Inflation sealing mechanism of inflator

An inflatable seal and inflator technology, applied in the direction of mechanical equipment, container filling method, container discharge method, etc., can solve the problems of unsatisfactory sealing effect of sealing mechanism and inability to ensure that the gas is completely filled, so as to achieve reasonable structural design and ensure normal operation The effect of filling and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

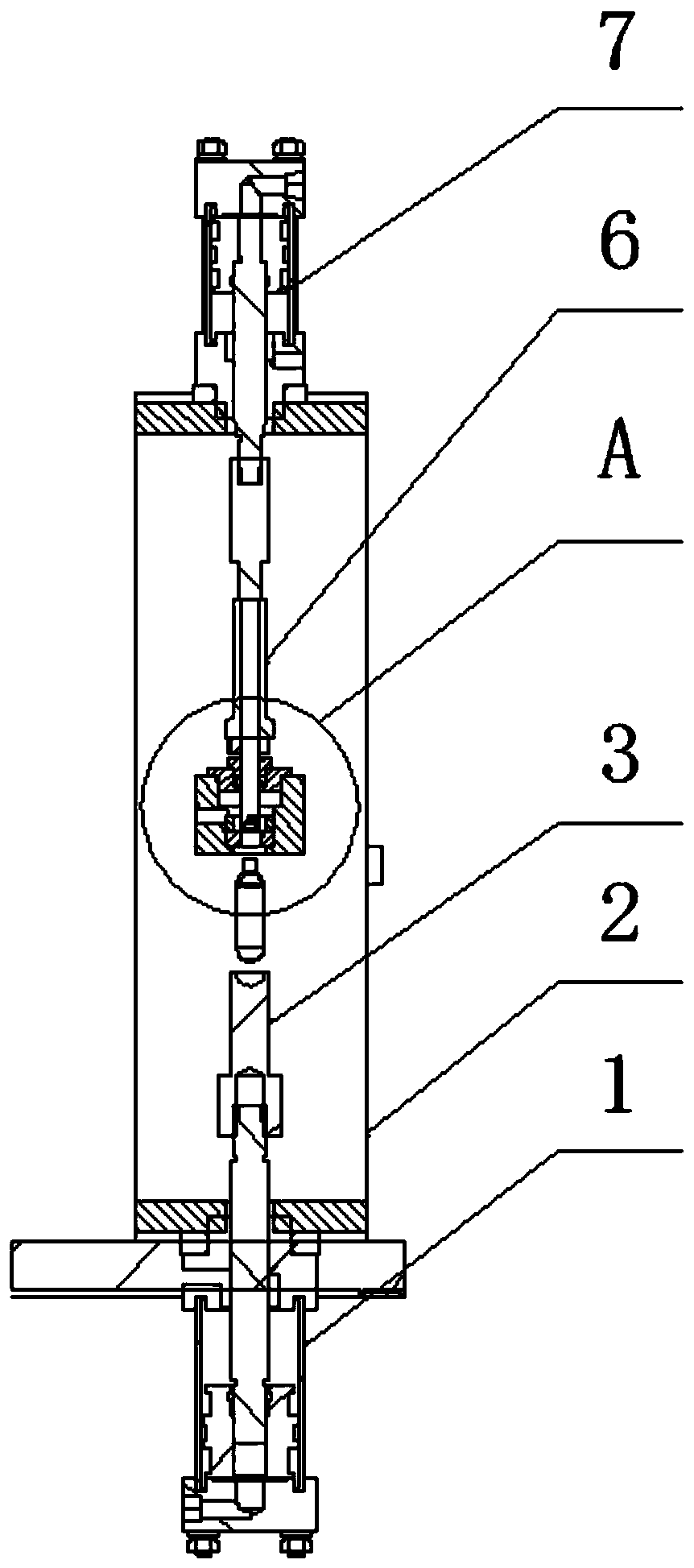

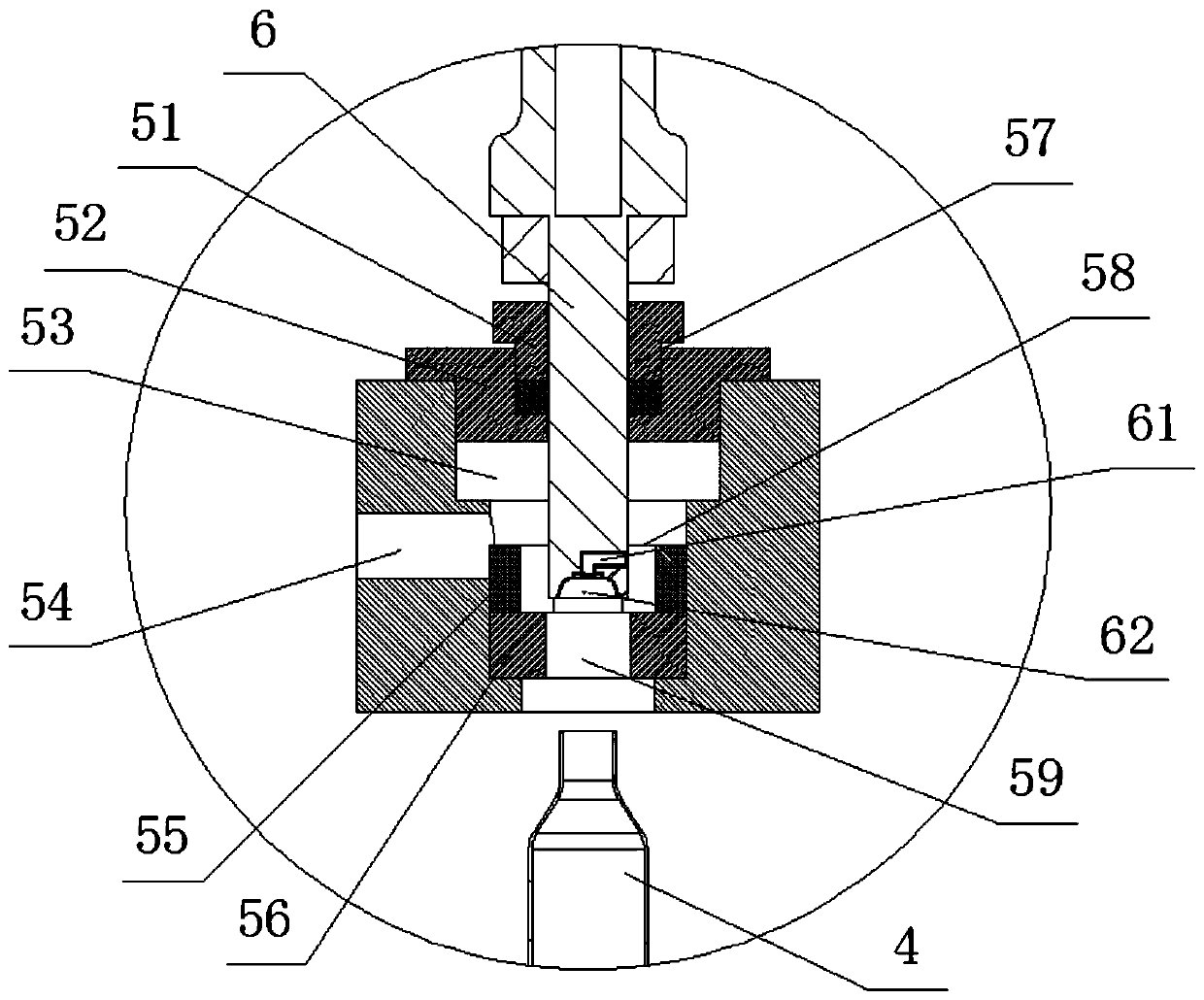

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Preferably, the present invention is used for the filling of " laughing gas ", and its packaging bottle 5 is an air bomb bottle (see Figure 5 ), the packaging bottle 5 includes a bottle body and a bottle cap, and the bottle cap is placed at the mouth of the bottle, then the gas is filled into the inside of the packaging bottle 5 by the present invention, and then the structure at the mouth of the packaging bottle is recessed to wrap the bottle cover, so as to seal the packaging bottle 5, and the structure of the packaging bottle after inflating and sealing is as follows: Figure 6 shown.

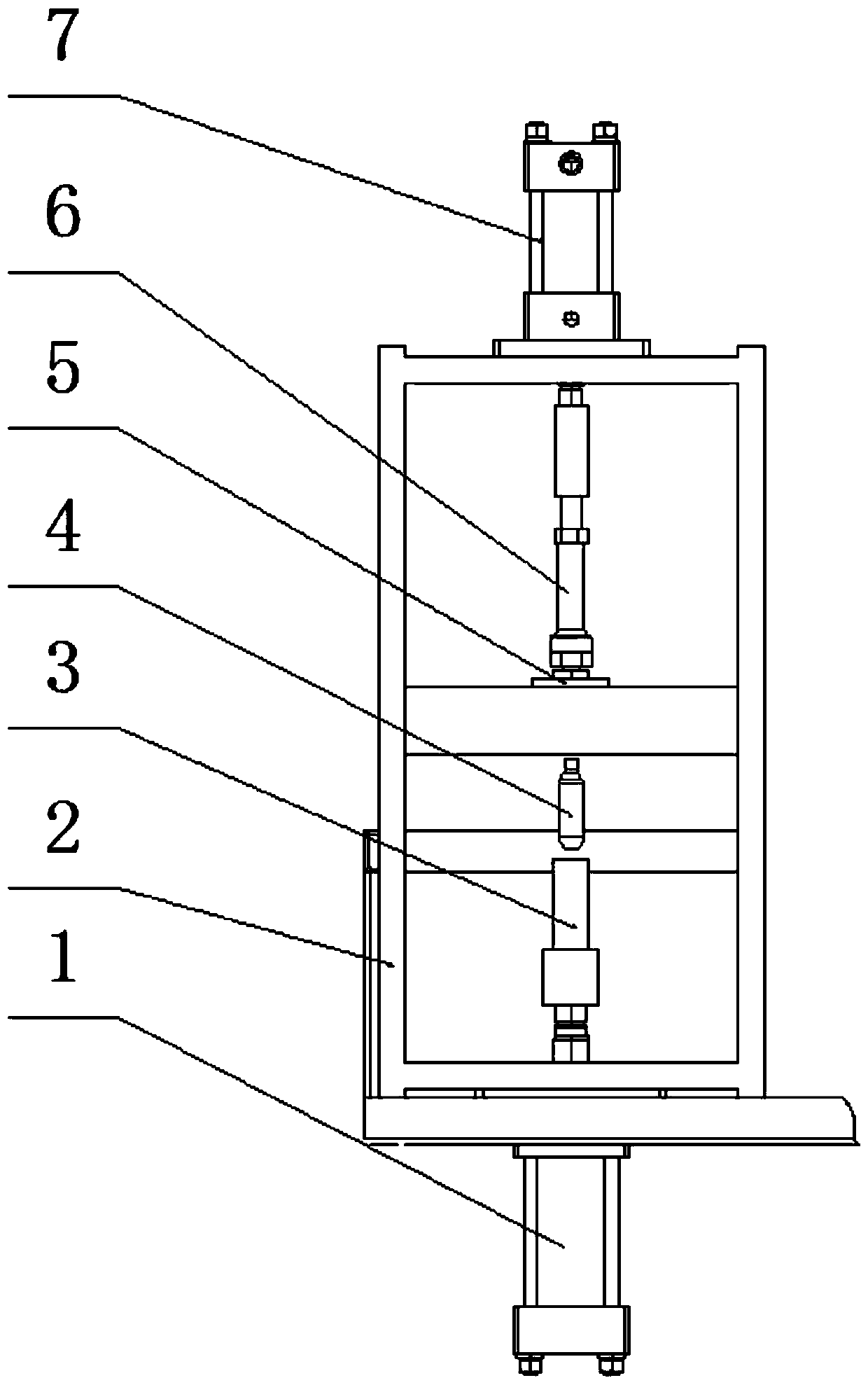

[0022] Such as figure 1 , figure 2 As shown, an inflatable sealing mechanism of an inflator is installed on the working frame 2, including an upper sealing mechanism and a sealing block 5, the upper sealing mechanism is located above the sealing block 5, and the working f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com