Contents-filling vessel reversing apparatus and a vessel for use with the apparatus

a technology for reversing apparatuses and filling vessels, which is applied in the direction of packaging, special packaging, packaged goods types, etc., can solve the problems of imperfect discharging of contents from the vessel, unsatisfactory attempts, and inability to present a perfect solution, so as to avoid vessel breakage, avoid noise generation, and facilitate working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

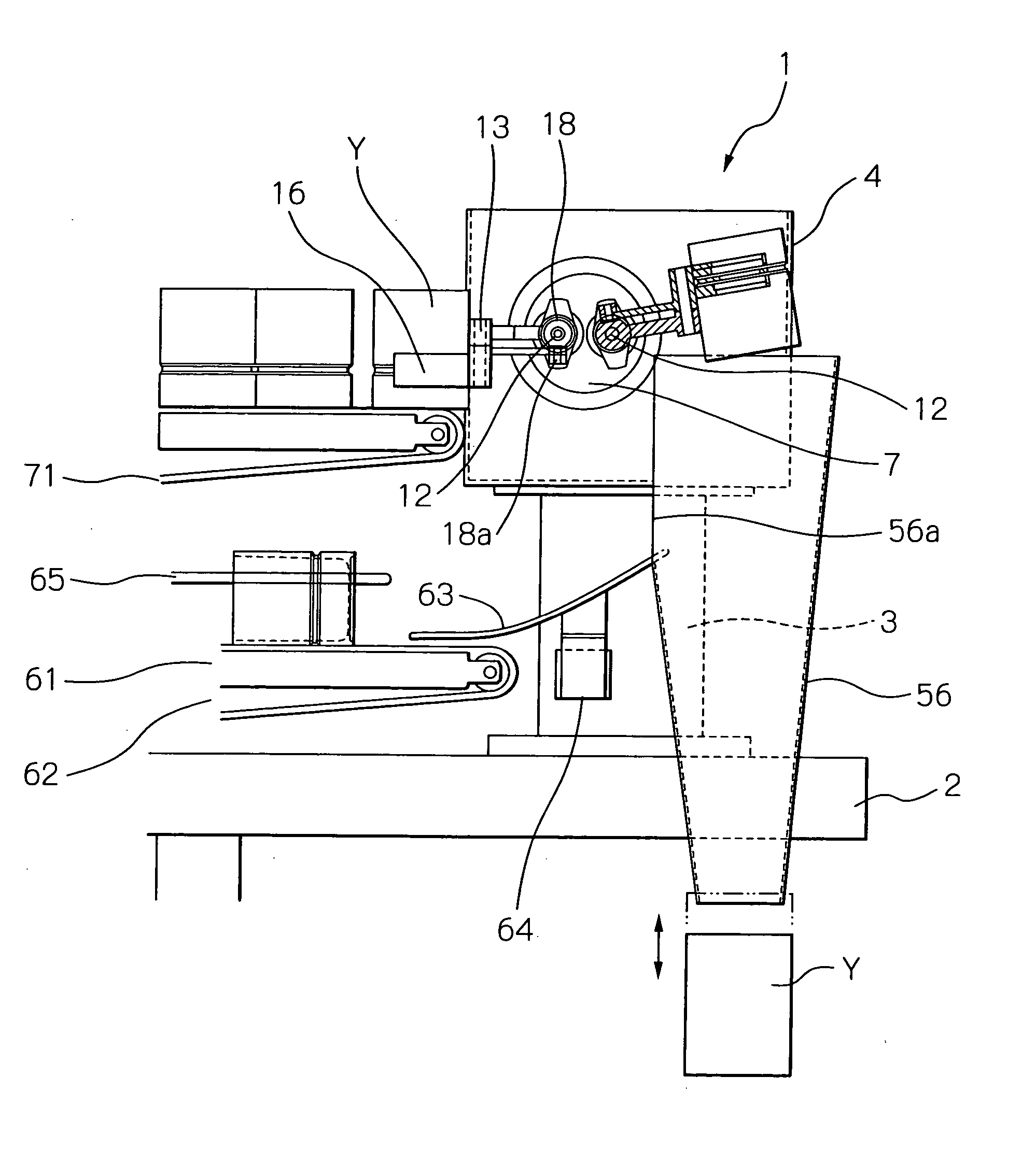

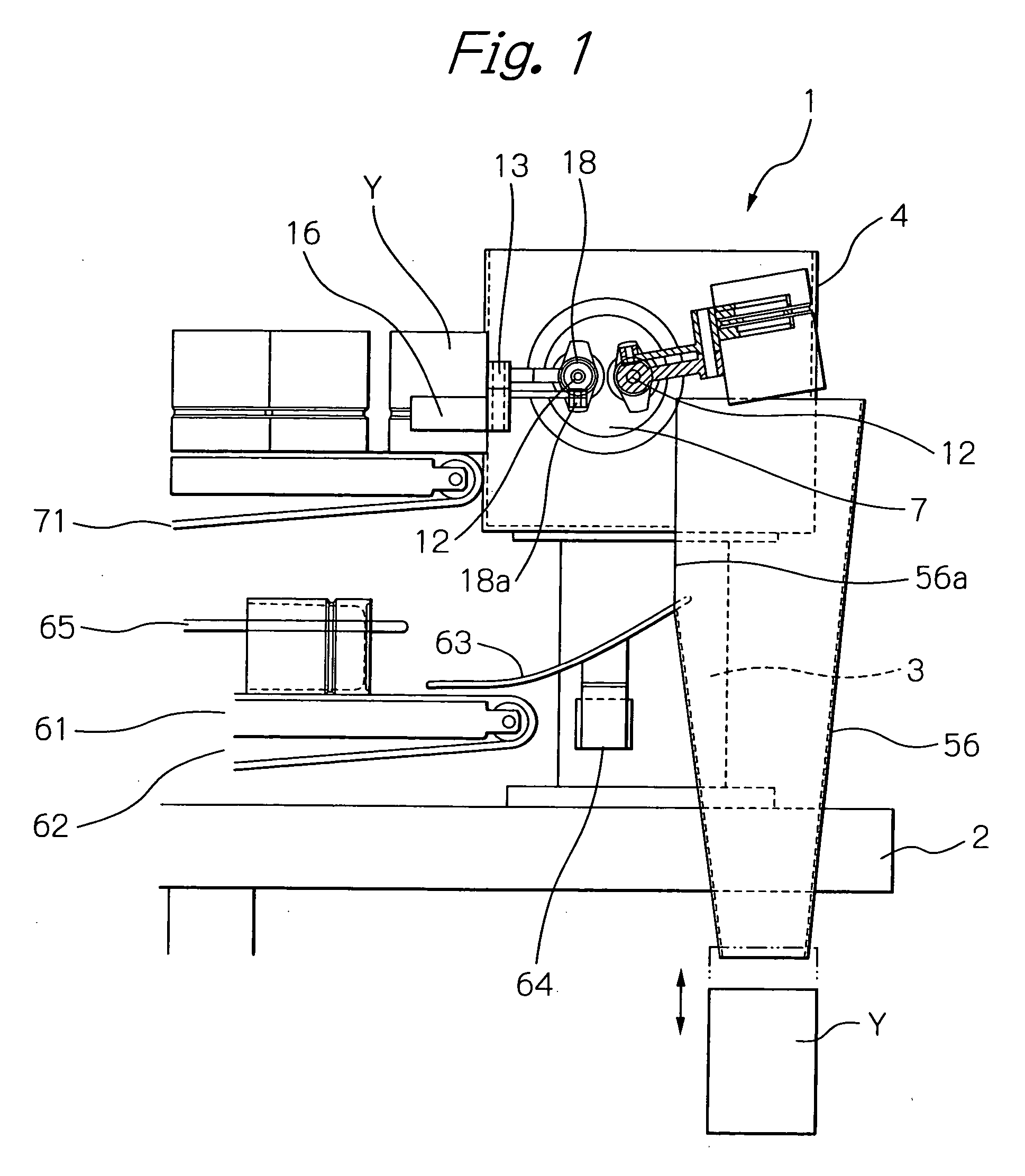

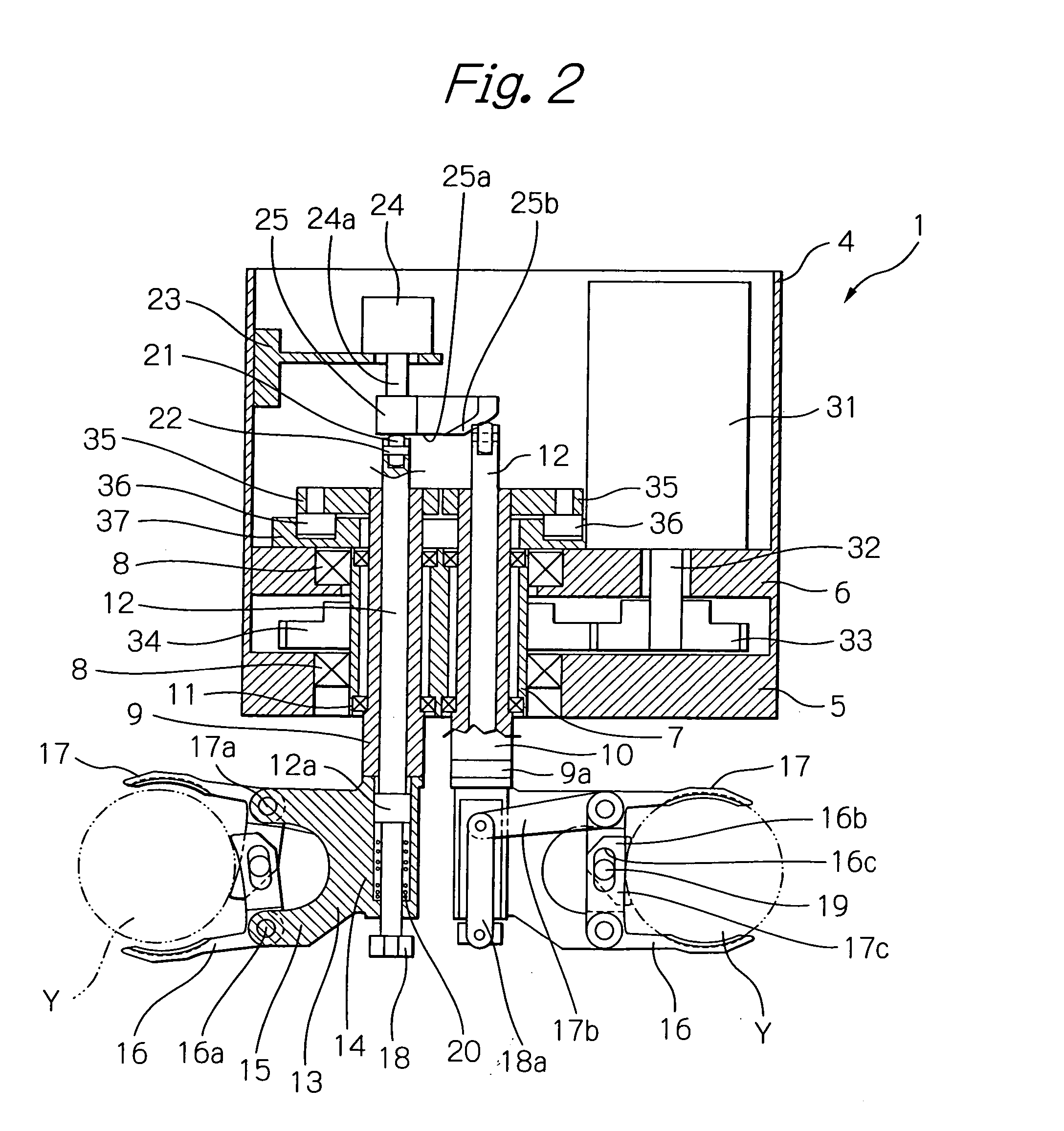

[0042] Referring now to the drawings, a preferred embodiment of the present invention will be explained hereinafter. FIG. 1 is a partly sectioned front view showing a contents-filling vessel reversing apparatus 1 (referred to simply as “apparatus” hereinafter) for reversing a contents-filling vessel (referred to simply as “vessel” hereinafter) accommodating contents to be filled according to a preferred embodiment of the present invention. FIG. 2 is a sectional plan view, FIG. 3 is a partly sectioned side view, and FIG. 4 is a rear view showing the principal part of the apparatus. According to the present embodiment, two sets of mechanisms for gripping and reversing a vessel Y are provided as will be described hereinafter.

[0043] The apparatus 1 has a machinery mount 2. A stand 3 is erected on the machinery mount 2, and a frame 4 in a nearly box-shaped configuration is secured on the stand 3. Two vertical wall portions 5, 6 are formed in parallel with and separated from each other a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com