Automatic storage warehouse equipment

A warehouse and equipment technology, applied in the field of automatic storage warehouse equipment, can solve problems such as low work efficiency, damage, deformation of underlying materials, etc., to improve work efficiency and avoid extrusion damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

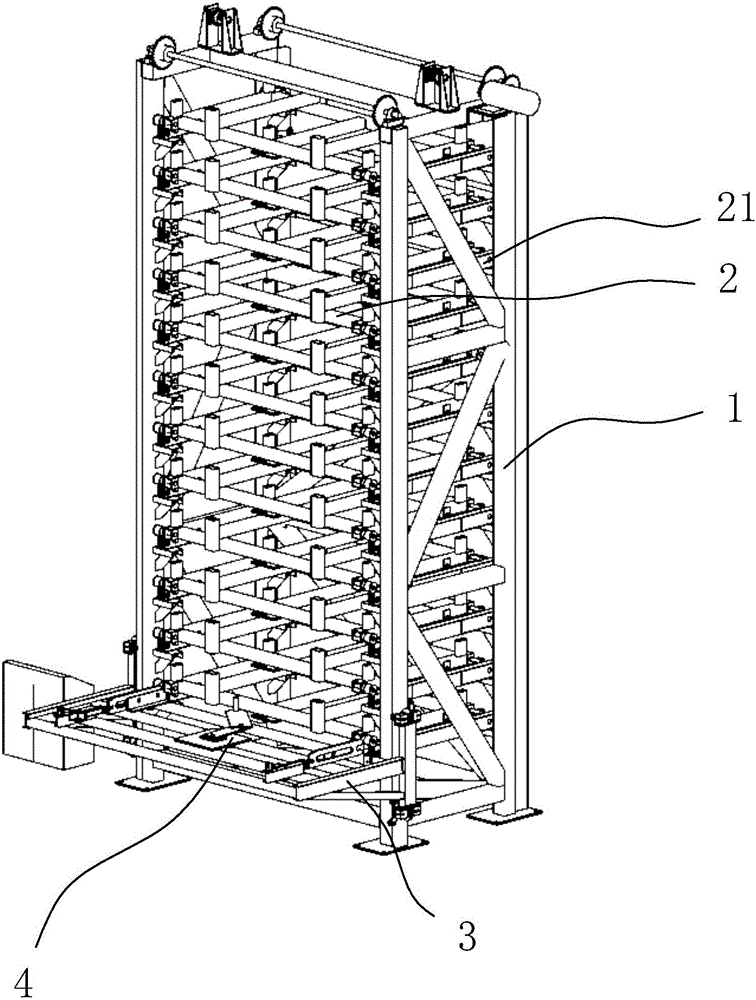

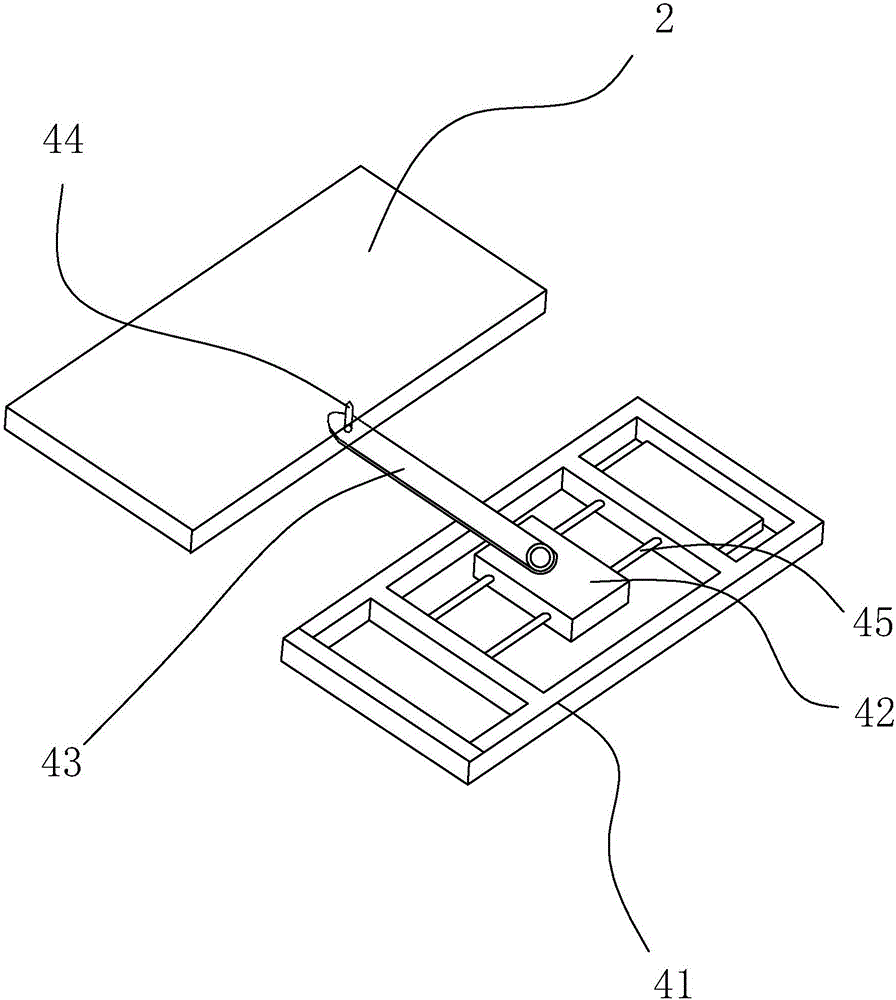

[0019] refer to figure 1 , figure 2 , the present invention is an automatic storage warehouse equipment, including a vertically placed storage rack 1 and a number of loading trolleys 2 arranged in parallel from top to bottom in the storage rack 1, and a number of loading carts 2 are arranged in the storage rack 1 The translation track 21 that is positioned at both sides of loading trolley 2, the outside of storage rack 1 is also provided with the lift carrier 3 that can move up and down along storage rack 1, and access device 4 is installed on the lift transfer machine 3, access device 4. The trolley 2 can be dragged to slide along the translation track 21 to the lifting and transporting machine 3.

[0020] This automated storage warehouse equipment can place the goods layered on the loading trolley 2 in the storage rack 1 through the lifting conveyor 3 and the access device 4 on the lifting conveyor 3, and pass through when the goods need to be taken. The lifting conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com