Method for producing dielectric ceramic powder and method for producing composite dielectric material

A dielectric material and ceramic powder technology, applied in the field of dielectric ceramic powder, can solve the problems that the mixture is difficult to flow into the circuit pattern and cannot form the circuit pattern, etc., and achieve the effect of excellent fluidity, excellent formability and high dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Examples of the present invention will be described below.

[0080] Weigh SrCO 3 Powder, CaCO 3 Powder and TiO 2 The powders were made so that they became the main components shown in Fig. 3 after firing, mixed only for 16 hours with a wet ball mill, and pulverized. Next, the mixed raw material powders were calcined at 1200° C. for 2 hours.

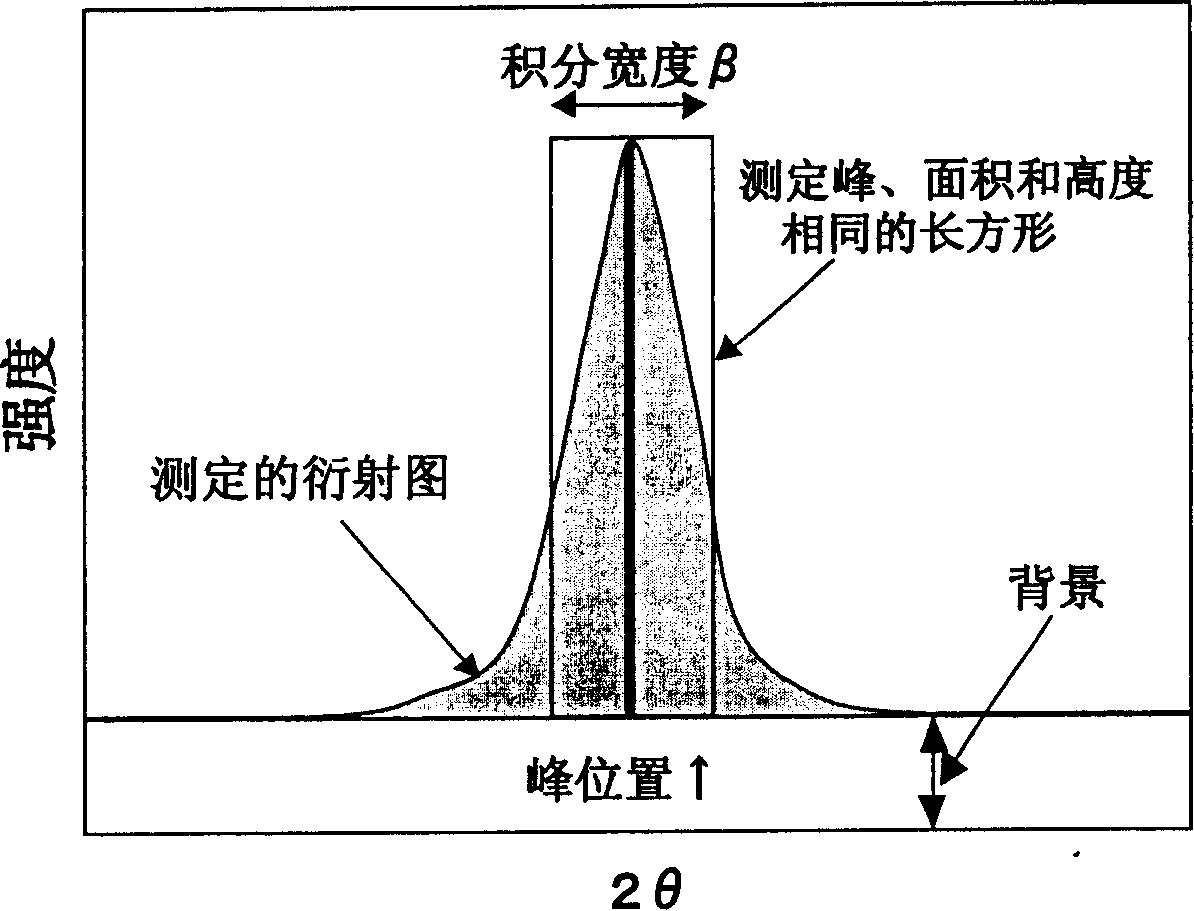

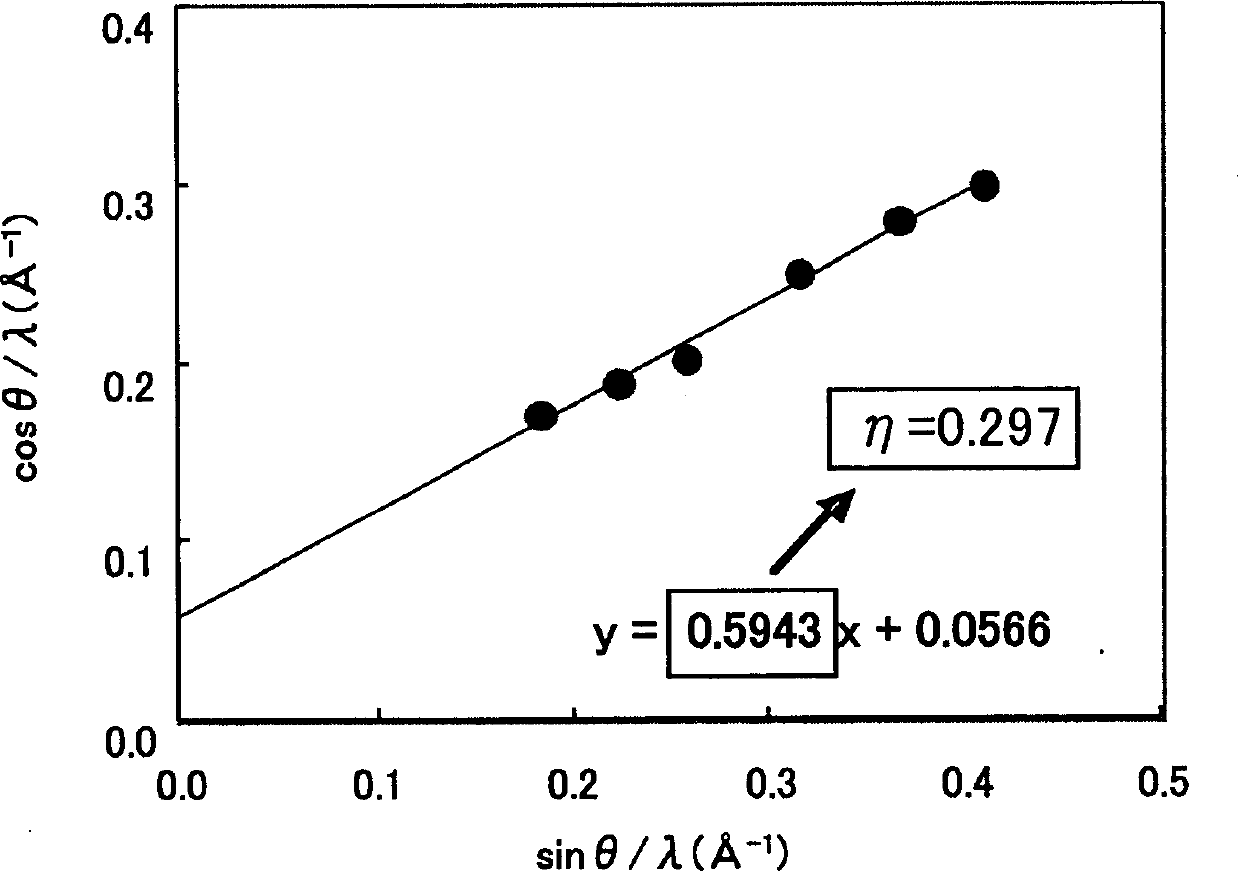

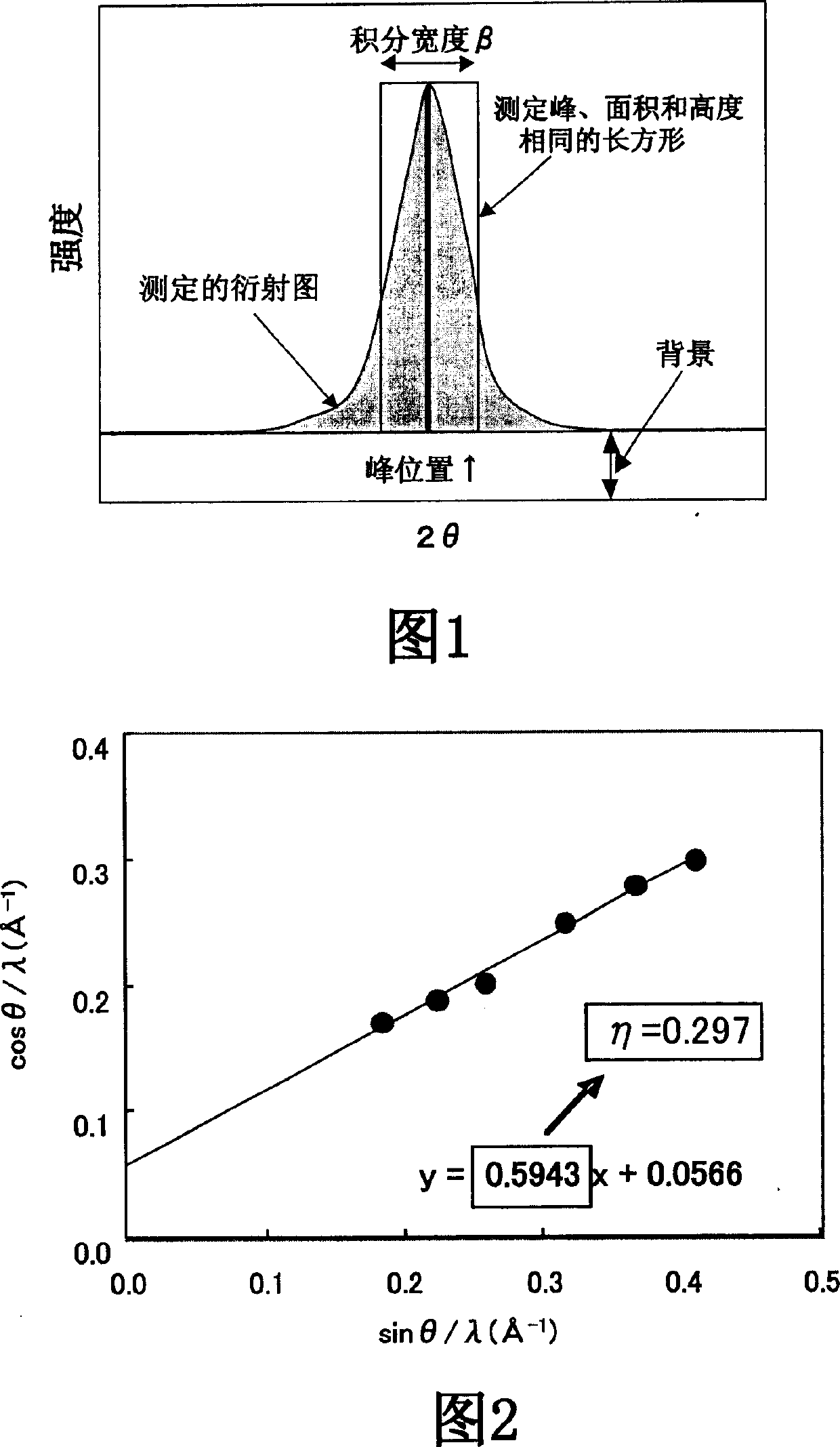

[0081] Next, the obtained calcined product (subcomponents shown in FIG. 3 were added to a part) was pulverized by a wet ball mill for only 16 hours. After the first firing of the obtained pulverized powder under the conditions shown in FIG. ) to obtain the first pulverized product.

[0082] Next, after the 1st pulverized material was subjected to the 2nd firing under the conditions shown in FIG. 2 crushing) to obtain the second crushed product.

[0083] Next, for several kinds of second pulverized products, after the third firing under the conditions shown in Fig. 3, coarse pulverization is carried out using a mortar until it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com