Screen printing device and screen printing method

A screen printing device and screen printing technology, applied in screen printing, screen printing machines, printing devices, etc., can solve problems such as uneven filling properties, and achieve the effect of ensuring filling properties and good filling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

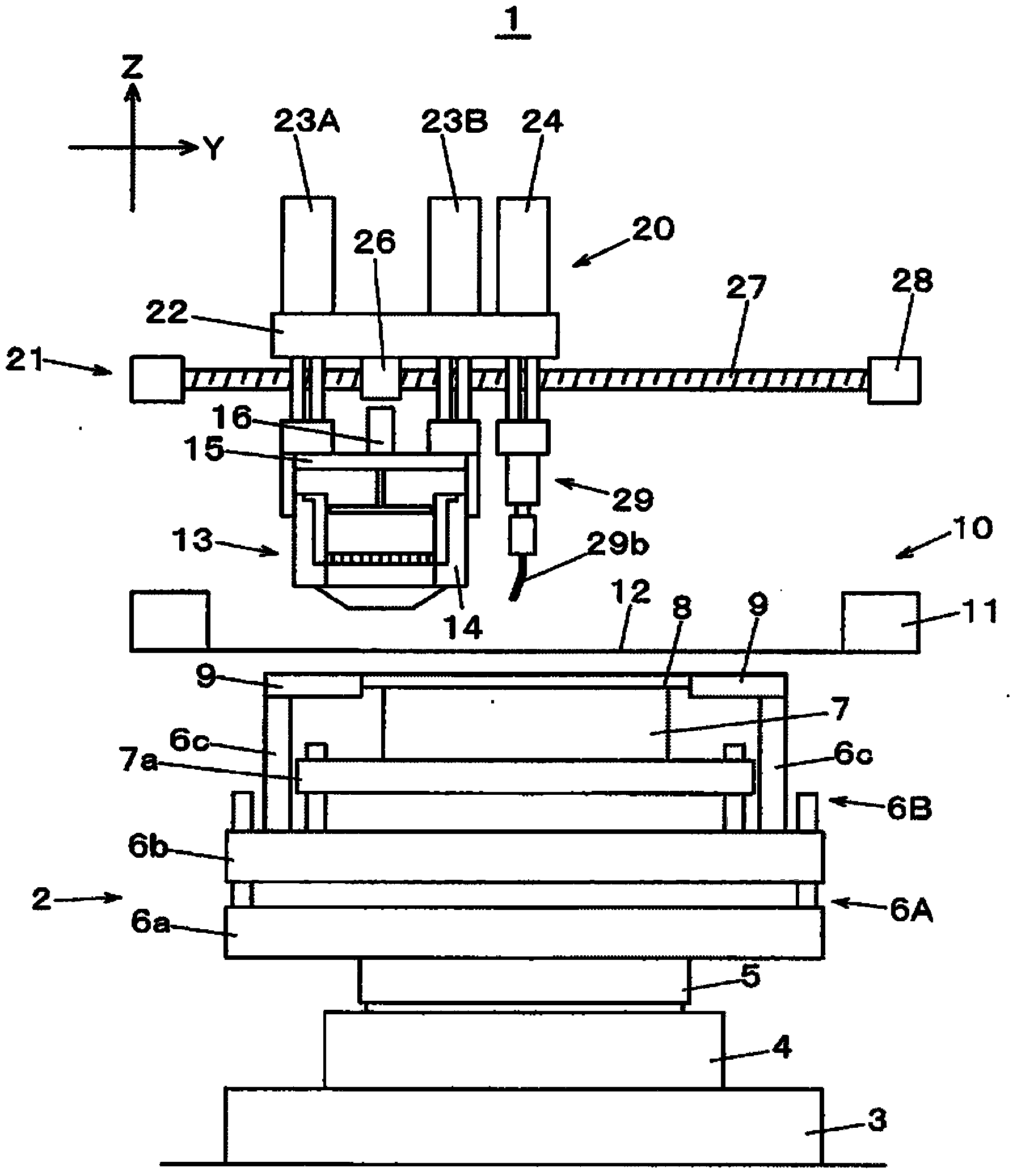

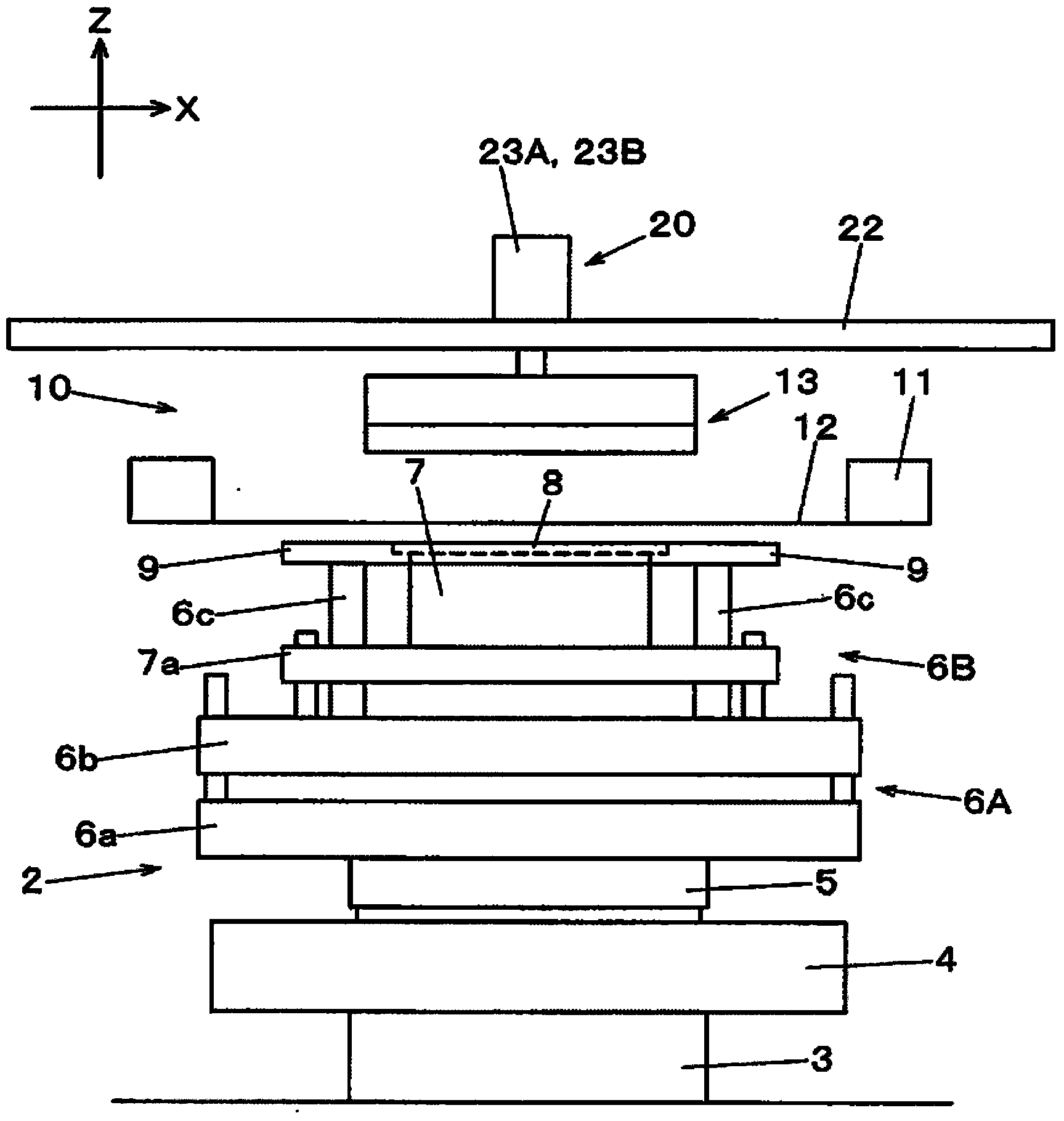

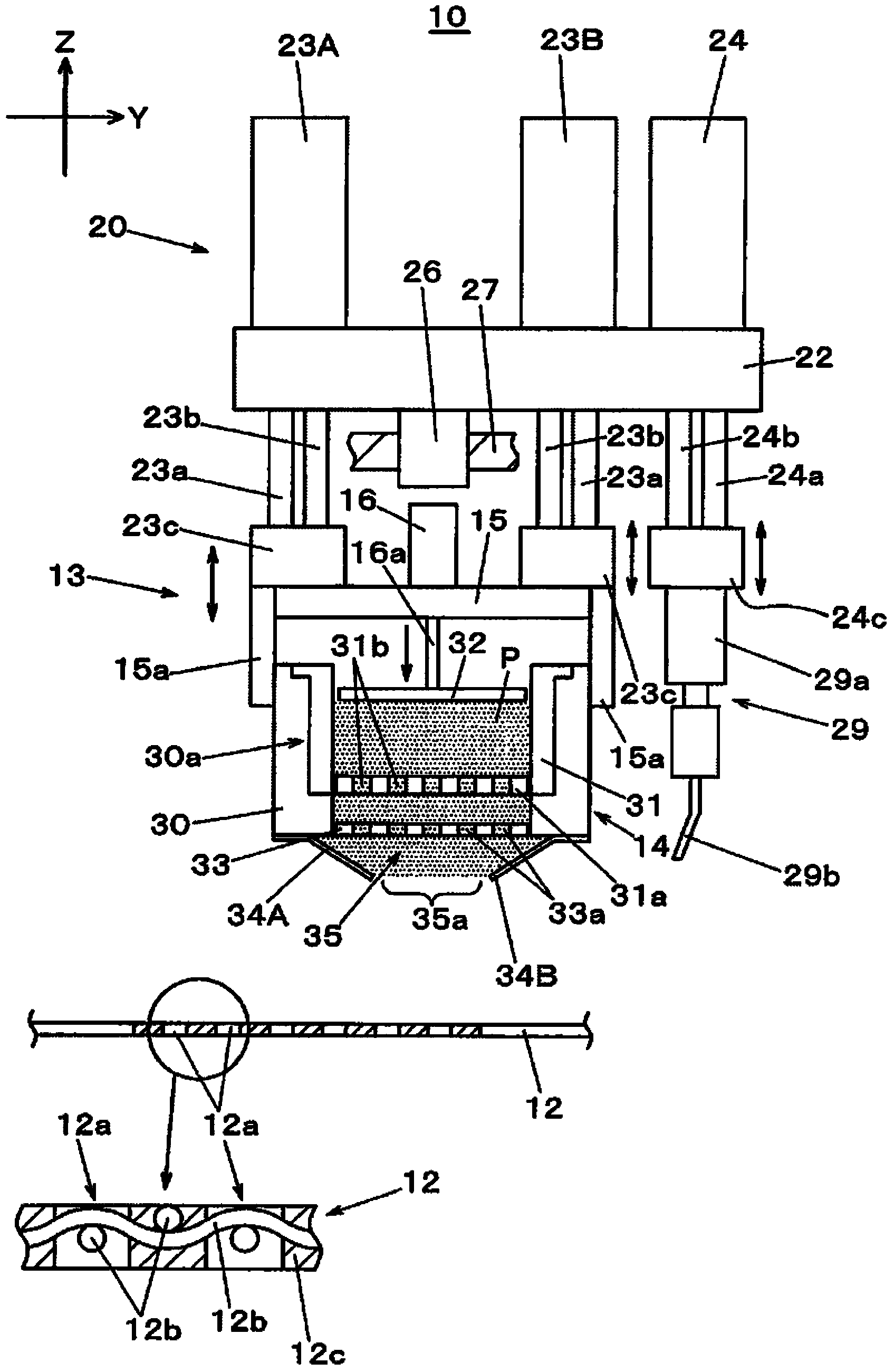

[0038] Next, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 The structure of the screen printing device 1 will be described. This screen printing device 1 has a function of printing a soldering or circuit on a substrate through a pattern hole by performing a squeegee operation in which the squeegee unit comes into contact with the upper surface of a mesh mask with a pattern hole and slides in the squeegee direction. The function of the paste used for forming.

[0039] exist figure 1 , figure 2 Among them, a screen printing unit 10 is disposed above the substrate positioning unit 2 of the screen printing device 1 . The substrate positioning unit 2 is configured such that a θ-axis table 5 is stacked on a movable table composed of a Y-axis table 3 and an X-axis table 4 , and a first Z-axis table is arranged on the θ-axis table 5 6A, the second Z-axis table 6B, and the substrate lower support portion 7 is dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com