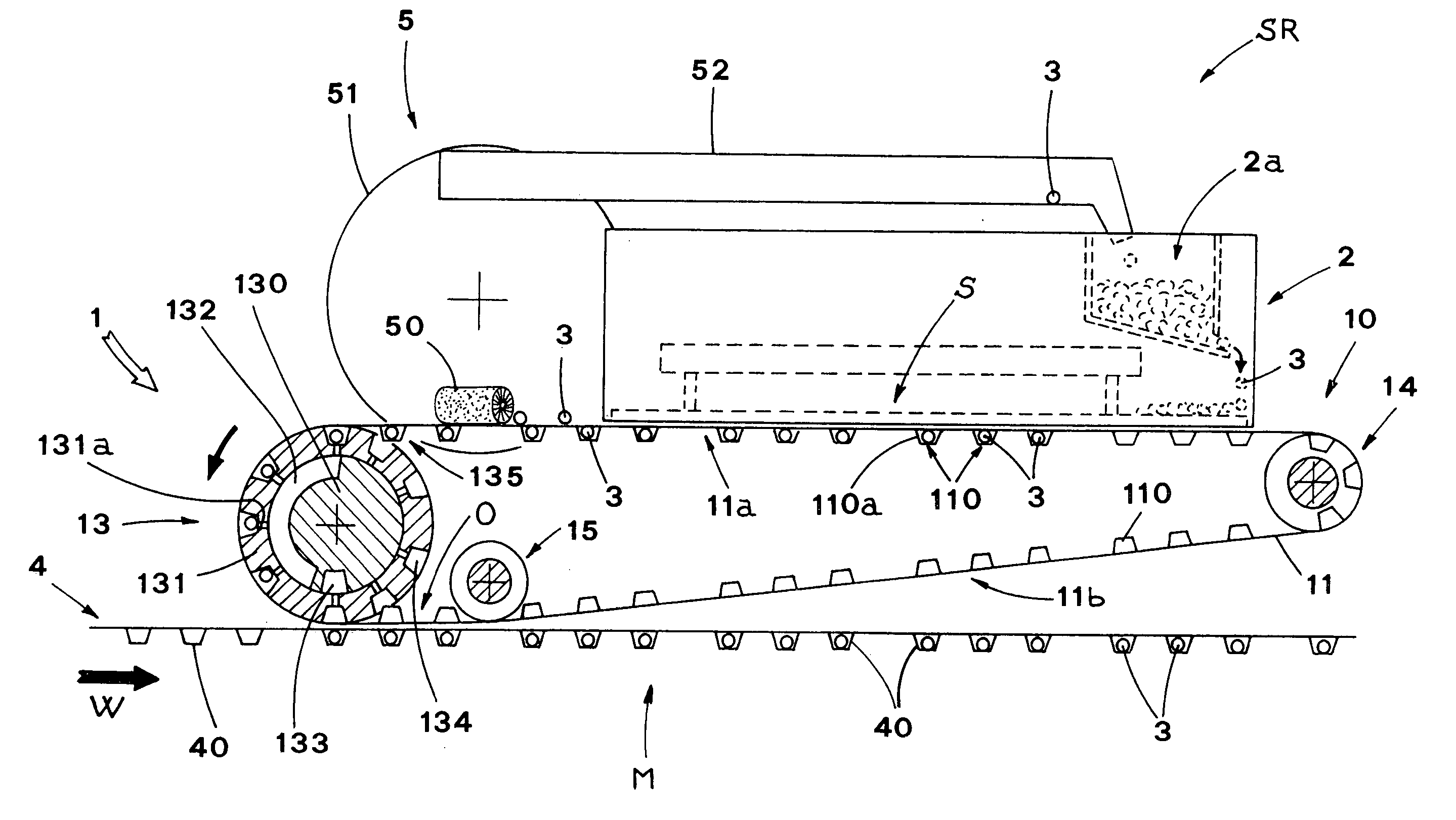

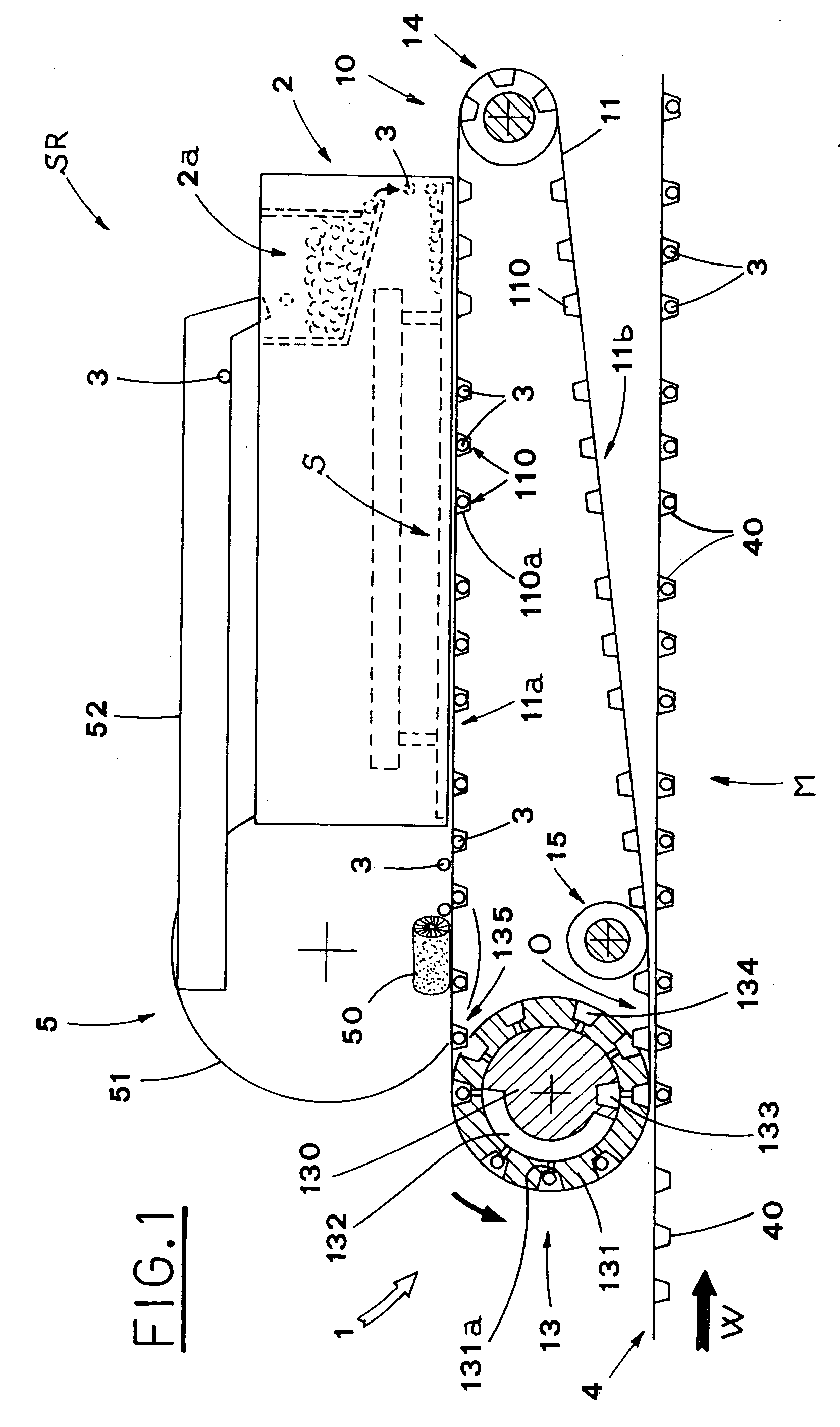

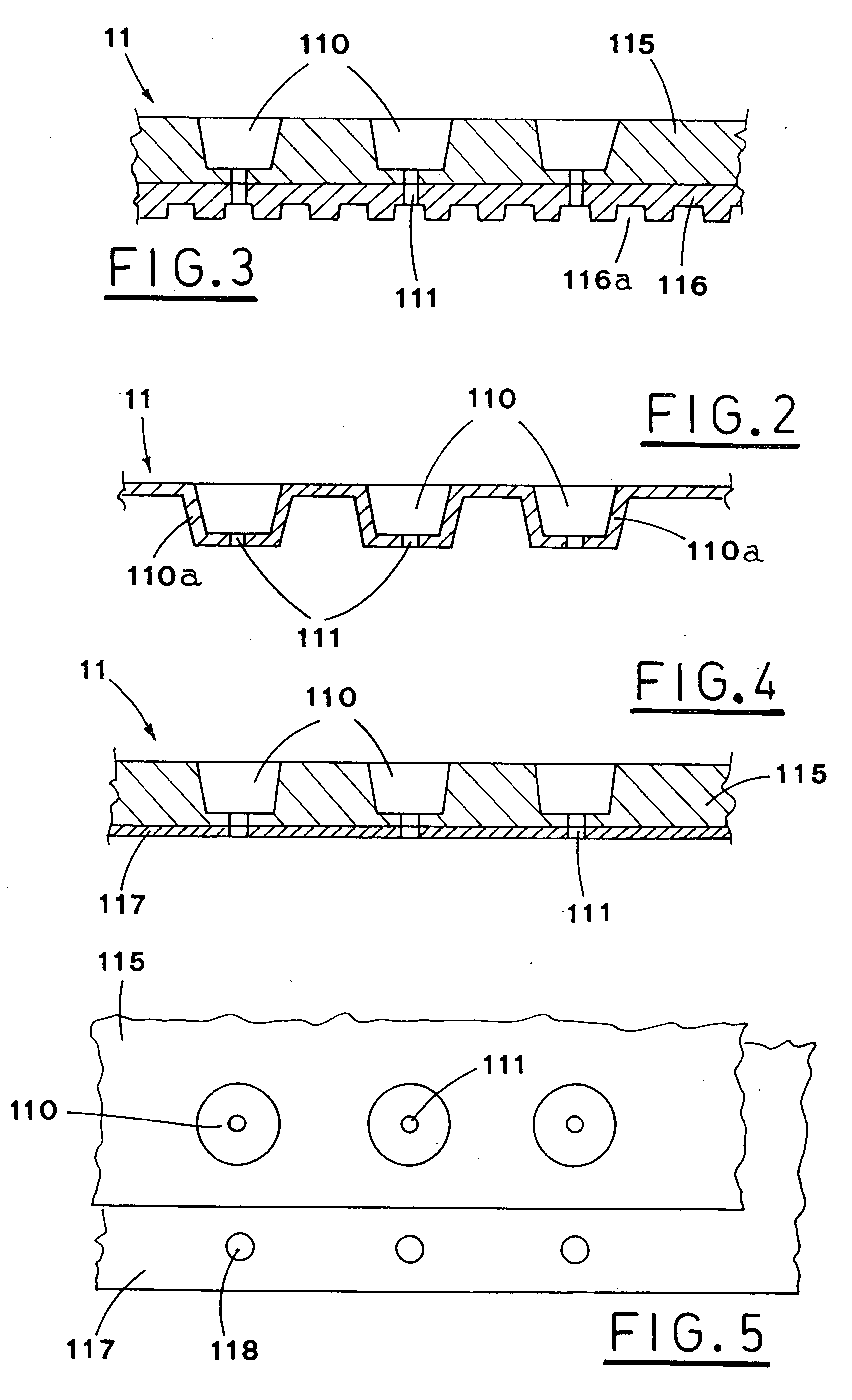

Unit for feeding products to a blistering machine

InactiveUS6945012B2Improve integrityEnsure fillingSolid materialLiquid materialBlistersStep Relation

A unit (1) for feeding products (3) to a blistering machine (M) includes a delivery group (2,2a,S) for selectively distributing products (3) to a station (SR), where the products (3) are introduced into respective blisters (40) of a blister band (4), moving in a forward direction (W) inside the blistering machine (M). The filling station (SR) is defined by conveying means (10) consisting of a belt (11) provided with seats (110). Each seat (110) receives a relative product (3) distributed by the delivery group (2,2a,S) and releases the products (3) into a respective blister (4). The conveying means (10) include at least one endless belt (11), moving in step relation with the blister band (4) and wound around respective pulling wheels (13,14), with an upper portion of the belt (11) defined by an upper run (11a) extending under the delivery group (2,2a,S) in a direction parallel to the forward direction (W), and with the lower portion of the belt (11) defined by a lower run (11b) extending, along at least a section (O) parallel to the forward direction (W), substantially very close to and above the blister band (4) and facing the blister band (4).

Owner:IMA IND MASCH AUTOMATICHE SPA

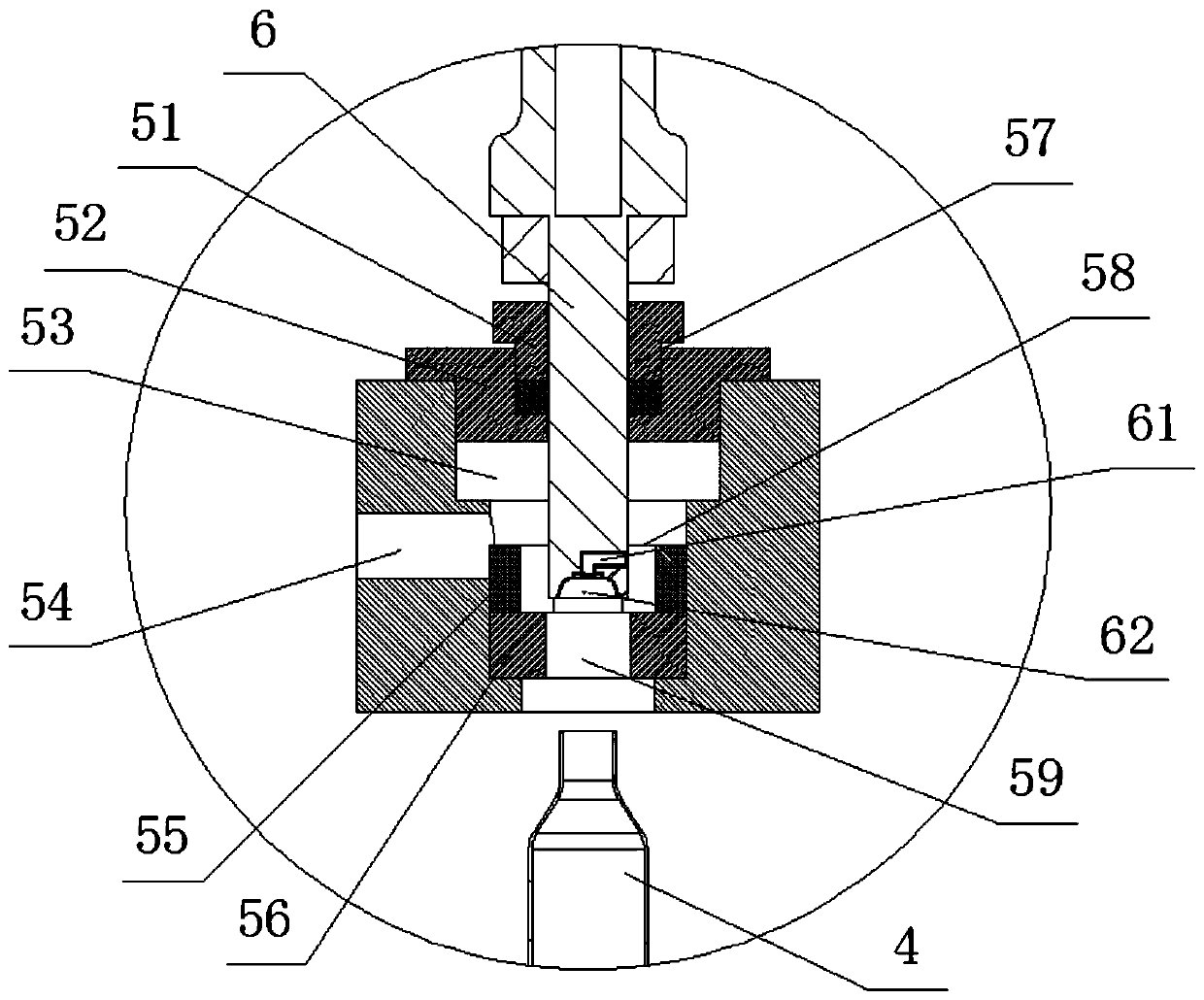

Bottle turning mechanism of filling machine

A bottle turning mechanism of a filling machine comprises a pressure-adjustable rotating cylinder, a bottle stirring rod and a buffer, wherein a bottle mouth rod is arranged at the bottom end of the bottle stirring rod; an anti-sticking rod is arranged on the bottle mouth rod and is horizontally fixed on the bottle mouth rod; the length of the anti-sticking rod is larger than the diameter of the bottle mouth of a bottle body to be filled; and the distance from the lower end of the bottle mouth rod to the junction of the anti-sticking rod and the bottle mouth rod is 1 / 2 to 1 of the diameter of the bottle mouth of the bottle body to be filled. When the conveying direction of the bottle mouth of the bottle body to be filled is outward, the bottle mouth rod at the lower end of the bottle stirring rod is positively inserted in the bottle mouth of the bottle body, so that the bottle body is forced to turn for 180 degrees, and then the inverted bottle body can be turned to be placed correctly; through the arrangement of the anti-sticking rod, the bottle mouth rod can be effectively prevented from being stuck in the bottle mouth of the bottle body to be filled; a rolling wheel is arranged at the lower end of the bottle mouth rod, so that the lower end of the bottle mouth rod can enter or go out of the bottle mouth more conveniently; and the bottle turning mechanism improves the adaptability to different bottle bodies, eliminates the phenomenon of bottle sticking and ensures that bottle bodies to be filled are regularly arranged and conveyed in a single direction.

Owner:常州市金坛晨光轻工机械有限公司

Method and device for producing pretensioned anchorings

InactiveUS7320371B2Simple and reliable processEnsure fillingReciprocating drilling machinesCaissonsEngineeringMechanical engineering

A method and device for boring, particularly percussion boring or rotary percussion boring, a hole in soil or rock material and for forming an anchoring. A borehole is formed by inserting a drill bit, and a casing tube is placed inside the borehole during the boring process. Once the borehole is completed, the boring rods are detached from the drill bit and removed from the borehole. The periphery of the casing tube is provided with a number of passage openings for discharging hardenable material. A tensioning device for the anchor, particularly an anchor plate and a screw that can be screwed onto the casing tube, can be fixed to the end of the casing tube protruding from the borehole. Anchoring or fixing elements for anchoring the casing tube on the surrounding inner wall of the borehole are provided, in particular, on the end area of the casing tube oriented toward the drill bit.

Owner:ALWAG TUNNELAUSBAU GMBH

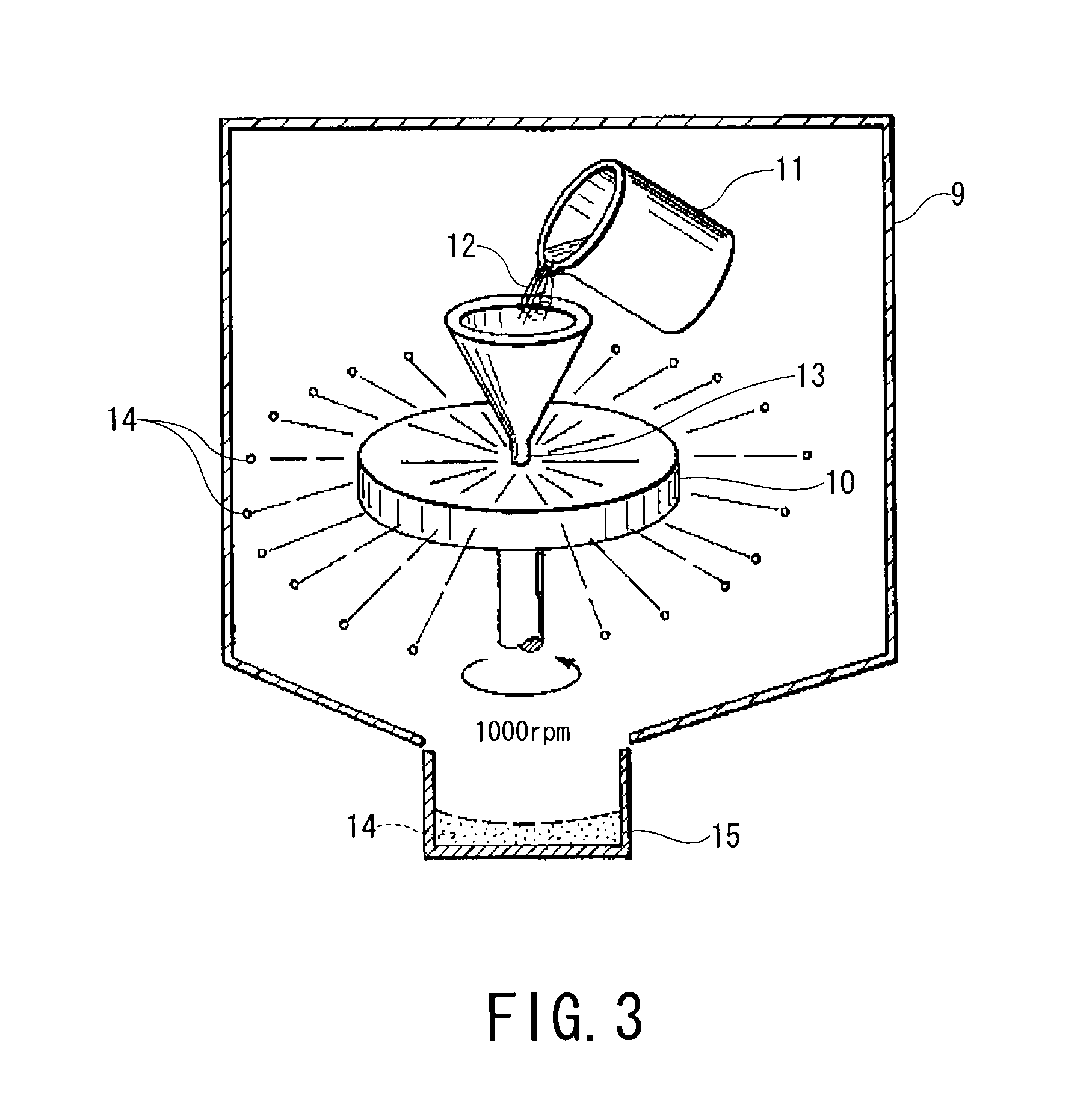

Method for producing dielectric ceramic powder and method for producing composite dielectric material

InactiveCN1690015AGuaranteed liquidityGood formabilityAlkaline earth titanatesOxide/hydroxide preparationMetallurgyMaterials science

A method for producing a dielectric ceramic powder which can secure fluidity of the mixture thereof with a resin, even when produced by milling, is provided. A composite dielectric material which secures, the fluidity of the mixture thereof with a resin and is excellent in dielectric properties can be obtained on the basis of the method for producing a dielectric ceramic powder, comprising a first firing step for firing a starting material at a first temperature to obtain a first fired substance; a first milling step for milling the first fired substance to obtain a first milled substance; a second firing step for firing the first milled substance at a second temperature lower than the first temperature to obtain a second fired substance; and a second milling step for milling the second fired substance to obtain a second milled substance.

Owner:TDK CORPARATION

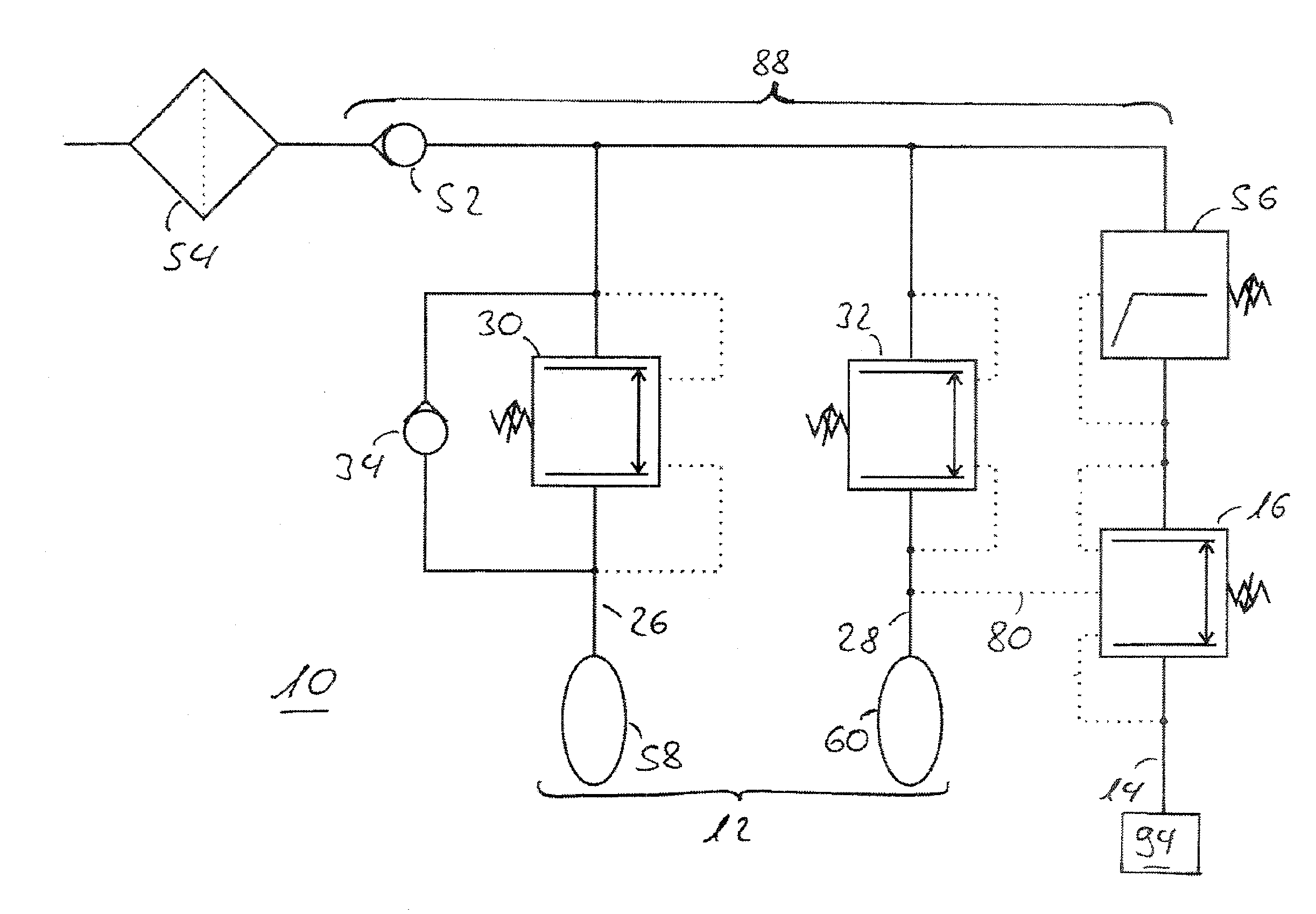

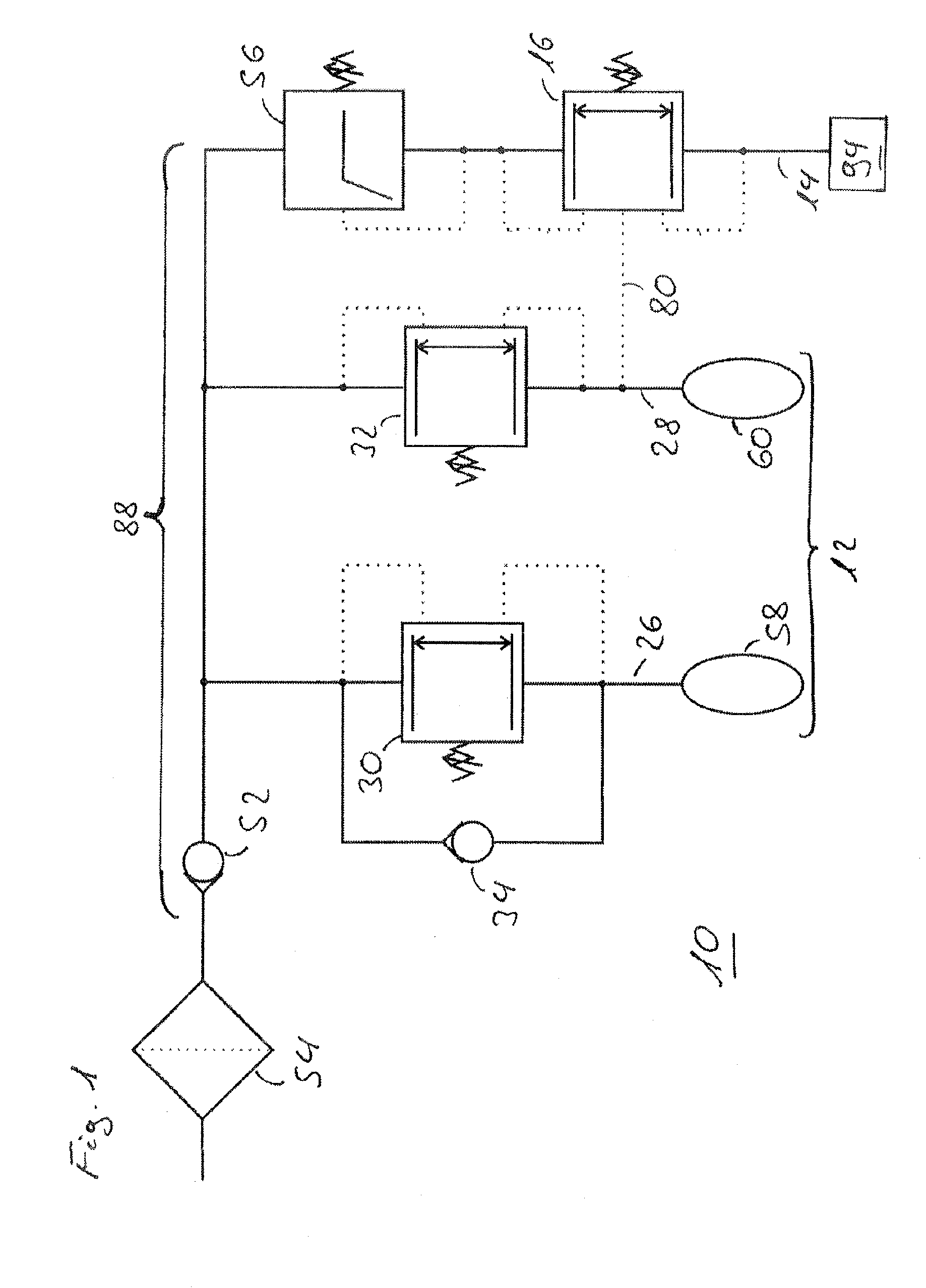

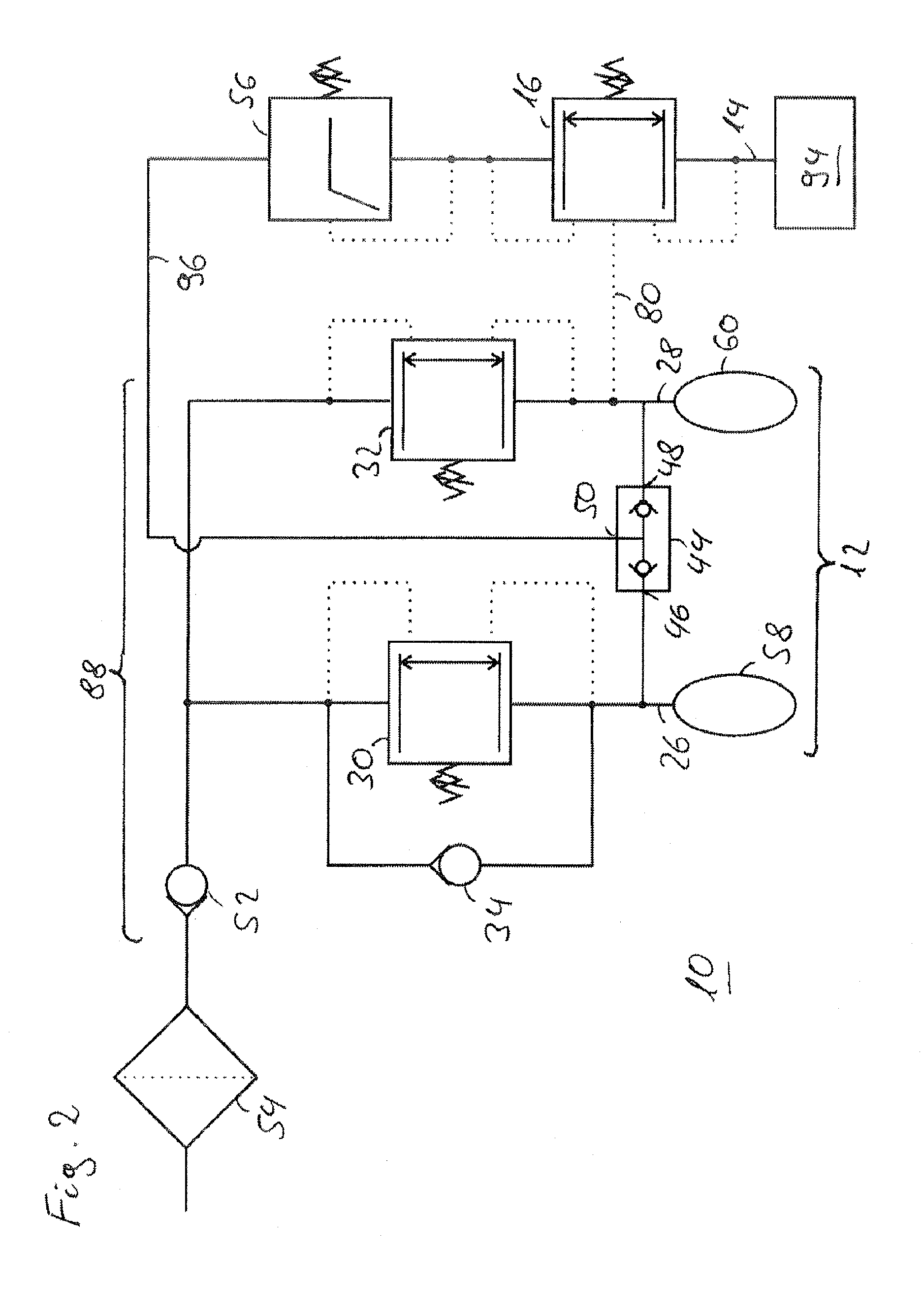

Multi-Circuit Protection Valve for a Compressed-Air Supply Device of a Vehicle, and Method for Operating a Multi-Circuit Protection Valve

InactiveUS20140054956A1Ensure fillingFluid braking transmissionPiping arrangementsBrake pressureCircuit protection

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

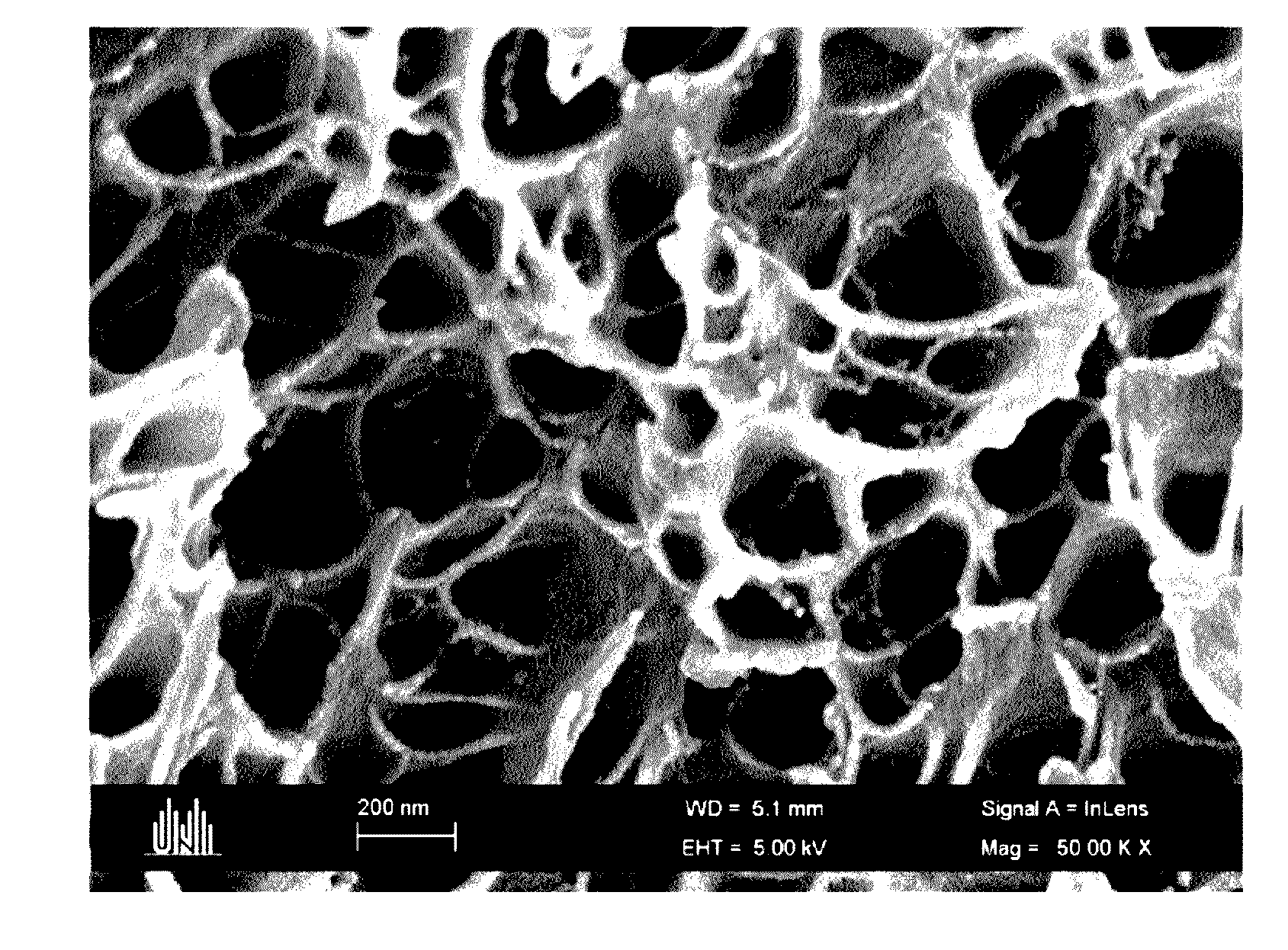

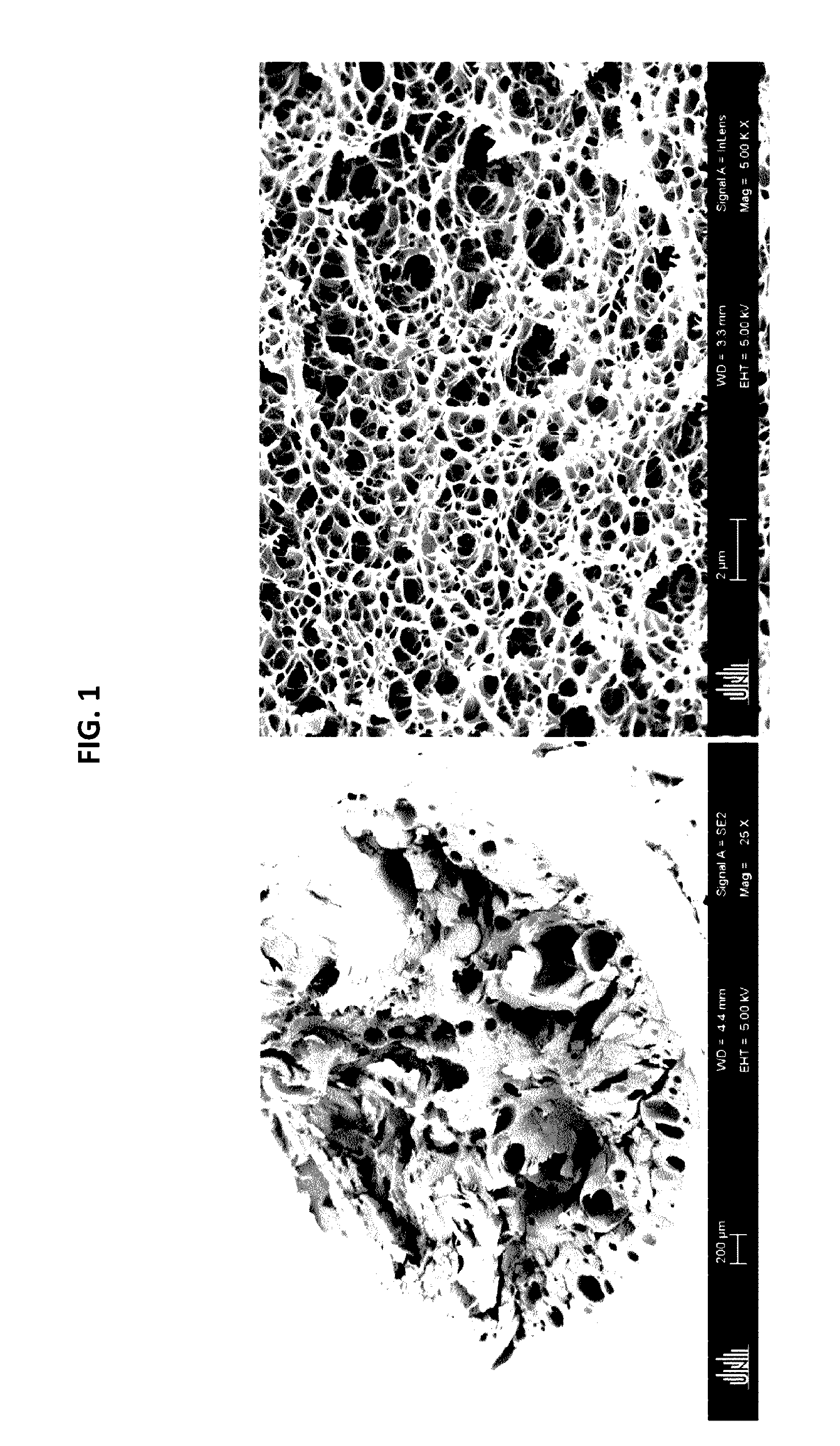

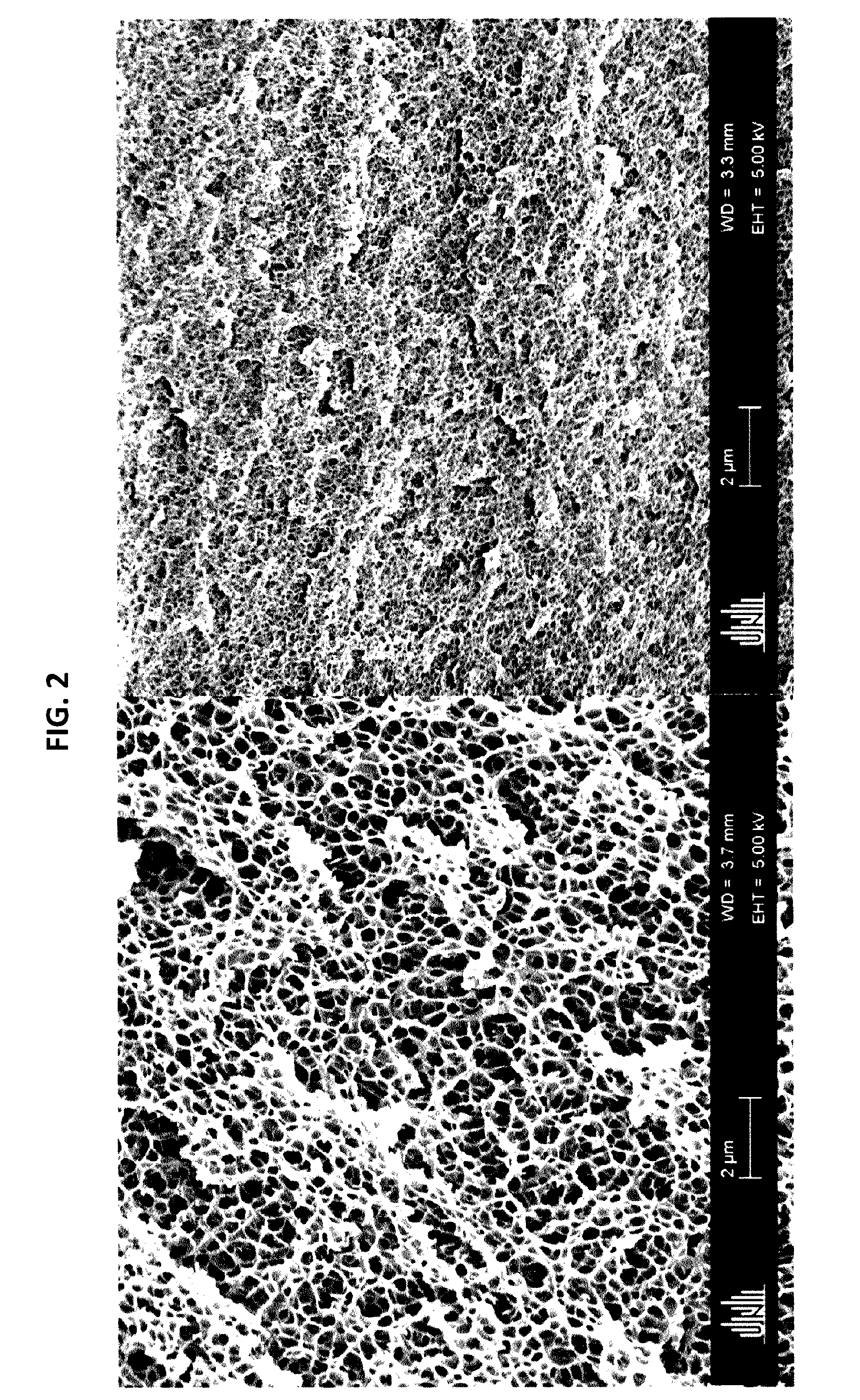

Production of porous materials by the expansion of polymer gels

The invention relates to a method for the production of porous materials by the expansion of polymer gels and to the porous materials produced by such a method and to a moulded body.

Owner:SUMTEQ GMBH

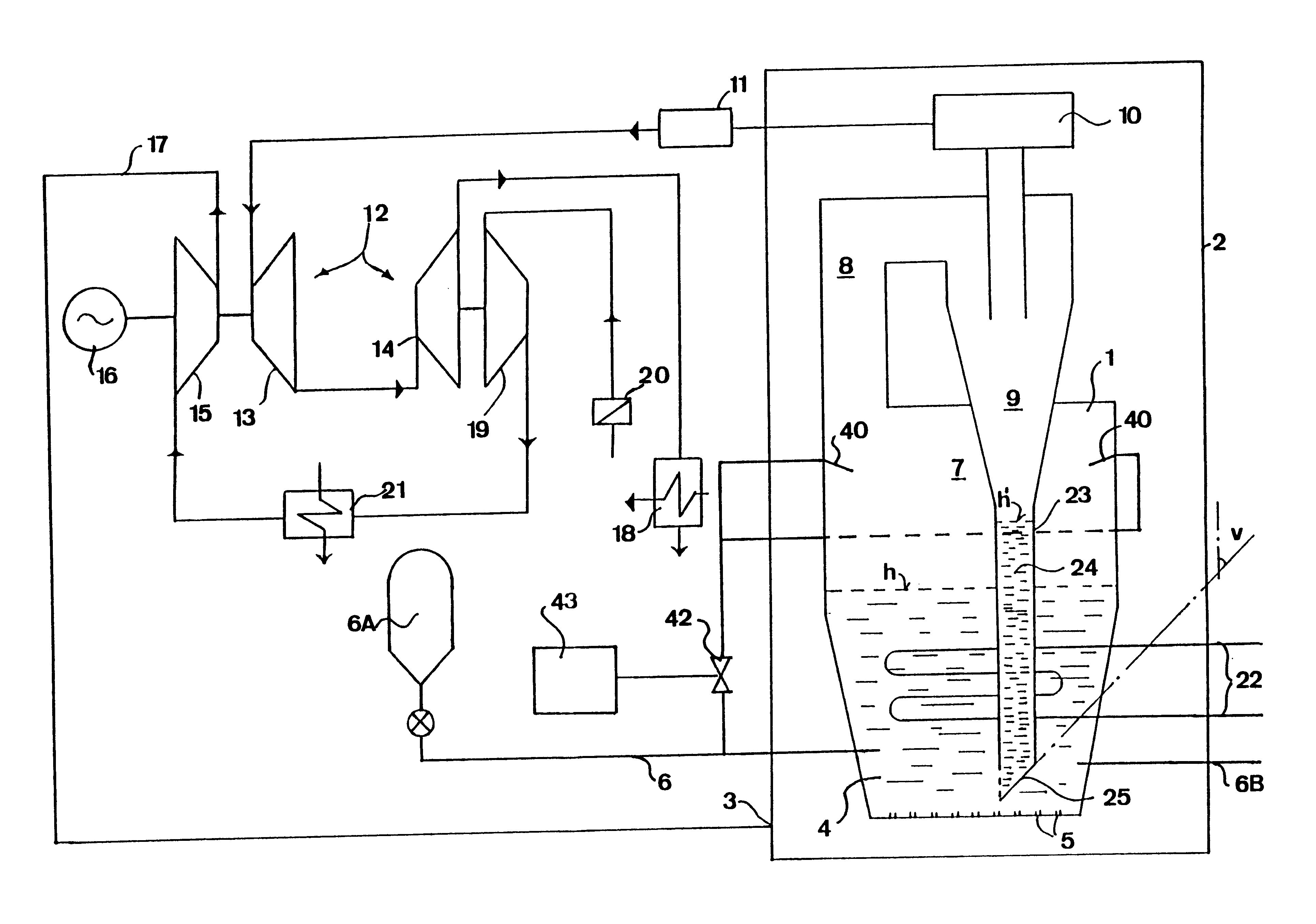

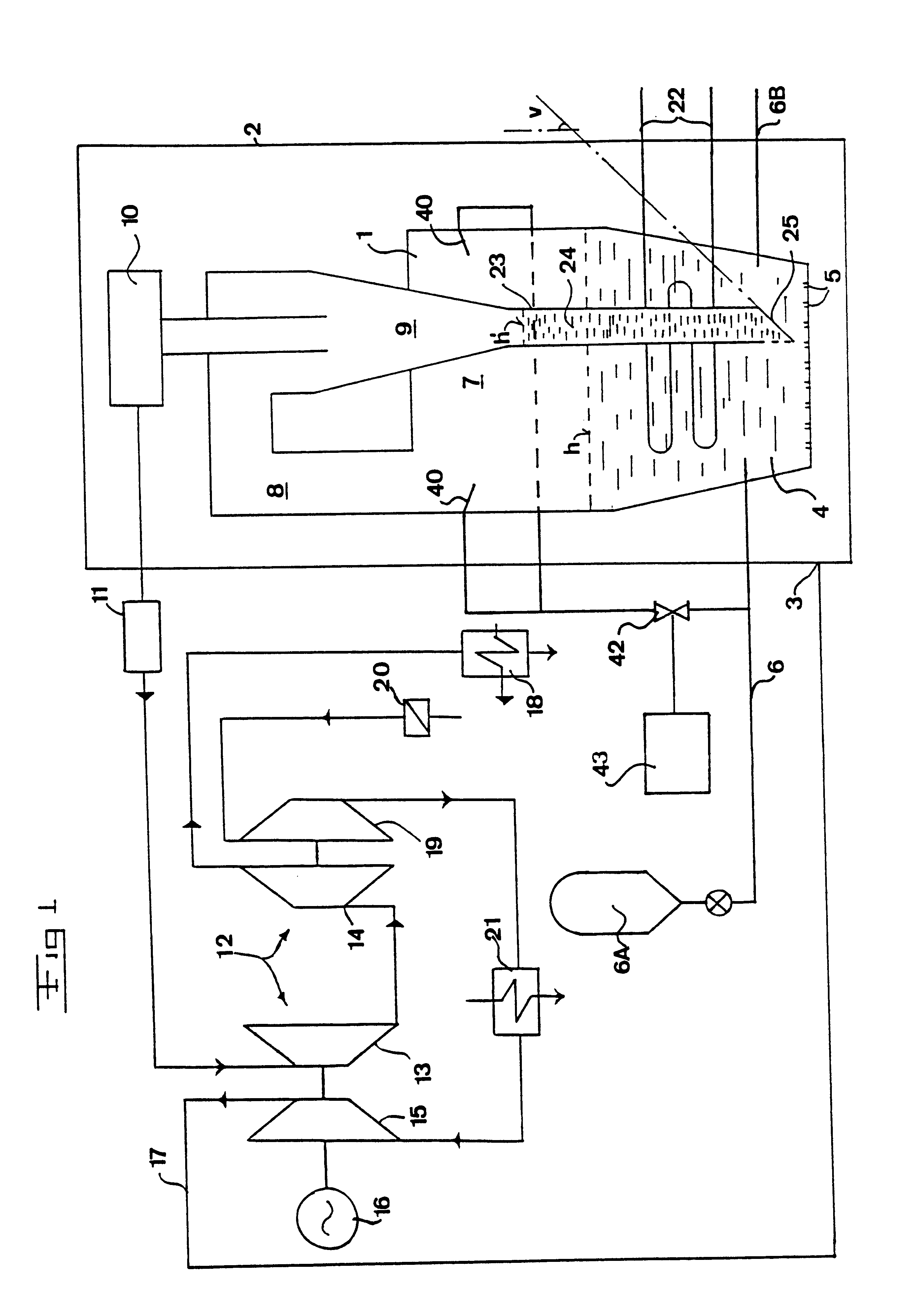

Method and apparatus for burning fuel in the free board of a pressurized fluidized bed with solids recirculation

InactiveUS6260492B1Increase temperatureImprove efficiencyFluidized bed combustionSolid fuel combustionProduct gasEngineering

A method of combustion in a pressurized, fluidized bed and in the freeboard thereof. The combustion method is further characterized by the recirculation of solid sulfur absorbing materials. A gas channel, designed so as to prevent fluidizing gas from entering the channel from below, is provided such that it opens to the freeboard and to a separating member which separates particulate matter from the combustion gasses.

Owner:GENERAL ELECTRIC TECH GMBH

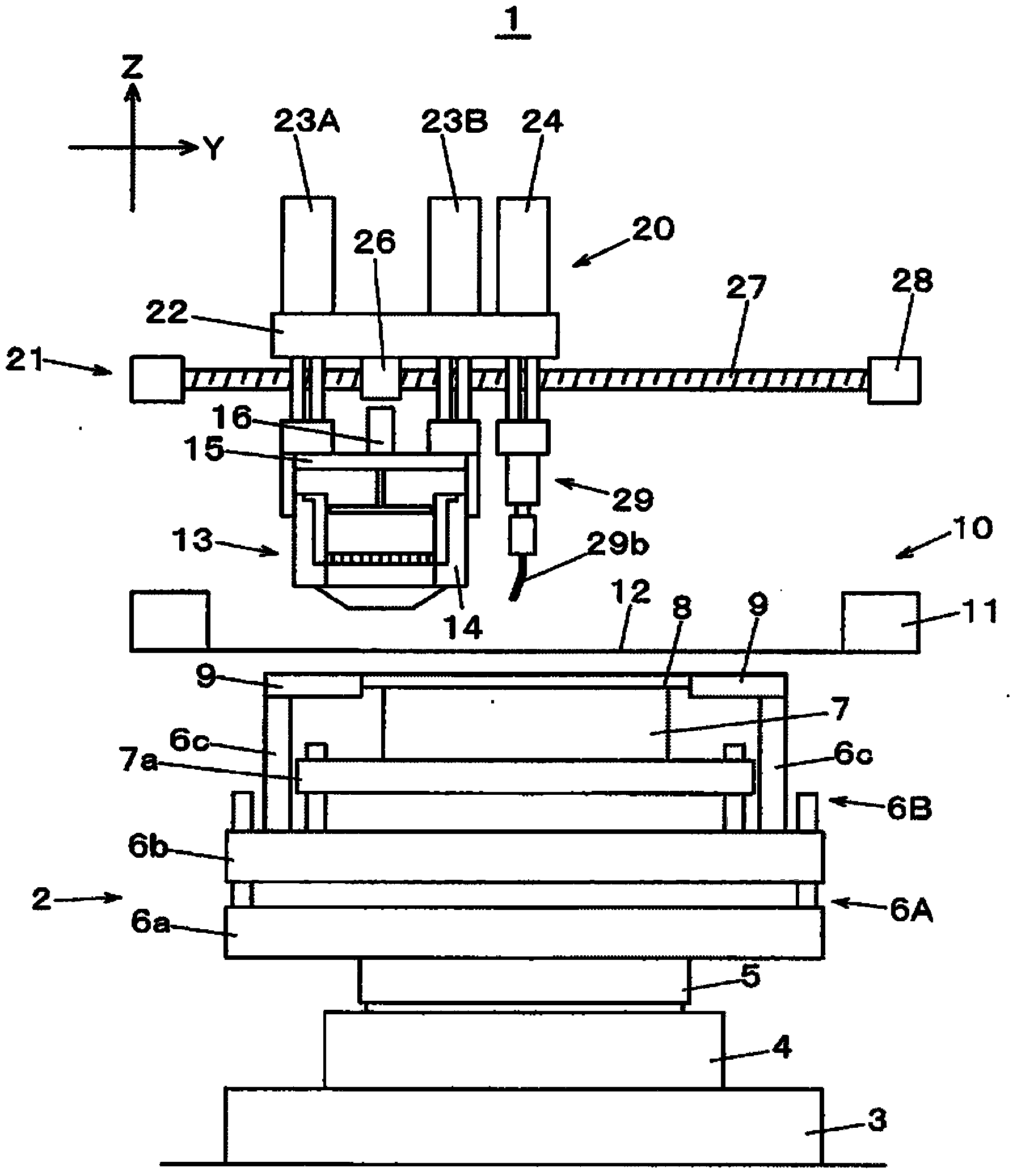

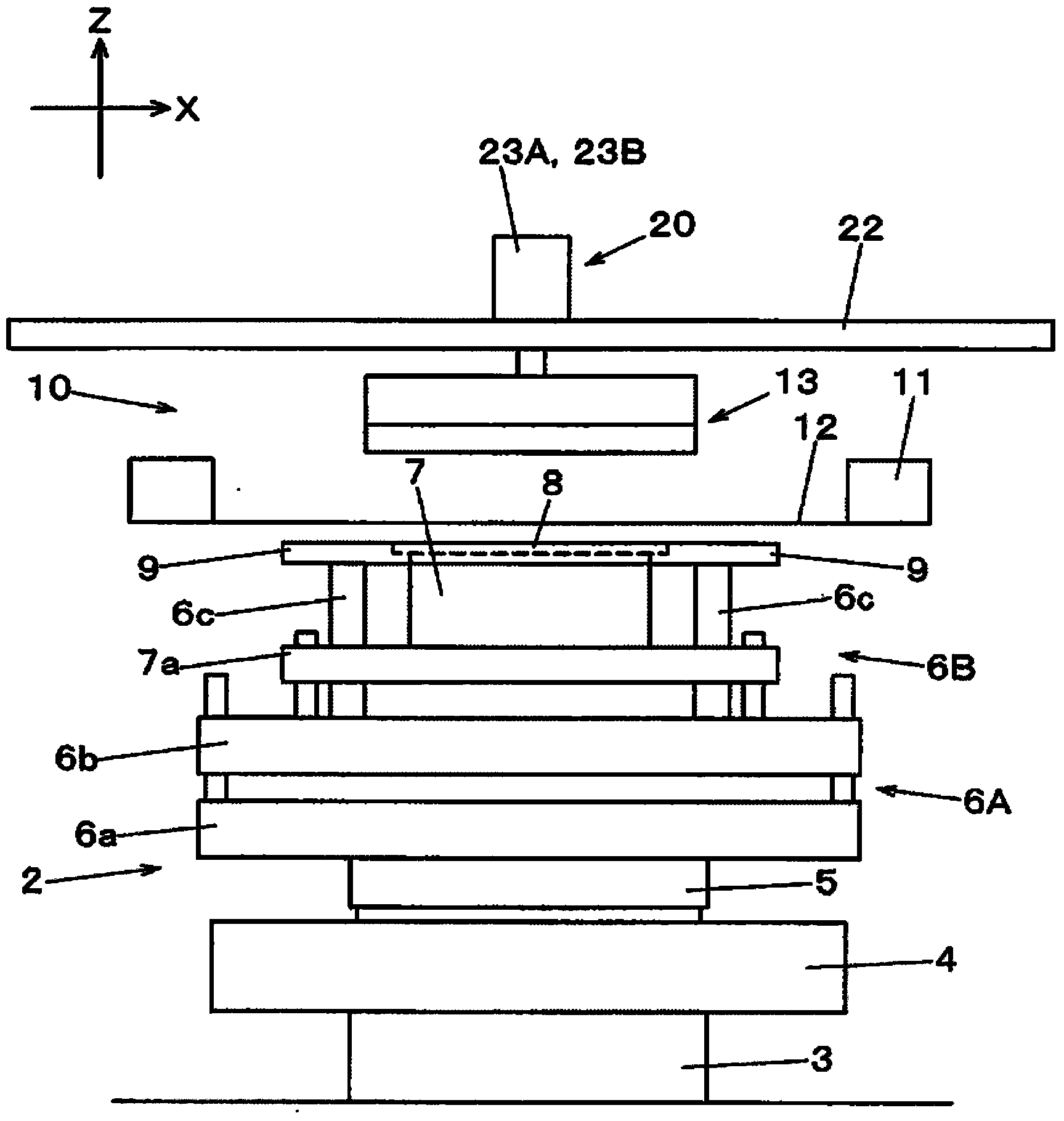

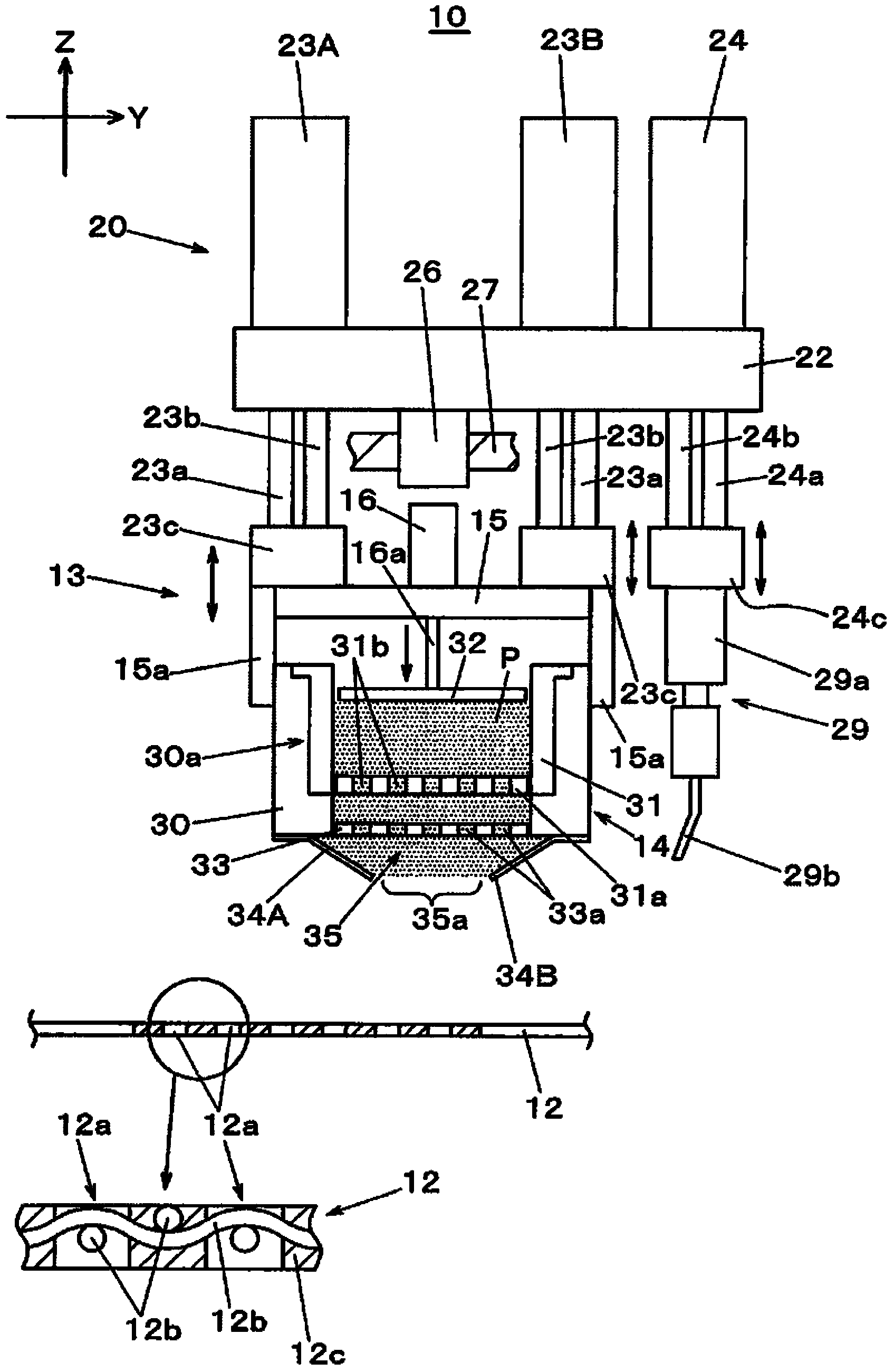

Screen printing device and screen printing method

ActiveCN103402769AEnsure fillingGood fillingPrinted circuit assemblingScreen printersMechanical engineeringScreen printing

In the present invention, in a screening operation by a closed squeegee mechanism (13) having therewithin the configuration of a compressed paste (P) filling from a printing aperture (35a) between a pair of sliding members (34A, 34B): before the filling of the paste into pattern holes (12a) via the printing aperture (35a), the sliding member (34B) positioned on the front side in the direction of squeegeeing of the pair of sliding members (34A, 34B) is moved in the squeegeeing direction, by which means the paste (P) supplied to the outside of the closed squeegee mechanism (13) at the upper surface of a mesh mask (12) fills the inside of the pattern holes (12a).

Owner:PANASONIC CORP

Contents-filling vessel reversing apparatus and a vessel for use with the apparatus

InactiveUS20060010834A1Improve working environmentAvoid breakingSolid materialLiquid materialEngineeringPackaging machine

A contents-filling apparatus for use in a bag packaging machine. The apparatus comprises a reversing device including a rotating device for rotating intermittently a main rotating member around an axis thereof in one direction and for stopping the rotating member at a first and a second positions, and a pair of gripping members attached to the rotating device and being capable of gripping and releasing said vessel. The gripping members are designed to stop at a gripping stop position where said gripping members can grip a vessel in an upright state when said main rotating member stops at the first stop position, and stop at a reversal stop position where said vessel is held in a nearly inverted state when said main rotating member stops at the second positions. The apparatus further comprises a reversal stop position regulating device for regulating said reversal stop position, an empty vessel carrying-out device provided at an empty vessel discharging position on the way along which said gripping members returns from said reversal stop position to said gripping stop position, said empty vessel carrying-out device receiving an empty vessel and transferring it to downstream process; and a gripping member opening / closing apparatus for making said gripping members close to grip a vessel and for making said gripping members opens, thereby discharging the empty vessel towards an empty vessel carrying-out device.

Owner:TOYO JIDOKI CO LTD

Multi-stroke delivery pumping mechanism for a drug delivery device for high pressure injections

ActiveUS9238112B2Facilitates injecting insulin and other medicamentIncrease heightAmpoule syringesAutomatic syringesInjection siteRisk stroke

A dual-chambered drug delivery device (201) includes a cartridge (211) having a first chamber (212) for storing a medicament and a second chamber (211) in fluid communication with the first chamber (212). A dose setting member (241) is used to set a medicament dose to be injected at an injection site. A piston (281) is disposed in the second chamber (221). An upward stroke of the piston (281) draw a portion of the medicament dose into the second chamber (221) and a downward stroke of the piston (281) expels the portion of the medicament dose. A needle (205) communicates with the second chamber (221) for sequentially injecting the portions of the medicament dose into the injection site.

Owner:BECTON DICKINSON & CO

Pressure control valve including a compensating chamber

ActiveUS9746071B2Simple and cost-effectiveGuaranteed ventilation effectOperating means/releasing devices for valvesGearing controlAutomatic transmissionEngineering

A pressure control valve, in particular for an automatic transmission in a motor vehicle, including a housing and including a control piston situated in the housing, the control piston being actuatable by an armature situated in a magnet chamber of a pole tube, the magnet chamber being hydraulically connected to a compensating chamber provided in the housing, which is delimited, in particular by a lateral surface of a solenoid coil and the housing.

Owner:ROBERT BOSCH GMBH

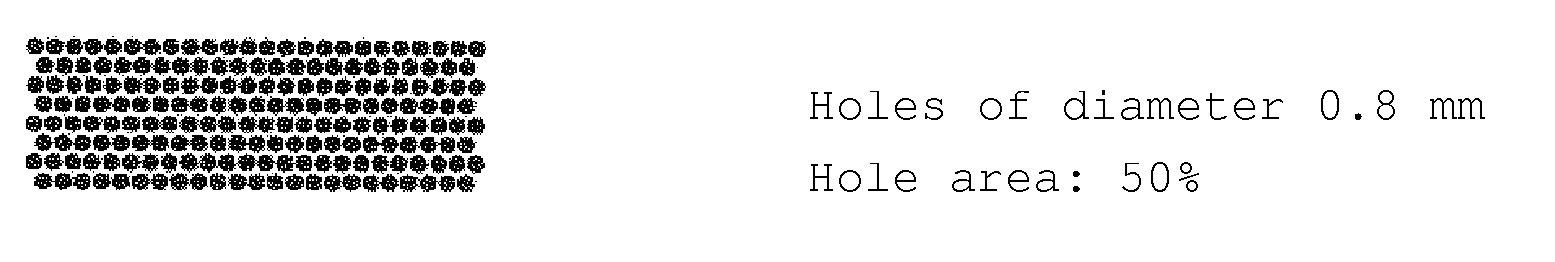

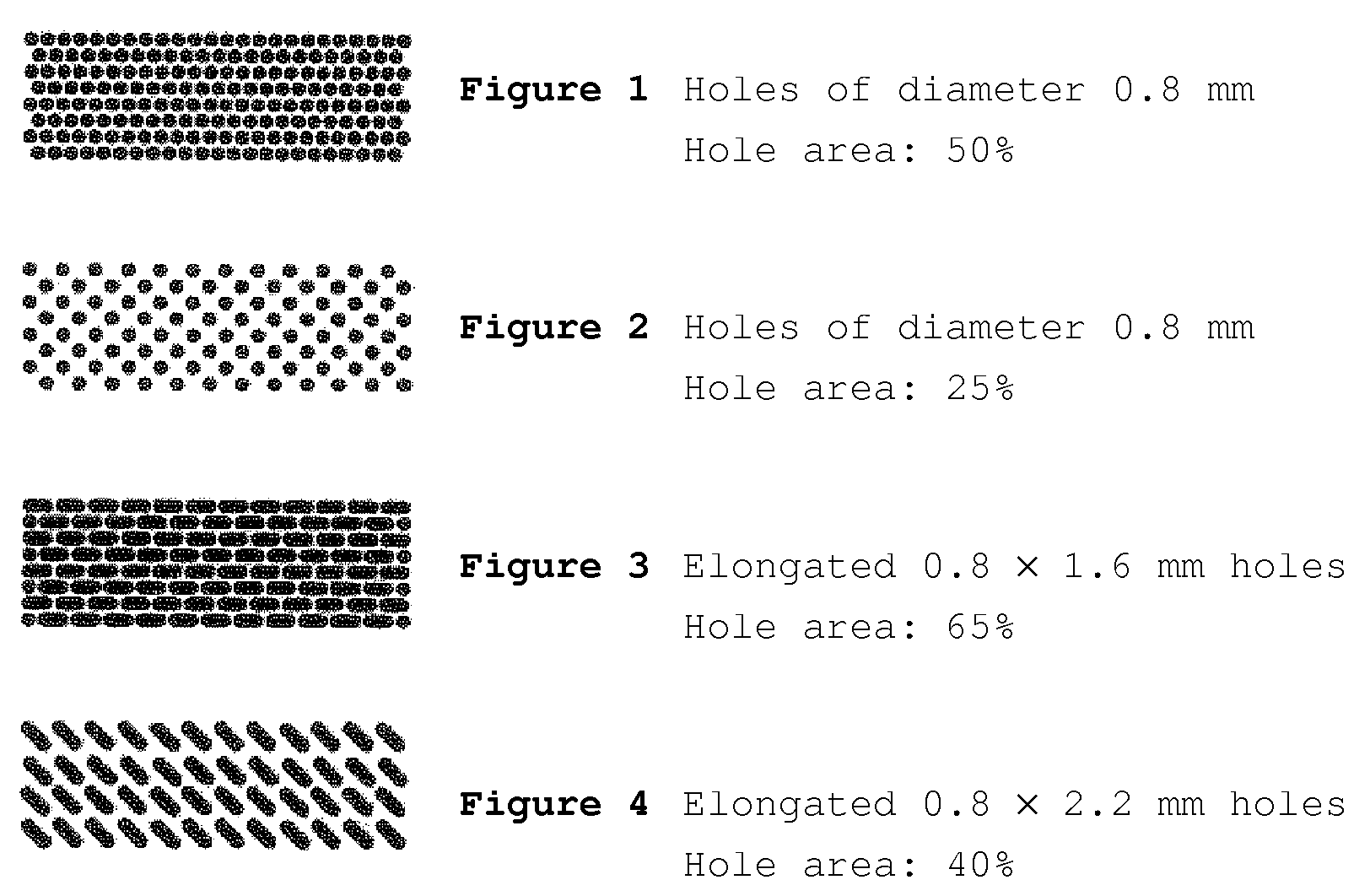

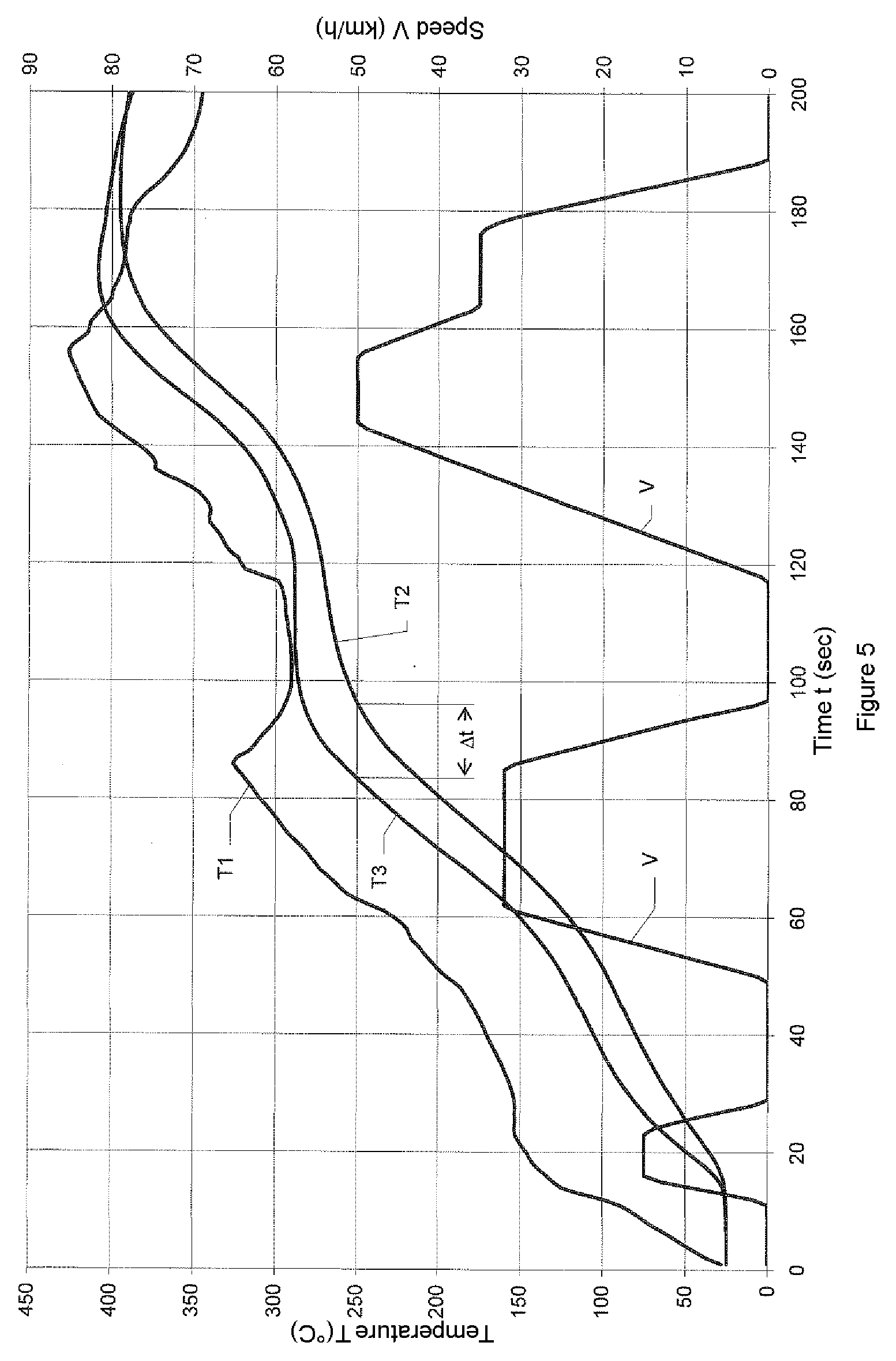

Catalytic converter with improved start-up behaviour

InactiveUS7767622B2Avoid disadvantagesLoss can be compensatedCombination devicesNitrogen compoundsOperating temperatureThermal conductivity

In automotive exhaust gas catalysts with a metallic honeycomb composed of corrugated and smooth sheet layers, it is known that the heat capacity and thermal conductivity of the honeycomb can be reduced by perforations in the sheet layers. As a result, the honeycomb heats up more rapidly and the catalytic coating applied on the honeycomb reaches its operating temperature more rapidly. A disadvantage here is the reduction in the support surface area by the perforations in the sheet layers. According to the invention, suitable adjustment of the properties of the coating suspension used for the catalytic coating and of the dimensions of the holes relative to one another allows the holes to be filled permanently with catalyst material. The resulting catalyst has, at the same coating concentration as a catalyst with unperforated sheet layers, a significantly reduced heat capacity and thermal conductivity.

Owner:UMICORE AG & CO KG

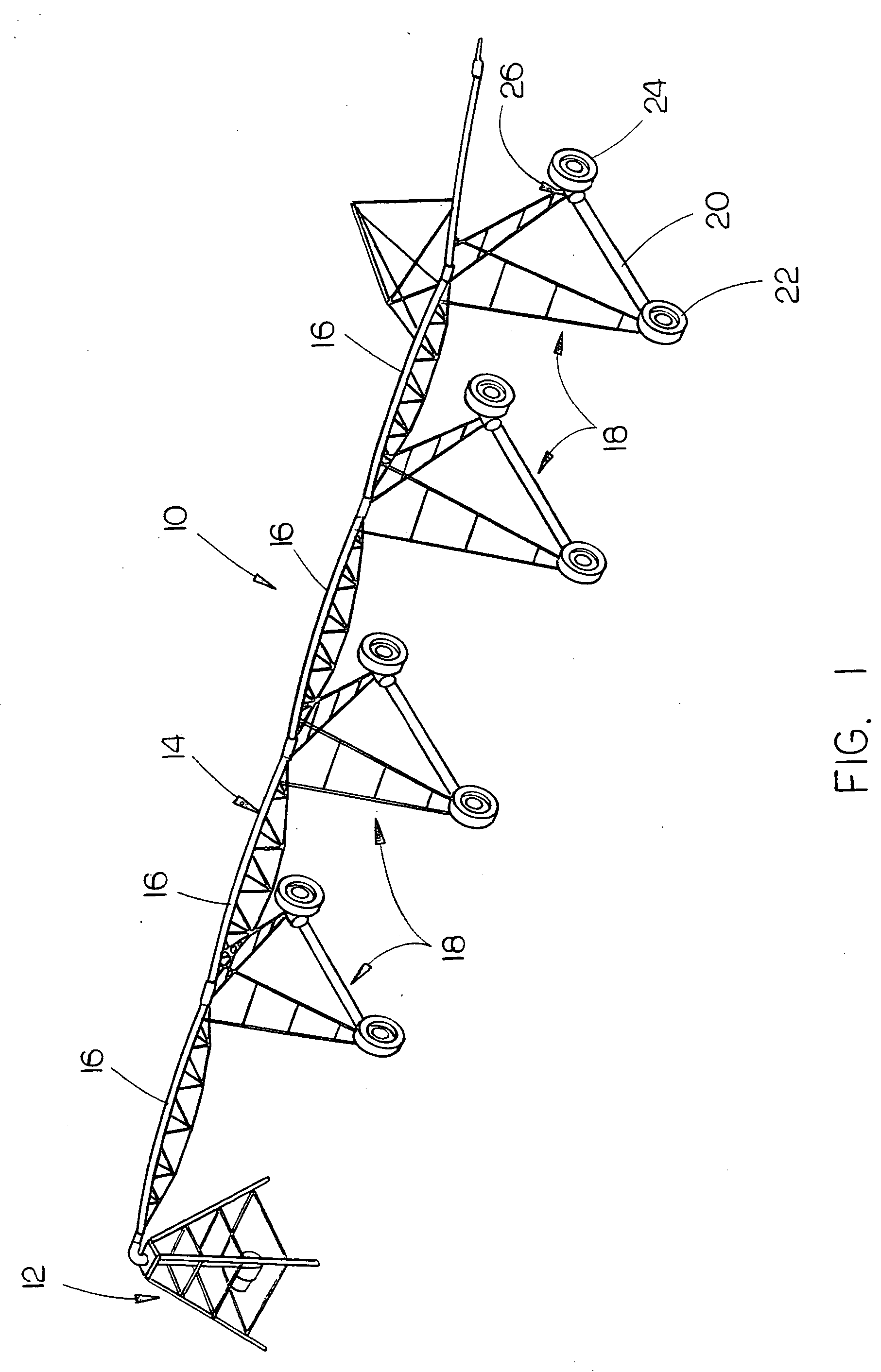

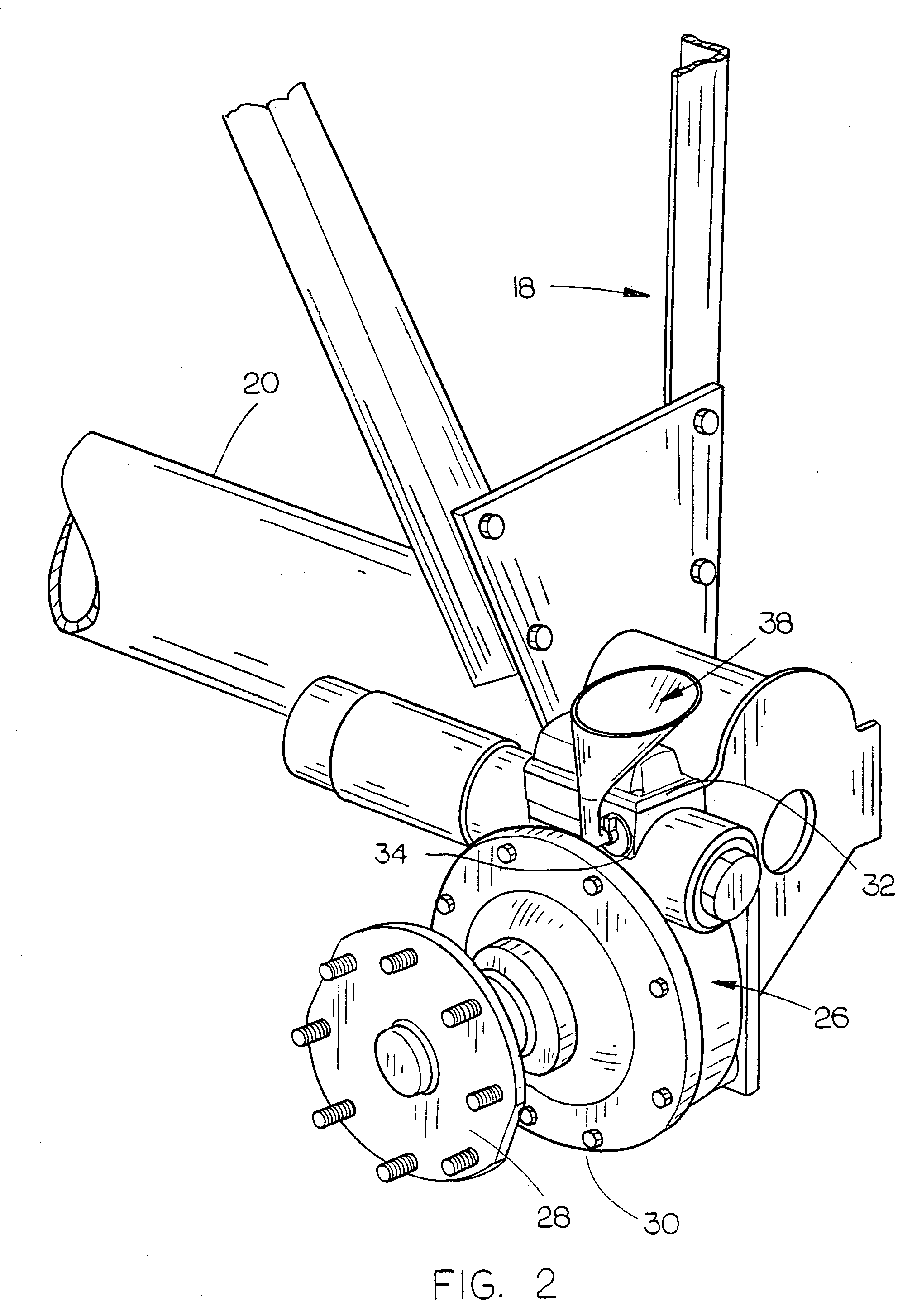

Tool for filling a gearbox with lubricant

A tool is provided for filling a gearbox with lubricant. The tool includes structure which prevents the gearbox from being over filled with lubricant. The tool of this invention enables access to the fill opening of the gearbox and prevents spillage or leakage. The tool is ideally suited for use with a gearbox mounted on the drive unit of a mechanized irrigation system.

Owner:VALMONT INDUSTIES INC

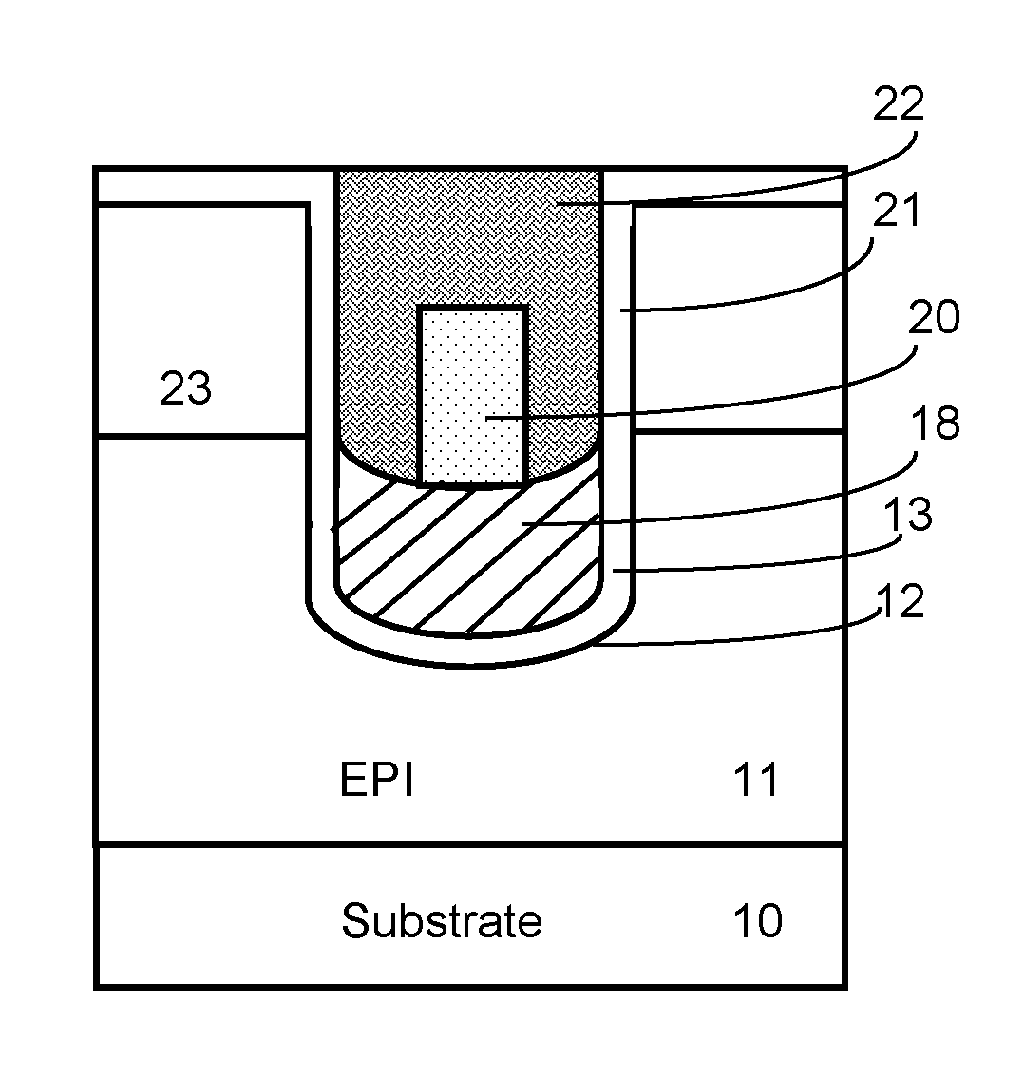

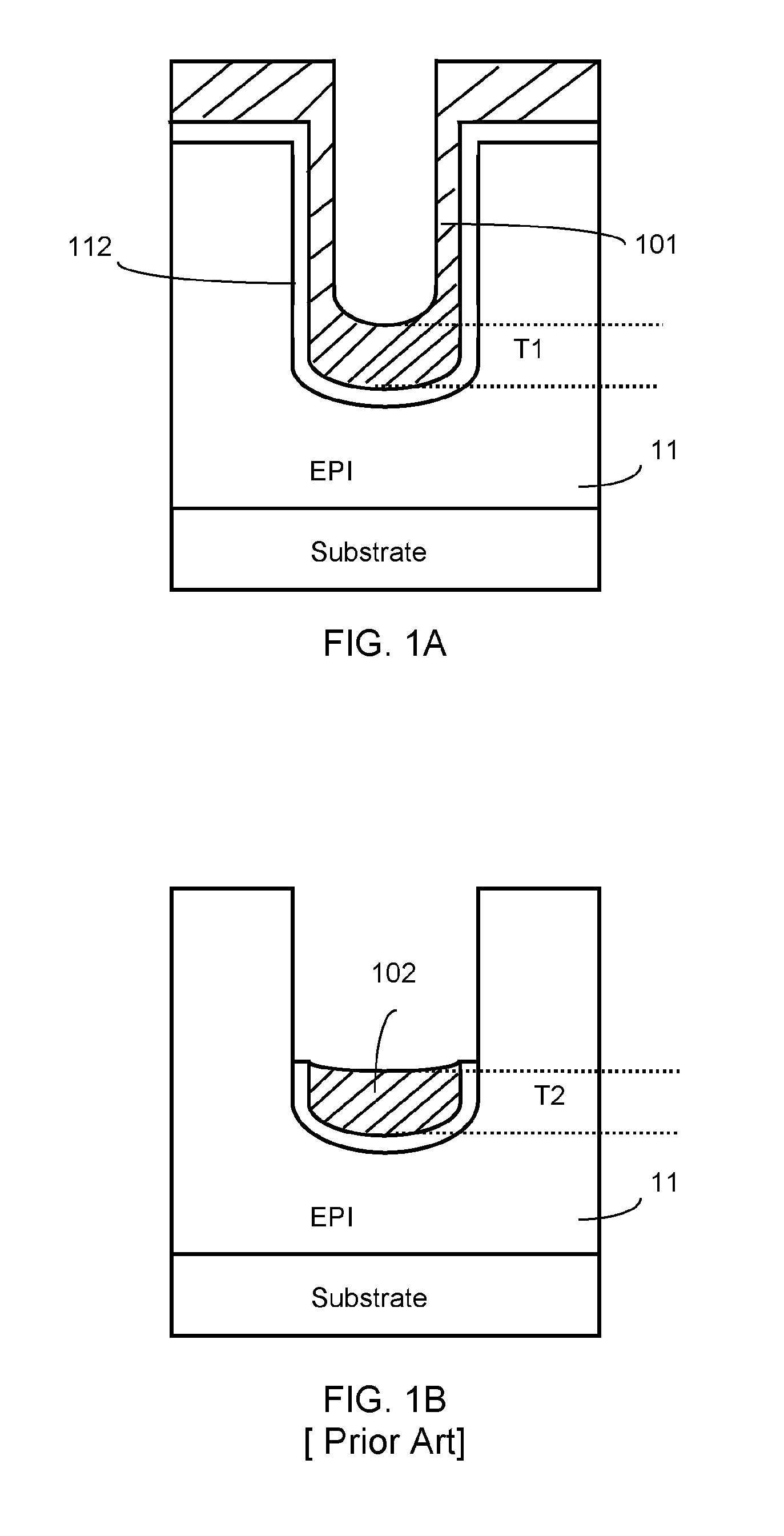

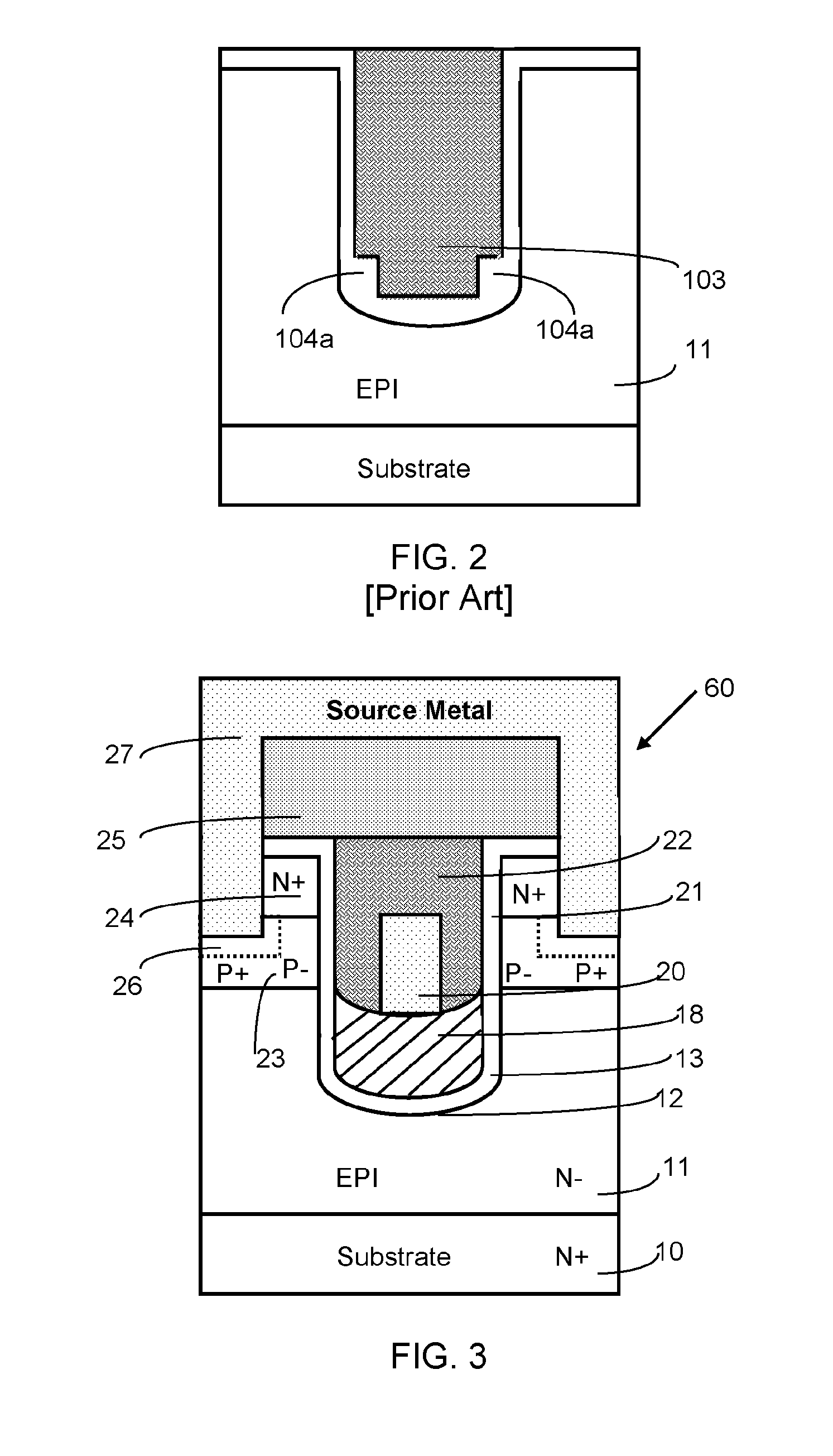

Semiconductor device

ActiveUS20140231905A1Increase cell densityReduce power consumptionSemiconductor/solid-state device manufacturingSemiconductor devicesBody regionPhysics

A trench MOSFET including: an epitaxial layer; a body region on the epitaxial layer, the body region and the epitaxial layer forming a first interface; a trench; a trench bottom oxide in the trench; and polysilicon in the trench, the trench bottom oxide and the polysilicon forming a second interface; where the first and second interfaces are substantially aligned or are at substantially the same level.

Owner:X FAB SEMICON FOUNDRIES

Unit for feeding products to a blistering machine

InactiveUS20060185754A1Improve integrityEnsure fillingLiquid fillingSolid materialEngineeringMachine

A unit for feeding products (3) to a blistering machine (M) includes a delivery group (2, 2a, S) for selectively distributing products (3) to a station (SR), where the products (3) are introduced into respective blisters (40) of a blister band (4), moving in a forward direction (W) inside the blistering machine (M). The filling station (SR) is defined by a conveyor (10) consisting of a belt (11) provided with seas (110). Each seat (110) receives a relative product (3) distributed by the delivery group (2, 2a, S) and releases the products (3) into a respective blister (4). The conveyor (10) include at least one endless belt (11), moving in step relation with the blister band (4) wound around respective pulling wheels (13, 14), with an upper portion of the belt (11) defined by an upper run (11a) extending under the delivery group (2, 2a, S) in a direction parallel to the forward direction (W), defined by a lower run (11b) extending, along at least a section (O) parallel to the forward direction (W), substantially very close to and above the blister band (4) and facing the blister band (4).

Owner:IMA IND MASCH AUTOMATICHE SPA

Inflation sealing mechanism of inflator

PendingCN110822281AEnsure fillingReasonable structural designVessel geometry/arrangement/sizeFluid handledEngineeringBottle

The invention discloses an inflation sealing mechanism of an inflator. The inflation sealing mechanism is mounted on a work frame. The inflation sealing mechanism comprises a sealing block connected with a pipeline for providing gas and an upper sealing mechanism used for sealing a packaging bottle. The inner portion of the sealing block is provided with a gas inlet channel for gas inlet, a lowerchannel allowing a mouth of the packaging bottle to extend therein, an upper channel allowing the upper sealing mechanism to extend into the sealing block to seal the mouth of the packaging bottle andan inflation chamber. The gas inlet channel, the upper channel and the lower channel are communicated through the inflation chamber. Sealing assemblies are arranged in the upper channel and the lowerchannel. The upper sealing mechanism comprises an upper sealing mold vertically mounted and a second cylinder for driving the upper sealing mold to carry out sealing. By the adoption of the inflationsealing mechanism of the inflator, gas filling and mouth sealing of the packaging bottle can be carried out in the sealing mechanism, the structural design is reasonable, the corresponding sealing assemblies are arranged at through ports, the sealing effect can be improved, and normal filling of the gas is guaranteed.

Owner:FOSHAN HUATE GASES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com